Liquid feedstock plasma spraying device

A spraying device and plasma technology, applied in metal material coating process, coating, molten spraying, etc., can solve problems such as difficult to achieve stable powder delivery, affect the stability of spraying process, and difficult to prepare coatings, etc., to achieve the suppression of nano The particle growth phenomenon, the stability of the coating preparation process, and the effect of improving the coating preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

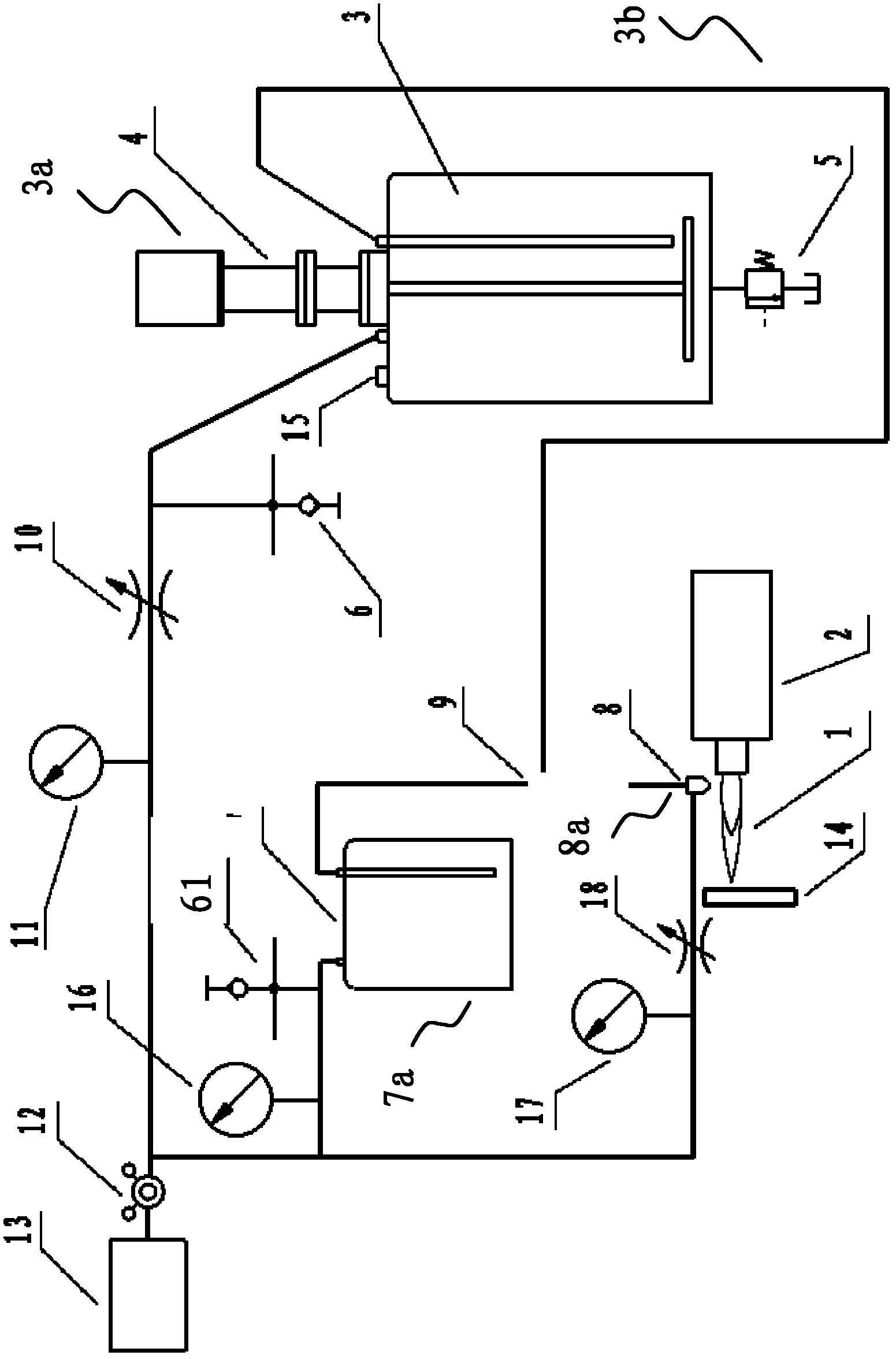

[0058] The liquid material plasma spraying device for preparing nanostructured thin ceramic coatings of the present invention includes a plasma system 2 and a liquid material delivery device 3a composed of a liquid material delivery system 3b, a liquid material injection system 8a and a cleaning system 7a. The liquid material delivery system 3b includes a liquid material storage pressure vessel 3 filled with compressed gas and corresponding gas and liquid material delivery pipelines, and the cleaning system 7a includes a cleaning medium storage pressure vessel 7 filled with compressed gas and corresponding gas and cleaning equipment. The medium conveying pipeline and the liquid material injection system 8a include a two-flow gas atomization nozzle 8 and corresponding tooling for clamping the two-flow gas atomization nozzle on the plasma system 2 and three-dimensionally adjustable. The liquid material is sent to the two-flow gas atomization nozzle 8 controlled independently by t...

