Electromechanical protection switch

A technology for electromechanical protection and protection switches, applied in the direction of electric switches, emergency protection devices, circuits, etc., can solve the problems of separation current damage, limit the number of switching cycles of protection switches, increase the maintenance cost of protection switches, etc., to reduce burning loss, safety Effect of separation and minimization of transition resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

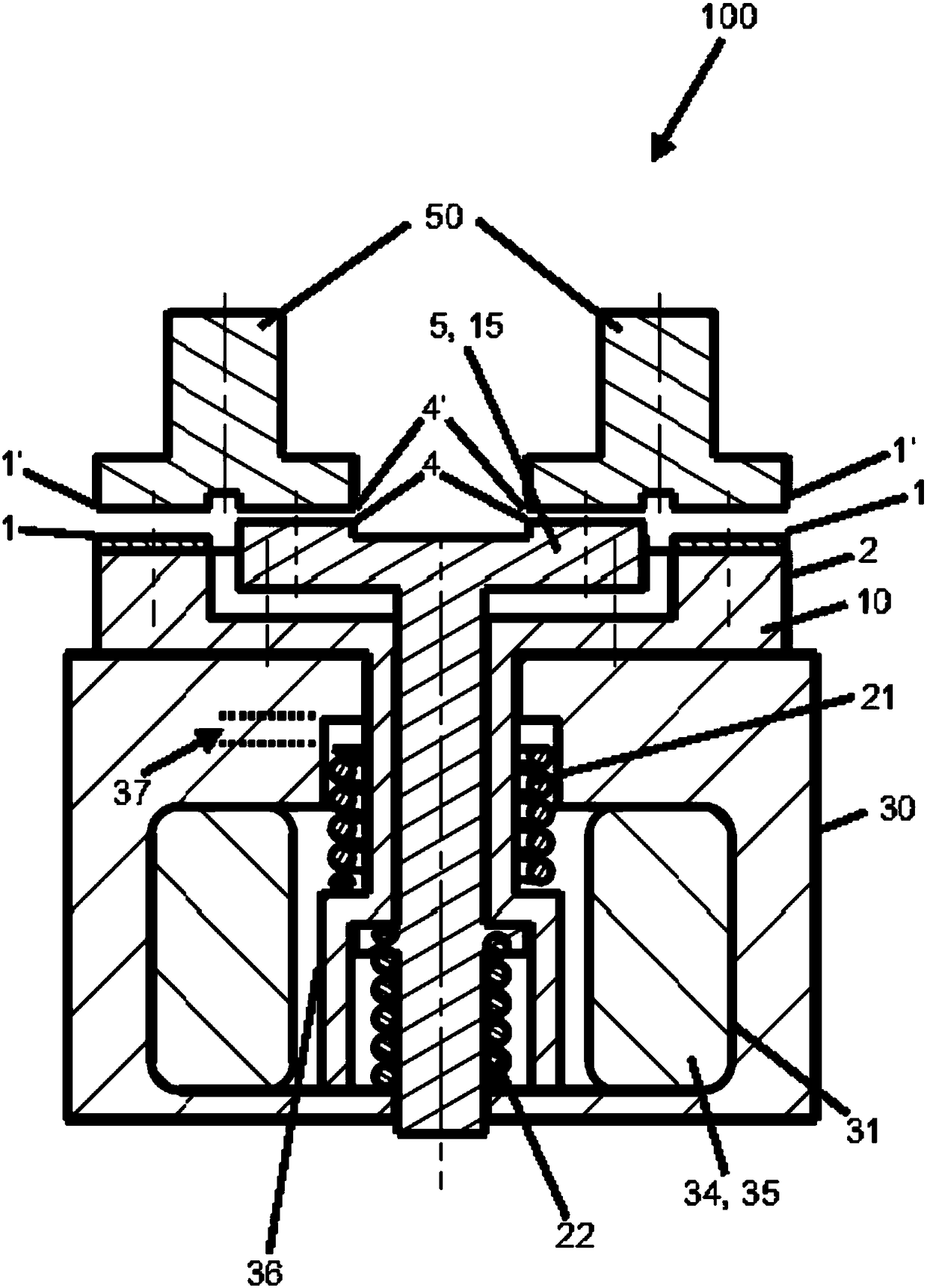

