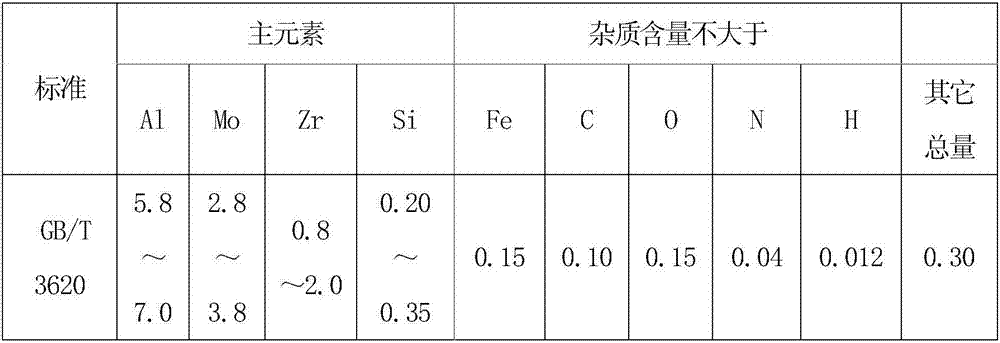

Ternary alloy for improving titanium alloy ingredient homogeneity and preparing method and application of ternary alloy

A titanium alloy, uniformity technology, applied in the field of titanium alloy, can solve the problems of hidden quality, uneven composition, TC11 performance fluctuation, etc., and achieve the effect of improving production efficiency, low content of inclusions and gases, and strong process operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The master alloy is Al, MoO 3 After mixing according to a certain proportion, Al-Mo is obtained by conventional aluminothermic reaction smelting; then crystalline Si is added according to the proportion, and the composition of each element is uniformed by vacuum induction melting and the gas impurities such as O are controlled to obtain an alloy ingot. After finishing, Crushed, selected and other processes are made into powder products with a particle size of ≤1mm. The composition of the product is: Al: 36.0%, Mo: 58.0%, Si: 5.33%, O: 0.04%, and the rest are impurities. After mixing the master alloy (109.1Kg) with sponge titanium (1867.52Kg), TiO2 (3.347Kg), sponge Zr (32.254Kg) and other raw materials, the vacuum auto The titanium alloy electrode used for smelting, after three smelting under vacuum self-consumption, a high-temperature and high-strength TC11 titanium alloy with uniform composition was obtained. The chemical composition of different parts of the ingot m...

Embodiment 2

[0031] According to the method of example 1, the powdered product with particle size≤1mm is made. The composition of the product is: Al: 35.8%, Mo: 58.3%, Si: 5.5%, O: 0.05%, and the rest are impurities. After the master alloy (84.384Kg) is mixed with sponge titanium (1440.33Kg), TiO2 (1.38Kg), sponge Zr (26.326Kg) and other raw materials, the vacuum self-consumption The titanium alloy electrode used for smelting is smelted three times by vacuum self-consumption to obtain a high-temperature and high-strength TC11 titanium alloy with uniform composition. The chemical composition of different parts of the ingot meets the corresponding technical requirements, and the composition uniformity of Mo and Si is good; the specific inspection results As shown in Table 3, it is suitable for key parts of aero-engines.

[0032] Table 3 Composition wt% of TC11 titanium alloy finished ingot

[0033]

[0034] The invention achieves the effect that only one kind of master alloy replaces mu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com