Vector spray pipe parallel-connection driving mechanism

A driving mechanism and vector nozzle technology, applied in the aviation field, can solve the problems of poor rectification and sealing, small rotation angle, poor flexibility, etc., and achieve the effect of good rectification and sealing, simple control and flexible rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

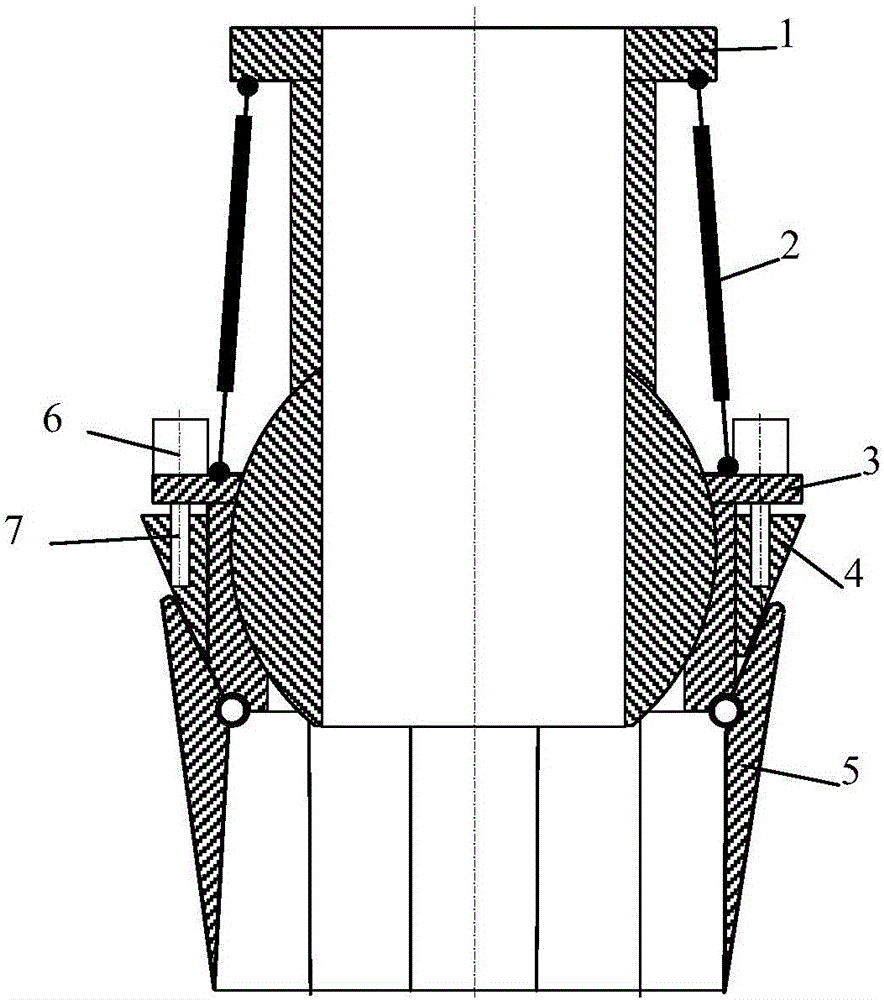

[0015] exist figure 1 In the schematic diagram of the vector nozzle parallel driving mechanism shown, the tube seat 1 is in the shape of a long cylinder, and the tube seat is provided with a through hole concentric with the cylinder in the axial direction, and one end of the tube seat is provided with a hole where the center of the ball coincides with the axis of the cylinder. Convex spherical surface, the other end of which is provided with a convex round table concentric with the cylinder; the ball sleeve 3 is in the shape of a short cylinder, and the center of the ball sleeve is provided with a concave spherical through hole whose center coincides with the axis of the cylinder, and one end of the ball sleeve is provided. The convex circular platform, the convex circular platform is provided with 3 axial through holes evenly distributed on the circumference, and the other end of the ball sleeve is provided with a plurality of through holes tangent to the same circumference; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com