Nodulizing agent for high-nickel austenite ductile iron as well as preparation and application methods of nodulizing agent

A nodulizer and austenite technology, which is applied in the field of nodularizer for high-nickel austenite ductile iron, can solve the problems of increasing the melting temperature of alloy smelting, increasing the content of magnesium oxide, weak stirring force of molten iron, etc. The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

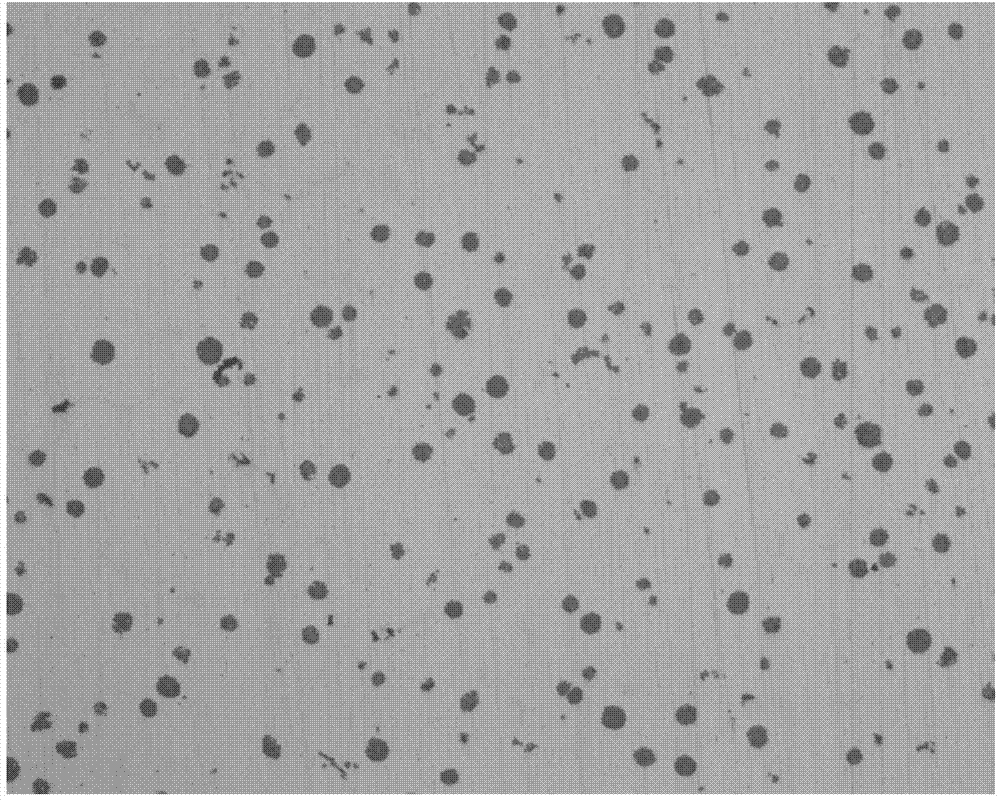

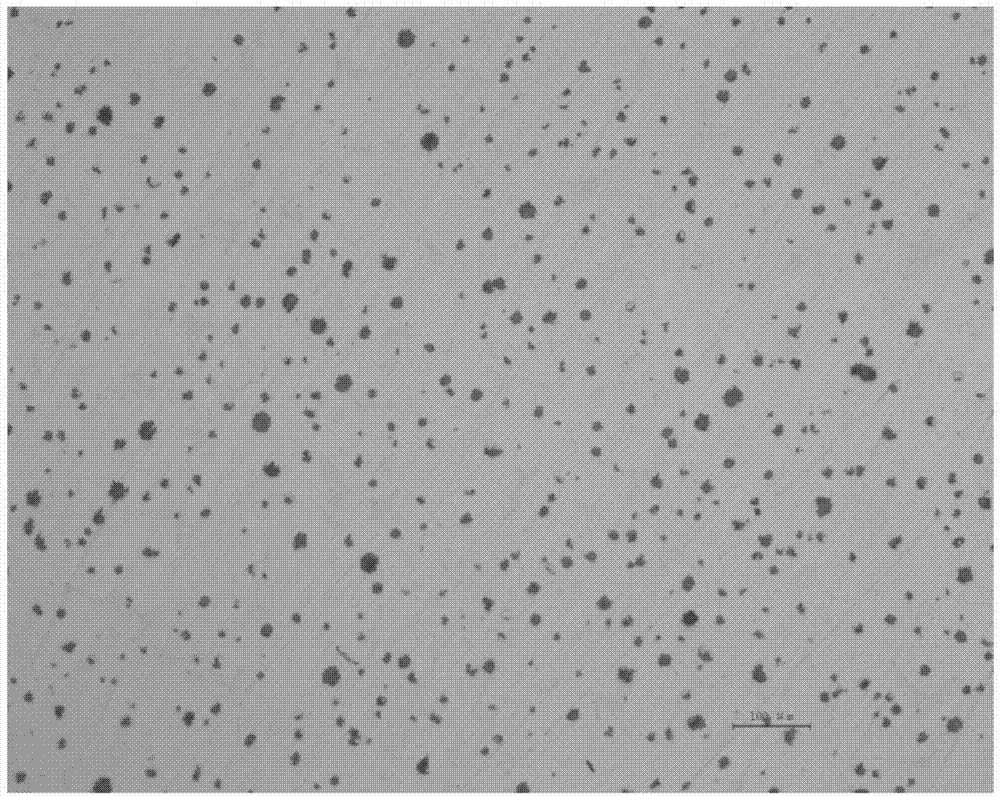

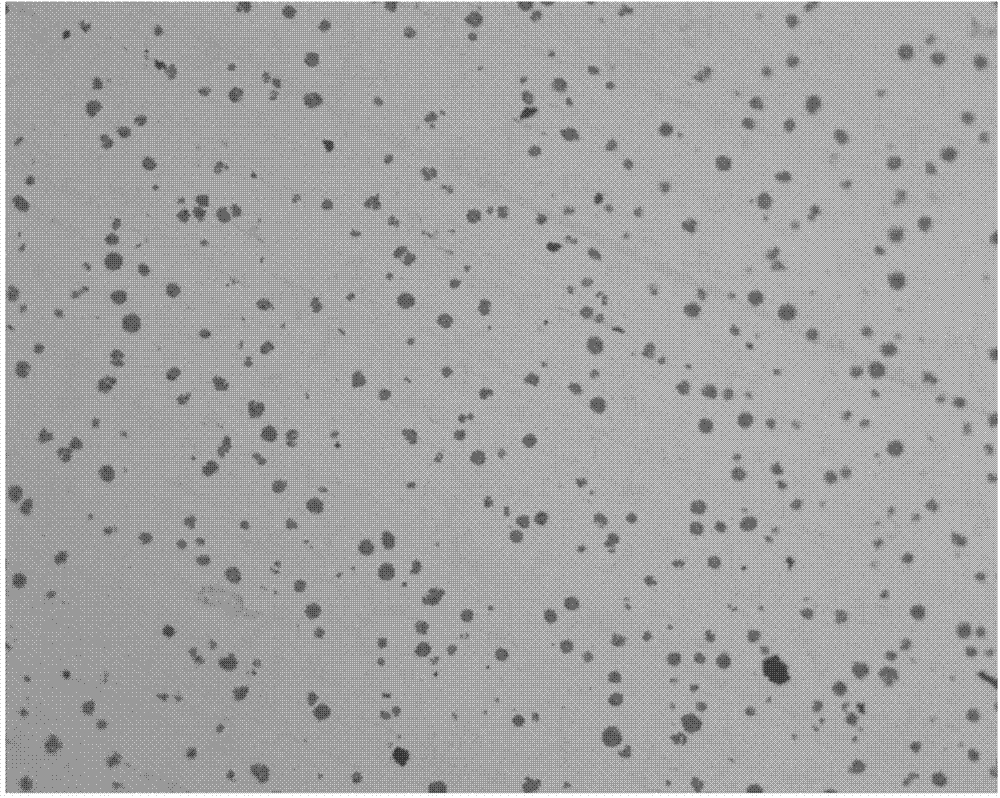

[0024] The nodulizer for high-nickel austenitic ductile iron of the present invention, the composition of the nodulizer includes nickel: 25% to 35%, magnesium: 8% to 15%, silicon: >30% to 40%. , Rare earth: ≤0.1%, and the balance is iron and unavoidable impurities, the particle size of the nodulizer is 10-20mm. The nodulizer of the present invention preferably includes nickel: 28% to 32%, magnesium: 10% to 12%, silicon: 32% to 38%, rare earth: ≤0.01%, and the balance is iron and unavoidable impurities, The nodulizer of the present invention preferably does not contain rare earths, and by strictly limiting the content of rare earths, it solves the problem that the rare earths lead to the generation of fragmented graphite, thereby obviously reducing the performance of the material.

[0025] According to the nickel-magnesium-silicon alloy phase diagram, it can be known that controlling the nickel-magnesium-silicon composition in the spheroidizing agent within the above-mentioned ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com