Patents

Literature

33results about How to "Small transition resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electrical plug, holder, system having an electrical plug and a holder, and method of making a connection between an electrical plug and a holder

InactiveUS7131857B2Done quickly and without toolsSmall transition resistanceLine/current collector detailsContact members penetrating/cutting insulation/cable strandsElectrical connectionEngineering

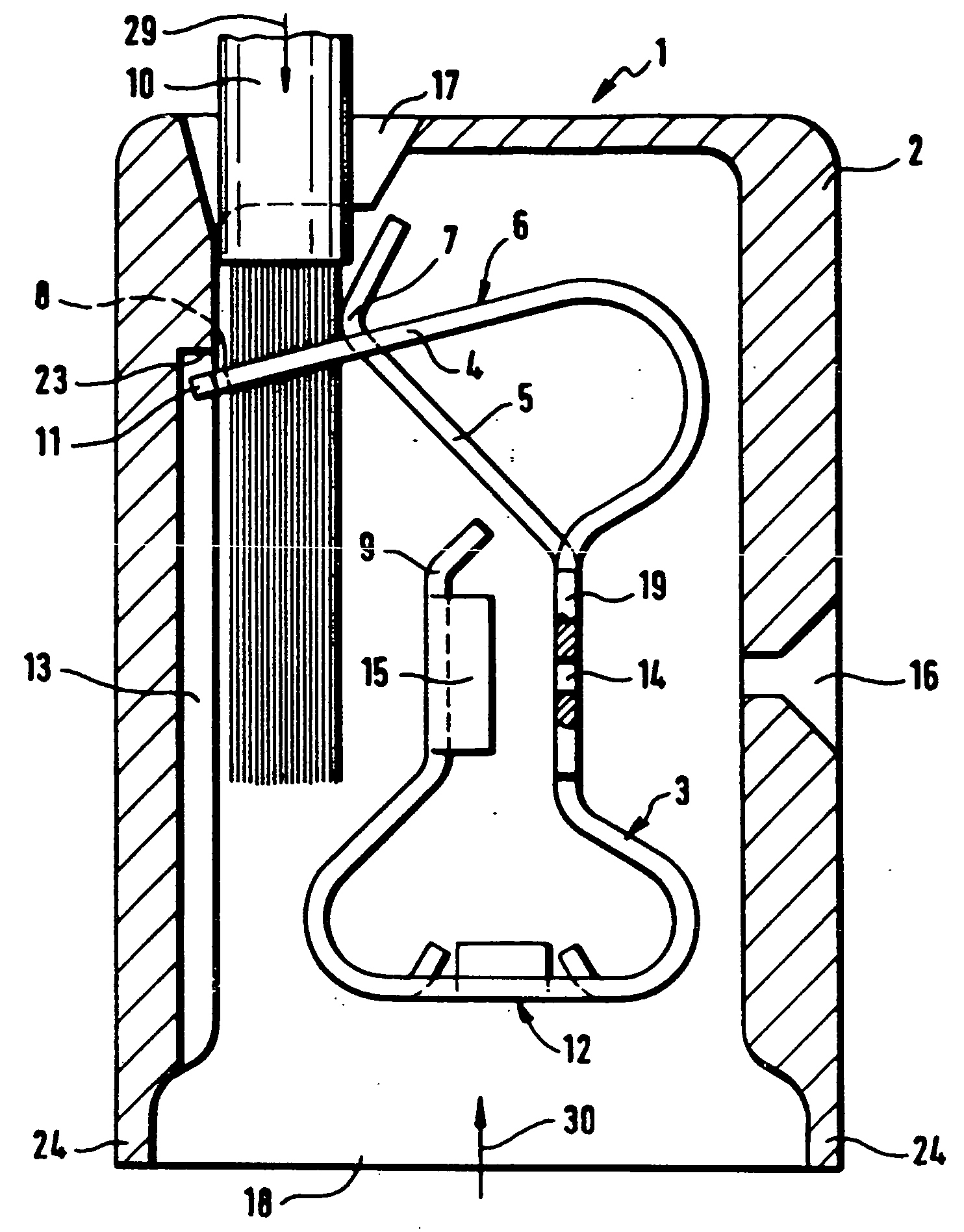

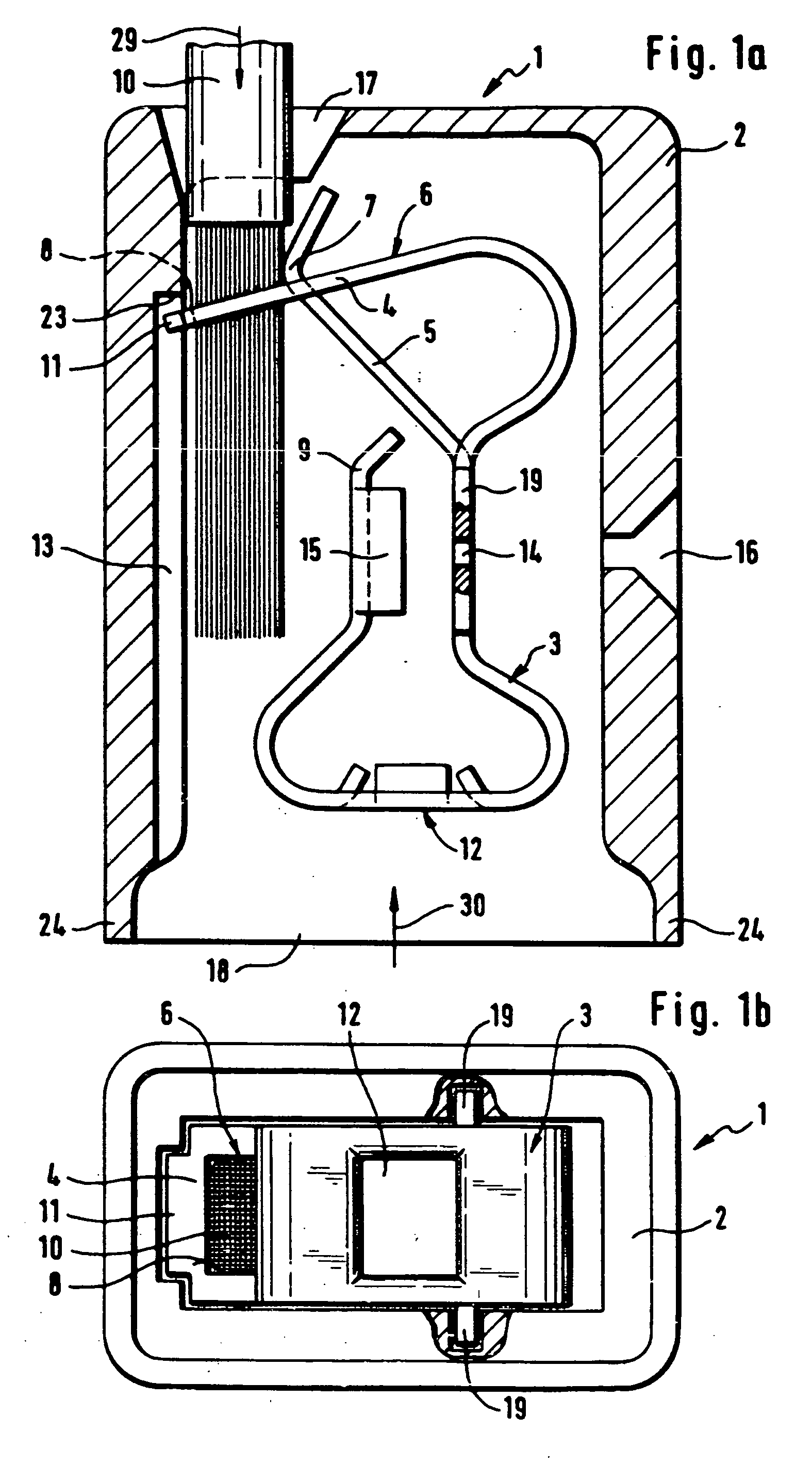

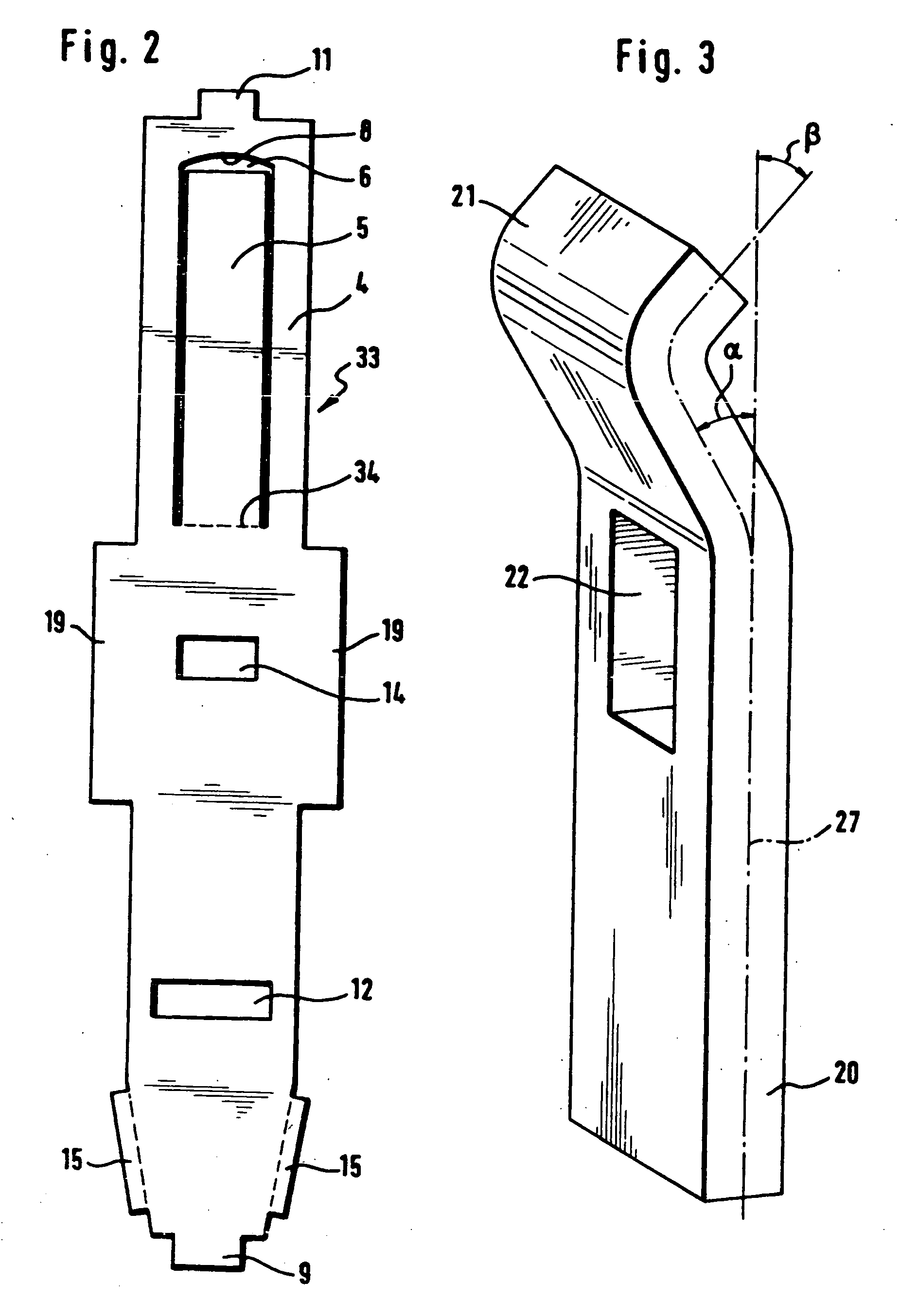

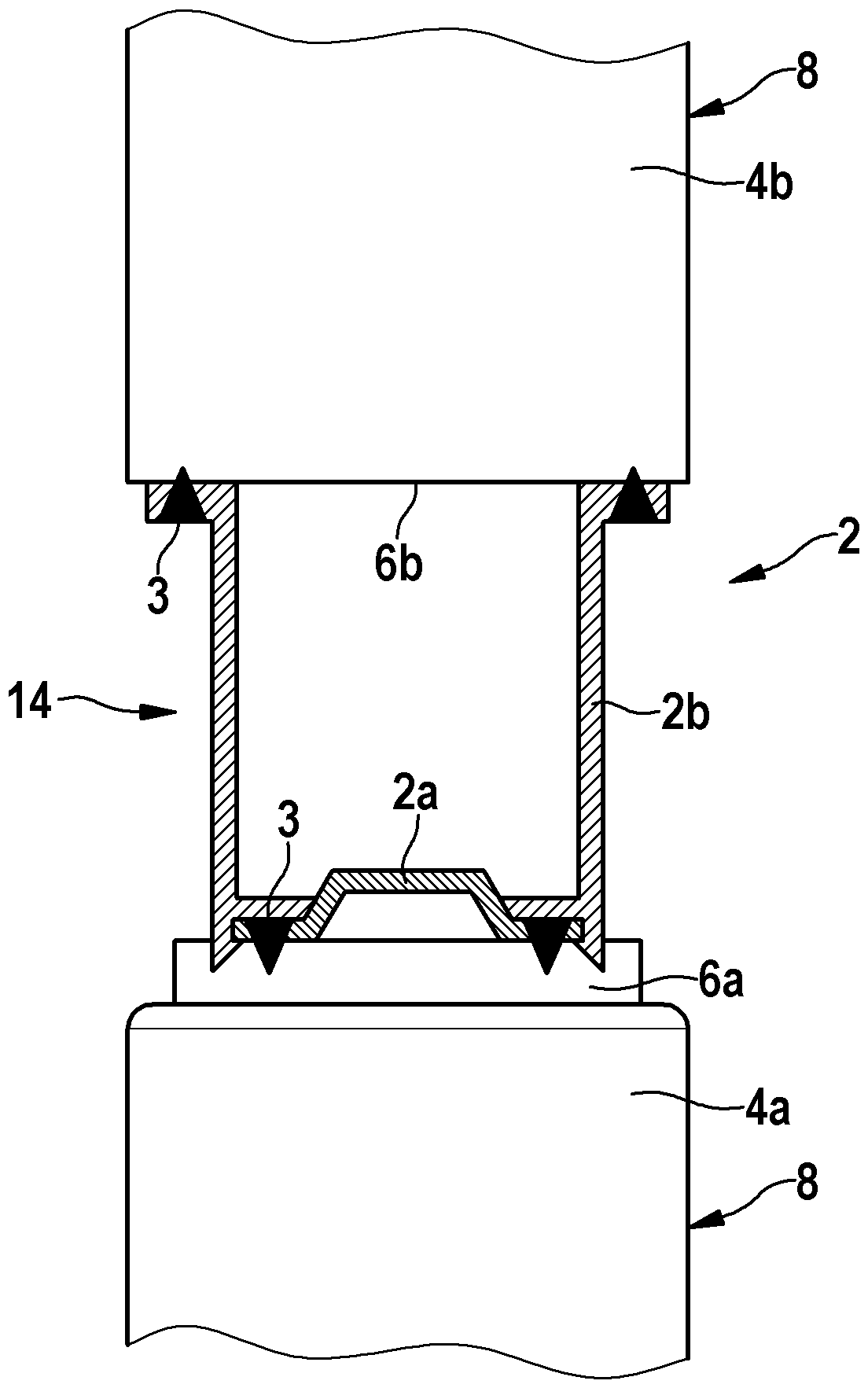

An electrical plug includes a housing and a spring clamp to connect a flexible electric conductor to an end piece of a rigid holder. The clamp spring includes a contact leg and a clamp leg. The clamp leg is bent closed in a loop onto the contact leg end providing a clamp opening through which the contact leg end protrudes. The clamp leg and a clamp opening edge positioned opposite to the clamp leg form a clamp location in which the electric conductor passed through the clamp opening is clamped before mounting the plug on the holder. After mounting, the holder extends through the clamp opening displacing the contact leg from the electric conductor. The holder and clamp spring clamp the electric conductor and form an electrical connection between the holder and electric conductor.

