Novel steel-aluminum composite contact rail expansion joint

A technology of steel-aluminum composite and expansion joints, which is applied in the direction of power rails, power lines, transportation and packaging, etc., can solve the problems of increased sliding resistance of slide rails, poor current connection performance, and large initial sliding force, etc., to achieve Steady current receiving, guaranteed current continuous connection performance, and stable continuous current effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

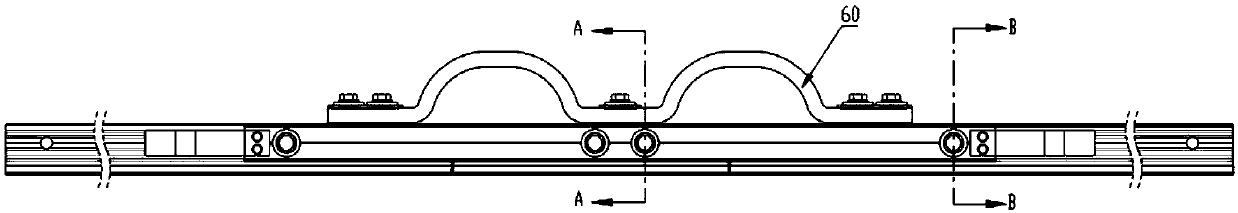

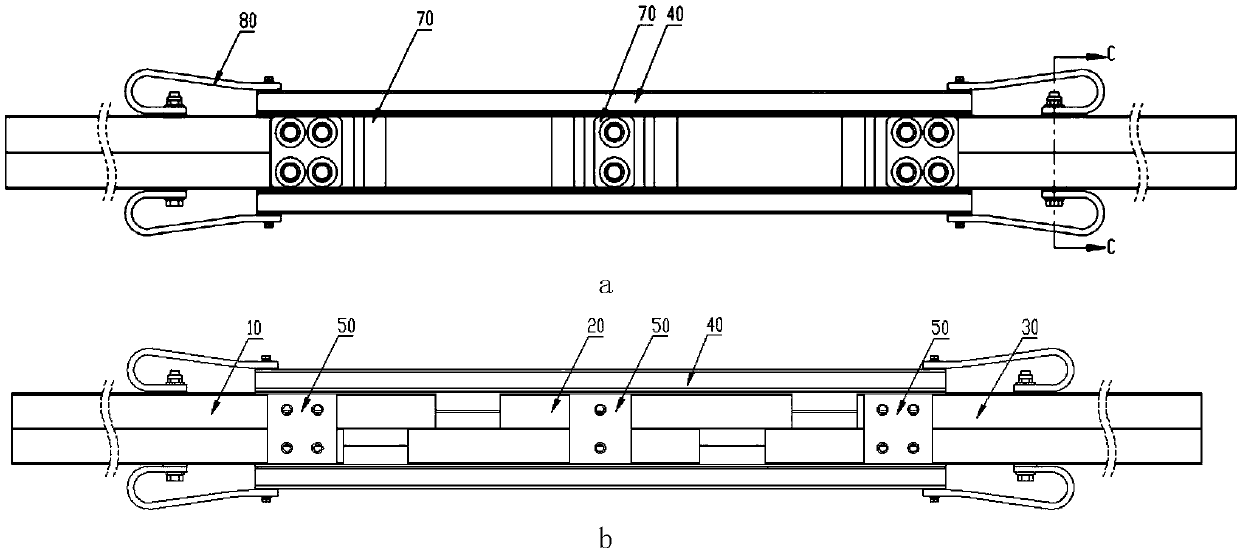

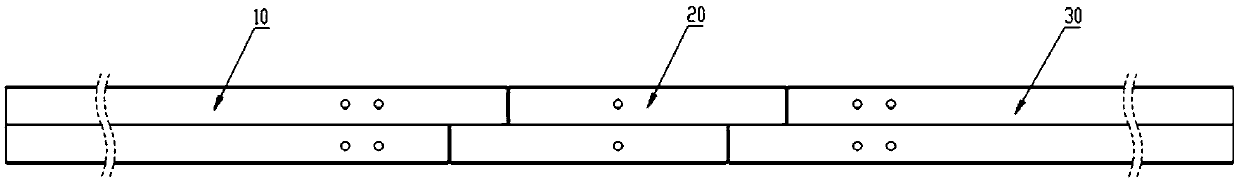

[0042] Such as Figure 1-4 As shown, it is a schematic diagram of the expansion joint of the new steel-aluminum composite contact rail in this embodiment, including the left slide rail 10, the middle slide rail 20 and the right slide rail 30 ( image 3 )’s rail waists are sequentially connected by fishtail splints 40 to form a slide rail structure, wherein the fishtail splints 40 are slidably connected to the rail waists of the left slide rail 10 and the right slide rail 30, and the rail waists of the fishtail splints 40 and the middle slide rail 20 Fixed connection; the bottoms of the left slide rail 10 , the right slide rail 30 and the middle slide rail 20 are all provided with a main soft copper strip 60 .

[0043] Between the side end of the fishtail splint 40 connected to the left slide rail and the left slide rail and between the side end of the fishtail splint 40 connected to the right slide rail and the right slide rail are connected by an auxiliary soft copper strip 8...

Embodiment 2

[0048] This embodiment is an improvement on the basis of Embodiment 1, as Figure 6 As shown, the first copper-aluminum transition plate 50 is set between the bottom surface of the main annealed copper strip that is in contact with the left slide rail, the middle slide rail and the right slide rail; There is a pressure plate 70, and the pressure plate 70 is made of anti-corrosion metal; the bolts connecting the left slide rail and the right slide rail on the fishtail splint are fitted with a limit sleeve 100 (see Figure 7 As shown), the limit sleeve 100 is located in the horizontal long hole; the bolts connecting the fish splint to the middle slide rail are fitted with a partition 90 that fits the shape of the inside of the fish splint, and the partition 90 is arranged on the fish splint and the middle slide. between the rail waists. The parts where the auxiliary annealed copper strip 80 is connected with the left slide rail and the right slide rail are provided with connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com