A method for CVI densification of an open container and a gas pipeline structure

An open container, densification technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problems of poor gas penetration quality, slow densification speed, etc., to improve deposition speed and deposition quality. , Simple equipment, uniform densification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

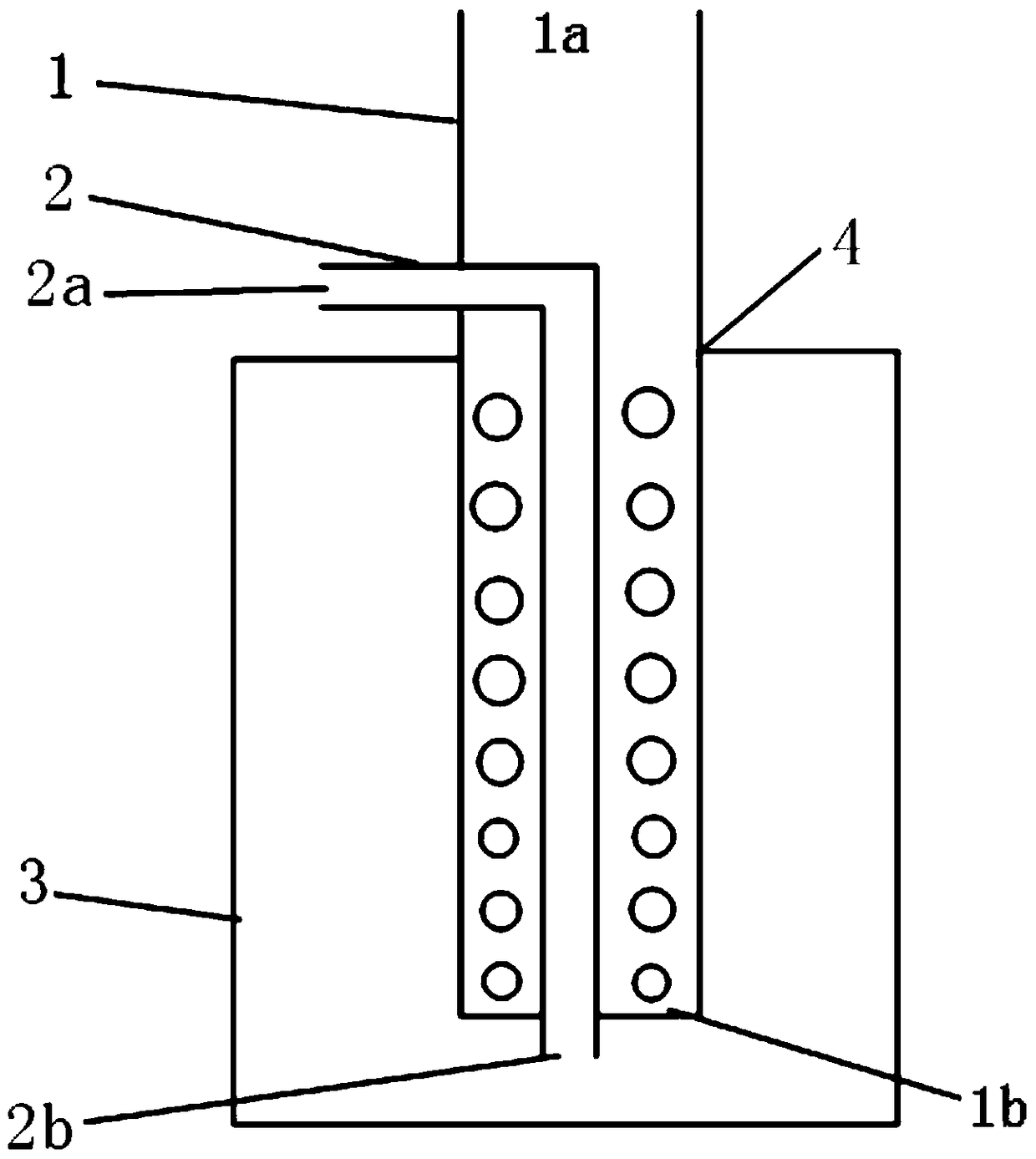

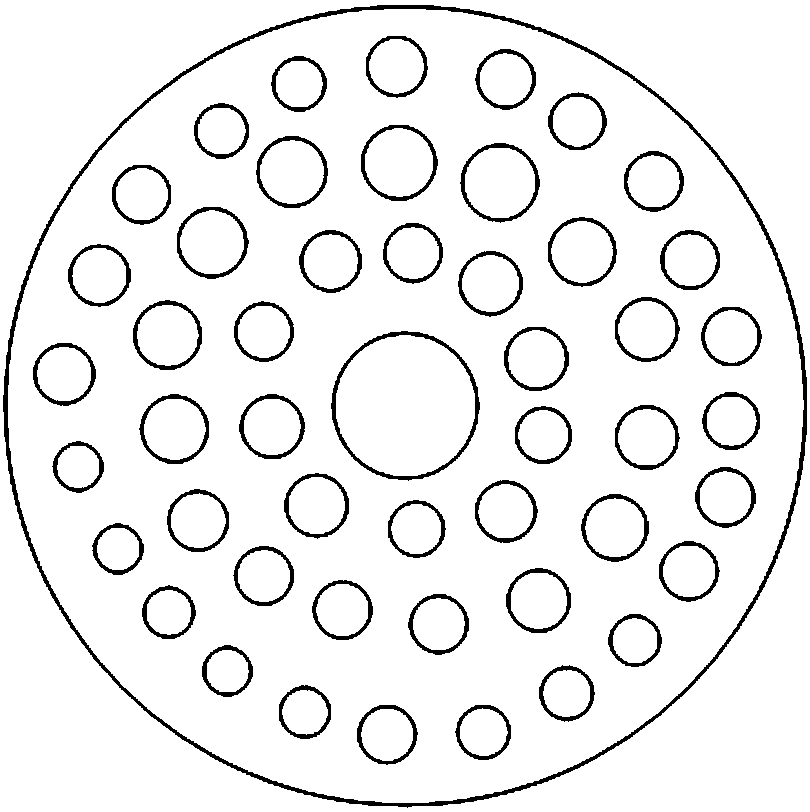

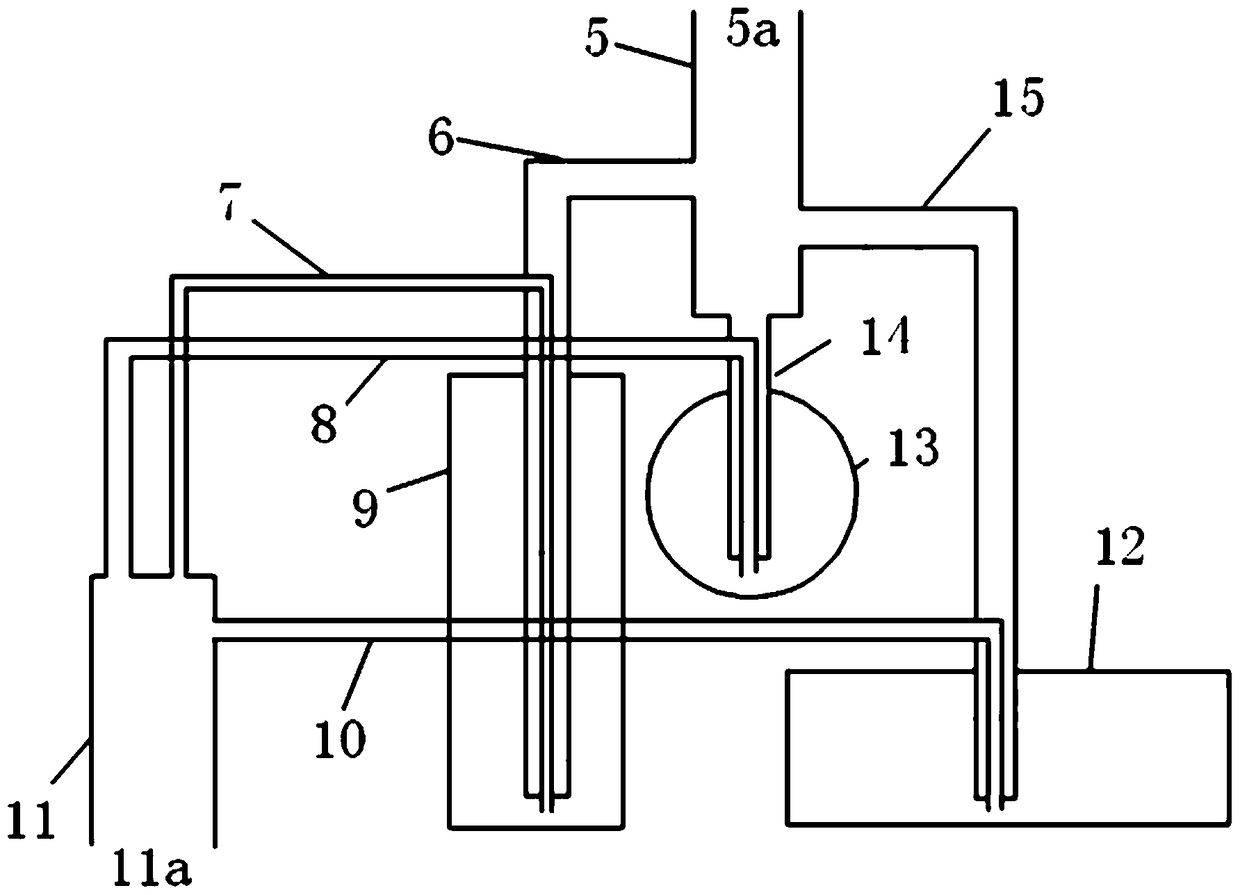

[0033] Taking the CVI deposition of silicon carbide in three complex containers with different shapes as an example, the three containers are arranged according to image 3 Connected to the schematic diagram, put into the deposition furnace, the container does not directly touch the crucible wall. According to the conventional CVI preparation process, the temperature is raised, and the precursors (hydrogen, argon, and MTS) are introduced to react. The generated silicon carbide can be continuously deposited from the inside to the outside. Similarly, the outer surface is deposited from the outside to the inside. The tail gas generated in the container passes through each row The gas pipe is discharged from the main exhaust pipe 11, the deposition time is increased by about 20% compared with the conventional deposition time, and the deposition effect is obviously improved.

[0034] Figure 4 Shown is a schematic diagram of the actual deposition in the furnace. The inlet of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com