Owner:NEWFREY

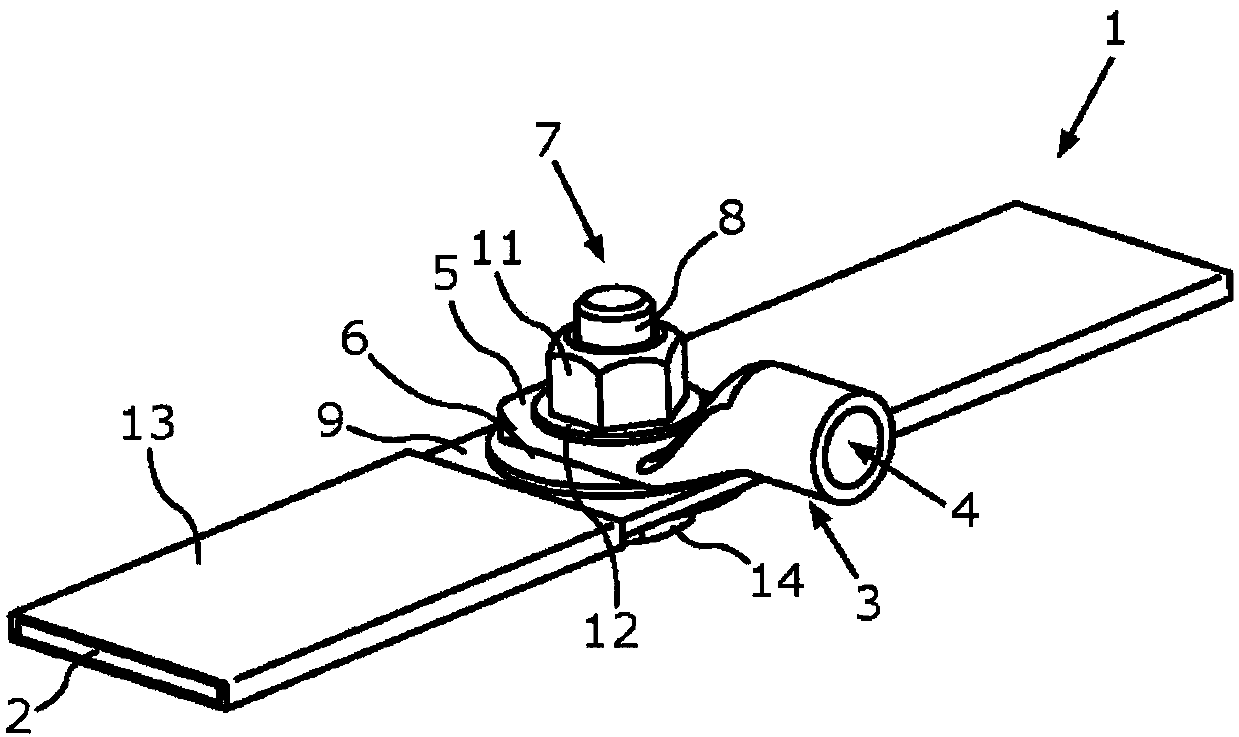

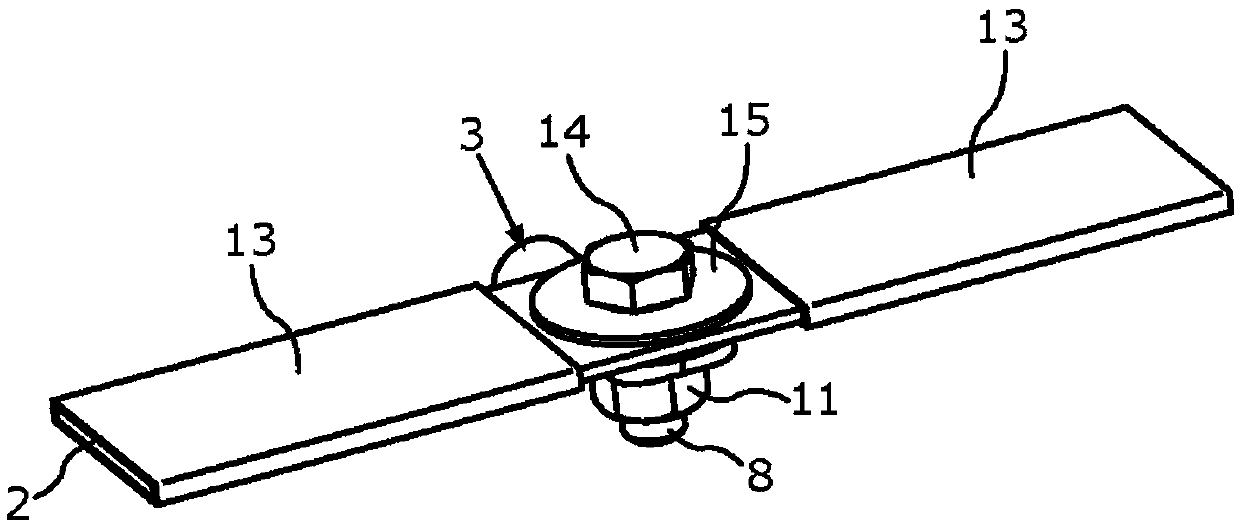

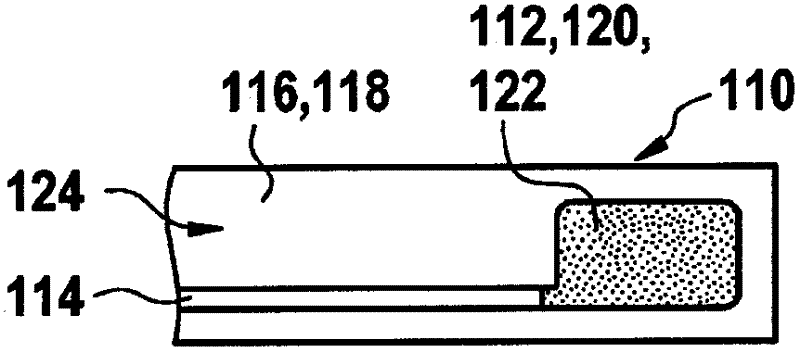

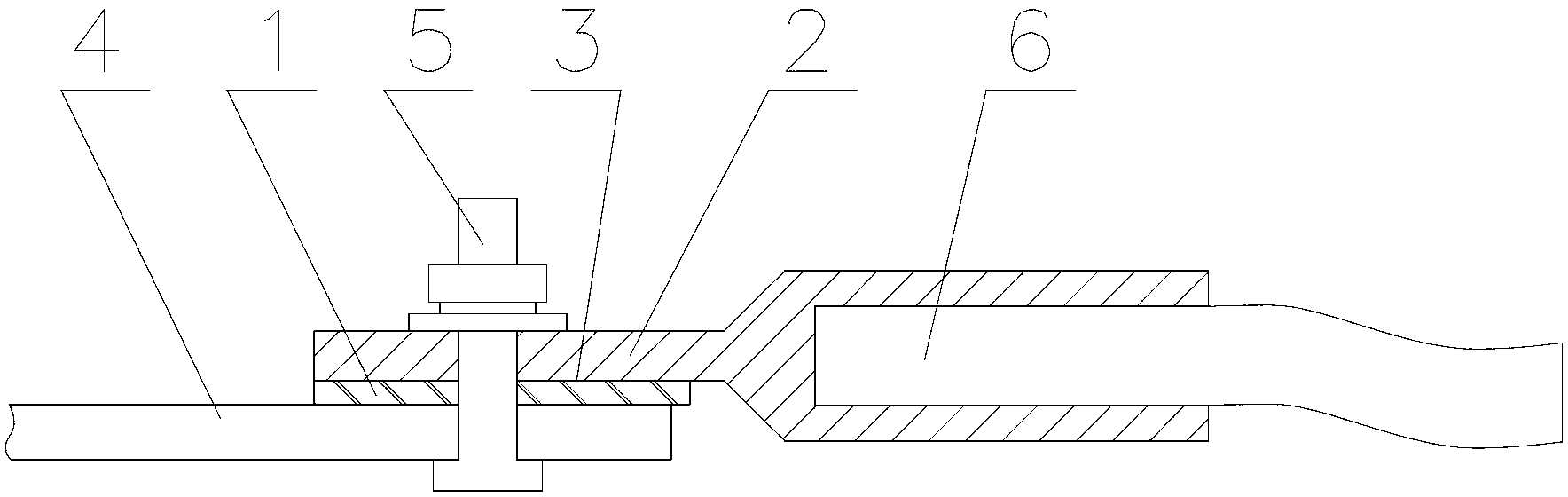

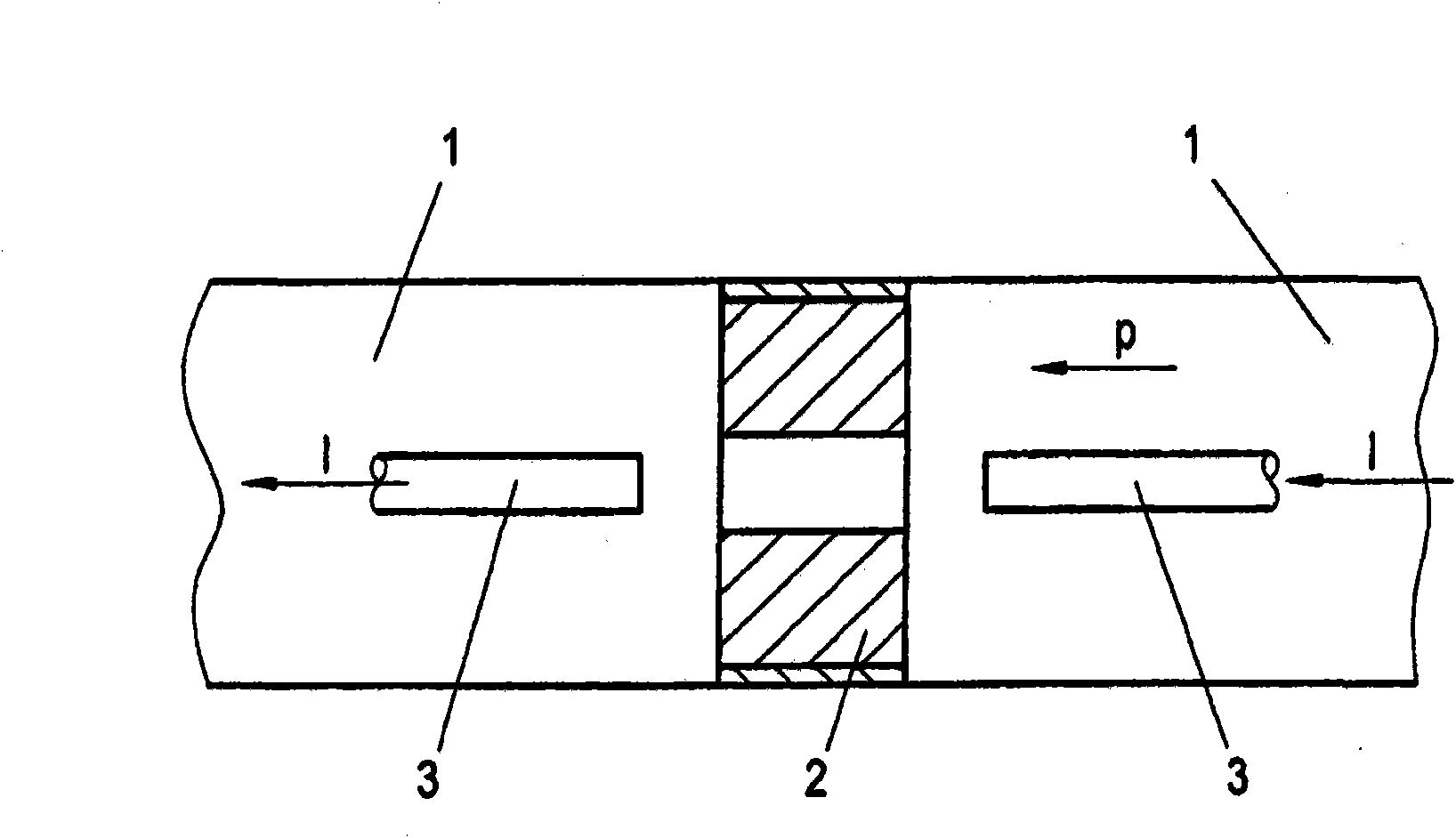

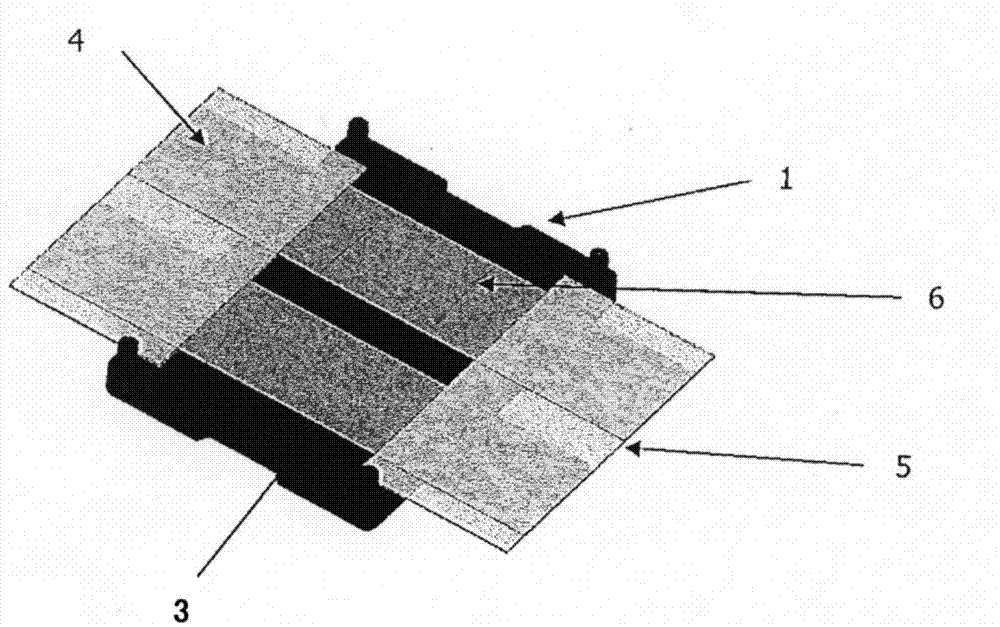

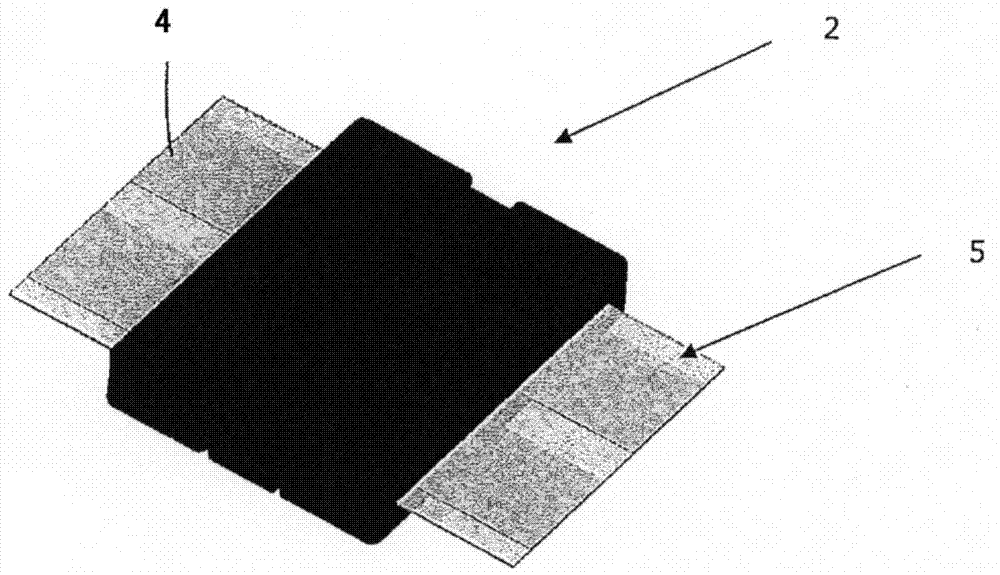

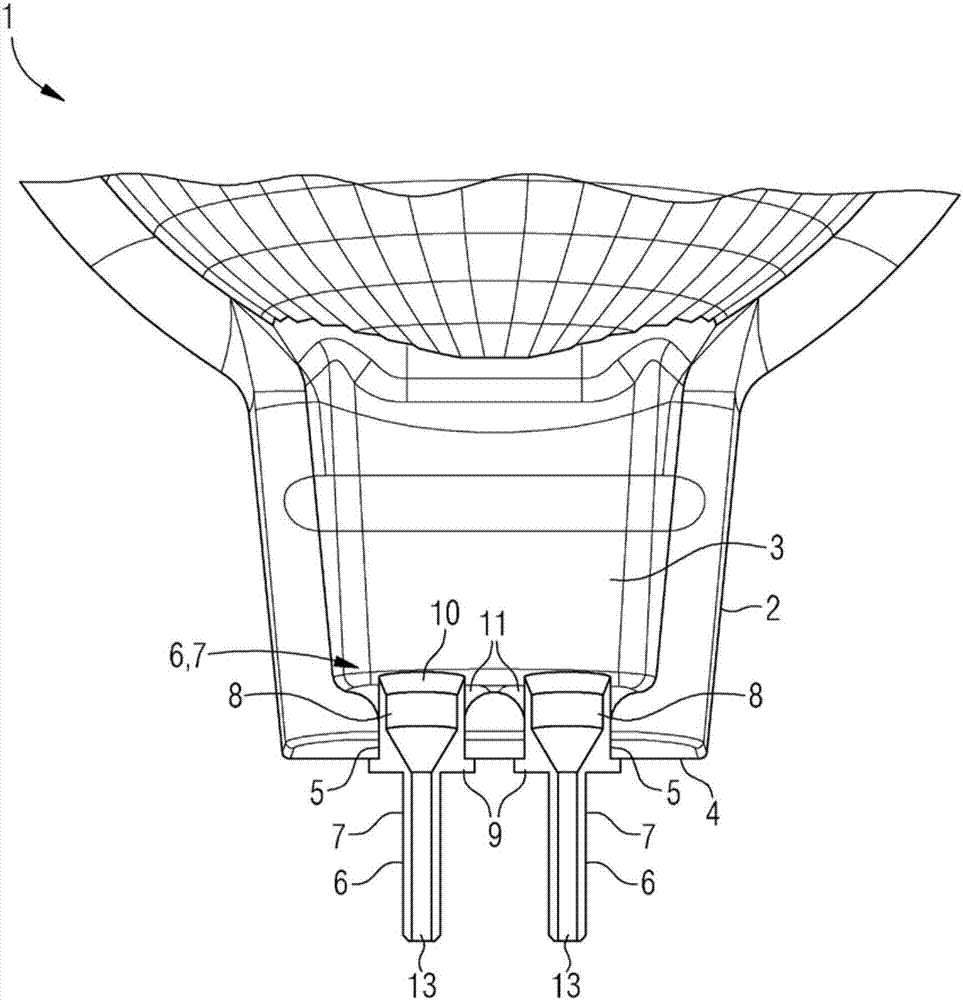

Electric connecting equipment and method for manufacturing same

InactiveCN107863610ASmall transition resistanceHigh mechanical strengthVehicle connectorsCoupling device engaging/disengagingBusbarEngineering

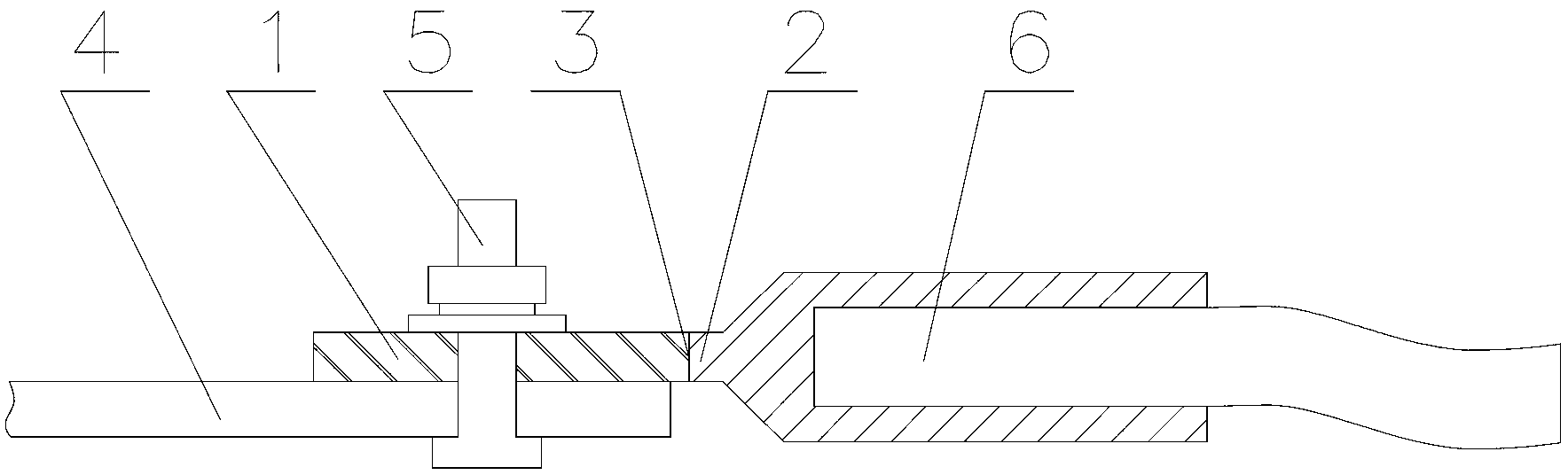

The invention relates to electric connecting equipment (1) which comprises the components of a flat busbar (2) with a through opening, wherein the through opening extends through the first surface side (9) and the second surface side (10) of the flat busbar; a cable receiving component (3) which is used for conductively connecting the cable with the flat busbar; a screw (7), wherein the rod (8) ofthe screw is guided from the second surface side through the through opening of the flat busbar and through the contact area (5) of the cable receiving component; a nut (11) which is screwed on the rod of the screw, wherein the contact area of the cable receiving component is at least indirectly clamped between the nut and the first surface side through the nut; and contact elements (6,14,19,24)which is connected with the flat busbar material in a combined manner in annular combining areas (16,21,25) which surround the through opening, and furthermore the contact area of the cable receivingcomponent is directly placed on the contact component. The invention further relates to a method for manufacturing the electric connecting equipment.

Owner:LISA DRAXLMAIER GMBH

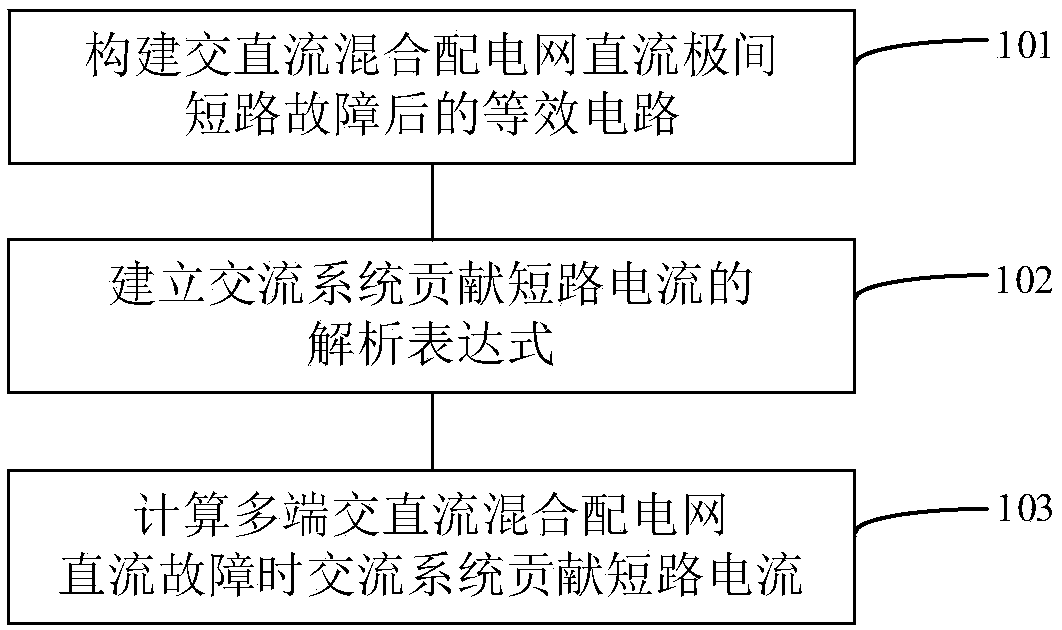

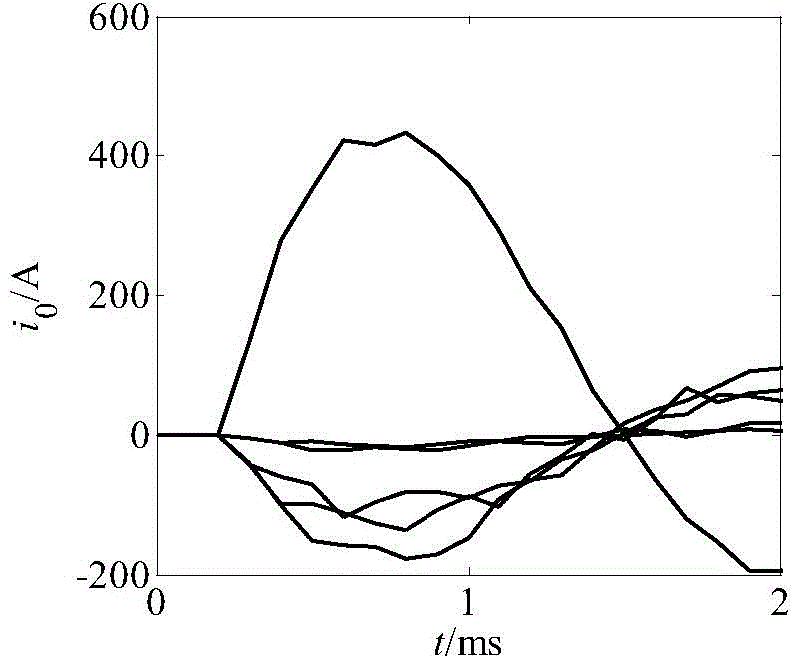

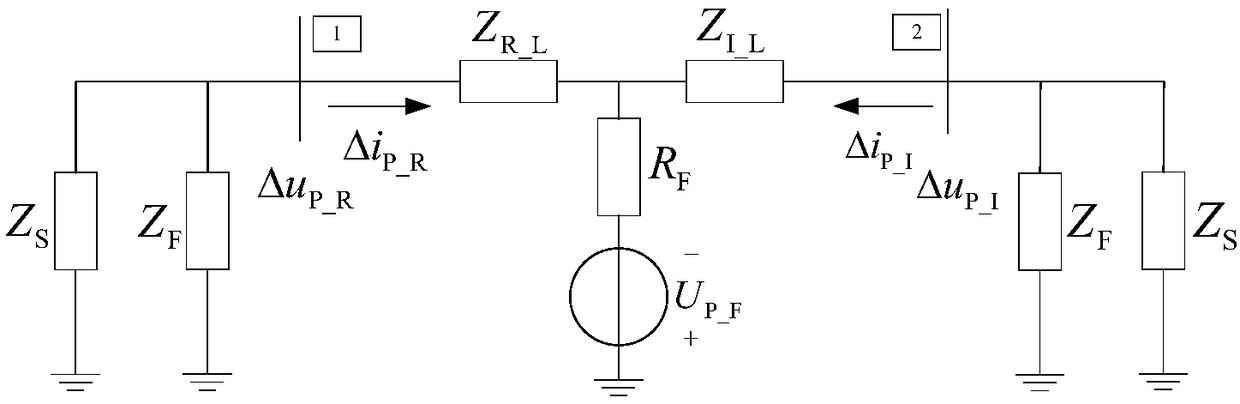

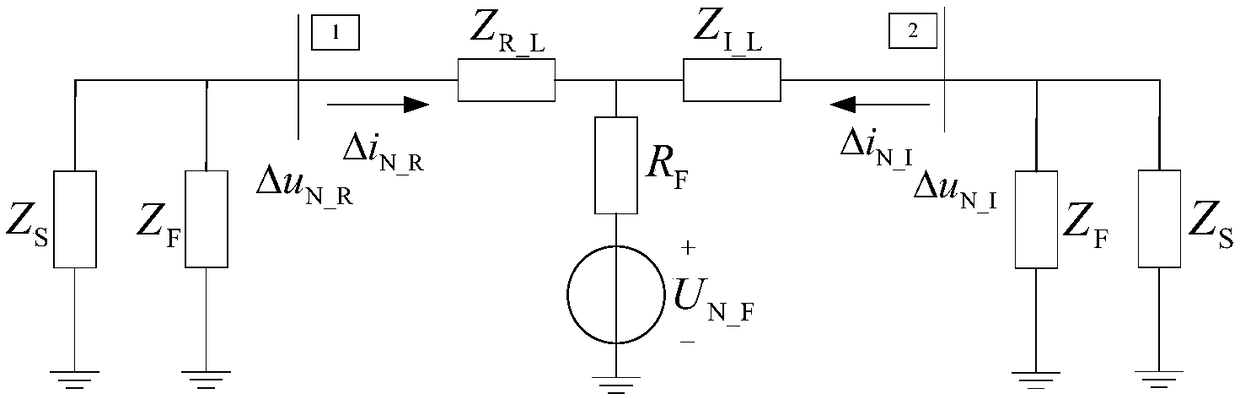

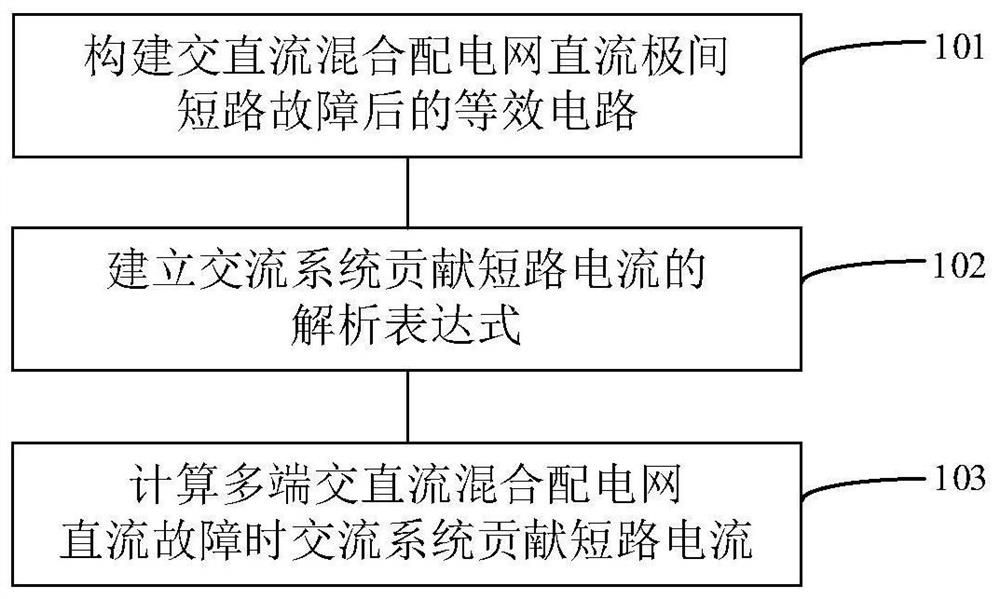

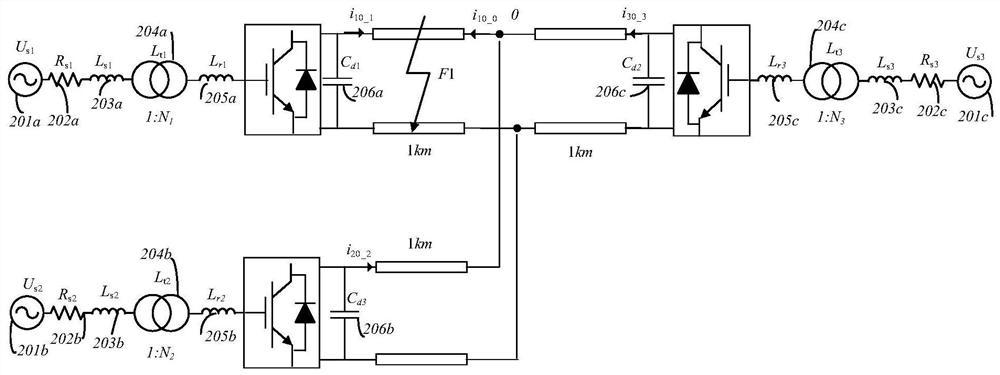

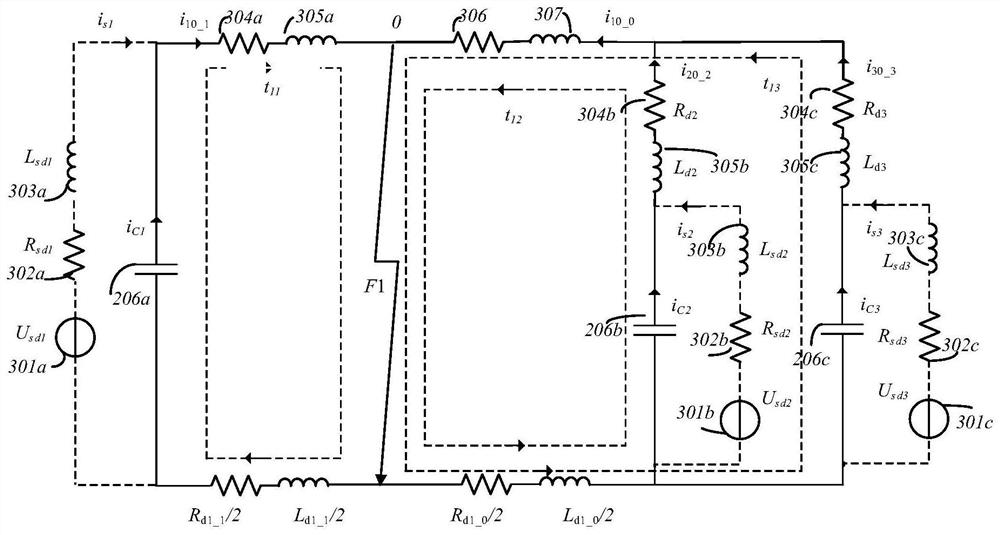

Calculation method of short-circuit current contributed by alternating-current system during direct-current fault of multi-end alternating current/direct current hybrid distribution network

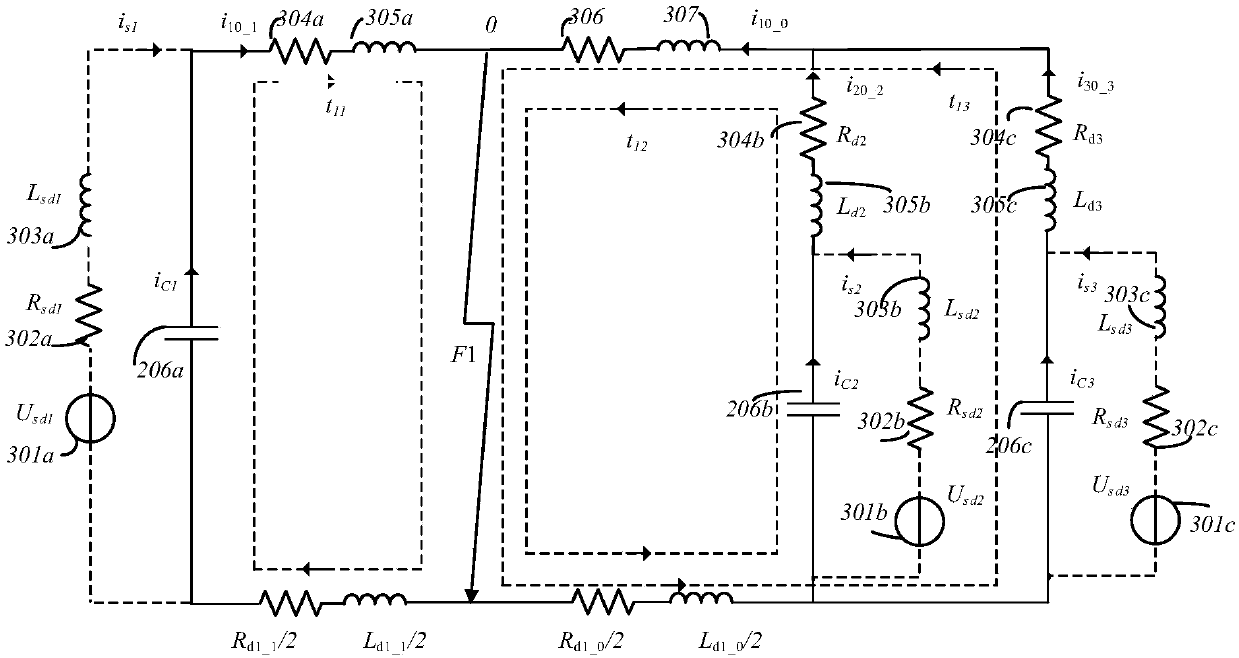

ActiveCN108429252AThe calculation process is simpleGuaranteed uptimeLoad forecast in ac networkElectric power transfer ac networkPeak valueVoltage source

