Electric power tool

A technology for power tools and circuit boards, which is applied in the direction of manufacturing tools, power components, electrical components, etc., can solve problems such as short circuits, and achieve the effect of improving heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

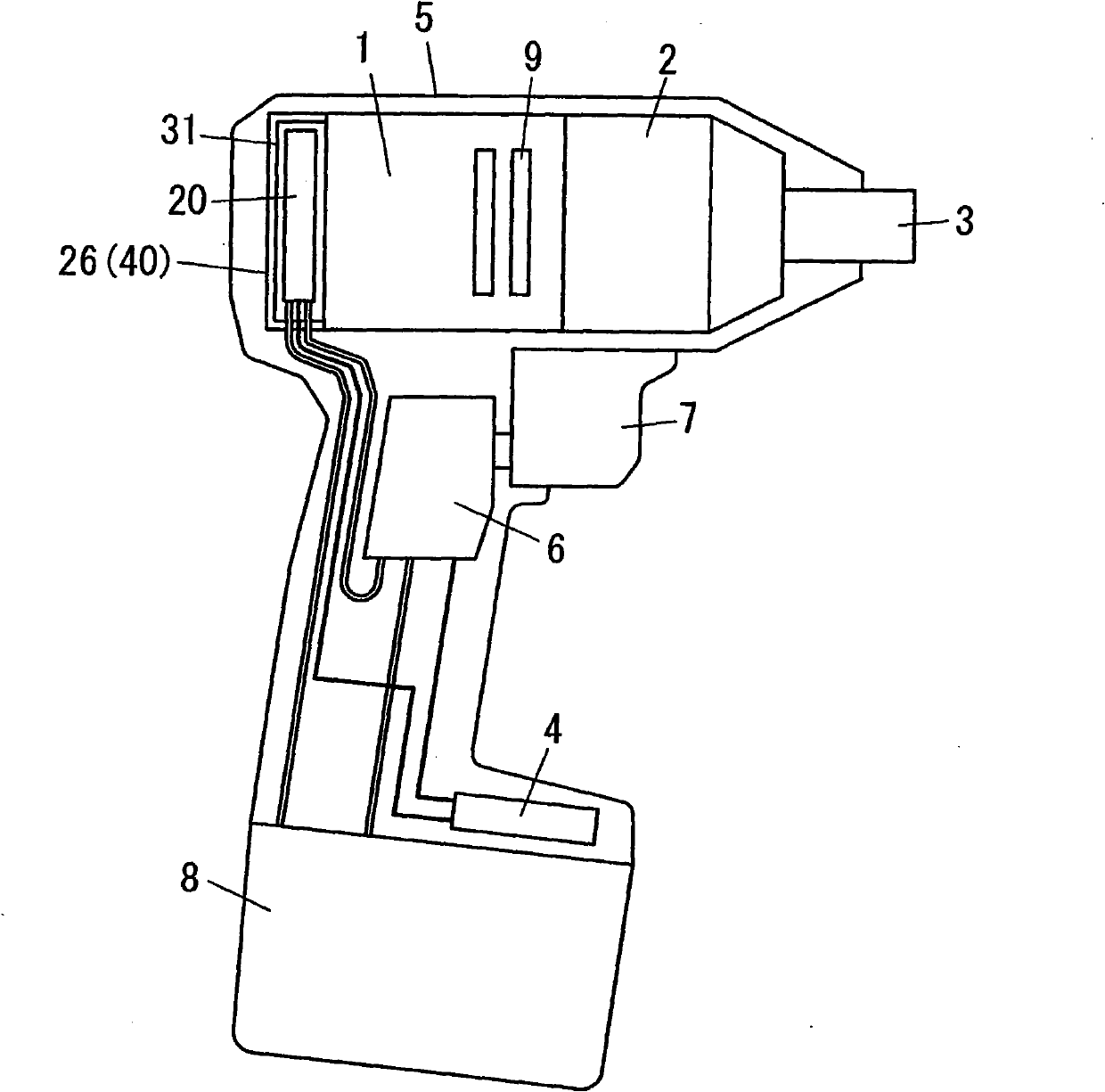

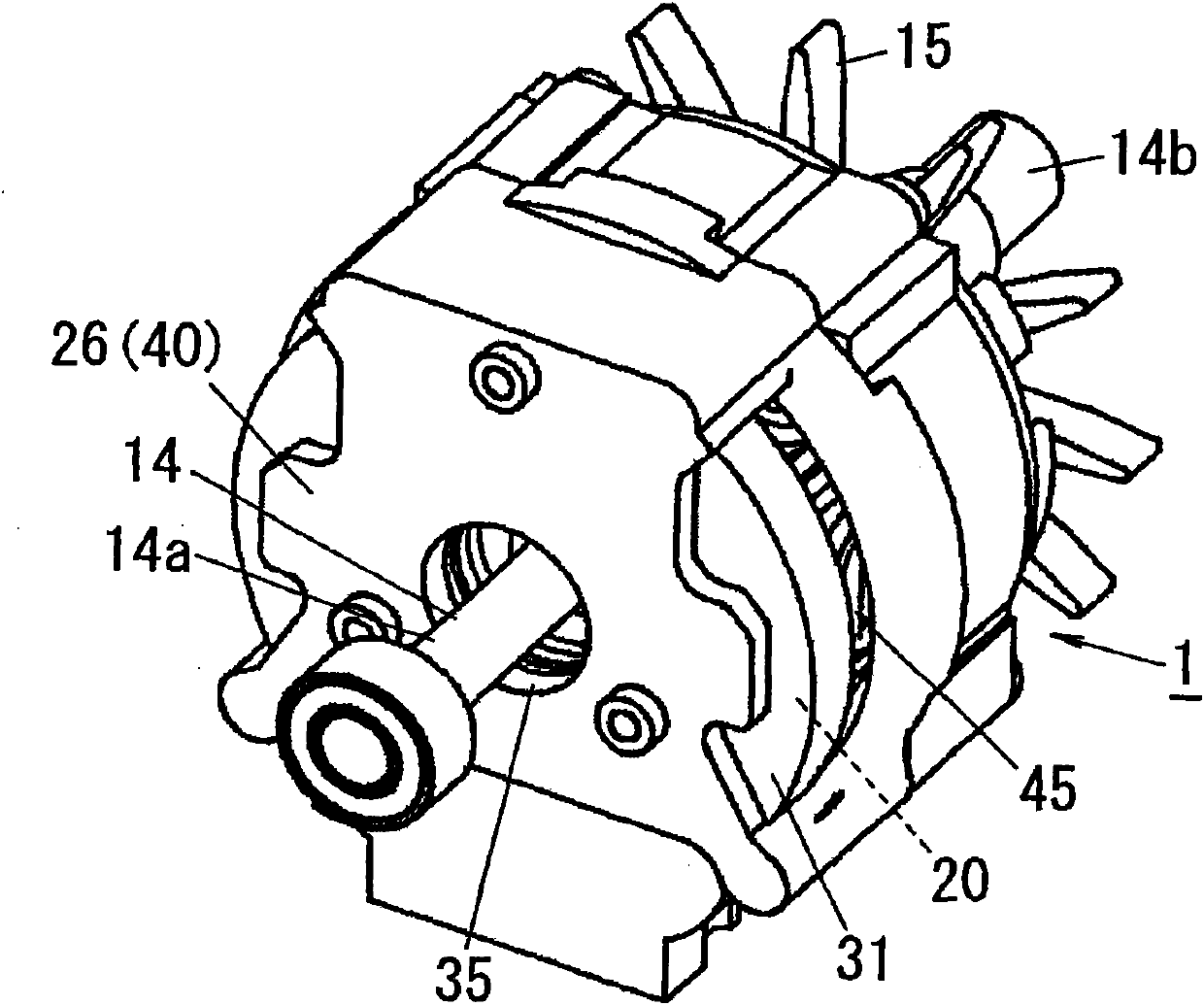

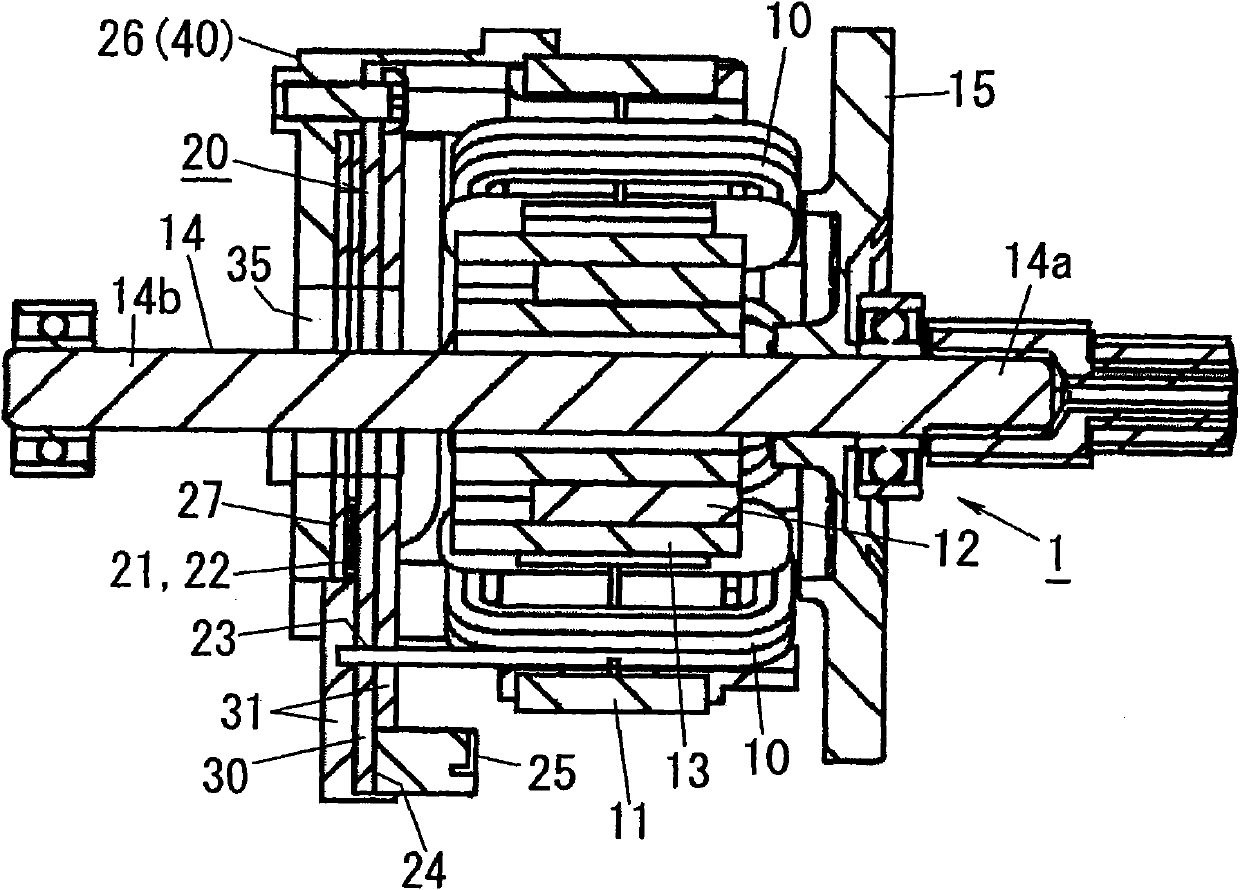

[0022] Embodiments of the present invention are described below with reference to the accompanying drawings forming a part of the present invention. figure 1 The overall configuration of an electric power tool according to one embodiment of the present invention is schematically shown.

[0023] The electric tool is a hand-held electric rotary tool, which includes a housing 5, a motor 1 used as a driving power source, a reduction mechanism 2 for transmitting the power of the motor 1, and a power output driven by the power transmitted through the reduction mechanism 2. Unit 3. The motor 1 , the reduction mechanism 2 , and the power output unit 3 are connected in series in the casing 5 . The housing 5 has air supply-exhaust holes 9 opened in the vicinity of the motor 1 . In this specification, the side to which power is transmitted (i.e., the side where the reduction mechanism 2 is located relative to the motor 1) is referred to as the "front side", and the opposite side (i.e.,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com