Battery cell connector for battery cells connected in series

A battery cell and series connection technology, which is applied in the field of battery cell connectors used to connect battery cells in series, can solve the problems of limiting and limiting the power capacity of the battery system, and achieve the effect of small temperature difference and high thermal reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

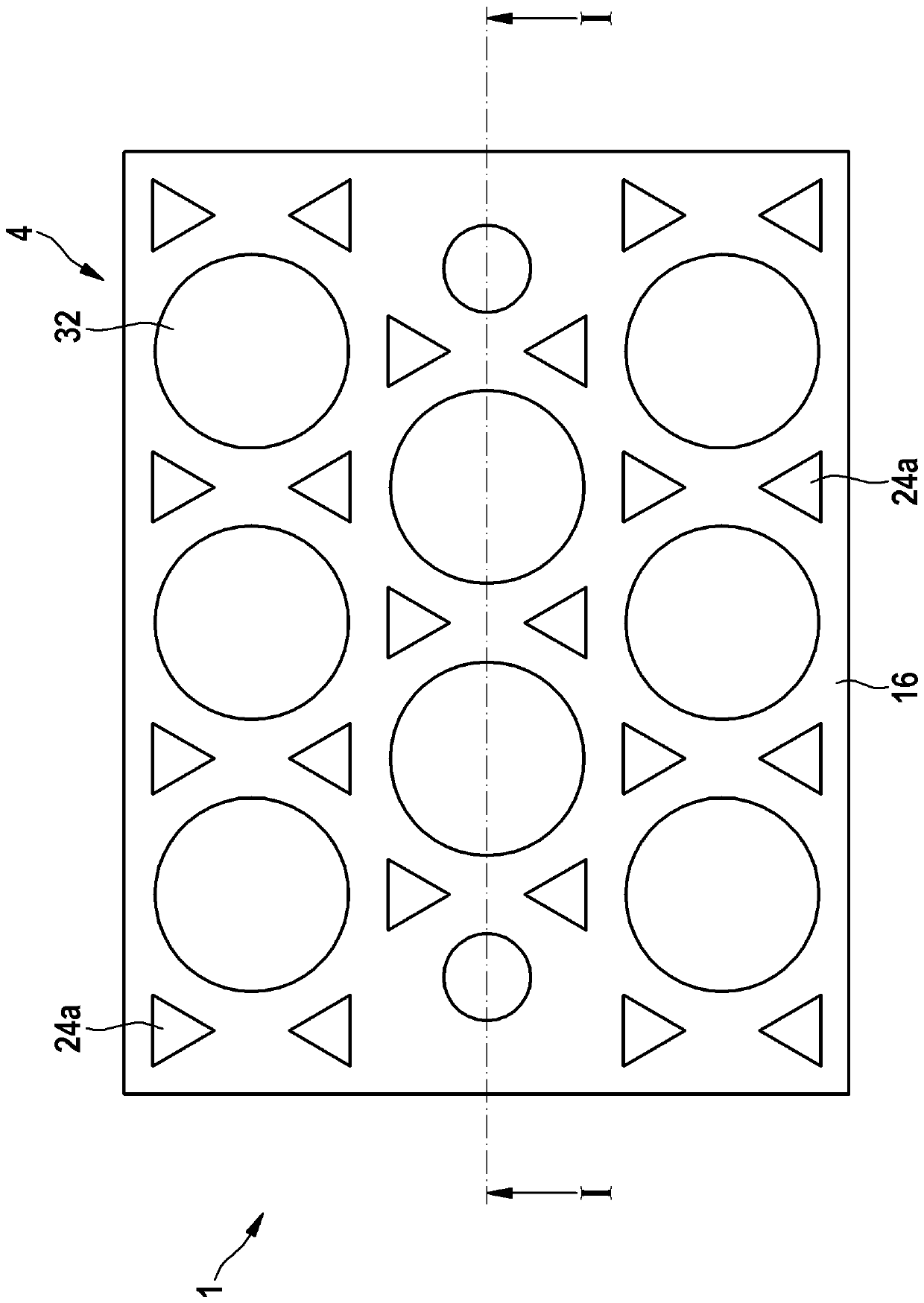

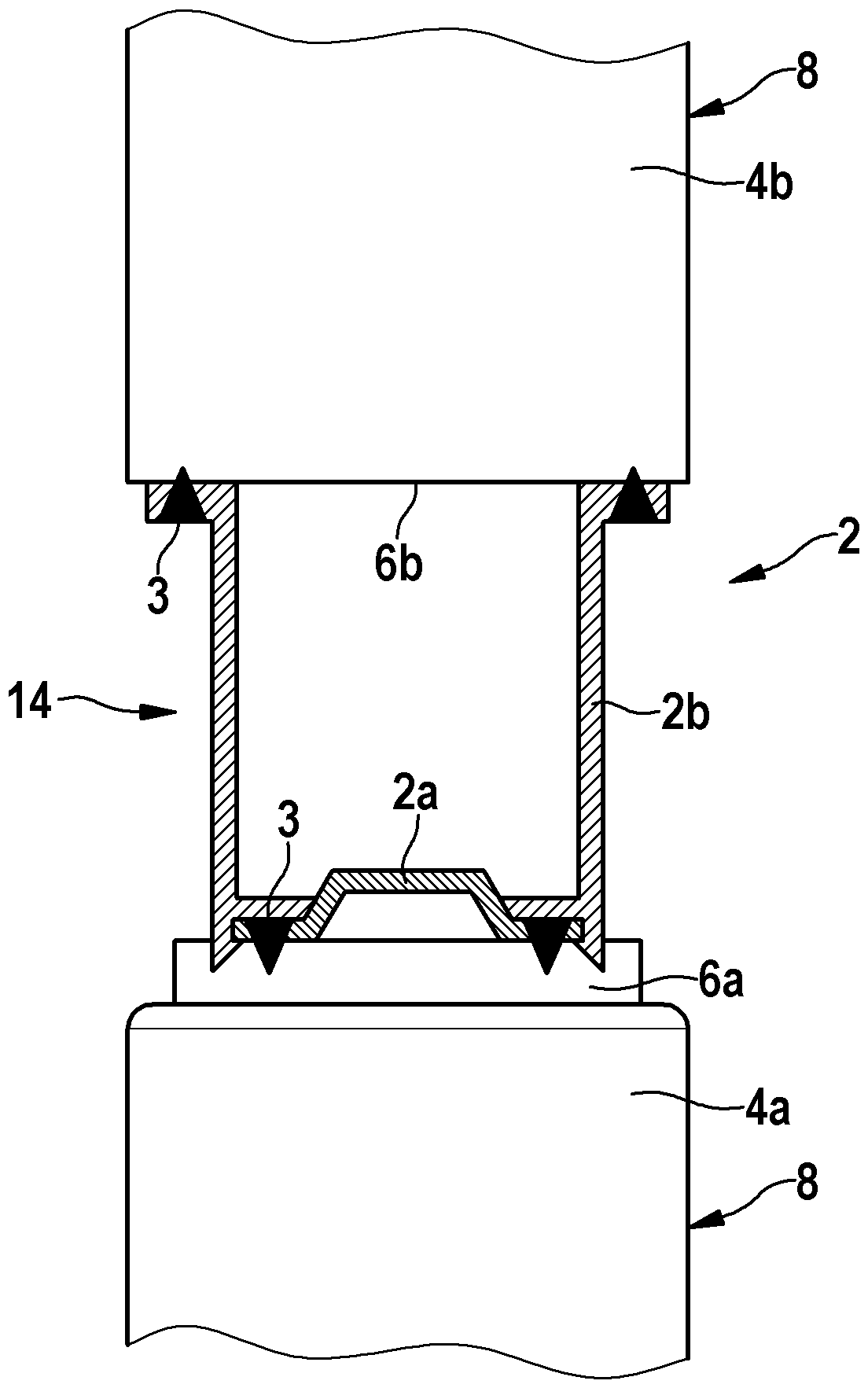