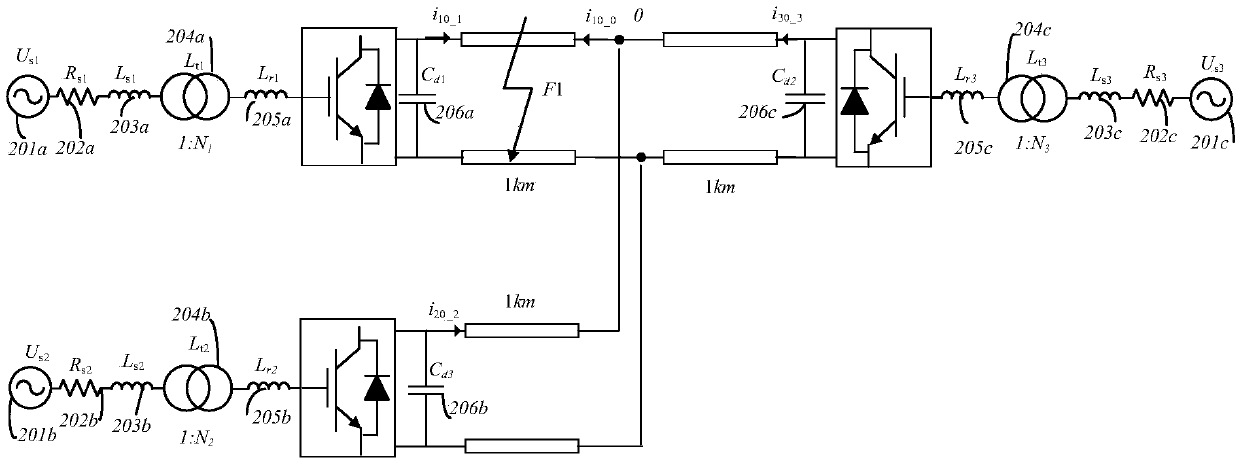

The invention relates to a calculation method of short-circuit current contributed by an alternating-current system during the direct-current fault of a multi-end alternating current / direct current hybrid distribution network. The method includes the following steps that: 101, a post-direct-current inter-pole short-circuit fault equivalent circuit of the alternating current / direct current hybrid distribution network is provided according to the characteristics of fault current and contribution made by the alternating-current system to the fault current after an inter-pole short-circuit fault of a direct-current line occurs, wherein the equivalent circuit is composed of an alternating-current voltage source 301, an alternating-current system equivalent resistor 302, an alternating-current system equivalent inductor 303, a converter station direct-current side capacitor 206, direct-current line resistors 304 and 306, and direct-current line inductors 305 and 307; 102, an analytical expression of the short-circuit current contributed by the alternating-current system is derived according to the analysis of the step 101; and 103, the calculation method of the short-circuit current contributed by the alternating-current system during the direct-current fault of the multi-end alternating current / direct current hybrid distribution network is provided according to the analysis of the step 102, the steady-state average value, transient peak value time and transient peak value of the method are calculated.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI +1

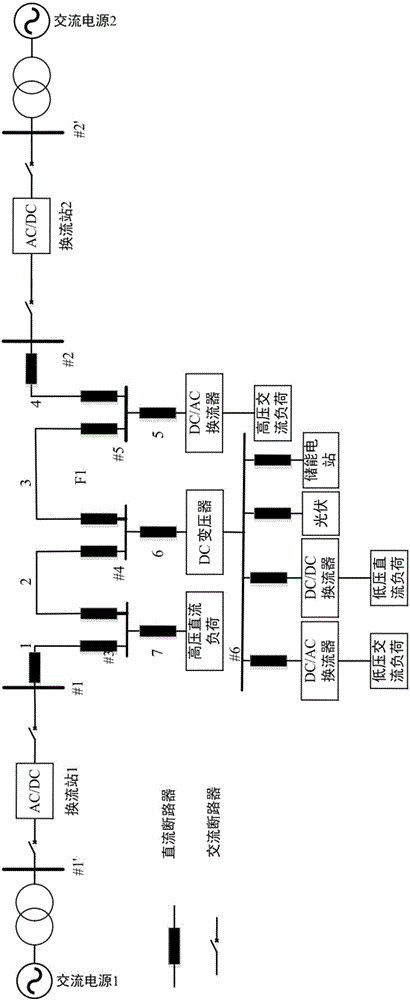

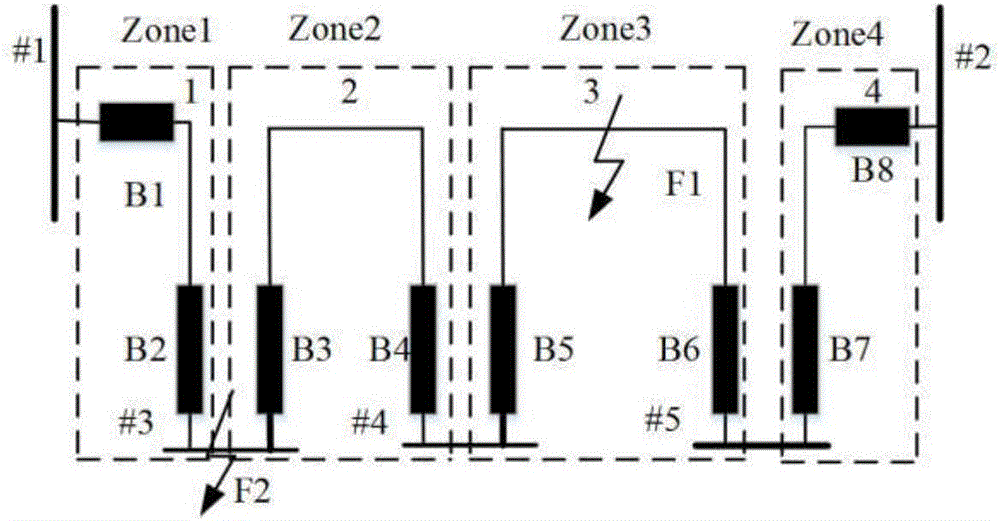

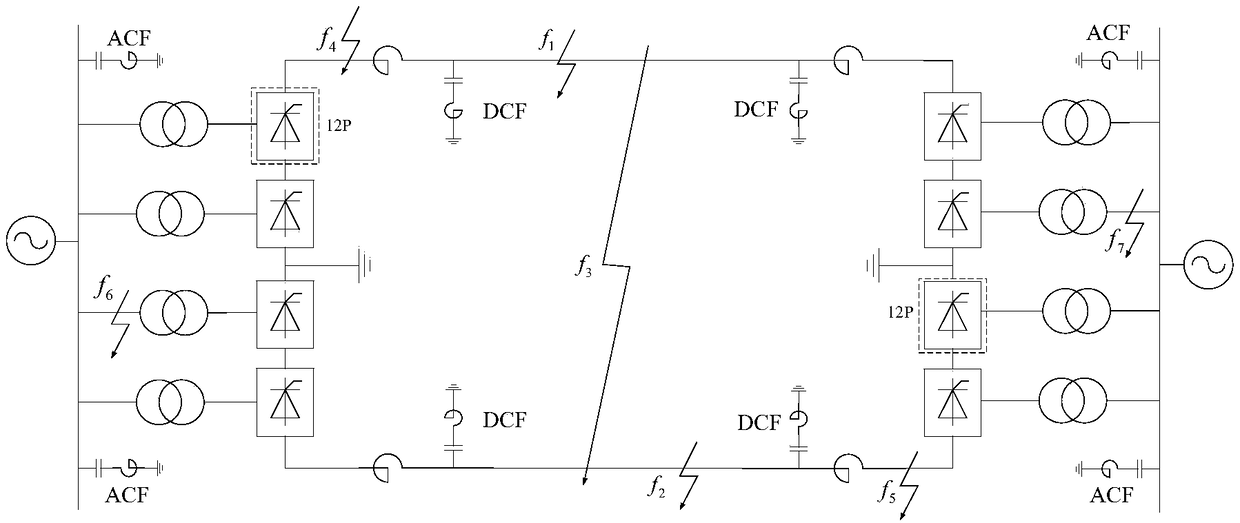

Method for protecting double-end direct current distribution network

InactiveCN106711971AQuick protectionFast actionEmergency protective circuit arrangementsPower flowDc circuit breaker

The invention discloses a method for protecting a double-end direct current distribution network. The method comprises the steps of: 1) performing regional division on the double-end direct current distribution network by using a direct current circuit breaker and a direct current bus; 2) when the direct current distribution network has a single-pole ground or double-pole short-circuit fault, judging the fault current direction in each divided region; 3) performing information interaction on the fault current direction in each region, thus distinguishing the fault type; and 4) removing the fault according to the fault type. The line of the direct current distribution network is short, and the information interaction is only performed in the adjacent regions, so that the influence of delay on data transmission can be ignored; only digital signals are transmitted, so that the transmission time can be nearly ignored; the current direction is changed on the millisecond level, and the fault is removed by using the solid direct current circuit breaker, so that the operation speed is high, and quick protection of the double-end direct current distribution network can be realized; and the scheme has certain transition resistance tolerance, and is thus universal for protection of double-end direct current distribution networks.

Owner:SOUTHEAST UNIV

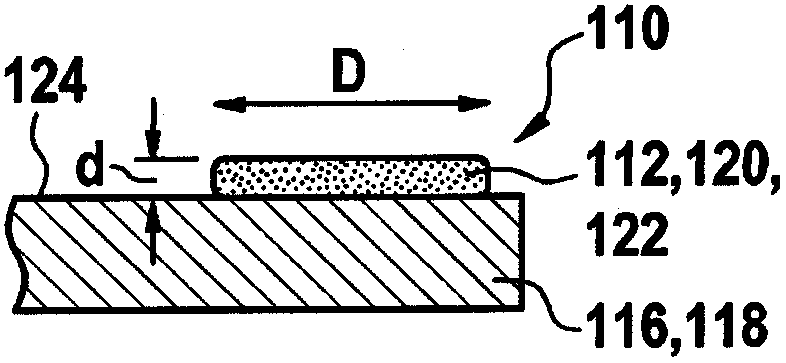

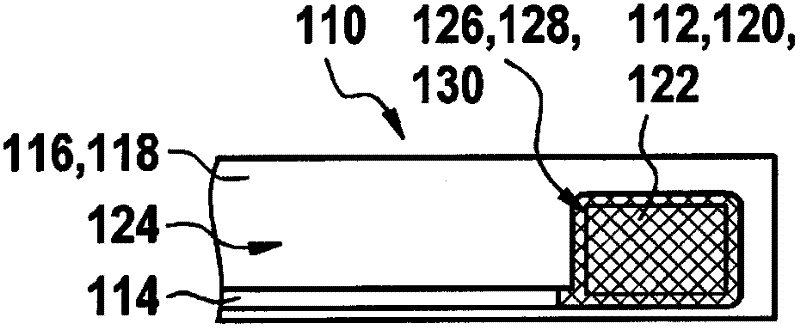

Structured electrode for ceramic sensor elements

ActiveCN102246028ALower internal resistanceImprove conduction abilityMaterial analysis by electric/magnetic meansMetallic materialsLateral extension

The invention relates to a sensor element (110), particularly for capturing a property of a gas in a measuring gas space. The sensor element (110) comprises at least one solid electrolyte layer (116) having at least one ceramic solid electrolyte material (118) and at least one electrode (112) contacting the solid electrolyte layer (116) directly or indirectly. The electrode (112) comprises at least one ceramic material (122) and at least one metal material (120). The electrode (112) has a lateral extension and has structuring (126, 140) extending parallel and / or perpendicular to the lateral extension within the lateral extension. The structuring (126, 140) is designed to enlarge an electrode surface of the electrode (112).

Owner:ROBERT BOSCH GMBH

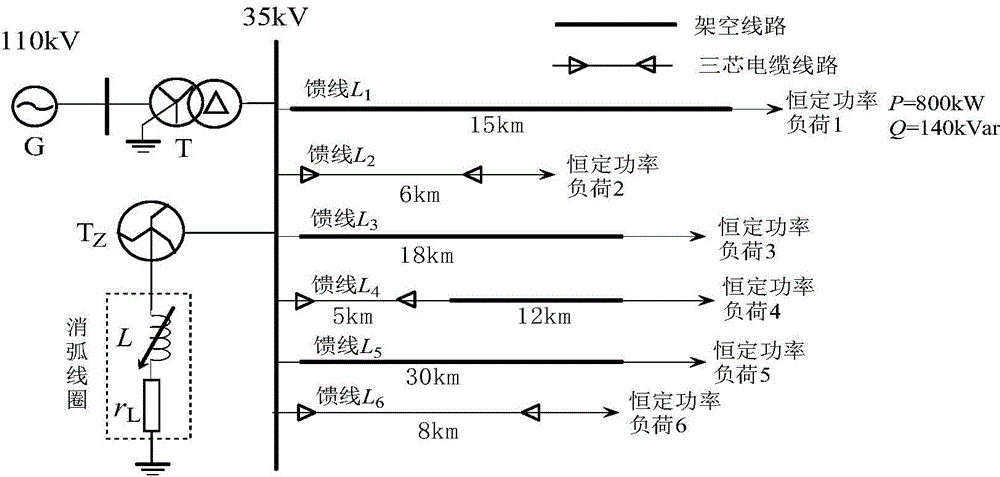

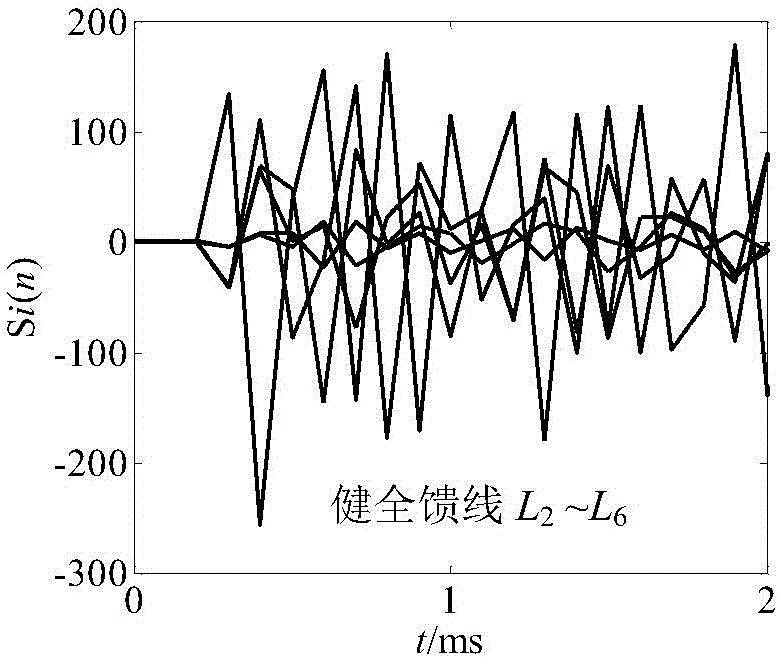

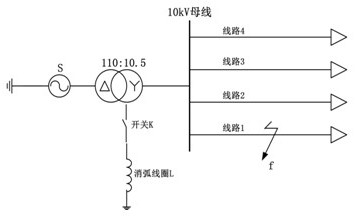

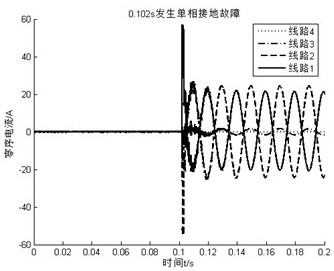

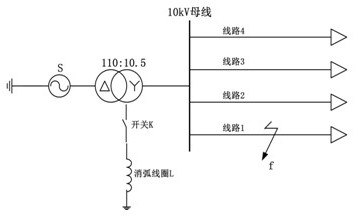

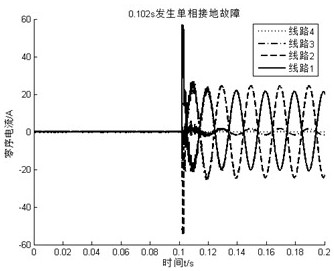

Distribution network fault line selection method based on zero-mode current multi-order difference transformation

InactiveCN104133158AAvoid compensatory effectsImprove reliabilityFault locationElectric power systemCompensation effect

The invention relates to a distribution network fault line selection method based on zero-mode current multi-order difference transformation and belongs to the technical field of power system relay protection. When feeder lines in a distribution network are in a single-phase earth fault, zero-mode current traveling wave data, recorded into a short time window, of the feeder lines are extracted for multi-order difference transformation; if a first nonzero value achieved after transformation is carried out is greater than zero, it is judged that the feeder lines are in the single-phase earth fault; if the first nonzero value is smaller than zero, it is judged that the feeder lines are not in the single-phase earth fault. By the utilization of the zero-mode current data, in the short time window, of the feeder lines after the fault occurs, at the moment, an arc suppression coil does not compensate for a system, so that the method avoids influence on the compensation effect of the arc suppression coil, and fault feeder lines can be judged out accurately and reliably.

Owner:KUNMING UNIV OF SCI & TECH

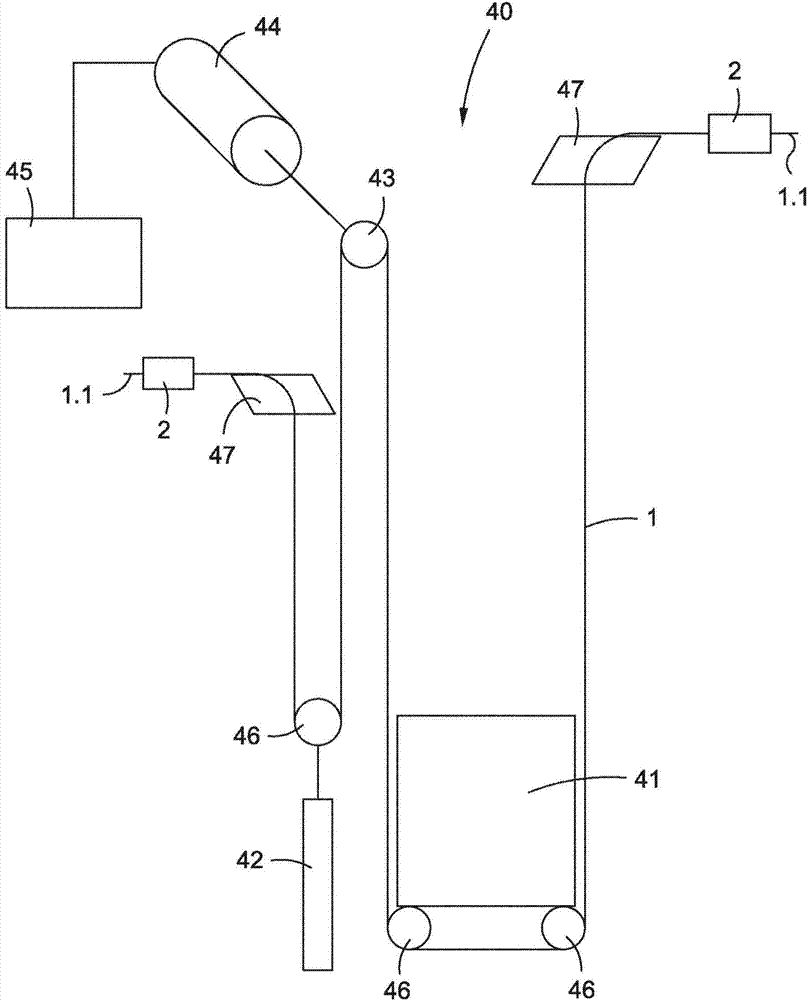

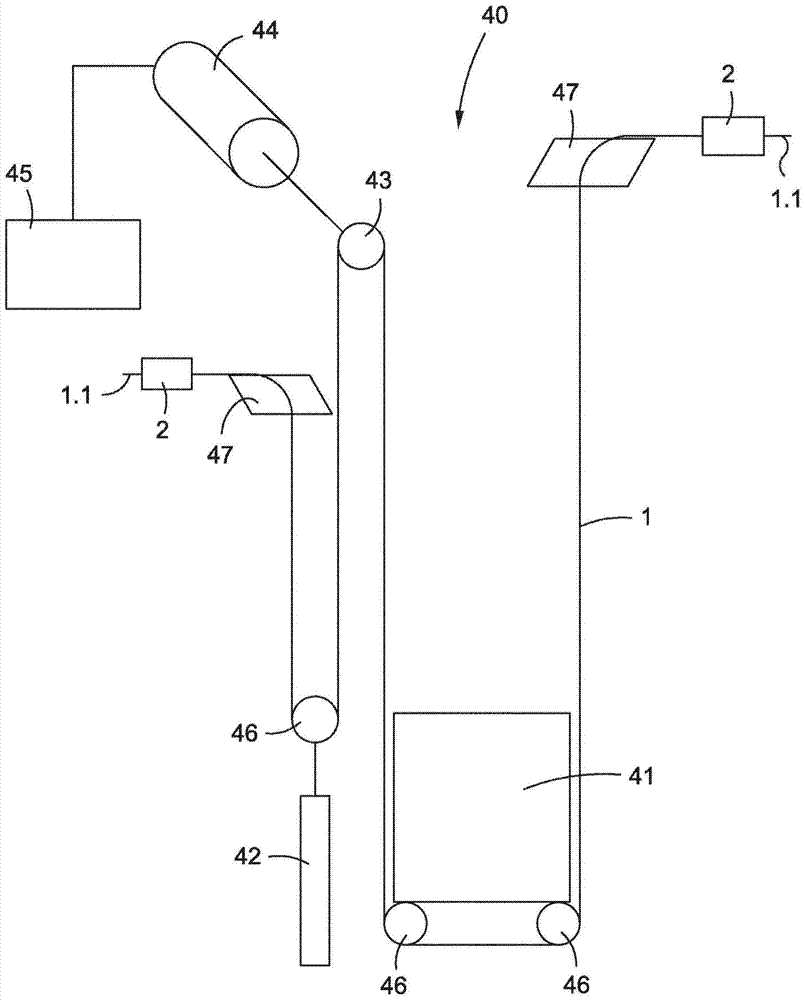

Monitoring of supporting means in elevator systems

InactiveCN104755405AReliable electrical connectionSmall transition resistanceMaterial analysis by electric/magnetic meansTwo-part coupling devicesElevator systemElectrical and Electronics engineering

The invention relates to supporting means for an elevator system comprising a plurality of tension-bearing elements arranged parallel to each other and a jacket. The tension-bearing elements are surrounded by the jacket, wherein the tension-bearing elements extend along a longitudinal axis of the supporting means. The jacket is at least partially removed from the tension-bearing elements in a segment of the longitudinal axis of the supporting means. Contact elements for electrically contacting the tension-bearing elements are fastened to the tension-bearing elements in said segment.

Owner:INVENTIO AG

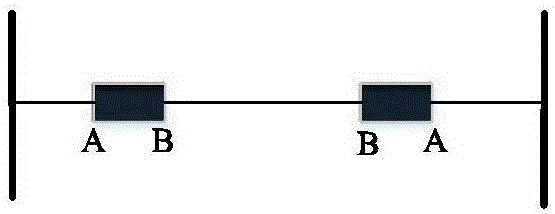

High-frequency transient component direction longitudinal protection method and system

ActiveCN109375052ARealize the areaRealize external fault judgmentElectric power transfer ac networkEmergency protective circuit arrangementsElectrical resistance and conductanceTransient state

The invention discloses a high-frequency transient component direction longitudinal protection method and system. The method is characterized by through extracting voltage and current high-frequency transient component data at a protection installation position, calculating the phase relation of a voltage and current high-frequency transient component according to Hilbert-Huang conversion, and realizing internal and external fault determination of a UHVDC power transmission system line; and on the basis of identifying a fault in a direct current line area, carrying out simple logic processingat the fault directions of the two sides of an anode and a cathode so that a fault pole can be selected without a complicated fault selection pole scheme. For various fault types, the faults in the line area and outside the line area can be accurately identified, and fault pole selection can be performed. The protection method is less affected by the factors of a transition resistor, a fault distance and the like.

