Low-air-permeable coal bed static blasting anti-reflection gas extraction method

A static blasting and gas extraction technology, applied in gas discharge, mining equipment, mining equipment, etc., can solve the problems of gas safety, high efficiency, economic extraction, heavy hydraulic strengthening equipment, etc., and improve extraction. volume and extraction rate, ease of operation, and the effect of maintaining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

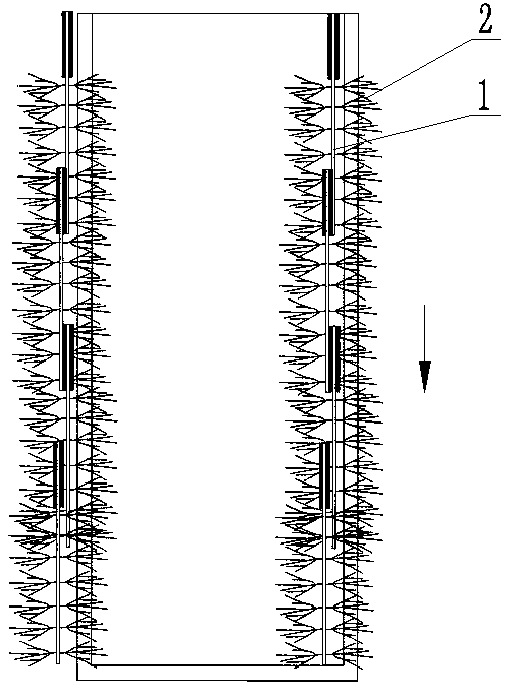

[0029] Such as figure 1 Shown, a kind of low-permeability coal seam static blasting anti-permeability gas drainage method of the present invention comprises the following steps:

[0030] Step 1: Screen the silent breaker: collect rock samples from the roof of the coal seam to be extracted (the roof refers to the rock layer covering the coal seam in the coal-bearing strata section of the normal sequence) to test the mechanical properties of the rock, and obtain the tensile strength of the roof. In terms of strength, the tensile stress of several common silent breaking agents (such as HSCA-I and HSCA-II, etc.) were compared with the tensile strength of the roof for 8 hours, and the ones that can be used for the static blasting of roof drilling 1 were preliminarily screened out. Silent breaker.

[0031] Among them, the empirical value of the tensile stress of the silent breaking agent that can be used for the static blasting of roof bedding drilling 1 is 1 / 5 to 1 / 4 of its expans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com