Method for preparing suspension arm with stage

A boom and step technology, which is applied in the field of semiconductor handling precision ceramics preparation, can solve the problems of molding failure, pressure difference, uneven density, etc., and achieve the effects of high yield, good application prospects, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Alumina with a purity ≥ 99.7% is used for batching, and a buffering device is used for dry pressing molding, with a pressure of 100 MPa, two-way pressure, and pressure holding for 1 minute to obtain a molded body;

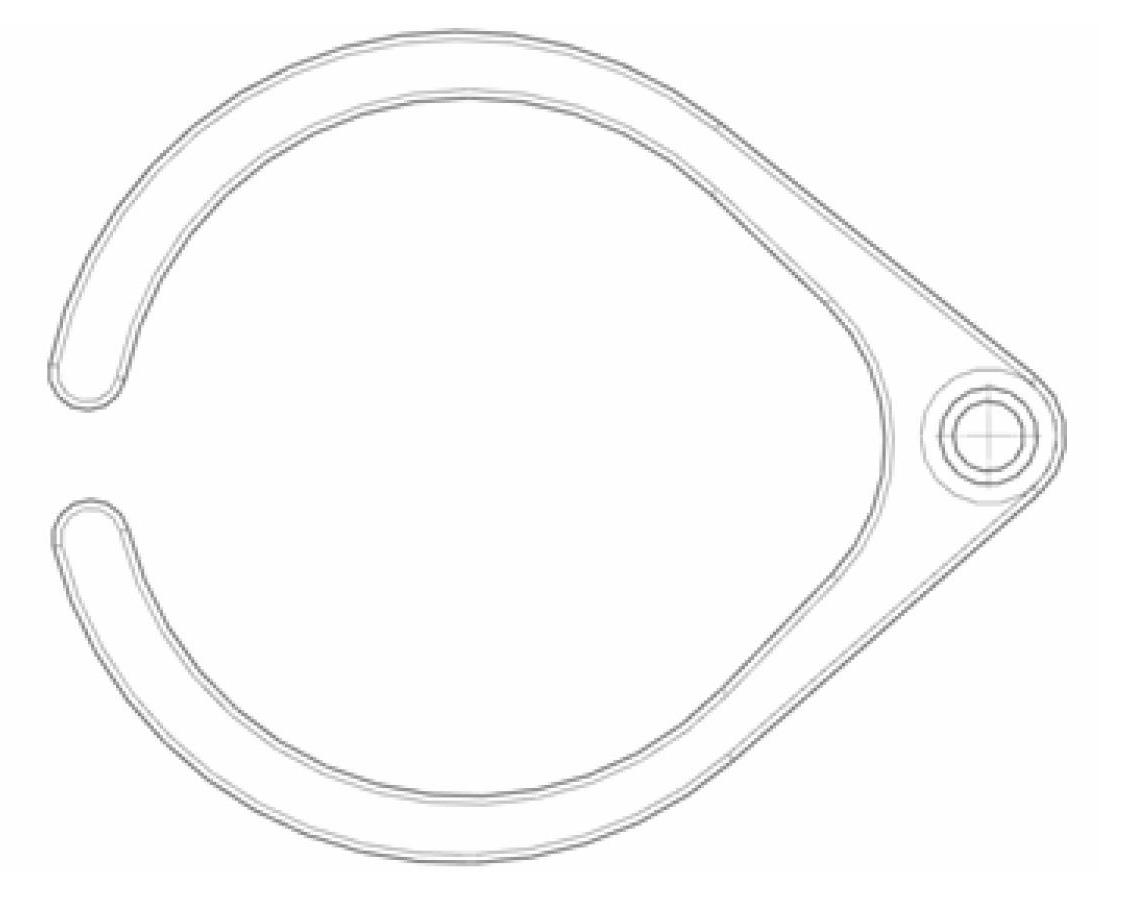

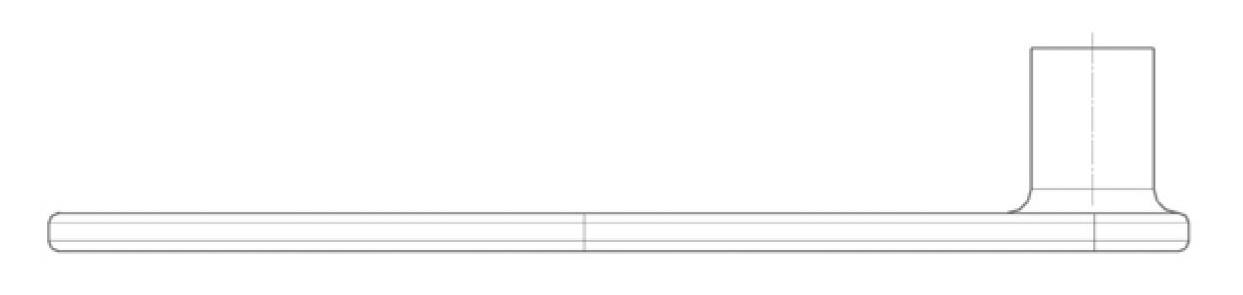

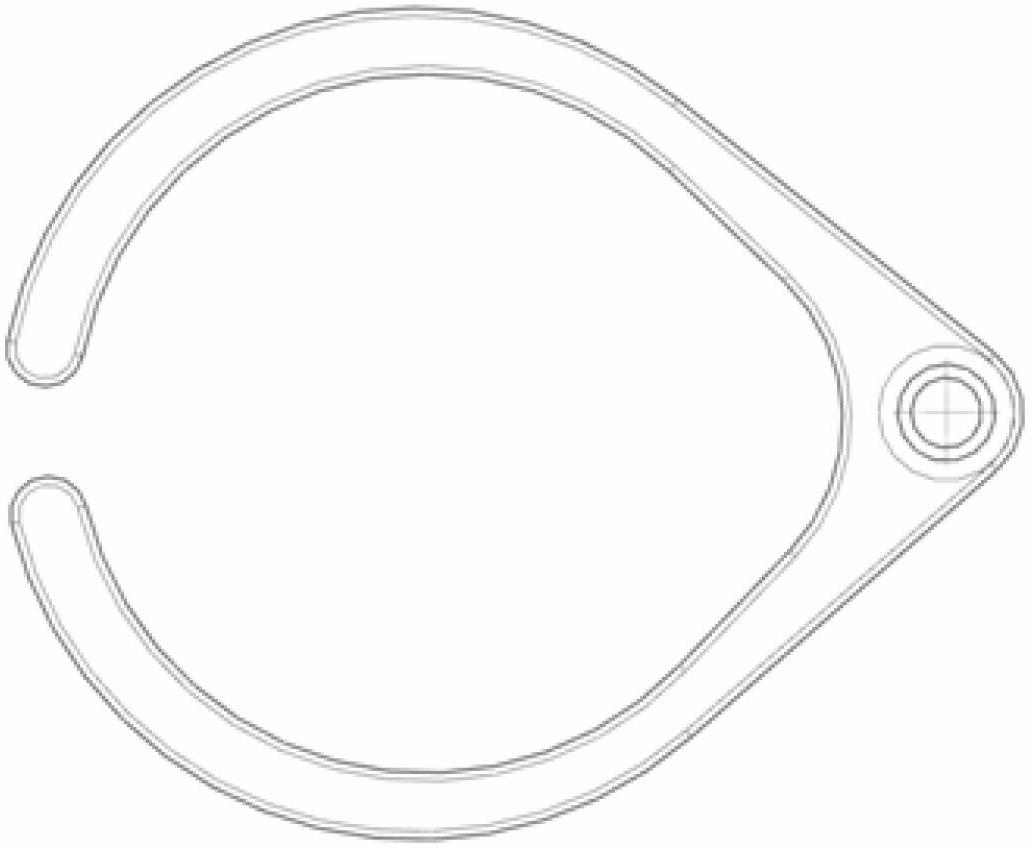

[0021] (2) Perform cold isostatic pressing on the above-mentioned formed green body at a pressure of 200MPa, hold the pressure for 3 minutes, and then sinter at 1650°C for 2 hours and finish machining to obtain a boom with steps (such as figure 1 , 2 shown).

Embodiment 2

[0023] (1) Alumina with a purity ≥ 99.7% is used for batching, and a buffering device is used for dry pressing molding, with a pressure of 150MPa, two-way pressure, and pressure holding for 3 minutes to obtain a molded body;

[0024] (2) Cold isostatic pressing is performed on the above-mentioned formed green body at a pressure of 300 MPa, and the pressure is maintained for 5 minutes, and then sintered at 1800°C for 4 hours and finished to obtain a boom with steps.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com