Owner:ELECTRIC POWER RES INST OF STATE GRID ZHEJIANG ELECTRIC POWER COMAPNY +2

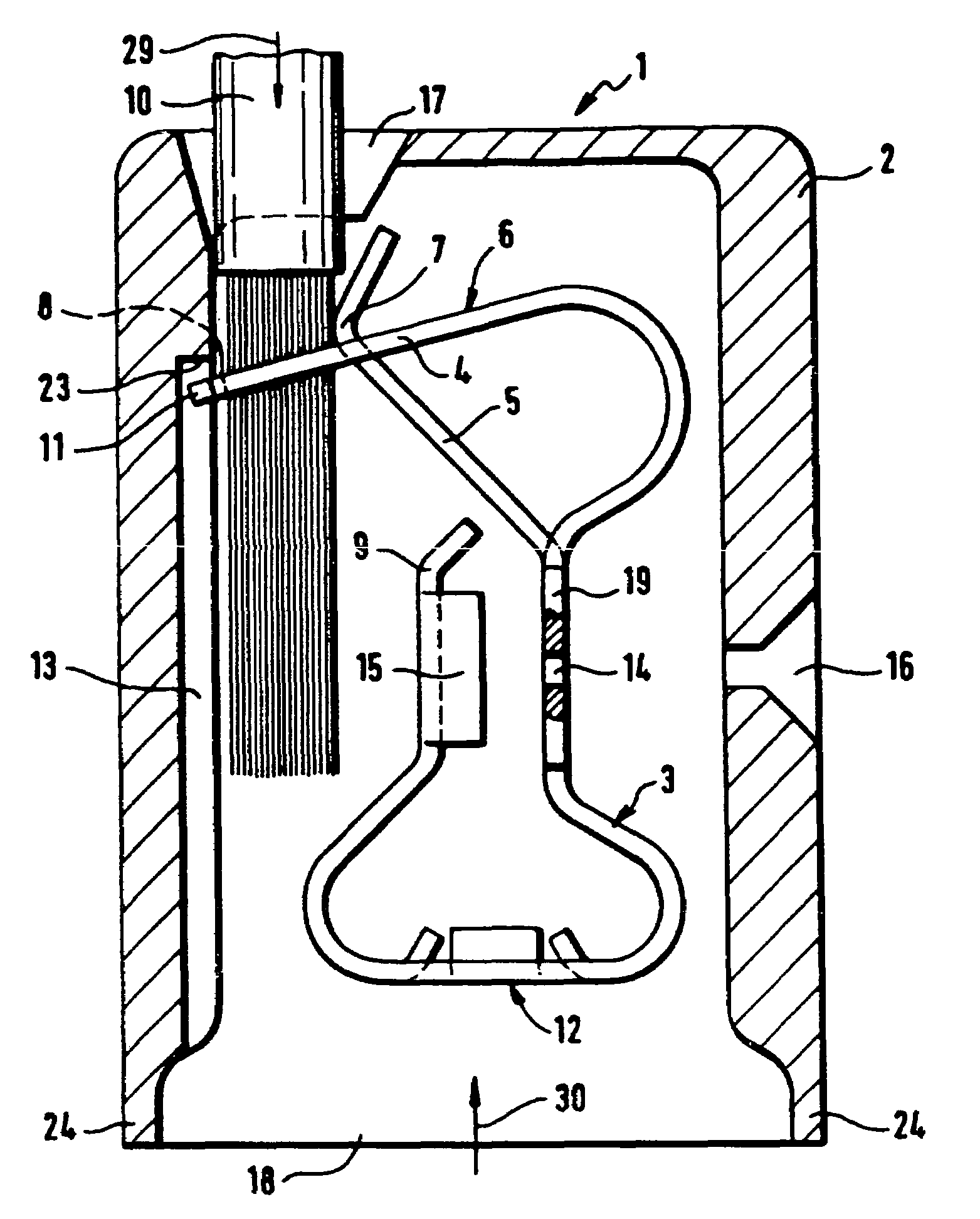

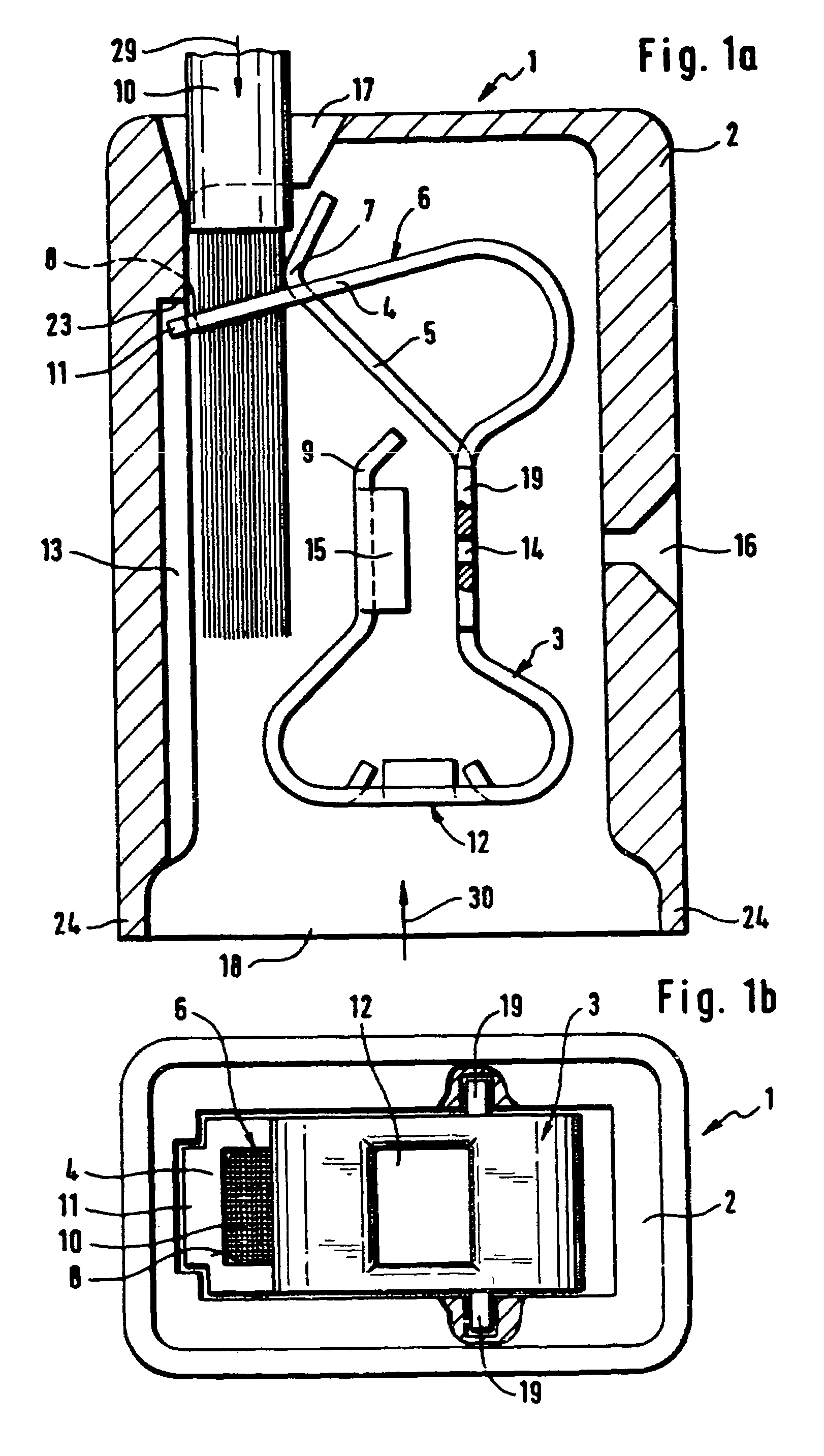

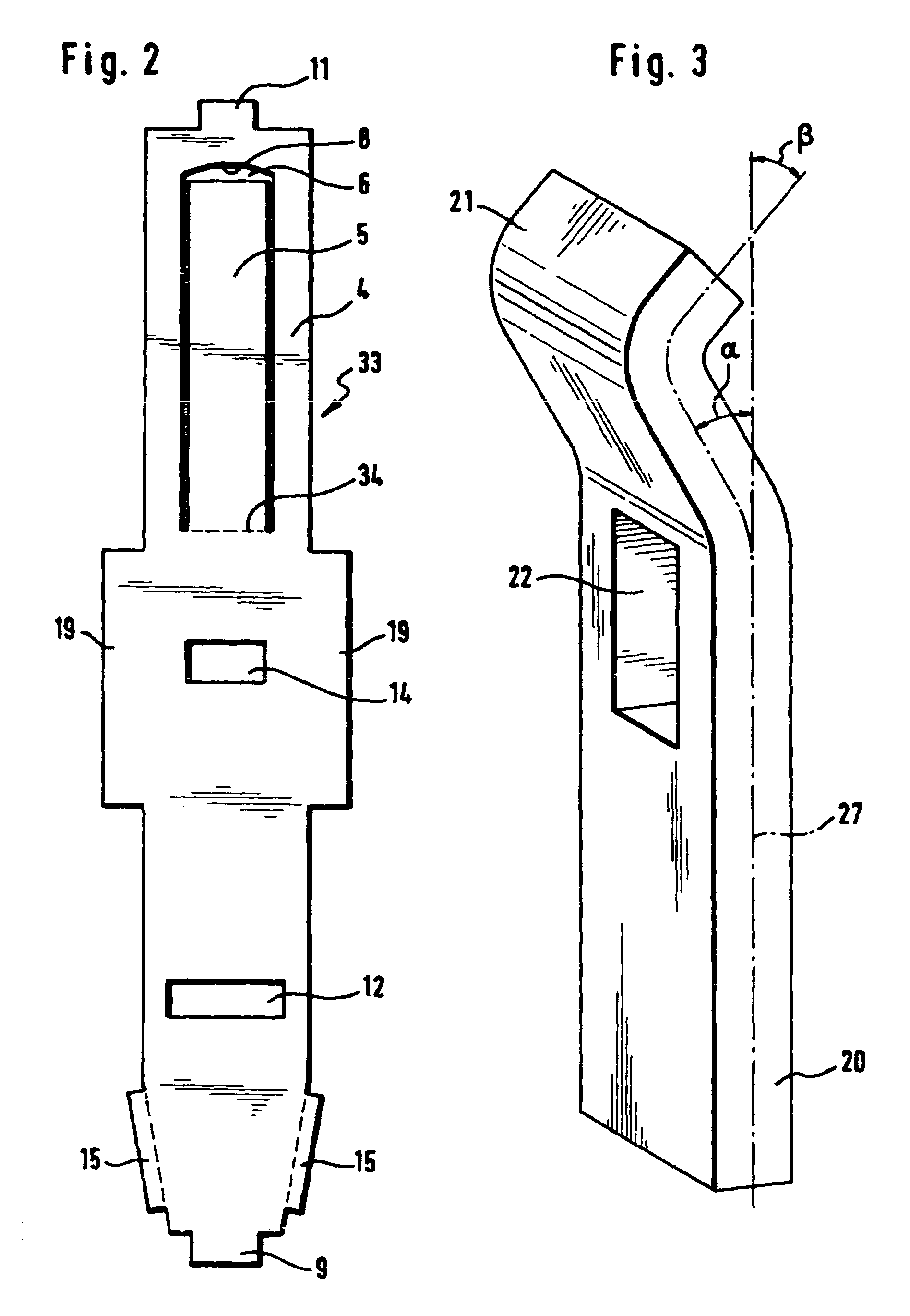

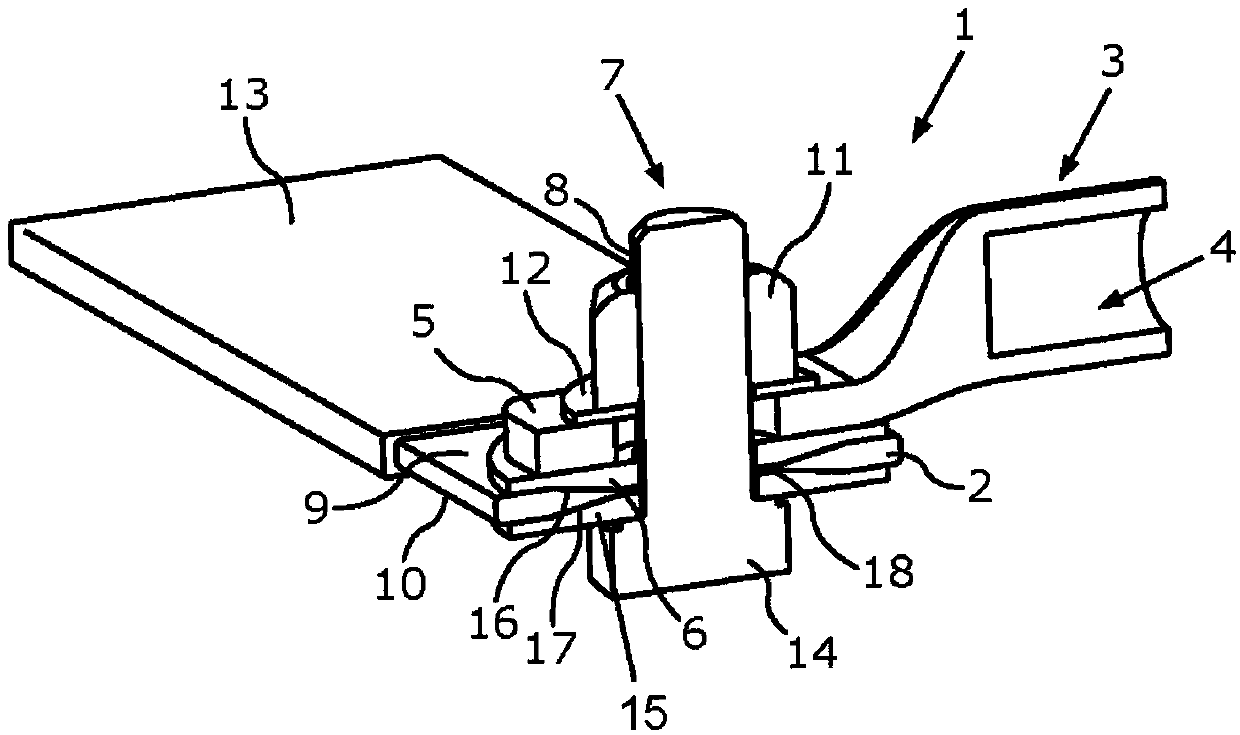

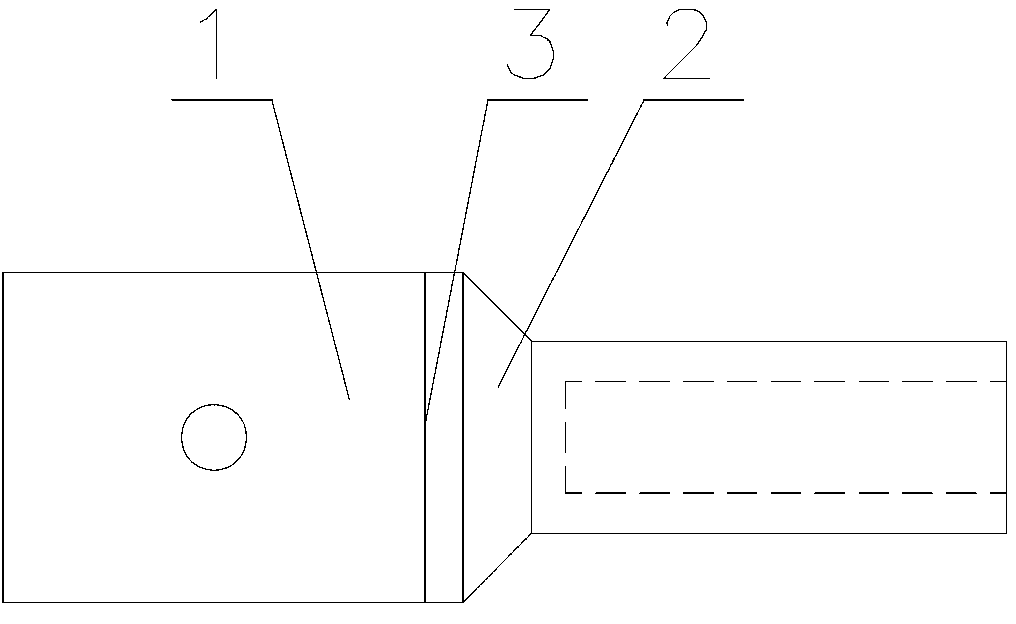

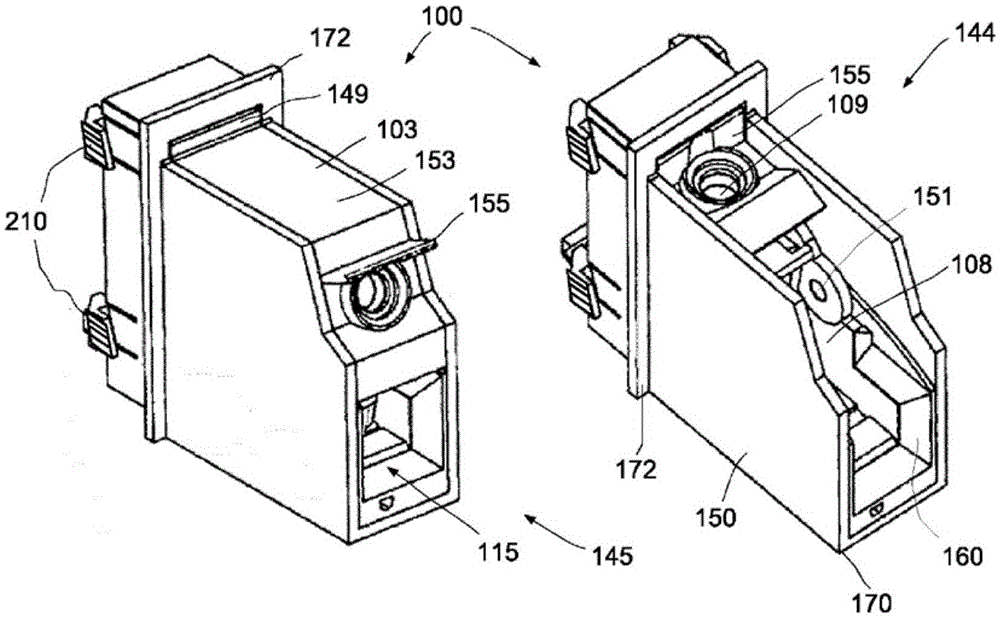

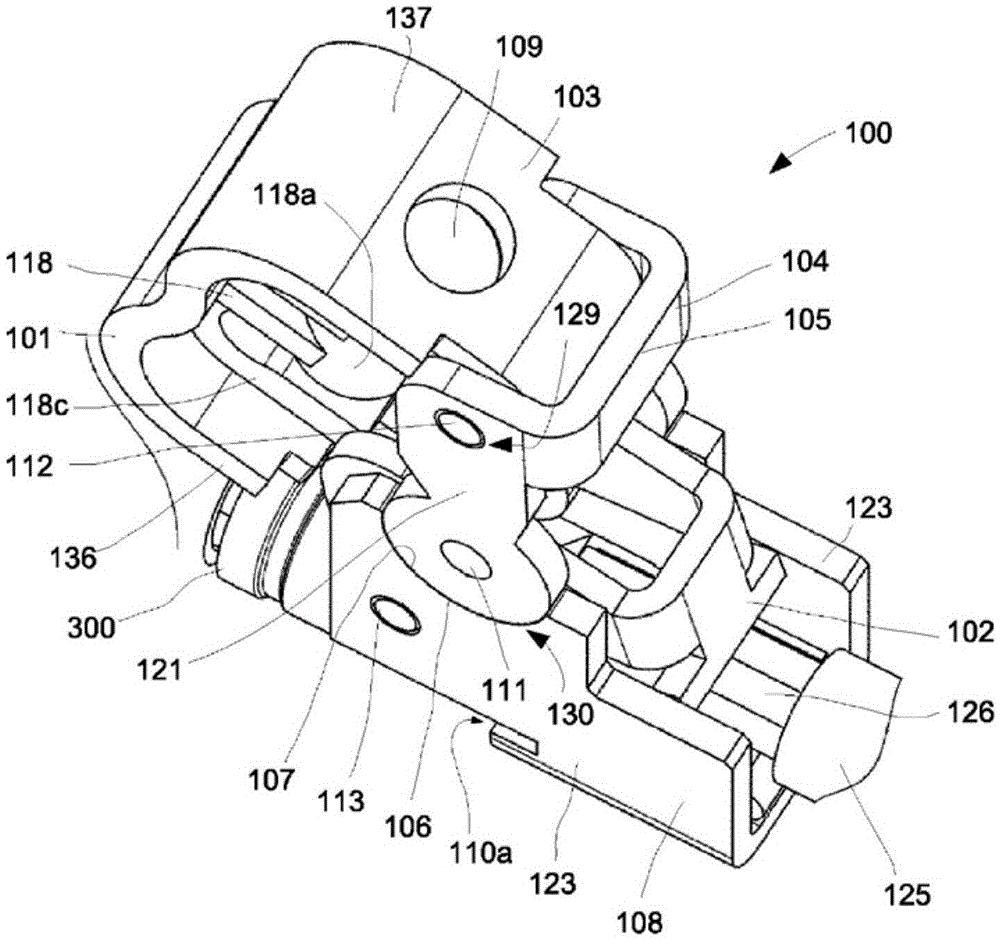

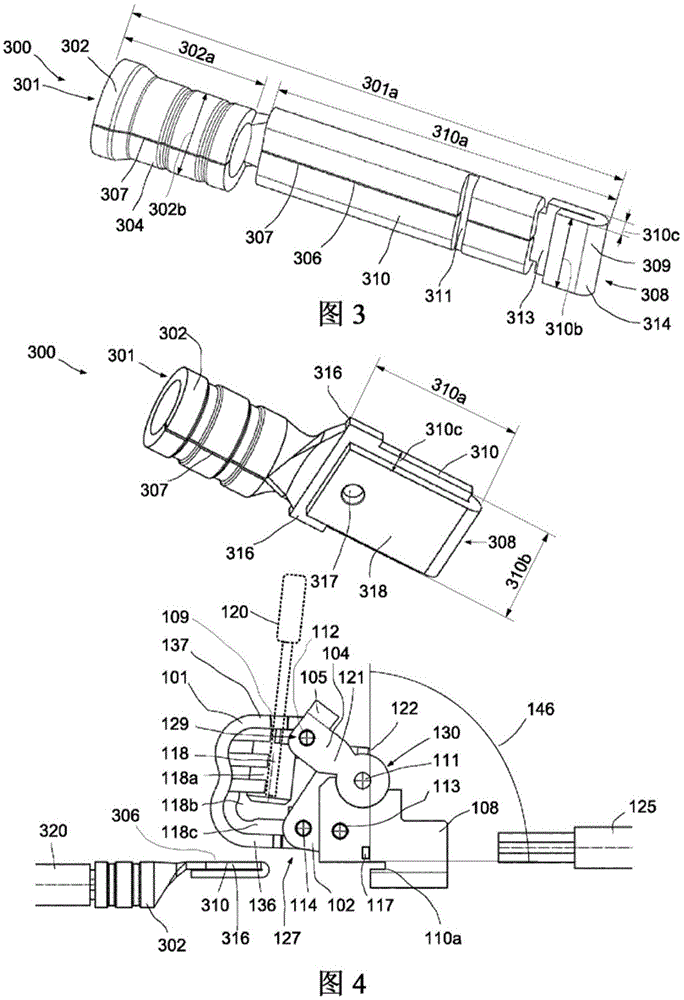

Electrical plug, holder, system having an electrical plug and a holder, and method of making a connection between an electrical plug and a holder

InactiveUS20050112915A1Done quickly and without toolsSmall transition resistanceLine/current collector detailsContact members penetrating/cutting insulation/cable strandsElectrical connectionEngineering

