Method for establishing a connection between an electric connection element for a motor vehicle electrical system and a cable of the motor vehicle electrical system

A technology for connecting components and vehicle power grids, which is applied in the direction of conductive connections, electrical components, and electrical components, and can solve problems such as increased transition resistance, and achieve the effects of reduced structural space, saving process steps, and weight saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

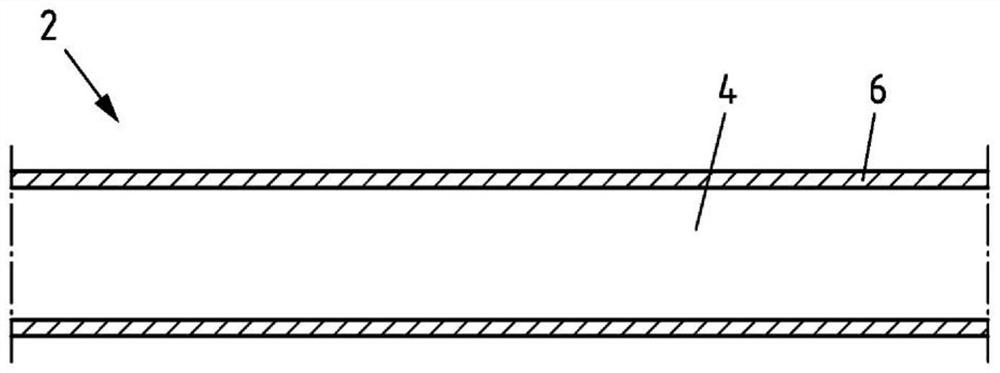

[0053] Figure 1a An electrical cable 2 with metallic stranded conductors 4 and insulation 6 is shown.

[0054] The metal conductor 4 is preferably a stranded conductor and is especially resistant to bending. The conductor 4 is preferably a round conductor. The material of the litz wires of the conductor 4 is preferably aluminum, in particular aluminum 99.5. The bending resistance of the cable 2 is obtained if the cable 2 does not undergo plastic deformation due to its own weight. A force greater than gravity is required to cause plastic deformation of the cable 2 .

[0055] The insulation 6 preferably consists of PVC or silicone.

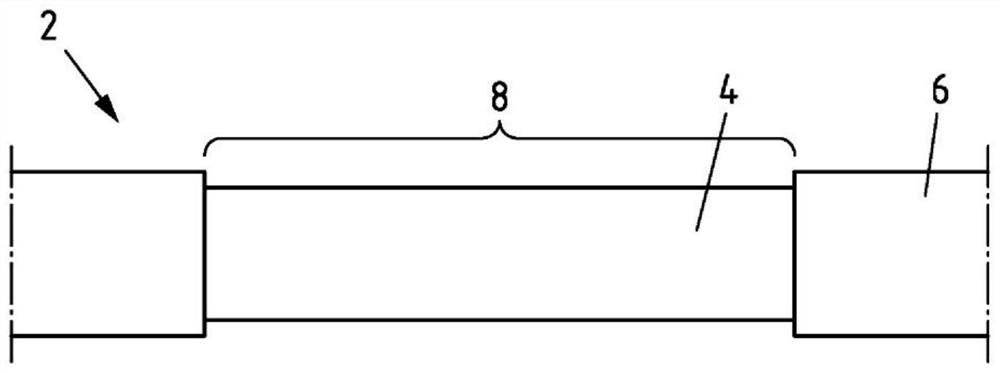

[0056] Such as Figure 1b As shown, the cable 2 is stripped of its insulation in an intermediate region, ie away from its respective distal ends, to form a stripped region 8 . In the stripped region 8 the conductor 4 is free of the insulation 6 .

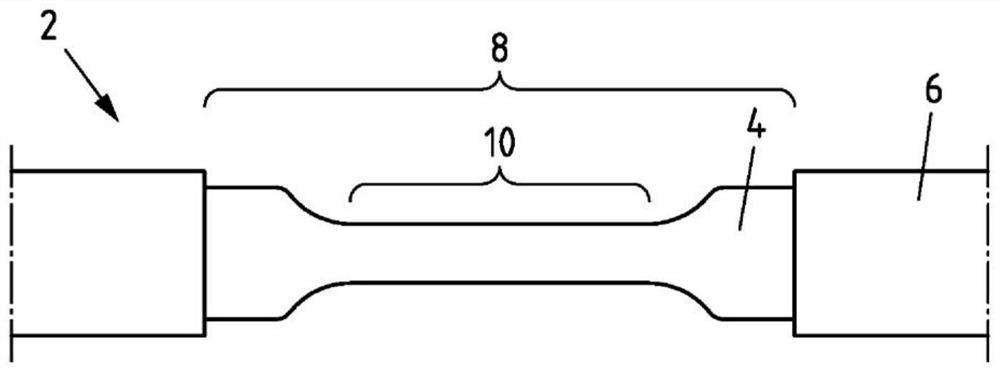

[0057] After the stripped region 8 has been produced, the cable 2 or its conductor 4 can be den...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com