Novel heading machine cutting device and working method thereof

A roadheader and a new type of technology, used in earth-moving drilling, mining equipment, tunnels, etc., can solve the problems of lateral force generation and small cutting area, and achieve increased stability, large cutting area, and improved cutting efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

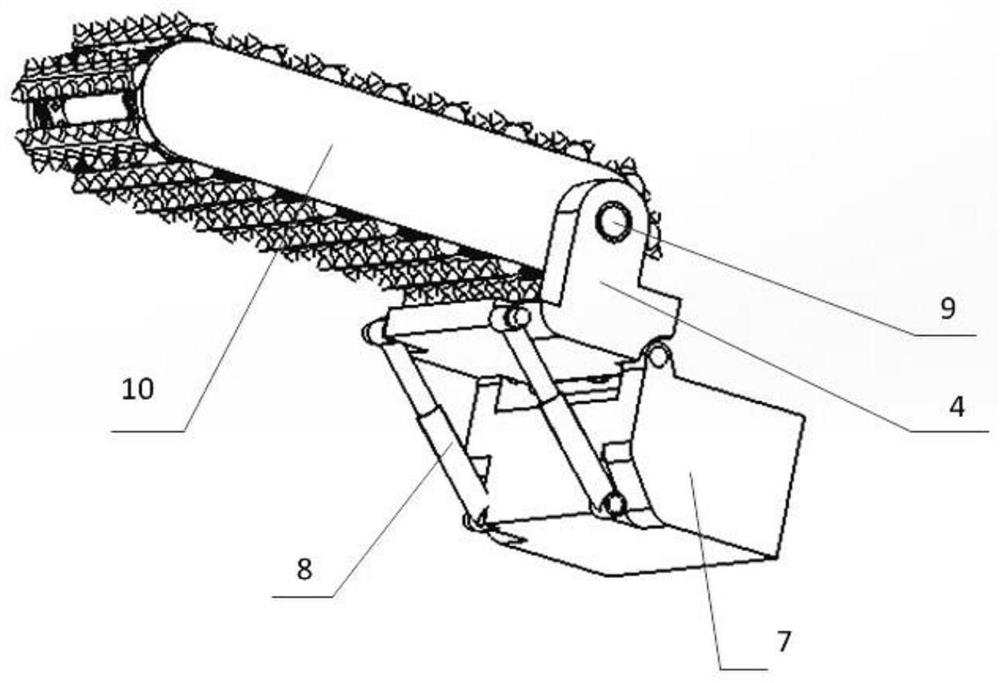

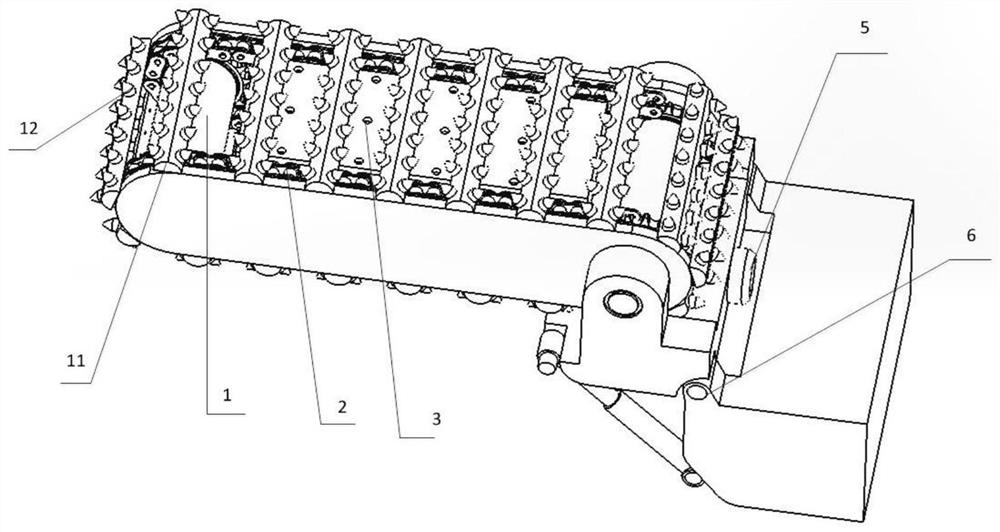

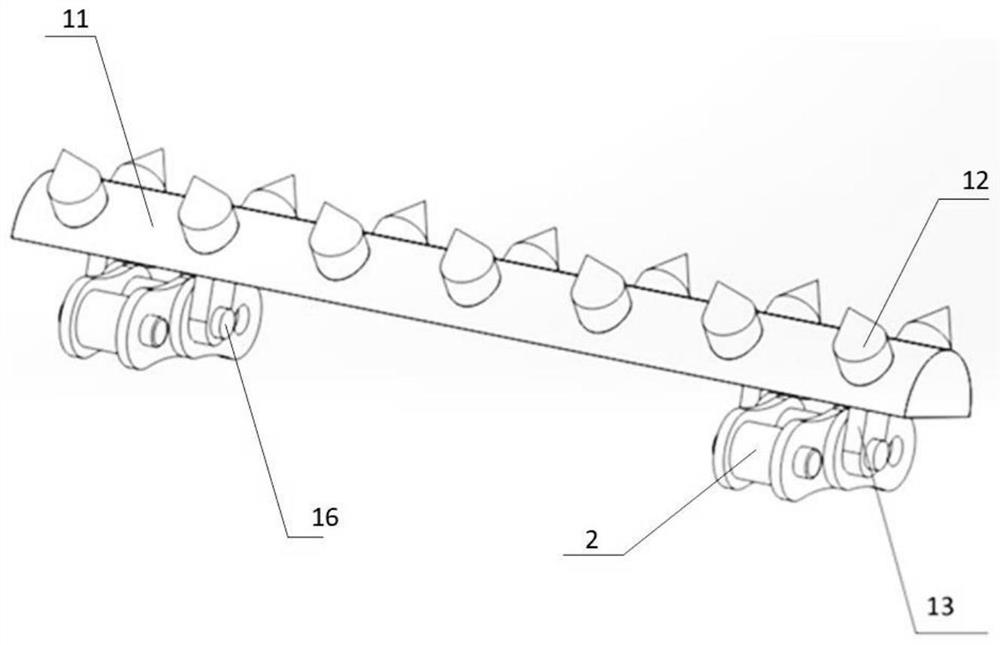

[0048] A new type of roadheader cutting device, such as Figure 1-8 As shown, it includes a main body 10, a supporting driving device 4 and an adjusting hydraulic cylinder 8, the main body 10 is fixedly connected with the supporting driving device 4, and the main body 10 is provided with a sprocket 1, a chain 2 and a scraper 11;

[0049] The supporting driving device 4 is located at one end of the body 10, and is provided with a motor 5 and a reducer 9, the output shaft of the motor 5 is connected with the input shaft of the reducer 9, the output shaft of the reducer 9 is connected with the sprocket 1, and the sprocket 1 is connected with the sprocket 1. The chain 2 meshes and drives the rotation of the chain 2. The chain 2 is provided with a plurality of scrapers 11, and the scraper 11 is provided with picks 12 for cutting;

[0050] One end of the supporting driving device 4 is connected with the connecting ear plate 6 on the upper part of the car body of the roadheader 7 thr...

Embodiment 2

[0055] A new type of roadheader cutting device, the structure of which is shown in Embodiment 1, the difference is that the number of adjustment hydraulic cylinders 8 is two, which are respectively located on both sides of the support drive device 4 and the roadheader 7, and the two adjustment hydraulic cylinders The cylinder expands and contracts at the same time to adjust the angle between the body and the horizontal plane, which improves the stability of the adjustment process.

Embodiment 3

[0057] A new roadheader cutting device, the structure of which is shown in Embodiment 2, the difference is that the upper and lower surfaces of the body 10 are provided with nozzles 3 for removing dust when cutting coal and rocks, and there are multiple nozzles 3, preferably The upper surface and the lower surface of the main body are provided with 12 nozzles, and a water supply pipe is provided inside the main body 10. The water supply pipe is connected with the nozzle 3 to provide water for the nozzle 3. The source of the water in the water supply pipe is the same as that of an ordinary roadheader. unanimous.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com