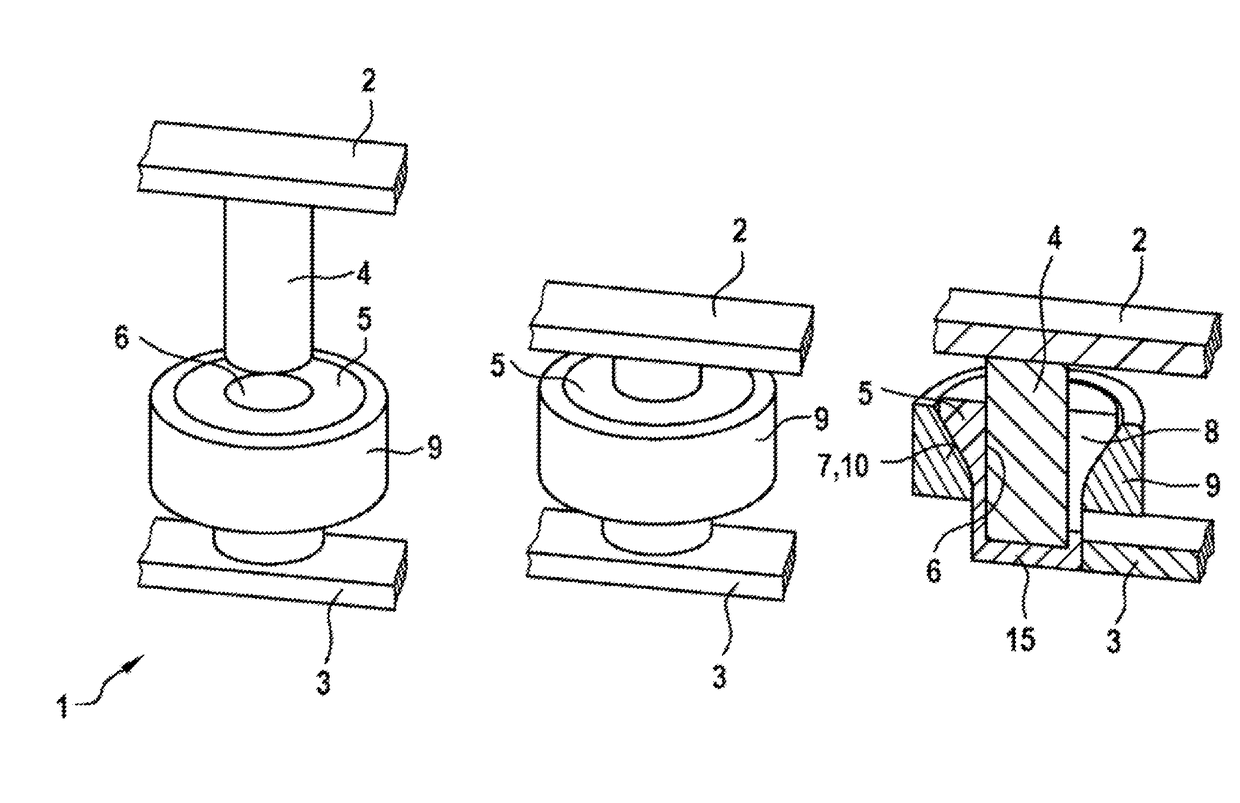

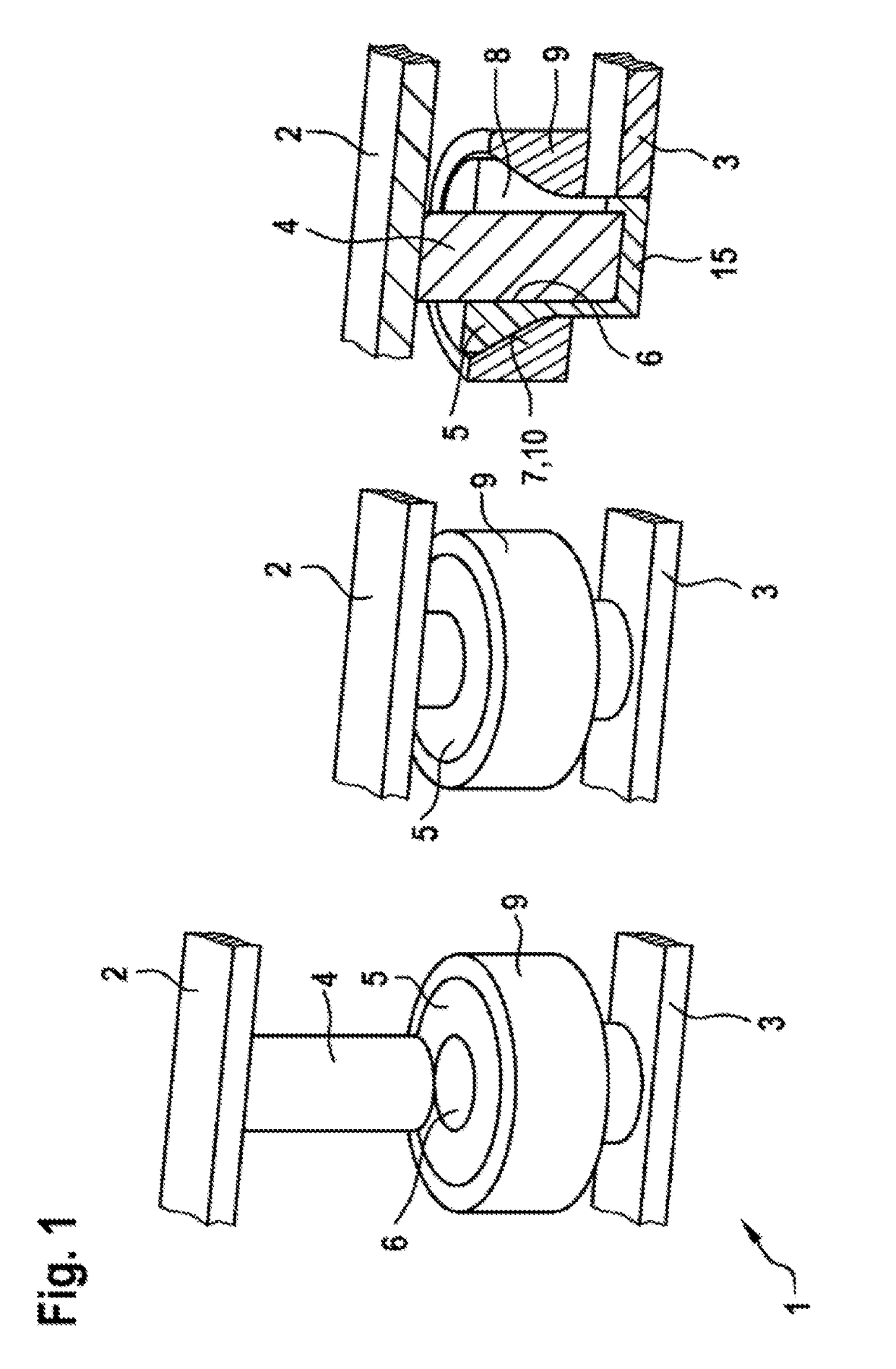

An electrical plug (1), a rigid holder, a system consisting of an electrical plug and a holder, and a method of making a connection between an electrical plug and a holder, are proposed, said electrical plug comprising a housing (2) and a spring clamp connection for connection of a flexible electric conductor (10) to the end piece of a rigid holder (20). The spring clamp connection is made out of a clamp spring (3) made of flat spring material, comprising a contact leg (5) and a clamp leg (4). The clamp leg is bent closed in the manner of a loop onto the end of the contact leg and comprises a clamp opening (6) through which the end of the contact leg protrudes. A clamp edge (8) of the clamp opening located opposed to the clamp leg, together with the clamp leg itself, forms a clamp location in which the electric conductor passed through the clamp opening is clamped before the plug is-mounted on the holder. After mounting of the plug on the holder, the holder extends through the clamp opening between the contact leg and the electric conductor, and the holder and clamp spring are so braced against each other that the electric conductor is clamped between the clamp edge and the holder, thereby forming an electrical connection between holder and electric conductor.

Owner:NEWFREY

Lap-joint type copper-aluminum transition wire clip

ActiveCN102709719ASimple structureEasy to useSoldered/welded conductive connectionsElectric connection structural associationsButt jointLap joint

The invention discloses a lap-joint type copper-aluminum transition wire clip, which comprises an apparatus clamping part and a lead wire clamping part. The apparatus clamping part and the lead wire clamping part are transited through lap joint, and fixed by welding. The copper-aluminum transition wire clip provided by the invention has the characteristics of simple structure and convenient application. The lap-joint structure substitutes for the conventional butt-joint structure, which effectively increases a copper-aluminum transition area, reduces a transition resistance, and alleviates heat generating phenomenon. Meanwhile, the stress of the wire clip during application is changed, and the mechanical strength of the wire clip is improved. By the adoption of the advanced brazing technique, the welding quality is improved.

Owner:STATE GRID CORP OF CHINA +2

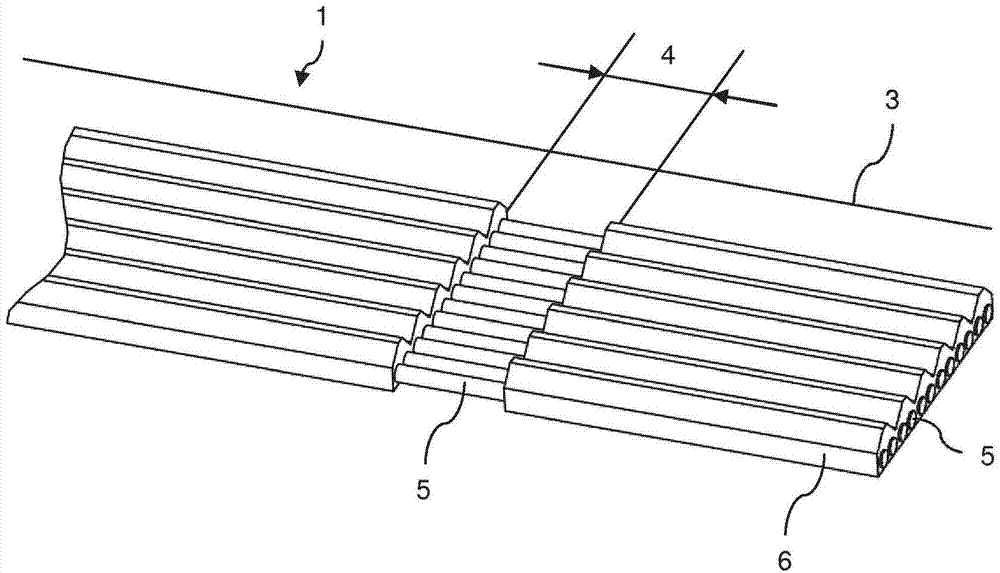

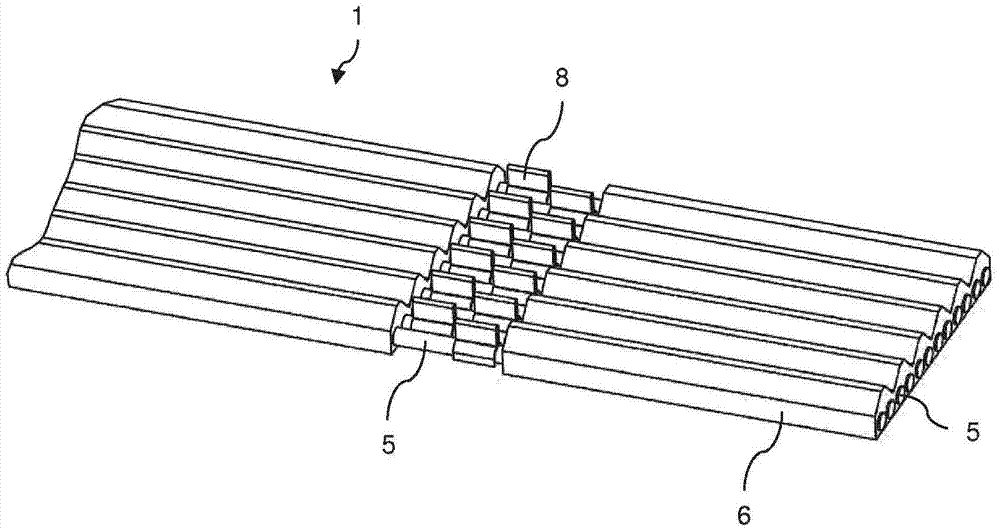

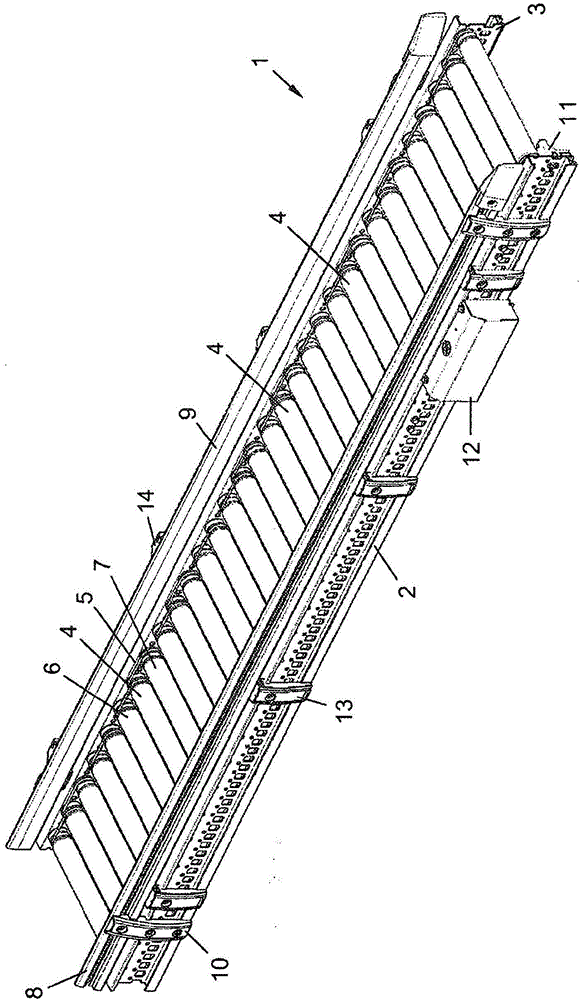

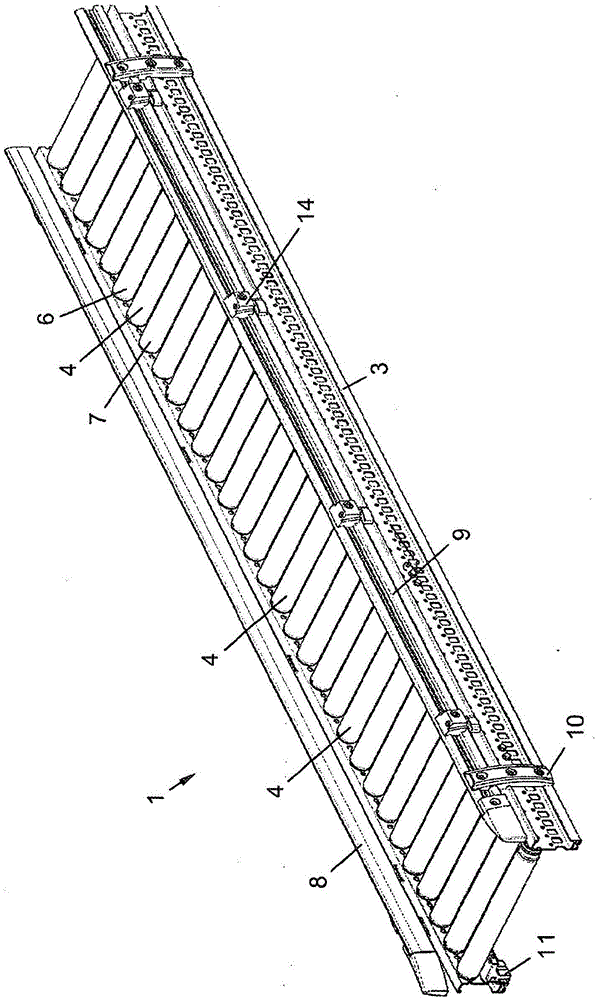

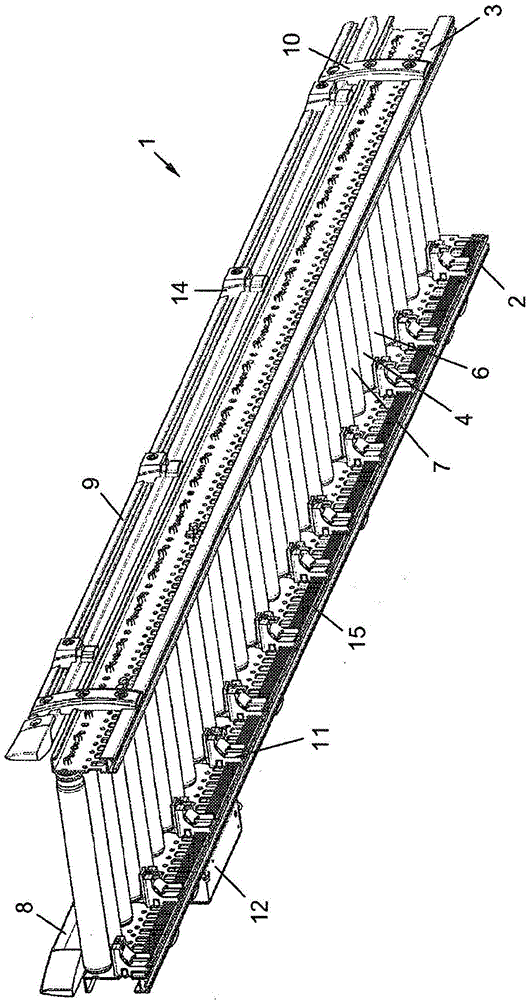

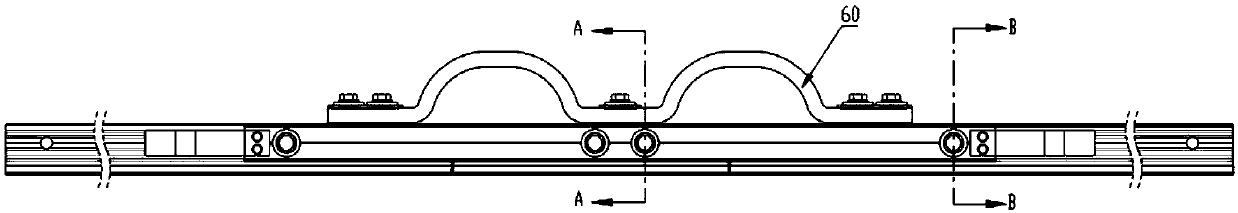

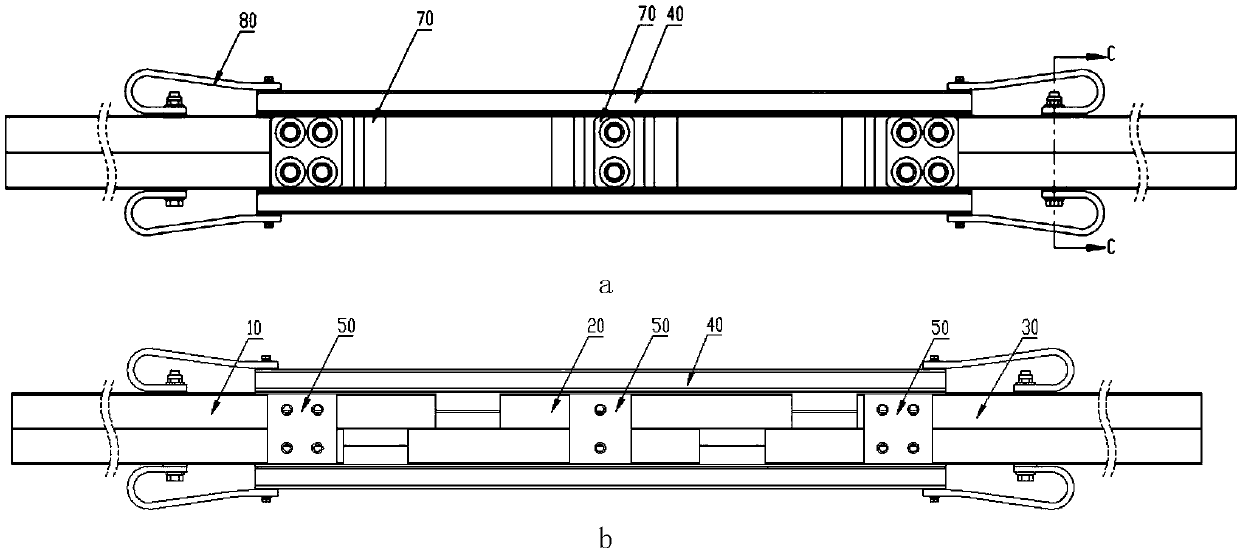

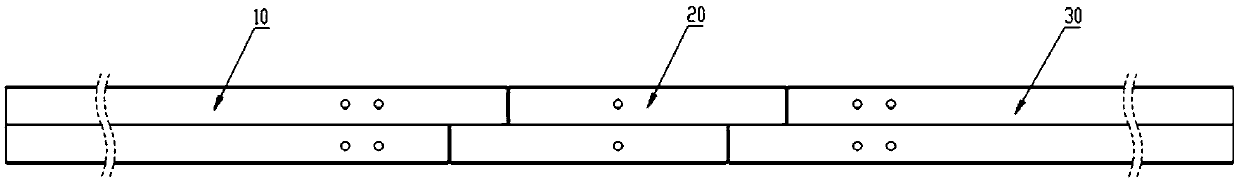

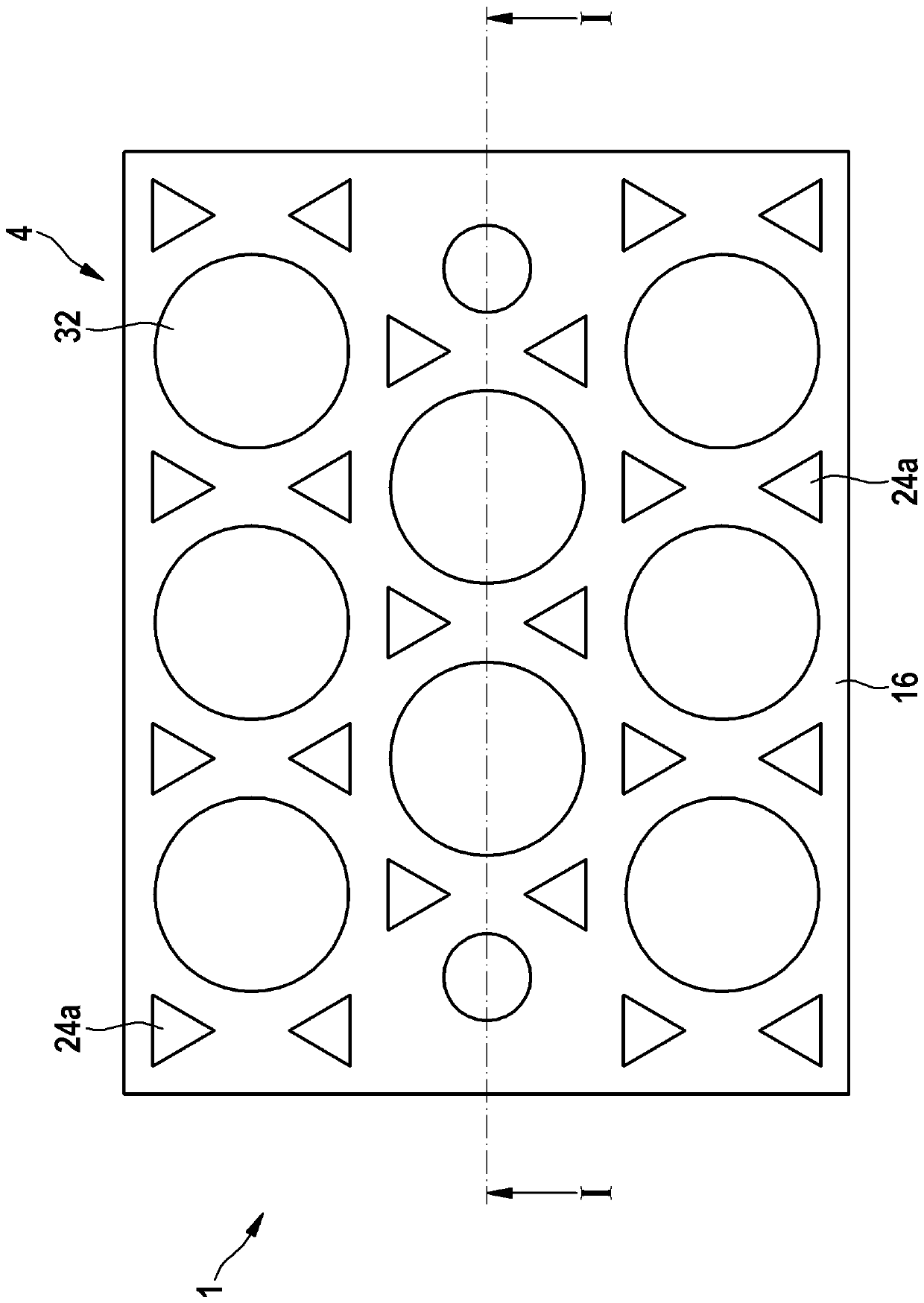

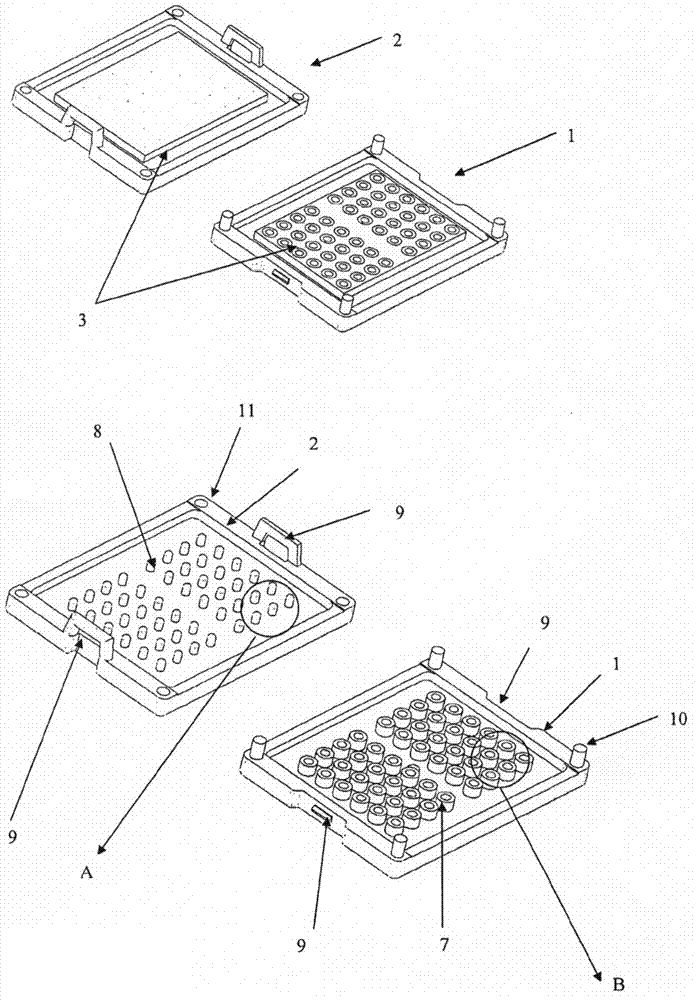

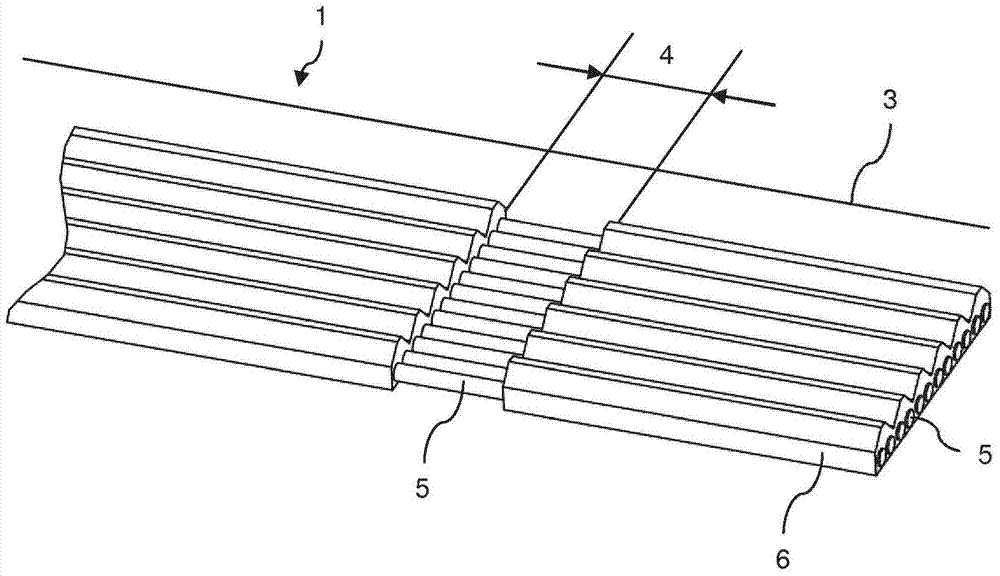

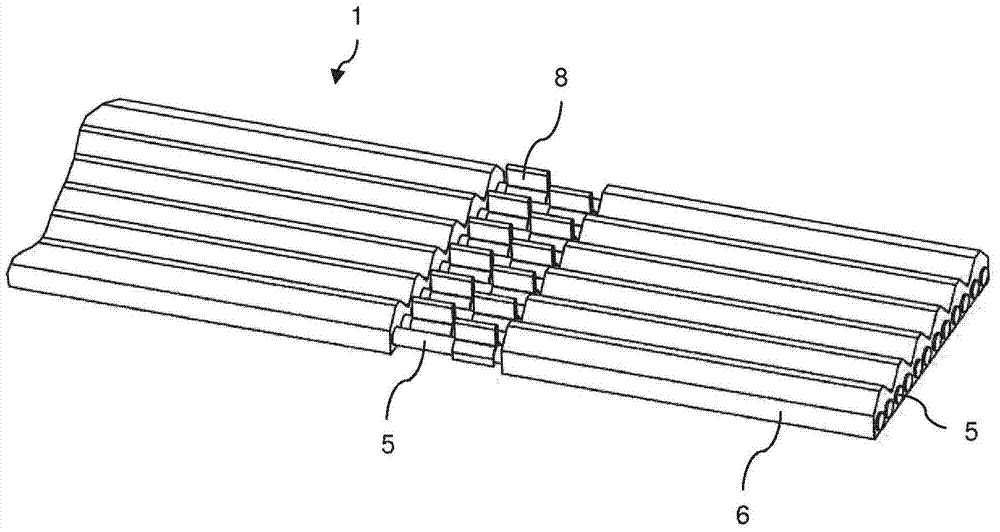

Conveyor system having substantially symmetrical longitudinally running electric conductors

ActiveCN105612114AFlexible installationAchieve conductionConveyorsControl devices for conveyorsElectricityElectrical conductor

The invention relates to a conveyor system (1), comprising two frame profiles (2, 3) which run such that they are spaced apart from one another, a plurality of motorized conveyor rollers (4) which are arranged in between, an insulator (19) which runs along the at least one frame profile (2) with a plurality of receptacles which are open on the longitudinal side, and a plurality of electric conductors (20) which are arranged in the insulator (19) and are connected electrically to drive electronics of the conveyor rollers (4), wherein in each case one electric conductor (20) is mounted in in each case one receptacle. The form factor f of an electric conductor (20), which is defined as a quotient of the circumference of a circle which is equivalent in area to the cross section of the electric conductor (20) and of the circumference of said cross section of the electric conductor (20), is selected here in the range from f = 0.88 to f = 1.00.

