Pole column removing device for recycling waste lithium ion battery

A lithium-ion battery and waste technology, which is applied in the field of pole removal devices for waste lithium-ion battery recycling, can solve problems such as inapplicable cutting methods, inability to remove the knife, short circuit of the battery cell, etc., achieve simple structure, improve work efficiency, and quickly separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

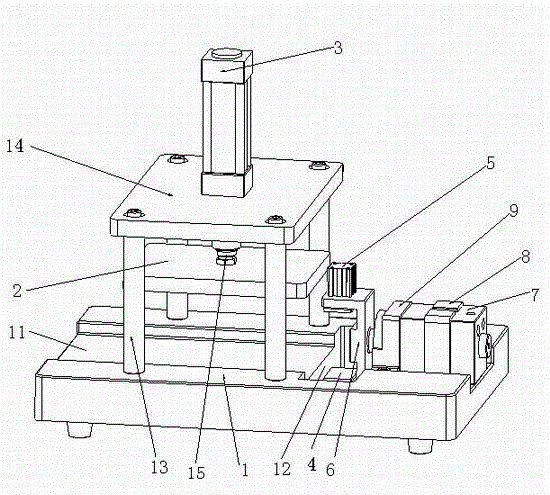

[0024] Such as figure 1 As shown, the pole removal device for recycling waste lithium-ion batteries includes a platform 1, which is used to place the battery cells after shelling. The platform 1 is provided with a battery cell fixing structure, a clamping mechanism, and a torsion drive from left to right. Institution 7. The cell fixing structure has the function of fixing the cell, and the clamping mechanism has the function of clamping the battery top cover and the pole. The clamping mechanism and the platform can rotate mutually under the driving action of the torsion driving mechanism 7 to screw off the battery top cover. The drive shaft of the torsion drive mechanism 7 is parallel to the platform 1. In this embodiment, the rotation axis of the torsion drive mechanism coincides with the central axis of the battery top cover to be processed, and the torsion drive mechanism is a reciprocating torsion drive mechanism.

[0025] In this embodiment, the platform 1 is arranged hori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com