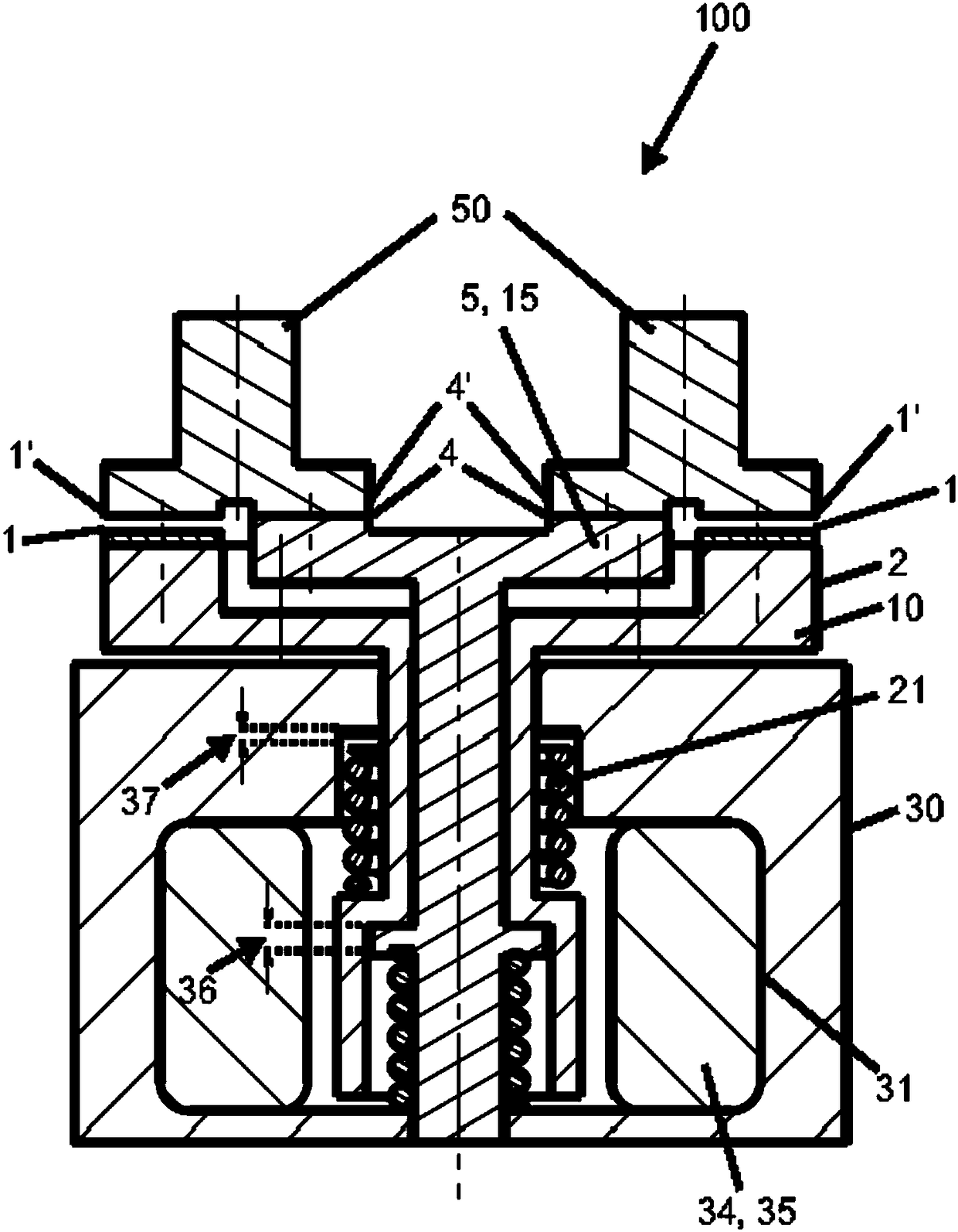

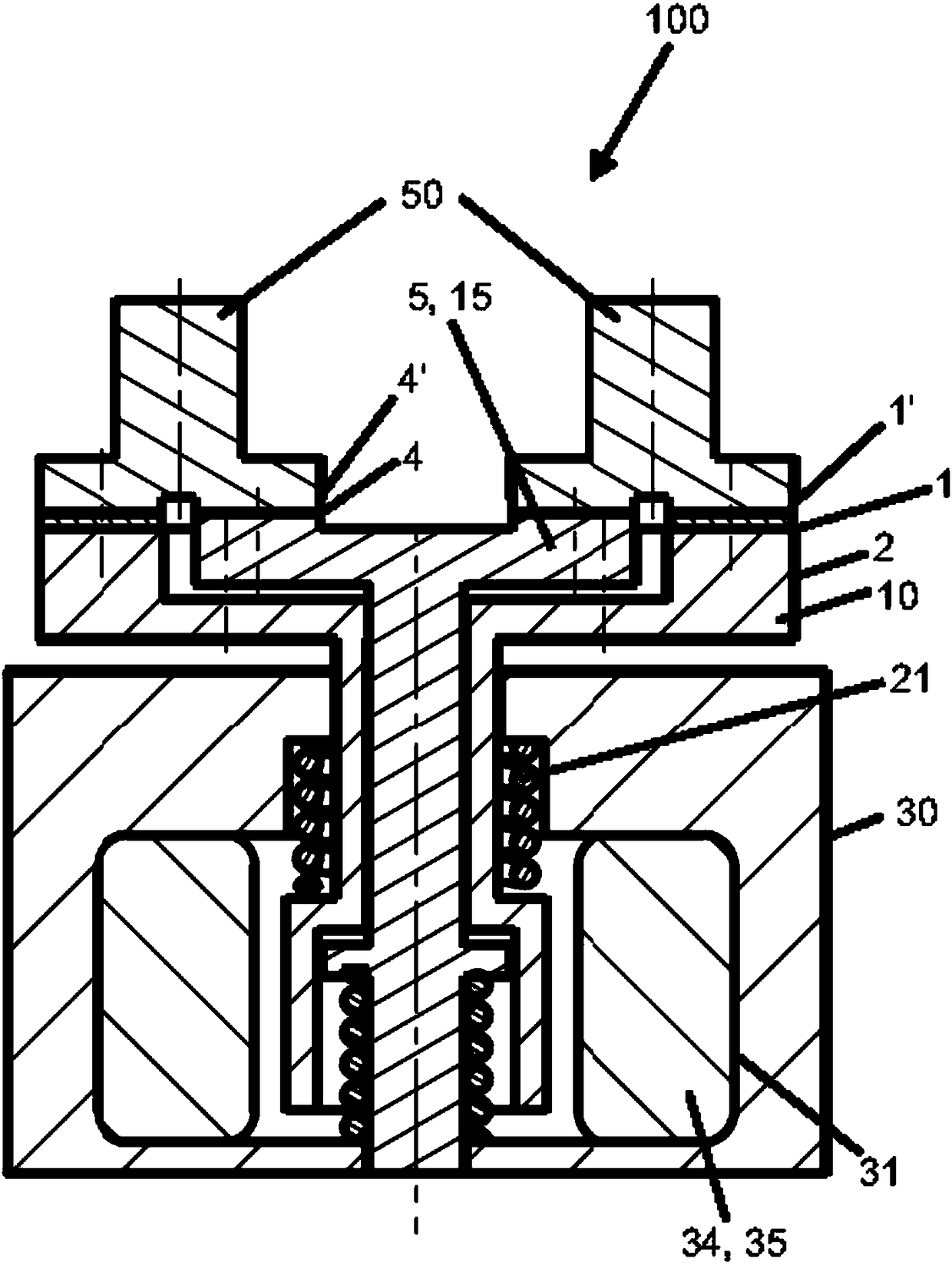

[0023] figure 1 A protective switch 100 is shown with two main contact pairs 1, 1', wherein the two main contacts 1 are arranged on the main contact bridge 2. The main contact pair 1, 1' is made of silver or a silver-containing material or is coated with silver or said silver-containing material. The protective switch 100 also comprises two secondary contact pairs 4, 4' having a material with a higher melting point than the main contact pair 1, 1'. The pair of secondary contacts 4, 4' is preferably made of or clad with tungsten. The two secondary contacts 4 are arranged on a secondary contact bridge 5 parallel to the main contact bridge 2 . The protective switch 100 also includes a first armature 10 for the movement of the main contact bridge 2 and a second armature 15 for the movement of the secondary contact bridge 5 . The armatures 10, 15 are formed such that the secondary contact pair 4, 4' opens after the main contact pair 1, 1' and closes before the main contact pair ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com