Owner:TGW MECHANICS GMBH

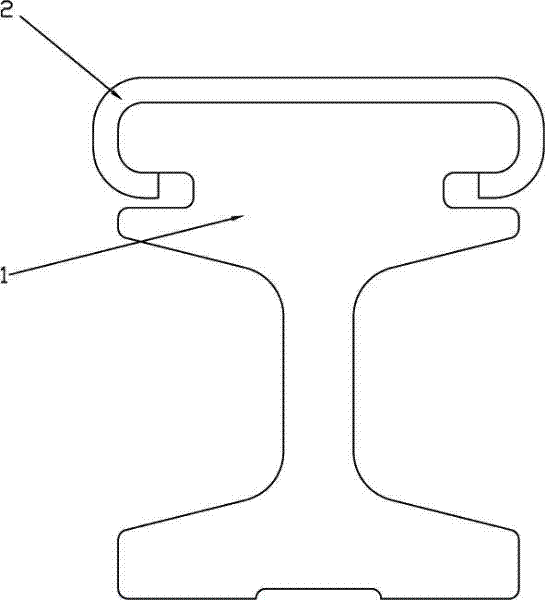

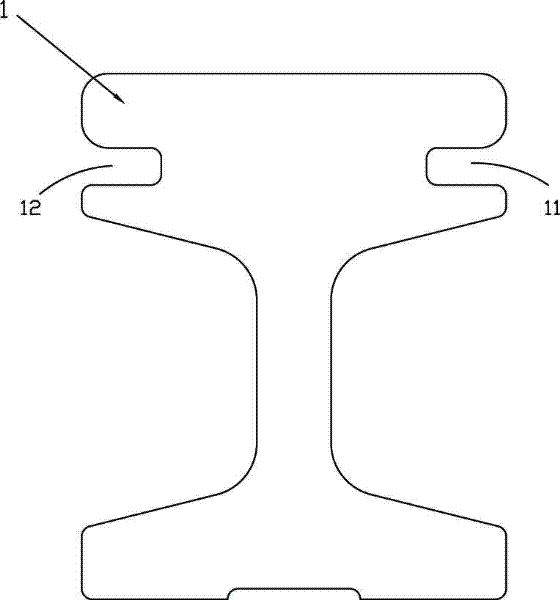

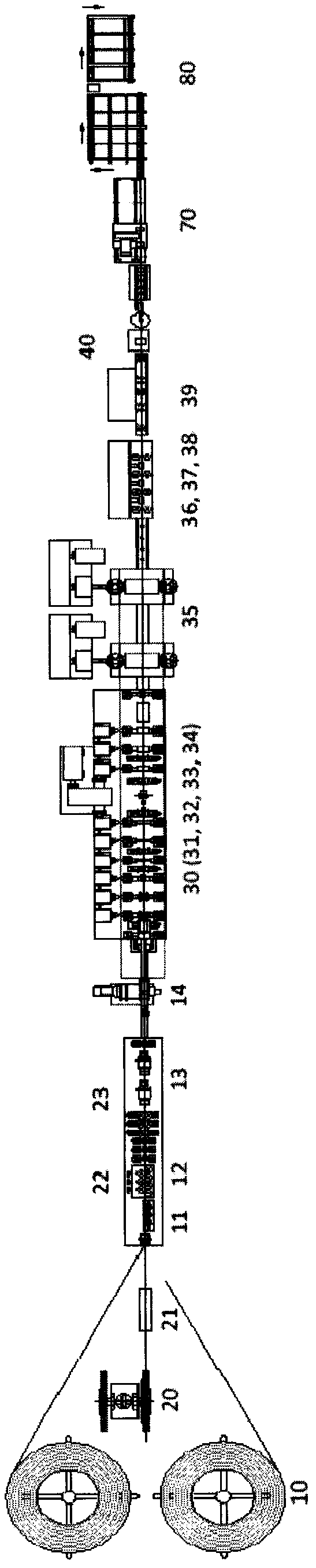

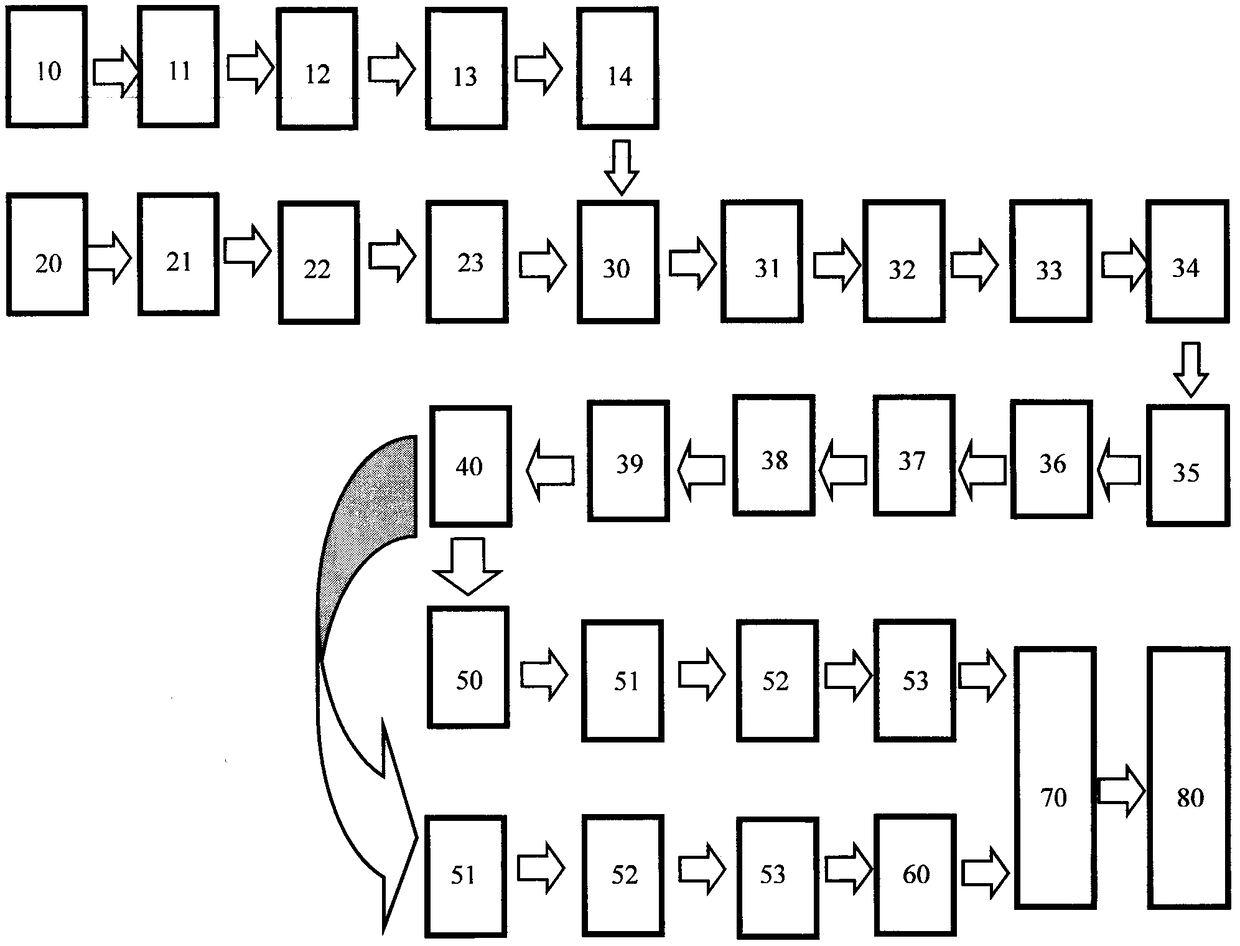

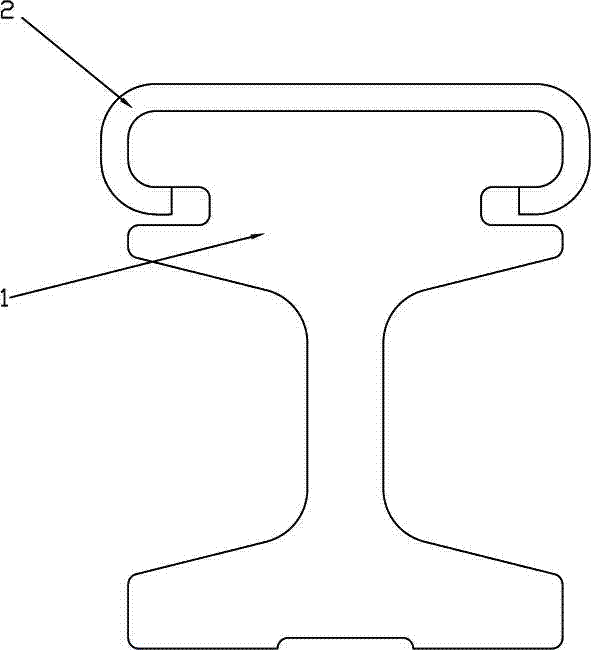

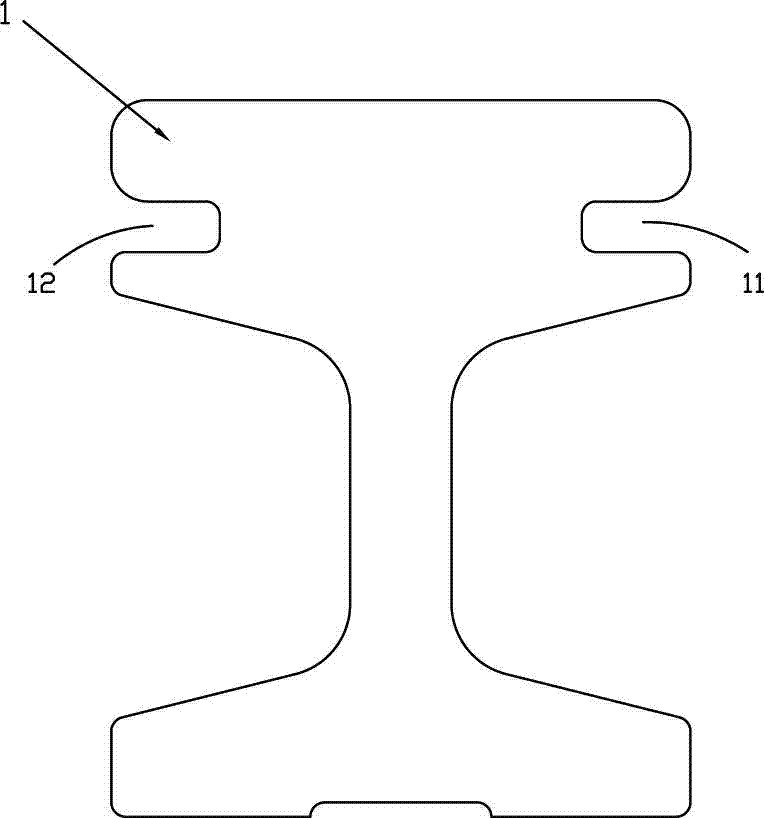

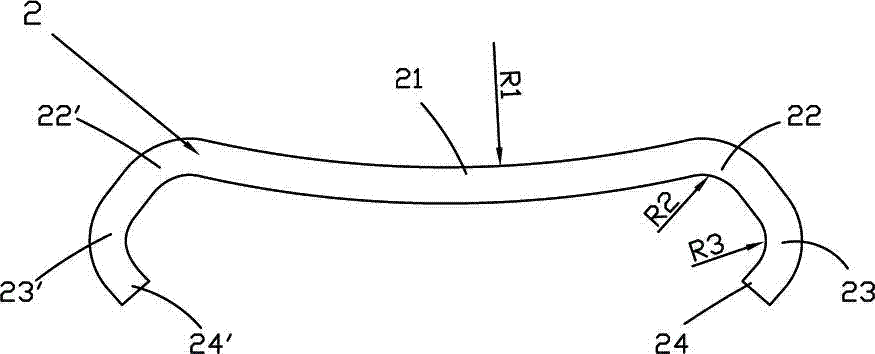

Method for manufacturing steel-aluminum composite conductor rail

The invention discloses a method for manufacturing a steel-aluminum composite conductor rail, comprising the following steps of: a) preparing an aluminum rail: preparing an I-shaped aluminum rail by a mould through hot extrusion molding, wherein the two side surfaces of the upper end of the aluminum rail are provided with grooves; b) prefabricating a C-shaped stainless steel strip: cutting a stainless steel coil into stripy stainless steel strips, and cold bending and rolling by a cold bending unit to form a stainless steel strip with a C-shaped section, wherein the formed stainless steel strip comprises a base part, a first bending part, a second bending part and a clip part, the first bending part is formed by extending from the two sides of the base part and bending downwards, the second bending part is formed by extending from the first bending part and bending inwards, and the clip part is formed by extending from the second bending part; and c), compounding the C-shaped stainless steel strip and the aluminum rail, wherein the clip parts at two ends of the C-shaped stainless steel strip are embedded in the grooves on the two sides of the upper end of the aluminum rail, and the C-shaped stainless steel strip is completely attached to the upper part of the aluminum rail. According to the method in the invention, the stainless steel strip and the aluminum rail are closely combined, the combined surface is large, the transition resistance is small, deformation is not liable to occur after forming, a local heating mode is adopted during rolling compounding to facilitate forming, machining is not needed after rolling forming, and the production efficiency is greatly improved.

Owner:SHANGHAI SANY PRECISION MACHINERY

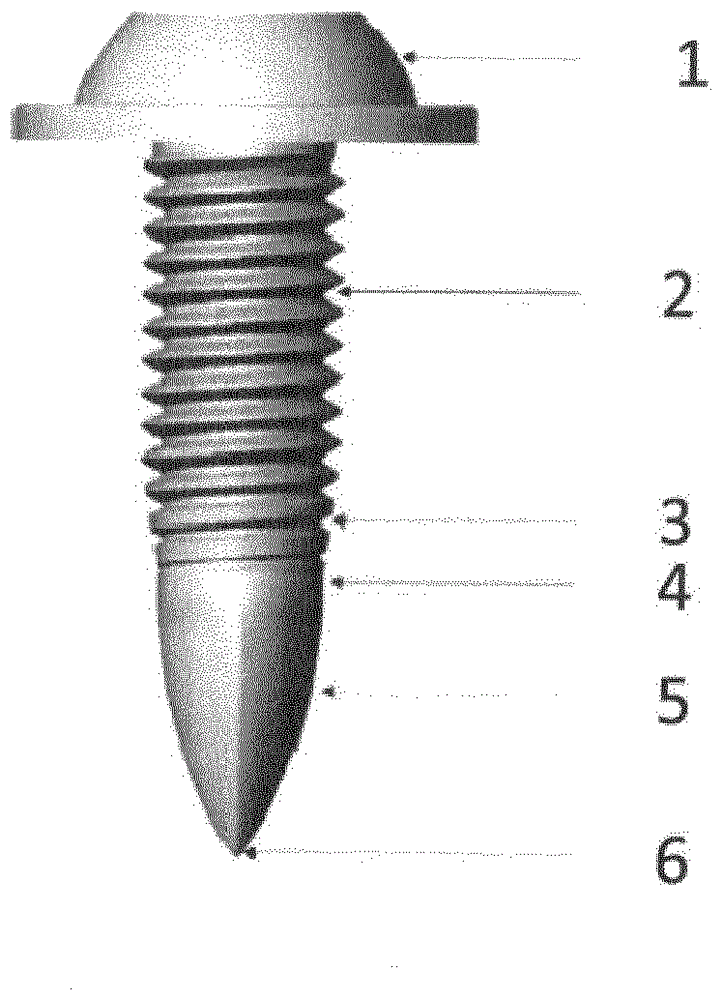

Plug-type connection for an electrical connection

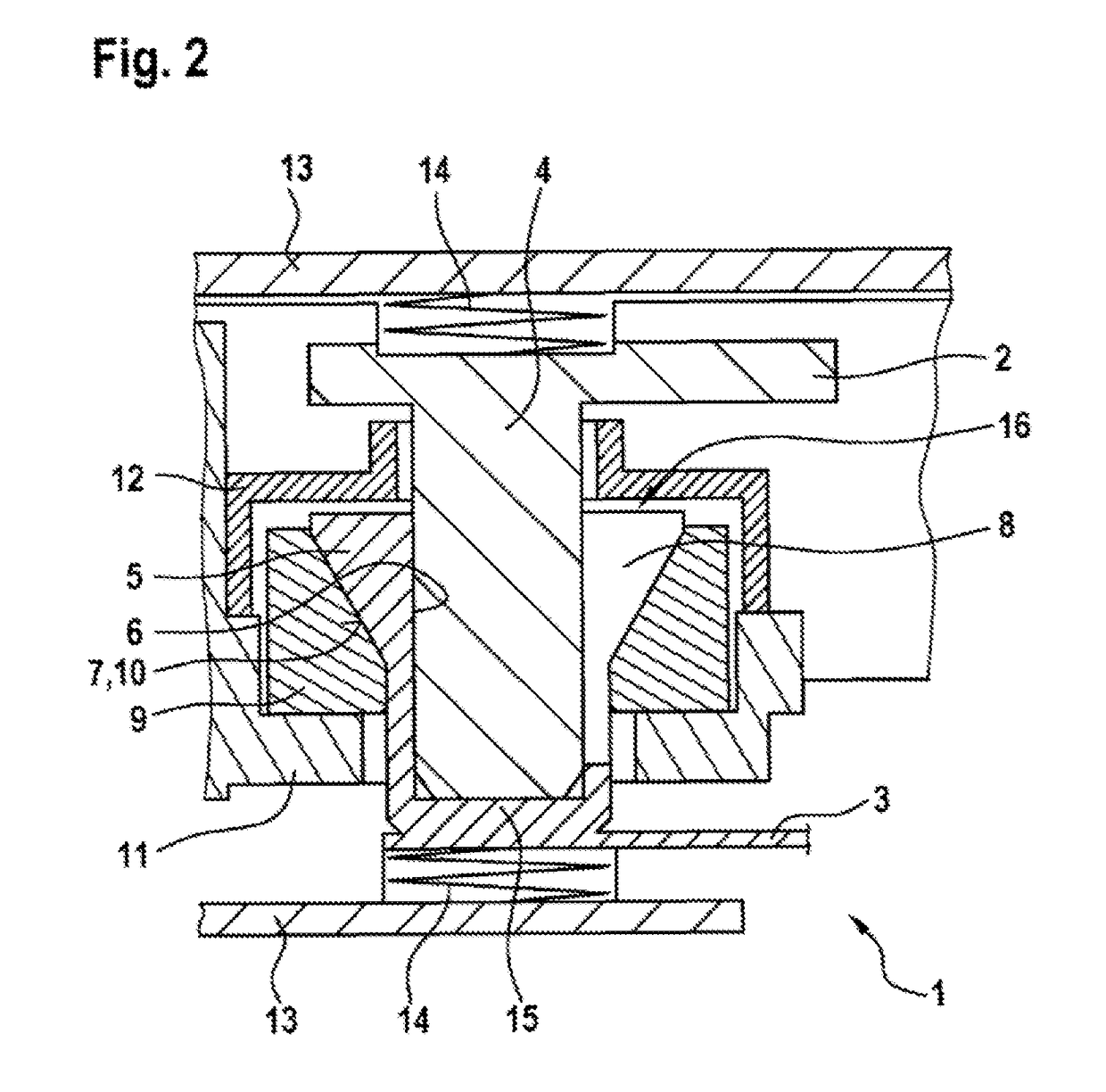

ActiveUS20180123264A1Withstands high vibration loadSmall transition resistanceCoupling device detailsElectric connection basesElectrical connectionEngineering

The present invention relates to a plug-type connection (1) for an electrical connection between a first line (2) and a second line (3), comprising a contact bolt (4) which can be connected to the first line (2), a collet (5) which can be connected to the second line (3) and has a cutout (6) for inserting the contact bolt (4), has a conical collet outer face (7) and has at least n slots (8) for forming n clamping jaws, where n≥1, and a clamping ring (9) with a conical clamping ring inner face (10) against which the conical collet outer face (7) bears, wherein the at least one clamping jaw can be clamped against the contact bolt (4) as a result of a relative movement between the collet (5) and the clamping ring (9).

Owner:ROBERT BOSCH GMBH

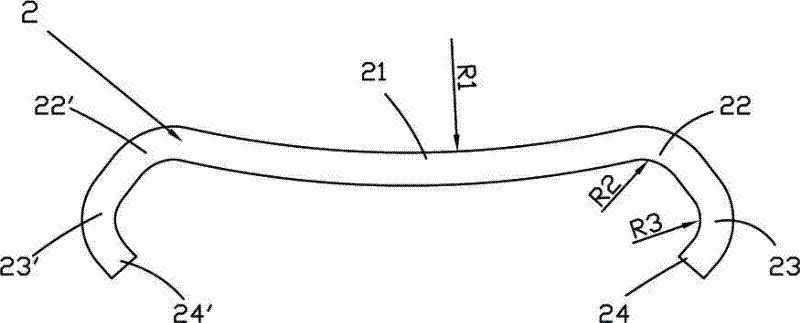

Novel steel-aluminum composite contact rail expansion joint

PendingCN109515254AFreewheeling stabilitySmall transition resistancePower railsElectrical performanceEngineering

The invention discloses a novel steel-aluminum composite contact rail expansion joint, comprising a sliding rail structure which are formed by sequentially connecting rail webs of a left sliding rail,a middle sliding rail and a right sliding rail through a fishtail clamping plate, wherein the fishtail clamping plate is slidably connected with the rail web of the left sliding rail and the rail webof the right sliding rail, and is fixedly connected with the rail web of the middle sliding rail; and main soft copper bands are arranged on rail bottoms of the left sliding rail, the right sliding rail and the middle sliding rail. Furthermore, due to the adoption of copper-aluminum transition plates, the main soft copper bands, pressing plates, auxiliary soft copper bands, partition plates, limiting sleeves, connecting transition blocks and so on, the defect of the expansion joint in the curve performance of the line is solved, and the condition that the mechanical connection, electrical performance and compensation ability can meet the requirements can be ensured. The needs of lateral current receiving can be met and the requirement on boundary can be reduced; and a current collecting shoe of the train can smoothly scratch across the current receiving surface of the expansion joint to ensure the current continuing smoothness of the contact rail.

Owner:ZHENJIANG DAQO SECHERON TRACTION POWER

Continuous preparation method of copper cladded aluminium composite bus

InactiveCN108941238ASmall transition resistanceImprove uniformityCable/conductor manufactureThermal stateSurface cleaning

The invention provides a continuous preparation method of a copper cladded aluminium composite bus. The continuous preparation method comprises following steps: raw material on-line surface cleaning,raw material aluminium continuous rehabilitation extruding and recrystallization, raw material copper continuous cladding raw material aluminium and blank material moulding, moulded blank material continuous deformation and temperature compensation, large deformation rate thermal state finish rolling, on-line finishing and on-line heat treatment, continuous rolling and off-line annealing, and straightening leveling and scaling cutting. The copper cladded aluminium composite bus prepared using the continuous preparation method possesses characteristics such as low copper aluminium transition resistance, high bonding strength, and excellent copper layer uniformity; copper aluminum layering is not caused through machining such as bending, shearing, stamping, and distortion, and excellent ductility and mouldability are achieved.