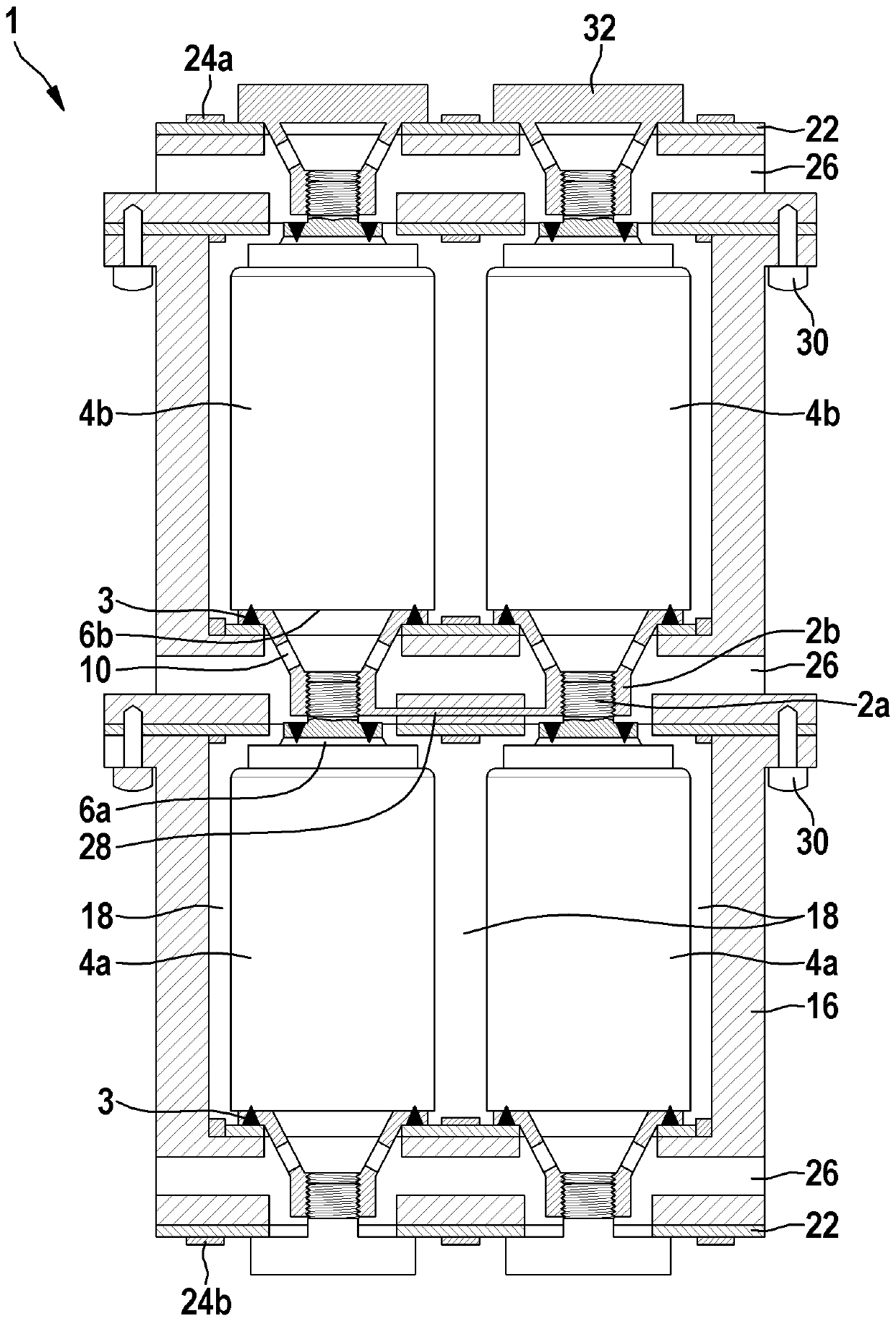

[0027] figure 1 A schematic diagram of a battery cell connector 2 according to the invention for connecting battery cells 4 in series according to a first embodiment is shown in a sectional view. In this case, the battery cell connector 2 comprises a first connection element 2a for establishing a connection to a first battery pole 6a of a first battery cell 4a and a second connection element 2a for establishing a connection to a second battery cell 4b. The second connection element 2b of the connection of the battery pole 6b, wherein the connection elements 2a, 2b are designed in a form-corresponding manner relative to one another and are connected in series with one another in such a way that the contact area 8 surrounding the battery cells 4 can be maximized. In order to ensure effective cooling of the battery cell 4. Here, the connecting elements 2 a and 2 b of the two-part battery cell connector 2 are connected to one another in a force-locking manner. For this purpose, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com