Embodiment 2

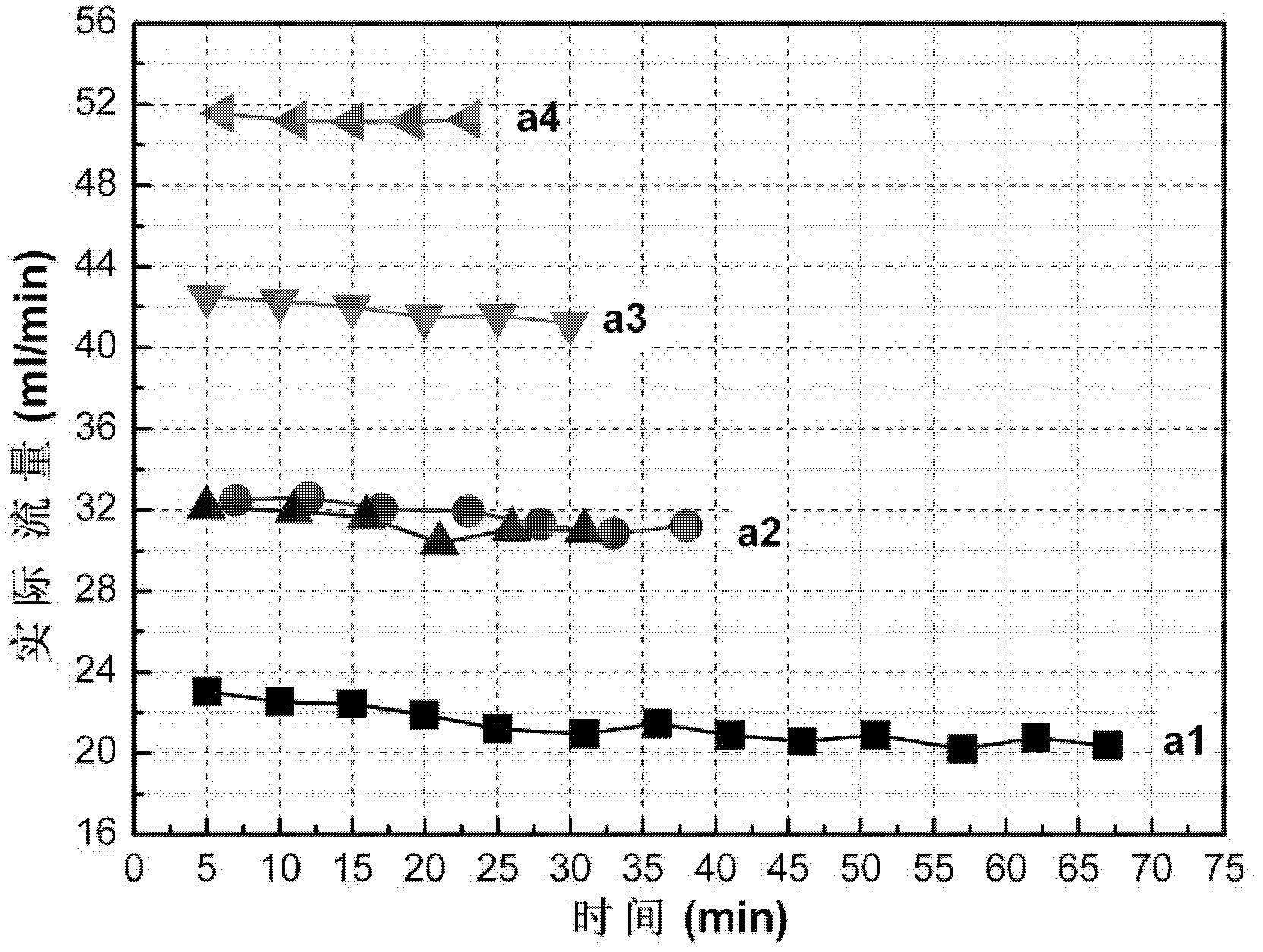

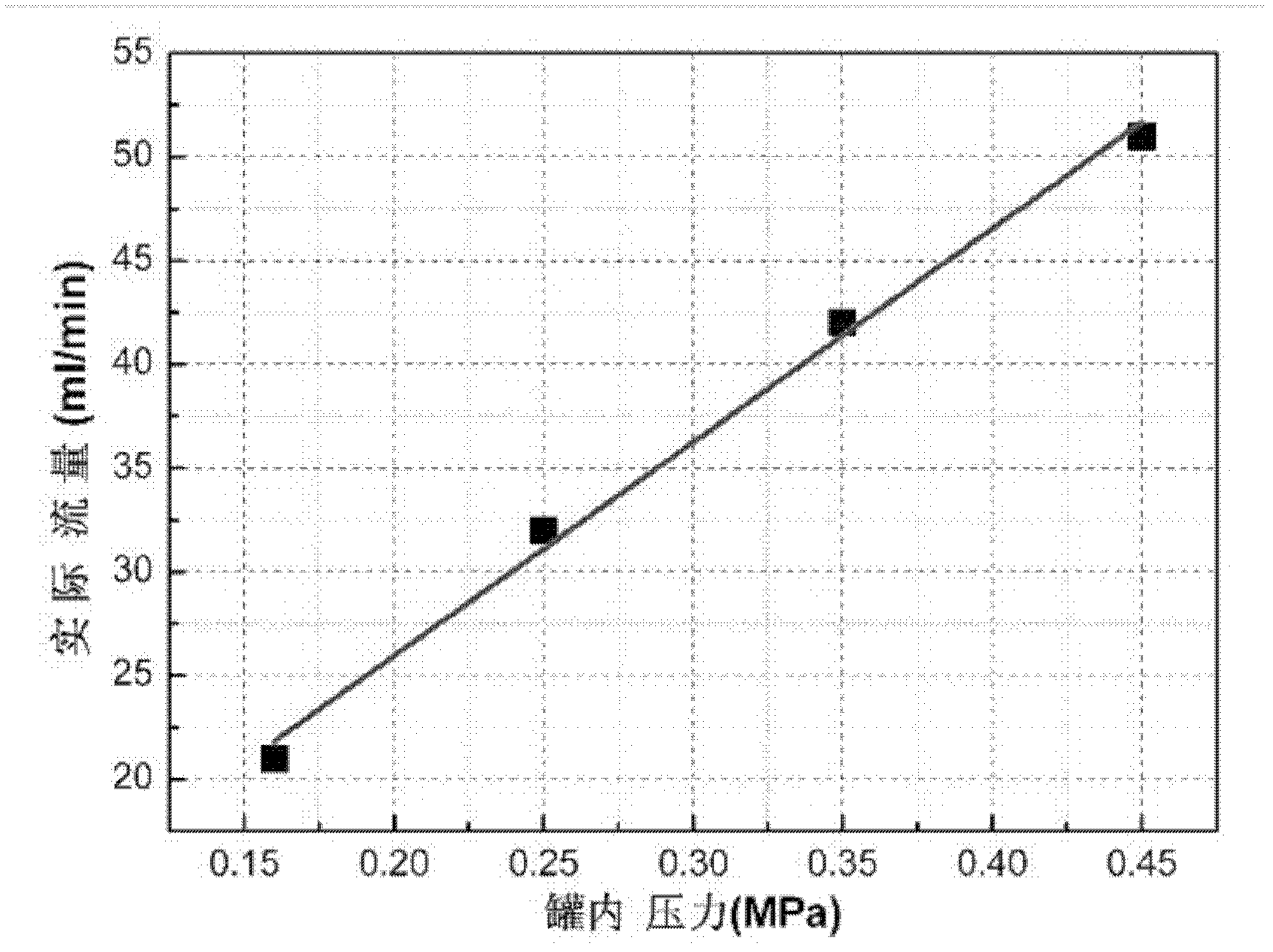

[0060] According to the technical scheme of the present invention, see Figure 2a and Figure 2b , Figure 2a , Figure 2b It is the curve of the solution precursor of yttria stabilized zirconia (YSZ) solution composed of zirconium salt and yttrium salt solution, which is quantitatively delivered by the liquid material delivery device according to an embodiment of the present invention. The solution precursor was tested under different tank pressures in the liquid material storage pressure vessel flow, Figure 2a Test at least 5 times under each pressure, each test is 5 minutes, and each test point in the figure is the average value of 5 minutes. The graphs a1, a2, a3, and a4 shown in the figure correspond to the flow rate of the solution precursor when the test pressure is 0.16MPa, 0.25MPa, 0.35MPa, and 0.45MPa respectively. At each test pressure, the flow rate of the solution precursor remains basically Constant, the flow fluctuation is less than ±5%. Figure 2b is the ...

Embodiment 3

[0062] The YSZ solution precursor is atomized through the two-flow gas atomization nozzle 8 at a flow rate of 25ml / min and then sent to the plasma jet 1. The atomization gas pressure is 0.1MPa. The YSZ coating is formed on the substrate 14 after processes such as solvent volatilization, solute precipitation, pyrolysis and melting. The surface morphology of the coating was observed with a scanning electron microscope, such as image 3 As shown, the results show that the coating has a nanostructure, the grain size is less than 100nm, and the flattened particle diameter is less than 5μm, which is far smaller than the flattened particle diameter of 30-200μm in the traditional plasma spray coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com