Owner:APPLIED COMPOSITE MATERIAL CO LTD

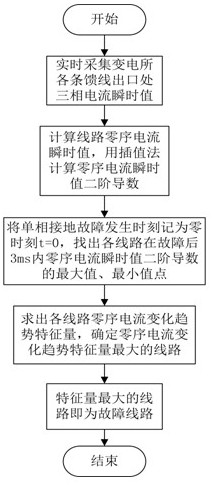

Rapid line selection method for single-phase earth fault of low-current grounding system

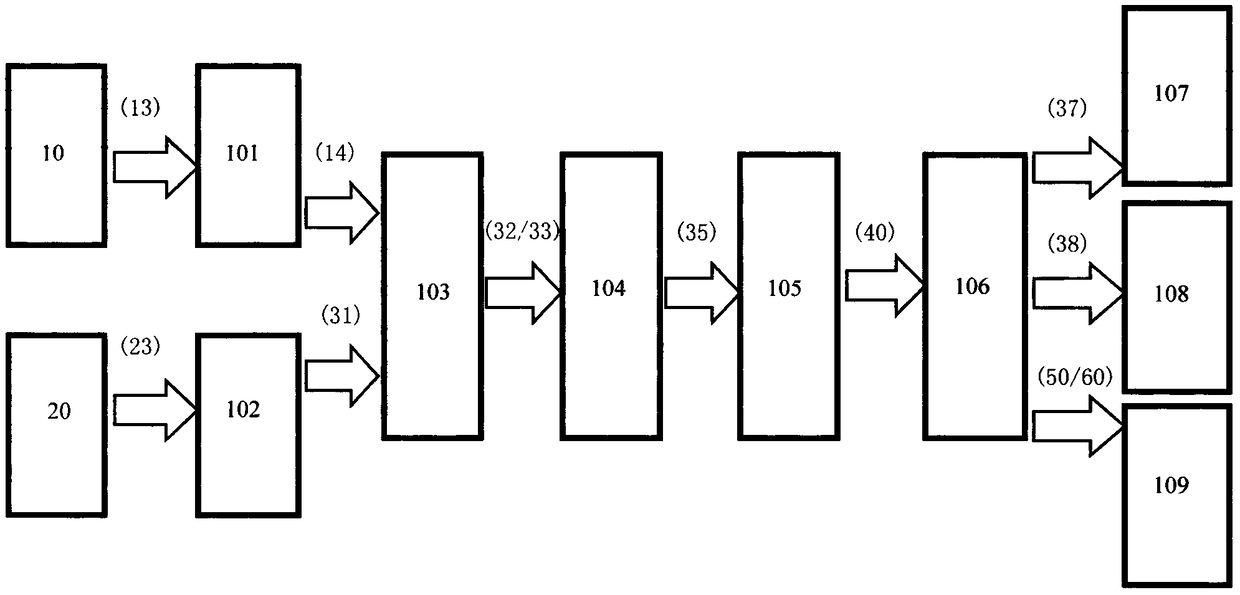

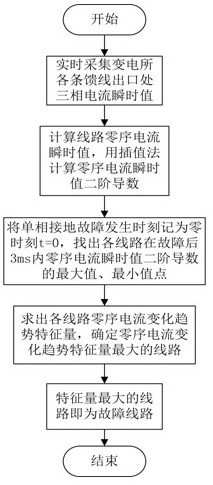

ActiveCN112162170ASmall amount of calculationSmall CPU requirementsFault location by conductor typesShort-circuit testingComputational physicsReal time acquisition

The invention discloses a rapid line selection method for a single-phase earth fault of a low-current grounding system. The method comprises the steps of firstly collecting the three-phase current instantaneous values at all feeder outlets of a substation in real time; secondly, calculating zero-sequence current instantaneous values of lines according to the current instantaneous values, and solving a second derivative of each zero-sequence current instantaneous value by utilizing an interpolation method; then, finding out the maximum value and minimum value points of the second derivative ofthe instantaneous value of each zero-sequence current instantaneous value of each line within 3ms by taking the fault occurrence moment as a zero moment; and finally, solving the zero-sequence currentchange trend characteristic quantity of each line, and finding out the line with the maximum characteristic quantity, i.e., judging the line as a fault line. The method is slightly influenced by theline length, the transition resistance and an arc suppression coil, and the single-phase earth fault line selection can be rapidly carried out.

Owner:国网湖北省电力有限公司黄冈供电公司

Cable lug device having current bar, and connection terminal

InactiveCN105580203AEasy to operateOperational safetyCoupling contact membersClamped/spring connectionsElectrical and Electronics engineeringStructural engineering

Owner:PHOENIX CONTACT GMBH & CO KG

Battery cell connector for battery cells connected in series

PendingCN111435726AReduce temperature differenceImprove thermal reliabilitySecondary cellsCell component detailsPhysicsElectrical and Electronics engineering

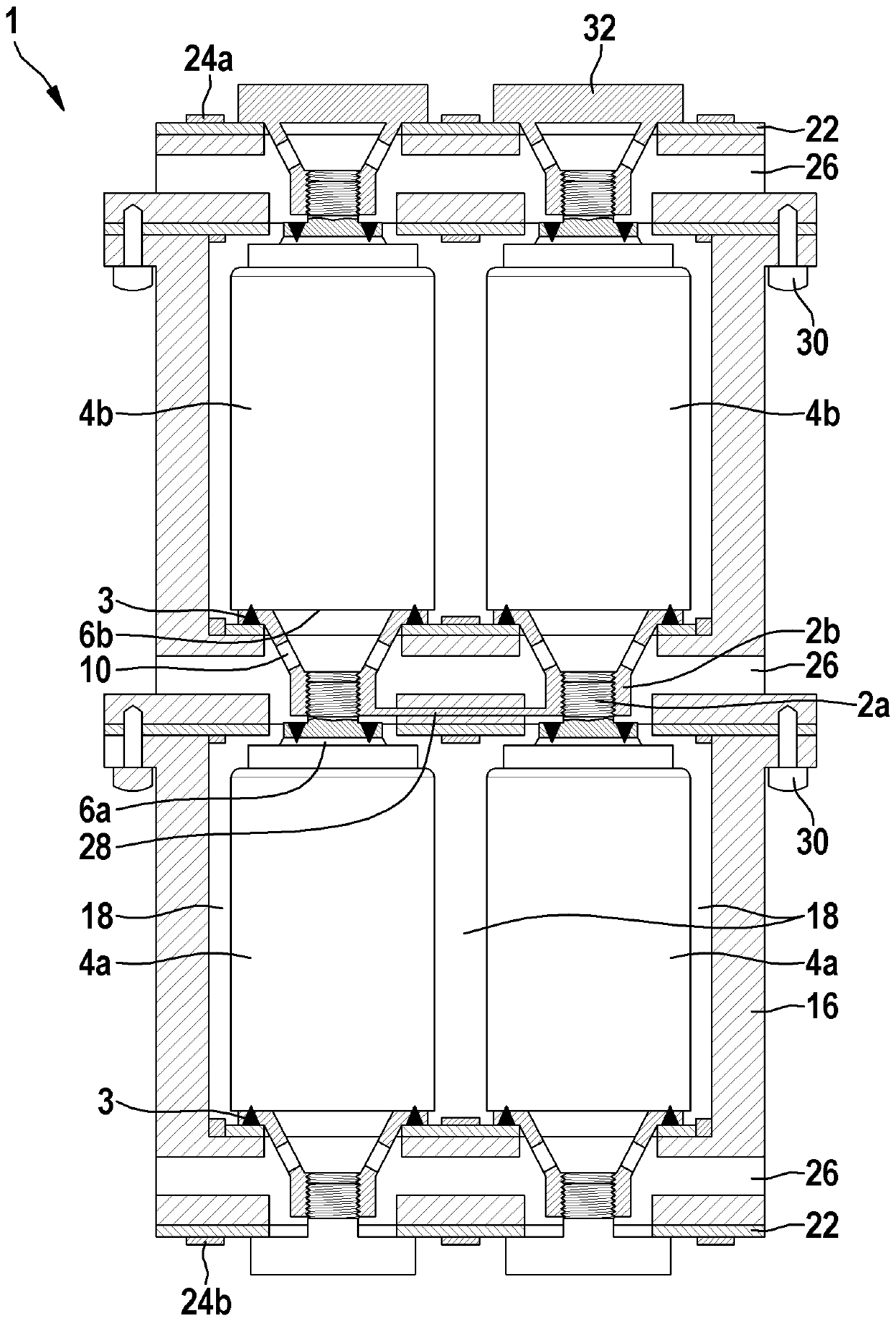

The invention relates to a battery cell connector (2) for battery cells (4) connected in series. The battery cell connector includes a first connecting element (2a) for establishing a connection witha first battery pole (6a) of a first battery cell (4a), and a second connecting element (2b) for establishing a connection with a second battery pole (6b) of a second battery cell (4b). The connectingelements (2a, 2b) are constructed corresponding to each other's shapes and can be connected in series with each other so that a contact surface (8) surrounding the battery cells (4) can be maximizedto ensure effective cooling of the battery cells (4).

Owner:ROBERT BOSCH GMBH

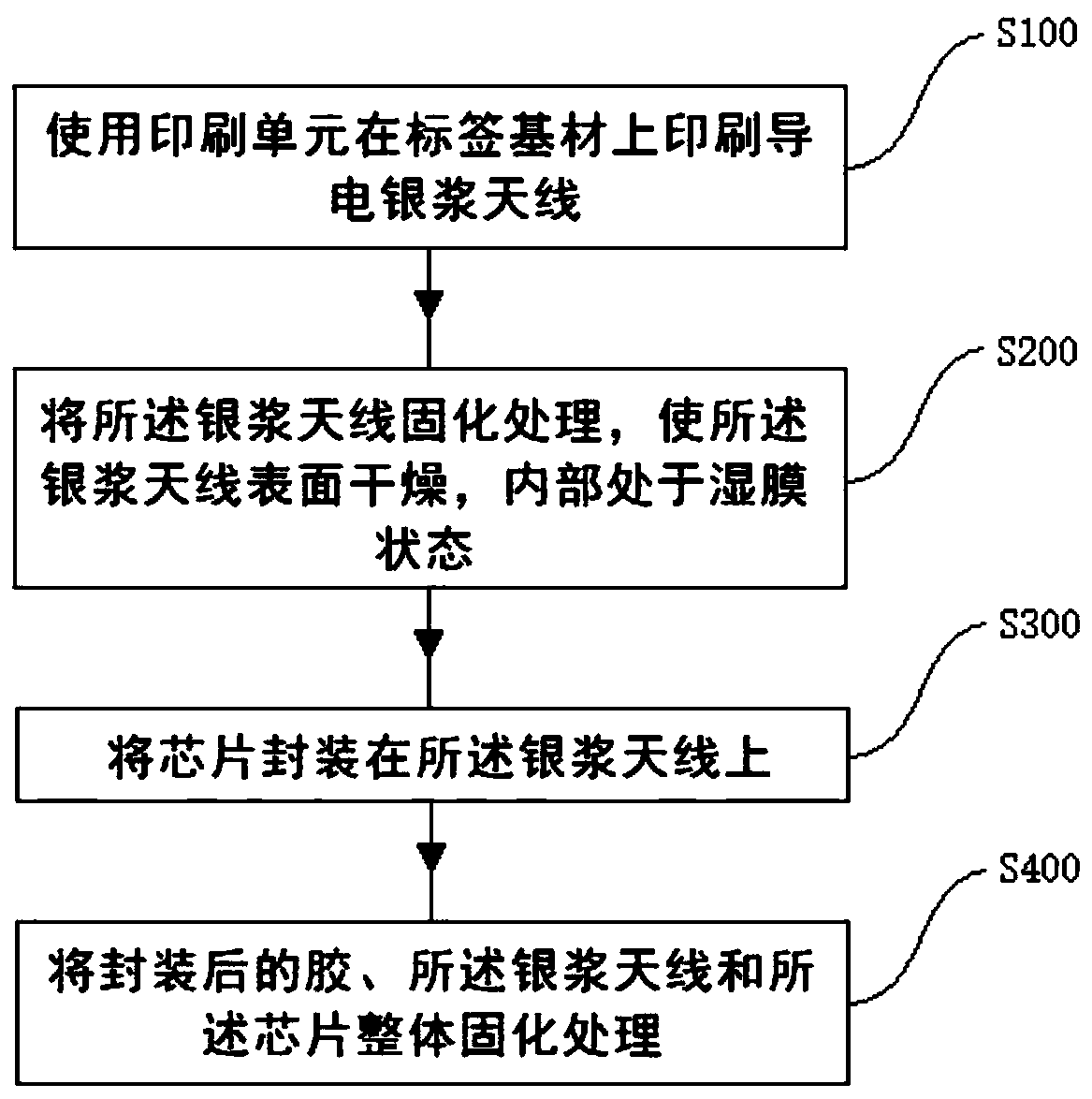

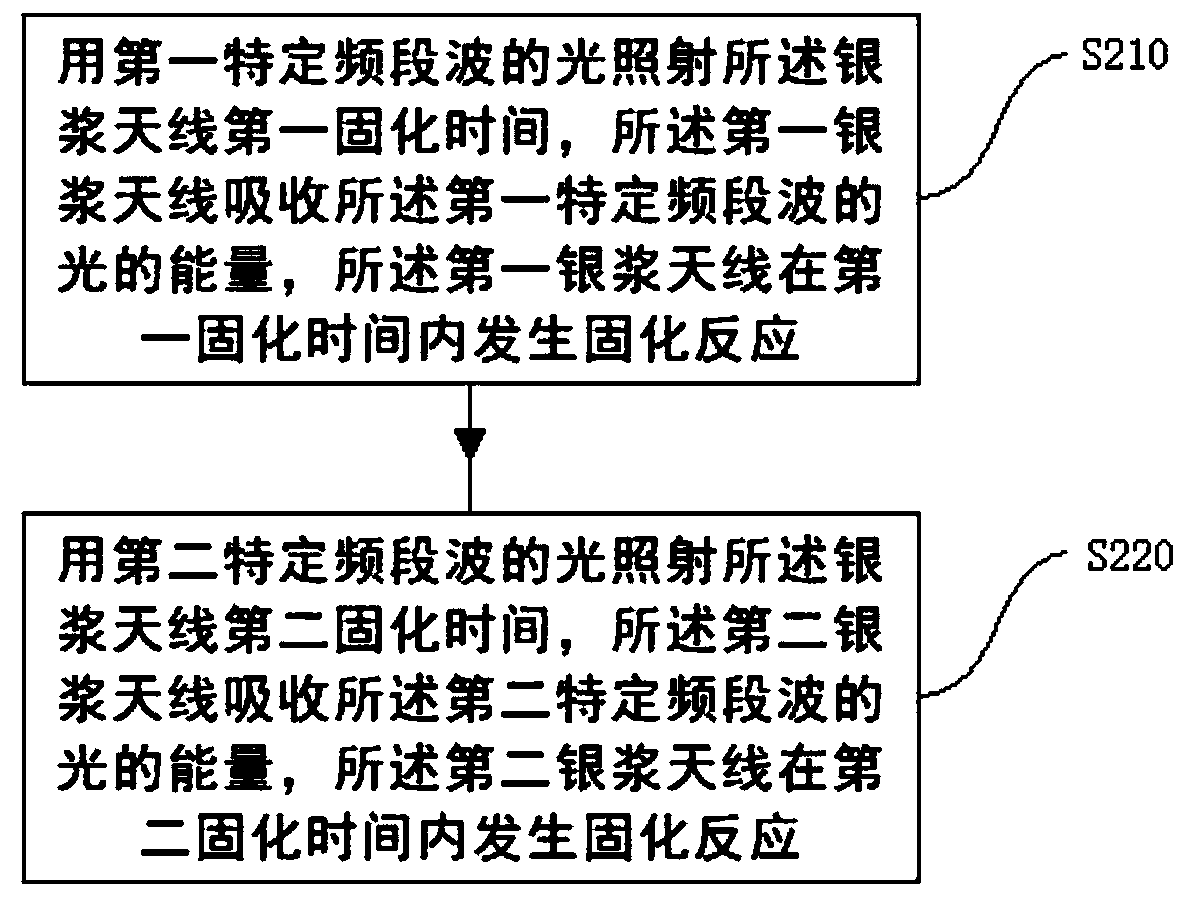

RFID tag of silver paste antenna process and chip packaging method

ActiveCN110569952AOptimize the printing processEasy to packRecord carriers used with machinesSilver pasteEnergy consumption

The invention relates to an RFID (Radio Frequency Identification Device) label of a silver paste antenna process and a chip packaging method, and an RFID label chip comprises a label base material, asilver paste antenna, glue and a chip, the packaging method comprises the following steps: printing a conductive silver paste antenna on a label substrate by using a printing unit; curing the silver paste antenna, so that the surface of the silver paste antenna is dry, and the interior of the silver paste antenna is in a wet film state; packaging a chip on the silver paste antenna; and integrallycuring the packaged silver paste antenna and the packaged chip. The RFID silver paste antenna packaging procedure can be optimized. Chip packaging is simpler, dependence on high-precision equipment isreduced, standardized and process production is achieved. Meanwhile, the packaging percent of pass is increased, cost and energy consumption are reduced. Optimization of the silver paste antenna printing process before packaging is driven, and the packaging capacity and the RFID label capacity are improved.

Owner:迈思成(北京)科技有限公司

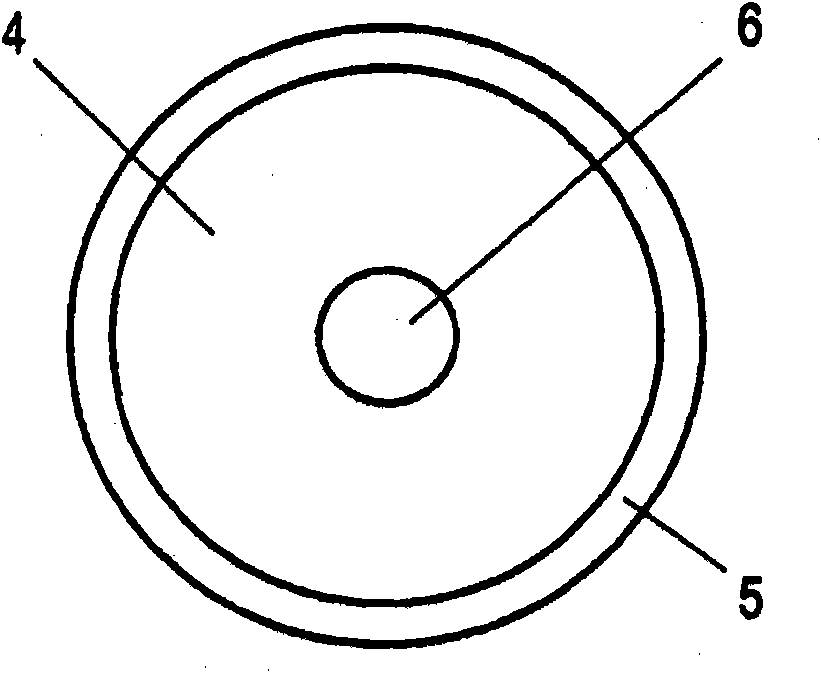

Partition insulator

InactiveCN101855804ASmall transition resistanceWell connected and attachedTotally enclosed bus-bar installationsInsulatorsCentral planeEngineering

The invention relates to a partition insulator consisting of an essentially disc-shaped insulation body, comprising a fastening flange, preferably metallic, and at least one electrode that is preferably rotationally symmetrical and that passes through said insulating body in an axial manner. The cross-section thereof, is greater in the central plane of the insulation body than in the region of the surfaces of the insulating body that are opposite each other. In order to enable said partition insulator to be used with high electric powers, and to also have high safety reserves that are adequate for load switching, and a high mechanical compressive strength with the highest possible rupture pressure, said insulator body has a thickness that reduces in all directions from the centre thereof to the outside. In order to ensure high mechanical strength, said partition insulator is fitted with electrodes and the largest cross-section in the central section thereof rests in the region of the central plane of the insulating body, and said cross-section has no point that is smaller than on the ends of the electrodes.

Owner:KUVAG

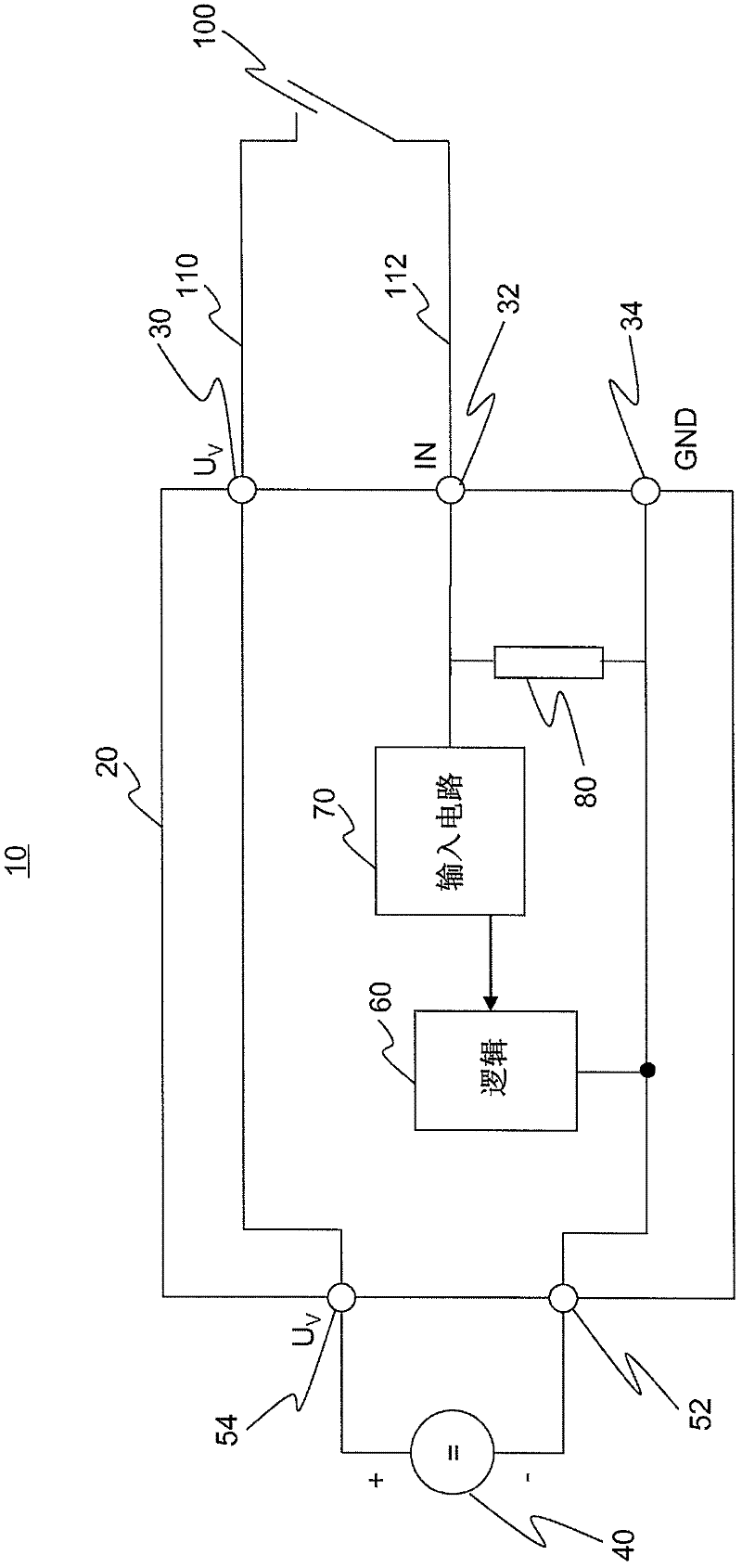

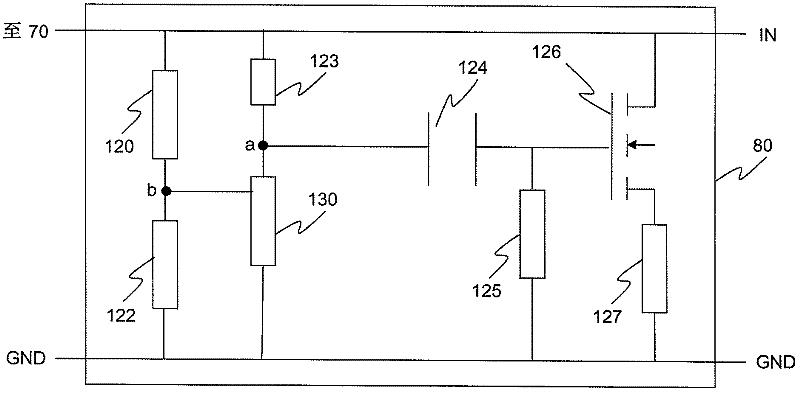

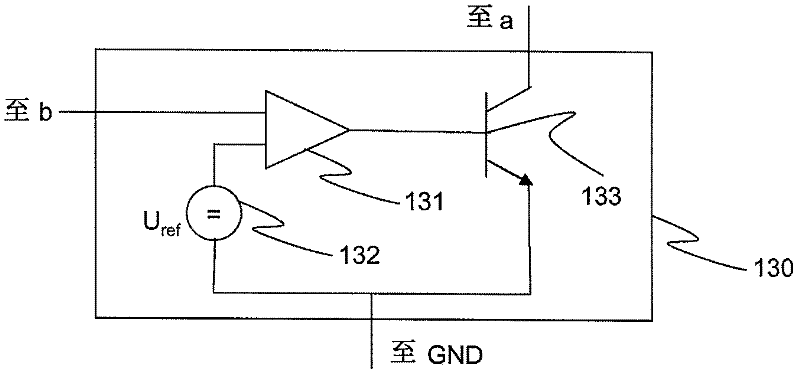

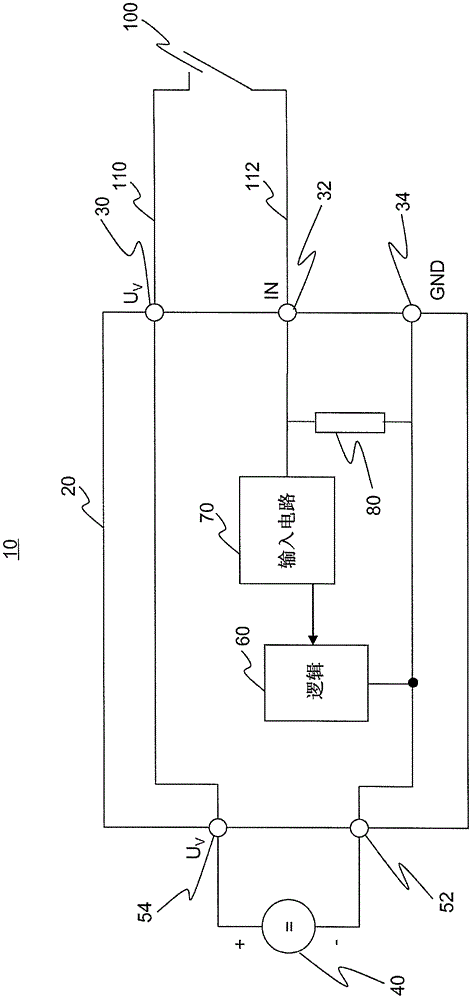

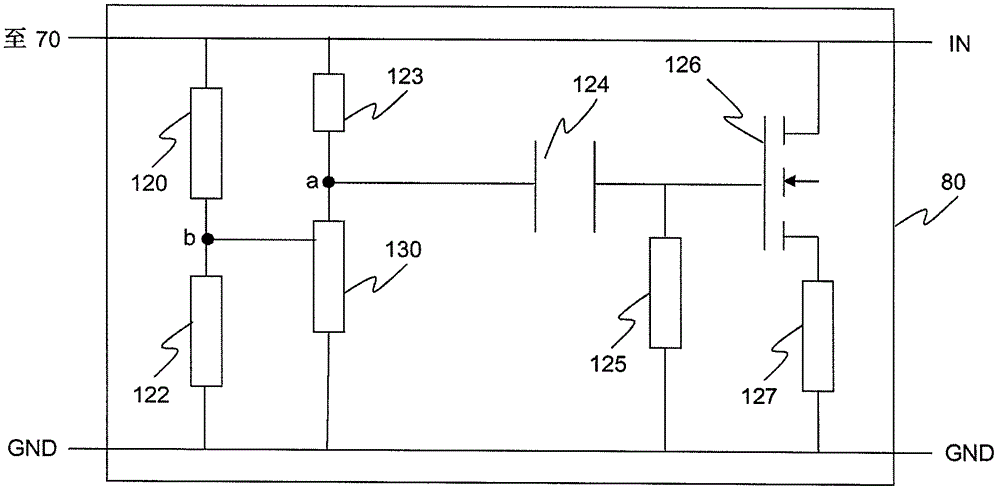

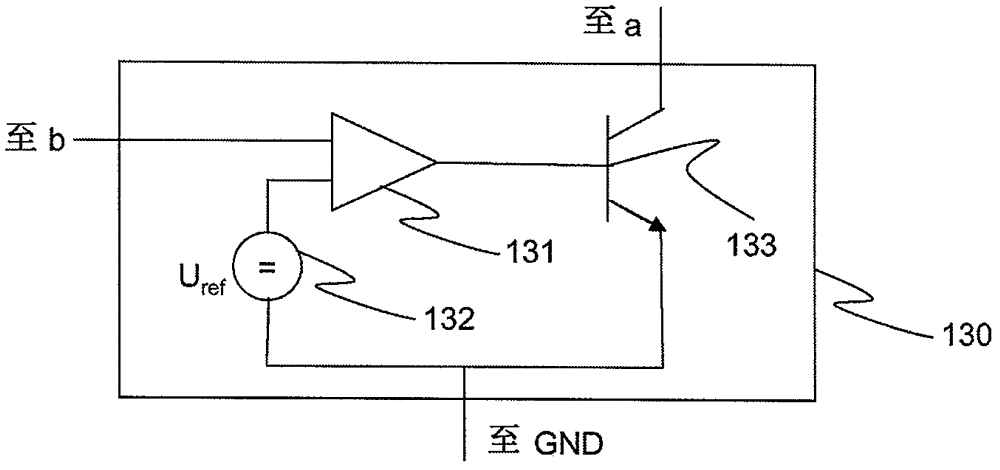

Communication system with monitored input state of an input device and voltage increasing device

ActiveCN102694539ASmall transition resistanceReduce transition resistanceSub-station arrangementsPower amplifiersVoltageInput device

The present invention concerns a communication system with monitored input state of an input device. The input device has an input connection, a ground connection and an input circuit connected between the input connection and the ground connection. The input circuit is designed to detect an input signal. A sensor device is also provided, which is connected to the input connection and optionally the ground connection. The communication system also has a current-increasing device connected to the input connection and the ground connection, which is designed to furnish an increased current for the input circuit for an adjustable time period as a function of the voltage lying on the input connection. A power supply is also provided to supply power to the sensor device.

Owner:PHOENIX CONTACT GMBH & CO KG

A Calculation Method of AC System Contributed Short-Circuit Current During DC Fault in Multi-terminal AC-DC Hybrid Distribution Network

ActiveCN108429252BThe calculation process is simpleGuaranteed uptimeLoad forecast in ac networkElectric power transfer ac networkCapacitanceShort circuit fault

The invention relates to a calculation method of short-circuit current contributed by an alternating-current system during the direct-current fault of a multi-end alternating current / direct current hybrid distribution network. The method includes the following steps that: 101, a post-direct-current inter-pole short-circuit fault equivalent circuit of the alternating current / direct current hybrid distribution network is provided according to the characteristics of fault current and contribution made by the alternating-current system to the fault current after an inter-pole short-circuit fault of a direct-current line occurs, wherein the equivalent circuit is composed of an alternating-current voltage source 301, an alternating-current system equivalent resistor 302, an alternating-current system equivalent inductor 303, a converter station direct-current side capacitor 206, direct-current line resistors 304 and 306, and direct-current line inductors 305 and 307; 102, an analytical expression of the short-circuit current contributed by the alternating-current system is derived according to the analysis of the step 101; and 103, the calculation method of the short-circuit current contributed by the alternating-current system during the direct-current fault of the multi-end alternating current / direct current hybrid distribution network is provided according to the analysis of the step 102, the steady-state average value, transient peak value time and transient peak value of the method are calculated.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI +1

Contact-making and connection arrangement on the basis of film conductors introduced in a housing

ActiveCN102884681BLow costAdequate airtightnessMachine supportsElectrically conductive adhesive connectionsElectrical resistance and conductanceElectrical conductor

The invention relates to a contact-making and connection arrangement on the basis of film conductors introduced in a housing, wherein ends of the film conductors have a contact-making section and at least partly lie one above another. According to the invention, a double-sided self-adhesive or adhesive-coated conductive nonwoven material is situated between the contact-making sections facing one another, said material mechanically and electrically connecting the ends of the film conductors. Furthermore, the housing is embodied such that it is divided in the plane of the film conductors that have been introduced or are to be introduced, wherein the housing parts form half-shells and, in at least one half-shell, stamp-like projections are provided which lead to a deformation of the contact-making layer in such a way that a reduction of the electrical contact resistance of the connection occurs.

Owner:FEW FAHRZEUGELEKTRIKWERK +1

Method for manufacturing steel-aluminum composite conductor rail

Owner:SHANGHAI SANY PRECISION MACHINERY

Communication system and current amplifying device with input device whose input state is monitored

ActiveCN102694539BSmall transition resistanceEasy accessSub-station arrangementsPower amplifiersCommunications systemSwitched current

The system (10) has input device (20) comprising input terminal (32) and ground terminal (34). An input circuit (70) is connected between input terminal and ground terminal for detecting an input signal. A sensor device (100) is connected to input terminal, and is optionally connected to ground terminal. A supply voltage source (40) is provided for supplying the sensor device with energy. A switched current increasing unit (80) is connected to input terminal and ground terminal, to supply high current to input circuit as a function of applied voltage for adjustable time period.

Owner:PHOENIX CONTACT GMBH & CO KG

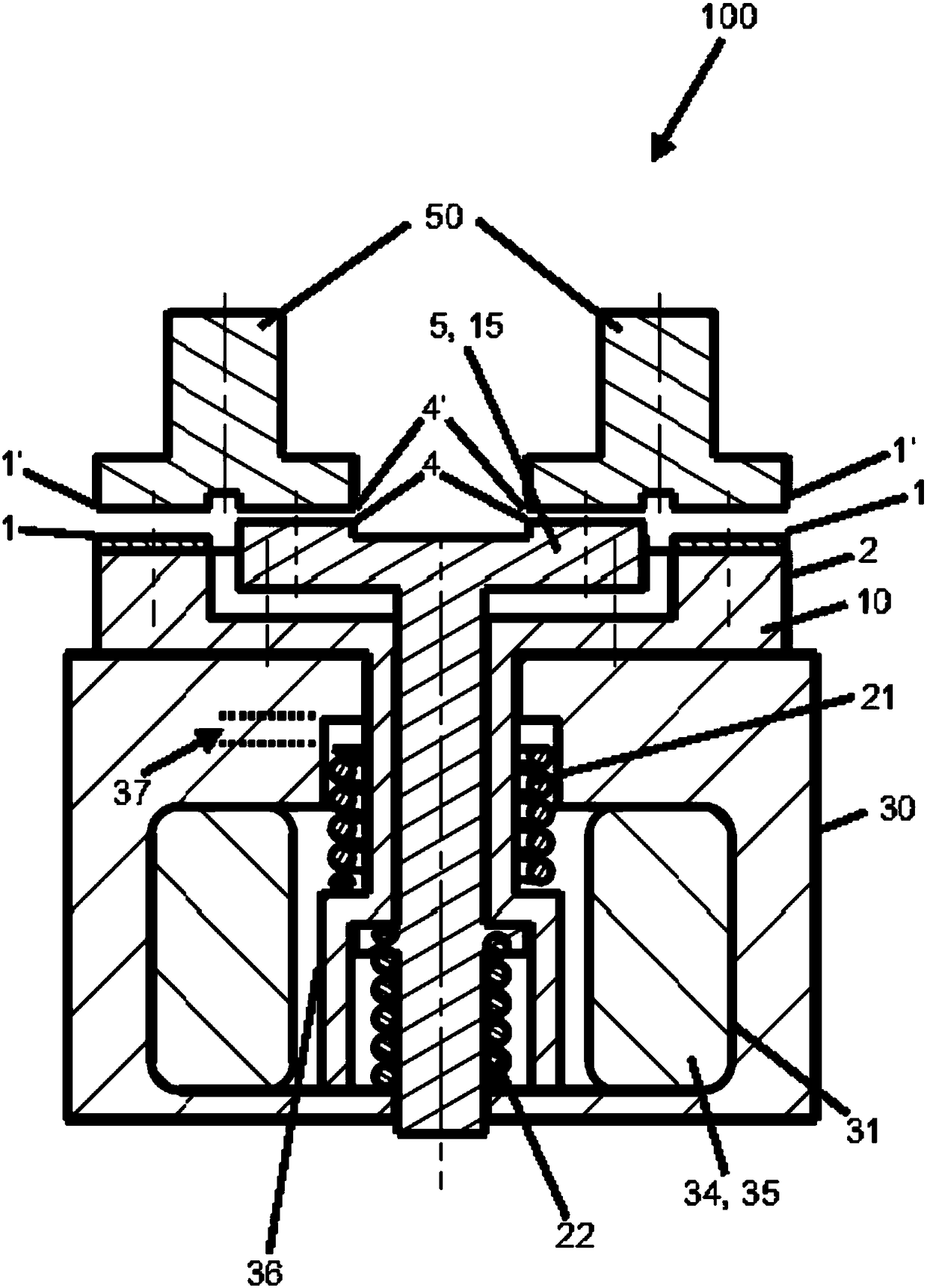

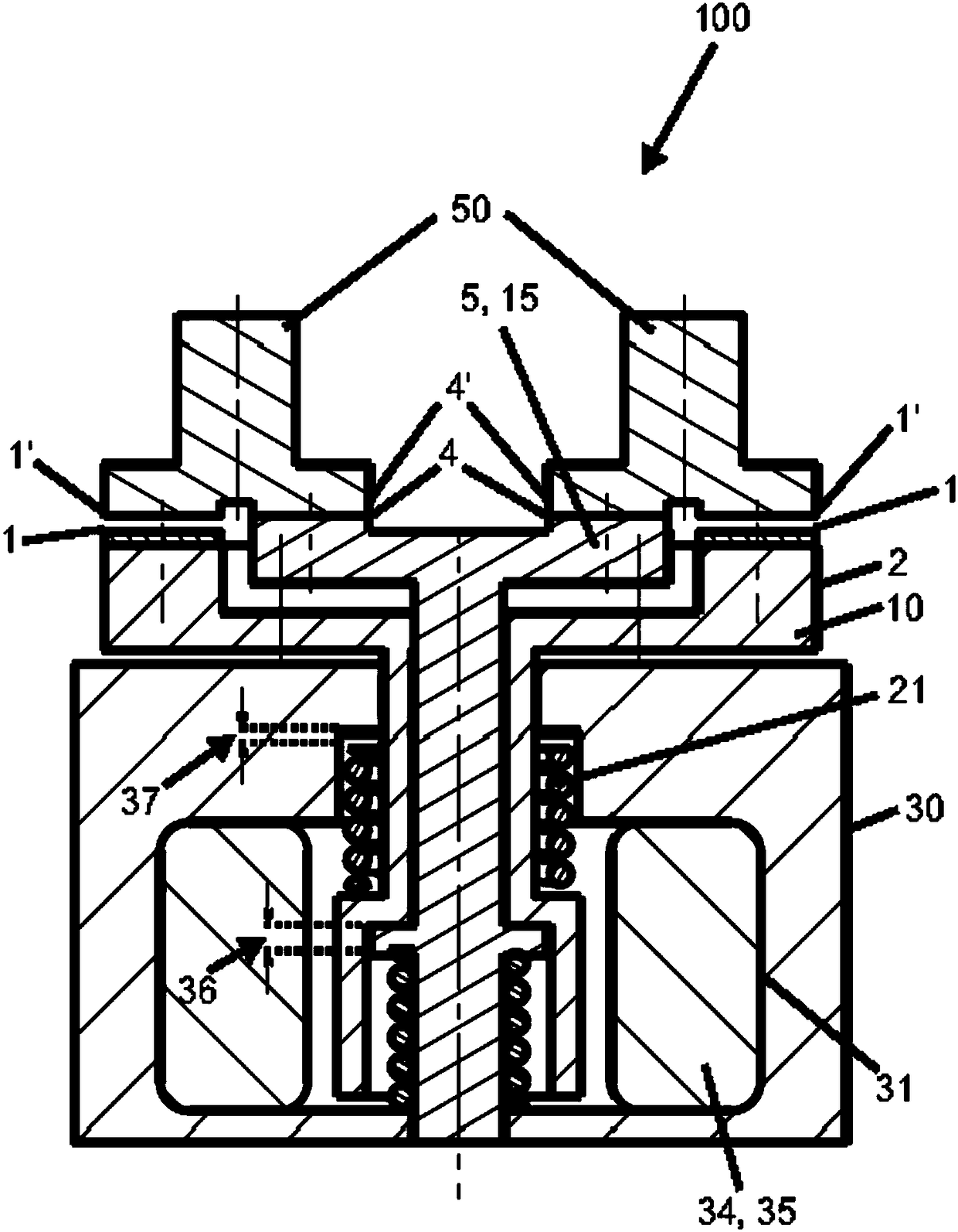

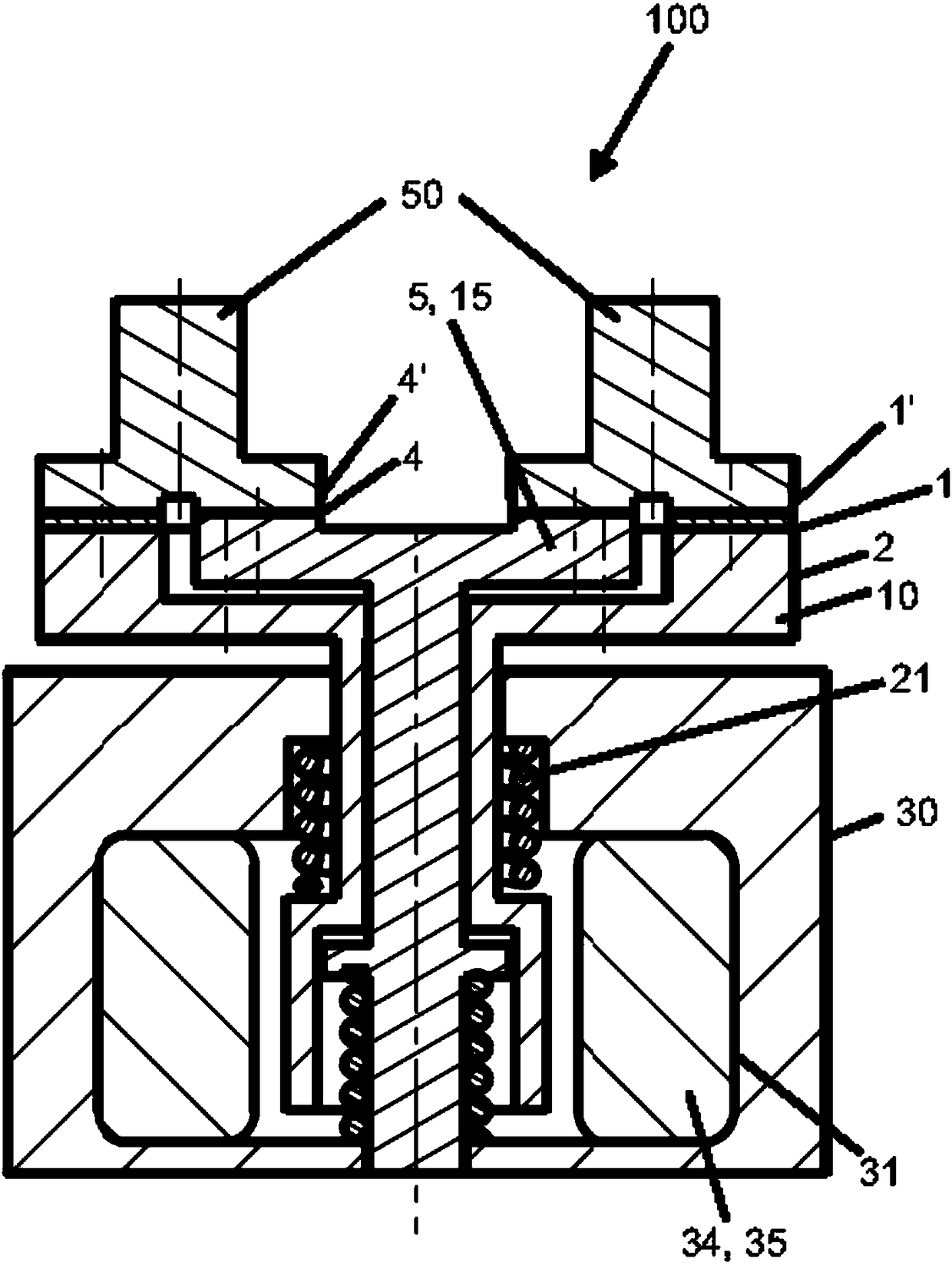

Electromechanical protection switch

ActiveCN106683951BImprove conductivityReduce the risk of being damagedEmergency springsElectromagnetic relay detailsEngineeringCircuit breaker

The invention relates to an electromechanical protection switch (100) with: - at least one main contact pair (1, 1'), wherein one main contact (1) is arranged on a main contact bridge (2) , - at least one pair of secondary contacts (4, 4') with a higher melting point material than the primary contact (1), wherein one secondary contact (4) is arranged in a On the secondary contact bridges (5) connected in parallel with the contact bridges (2), - the first armature (10) for the movement of the main contact bridge (2), - the second armature (for the movement of the secondary contact bridge (5) 15), wherein the armature (10, 15) is formed such that the pair of secondary contacts (4, 4') opens after the pair of primary contacts (1, 1') and before the pair of primary contacts (1, 1') closure.

Owner:LISA DRAXLMAIER GMBH

A fast line selection method for single-phase grounding fault in small current grounding system

ActiveCN112162170BSmall amount of calculationSmall CPU requirementsFault location by conductor typesShort-circuit testingPhase currentsElectrical resistance and conductance

The invention discloses a fast line selection method for a single-phase grounding fault in a small current grounding system. First, the instantaneous value of the three-phase current at the outlet of each feeder line in the substation is collected in real time; secondly, according to the instantaneous value of the current, the instantaneous value of the zero-sequence current of the line is calculated, and the second-order derivative of the instantaneous value of each zero-sequence current is obtained by interpolation method; then, Taking the fault occurrence time as the zero time, find out the maximum value and minimum point of the second order derivative of the zero-sequence current instantaneous value of each line within 3ms; finally, find out the characteristic quantity of the zero-sequence current change trend of each line, and find out the maximum characteristic quantity , that is, it is judged that the line is a faulty line. The method of the invention is less affected by line length, transition resistance and arc suppressing coil, and can quickly select a single-phase grounding fault line.

Owner:HUANGGANG POWER SUPPLY COMPANY HUBEI ELECTRIC POWER

Monitoring of load-carrying mechanisms in elevator installations

InactiveCN104755405BSmall transition resistanceMaterial analysis by electric/magnetic meansTwo-part coupling devicesElectricityEngineering

Owner:INVENTIO AG

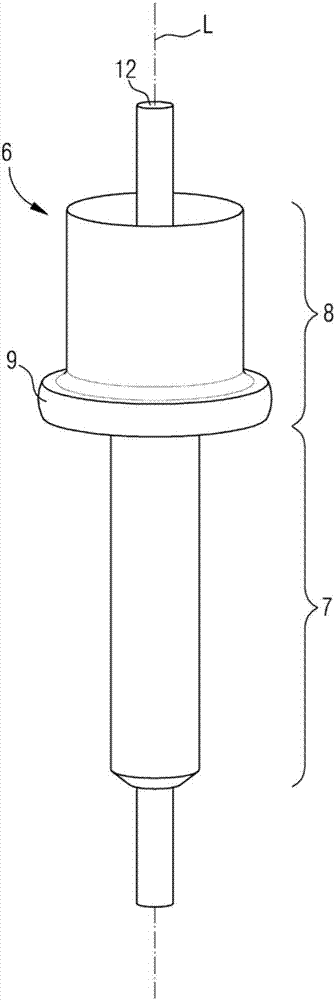

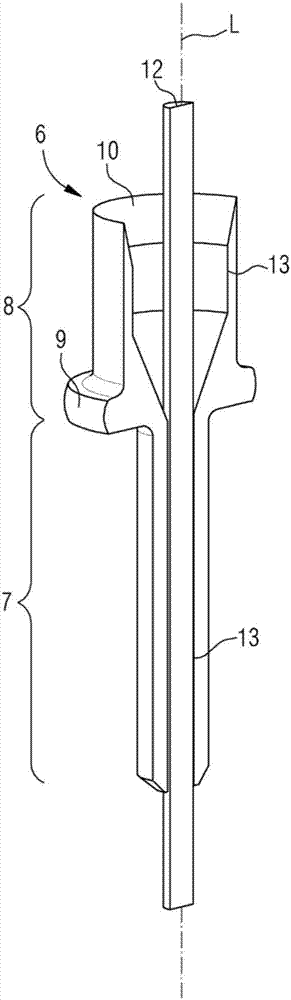

Semiconductor Lamp

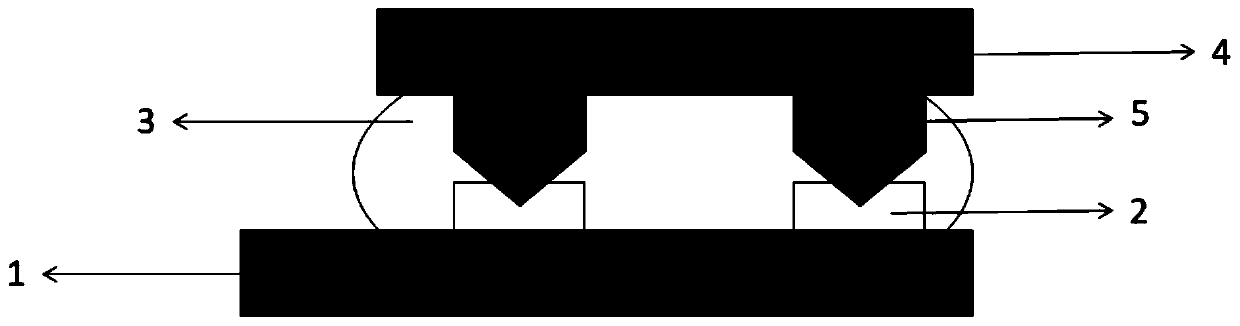

InactiveCN107152615AUniform forceReliable conductionElectric discharge tubesElectric circuit arrangementsHalogenElectrically conductive

A semiconductor lamp (1) comprises a housing (2) in which a driver (3) is accommodated and at least one contact pin (6) protruding from the housing (2) outwards, wherein the contact pin (6) is tubular and riveted to the housing (2) and the driver (3) is connected to the contact pin (6) via an electrically conductive connection element (12) which is inserted into a cavity (13) of the contact pin (6). A method serves for producing a semiconductor lamp (1), wherein at least one tubular contact pin (6) is inserted into a feedthrough (5) of a housing (2) from outside till the contact pin (6) abuts the housing (2), the contact pin (6) is next riveted with the housing (2) on the inside and a driver (3) is inserted into the housing (2), whereby an electrically conductive connection element (12) is inserted into the contact pin (6). The invention is particularly applicable to LED retrofit lamps for replacing bipin halogen lamps, in particular MR16 lamps.

Owner:LEDVANCE GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com