Lap-joint type copper-aluminum transition wire clip

A transition line, copper-aluminum technology, applied in the direction of connection, conductive connection, electrical component connection, etc., can solve the problems of easy heating, low mechanical strength, etc., and achieve the effect of improving mechanical strength, improving welding quality, and changing the force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

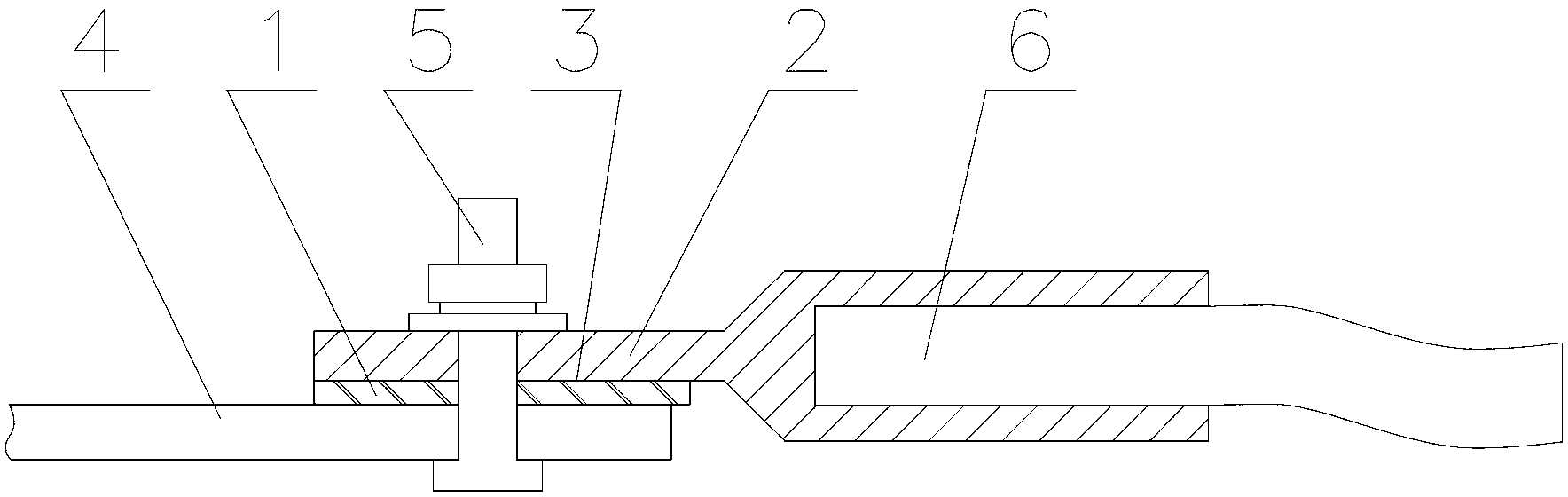

[0019] Such as image 3 , Figure 4 Shown is a lap-joint copper-aluminum transition clamp, which includes an equipment clamp 1 connected to the equipment wiring board 4 and a wire clamp 2 connected to the wire 6, the equipment clamp 1 and the wire clamp 2 There is an overlapping transition between them, and they are welded and fixed by brazing; the overlapping parts between the equipment clamping part 1 and the wire clamping part 2 are all square-shaped. When in use, the equipment wiring board 4 and the equipment clamping part 1 It is mechanically fixed with the wire clamp 2 by a fastener 5 .

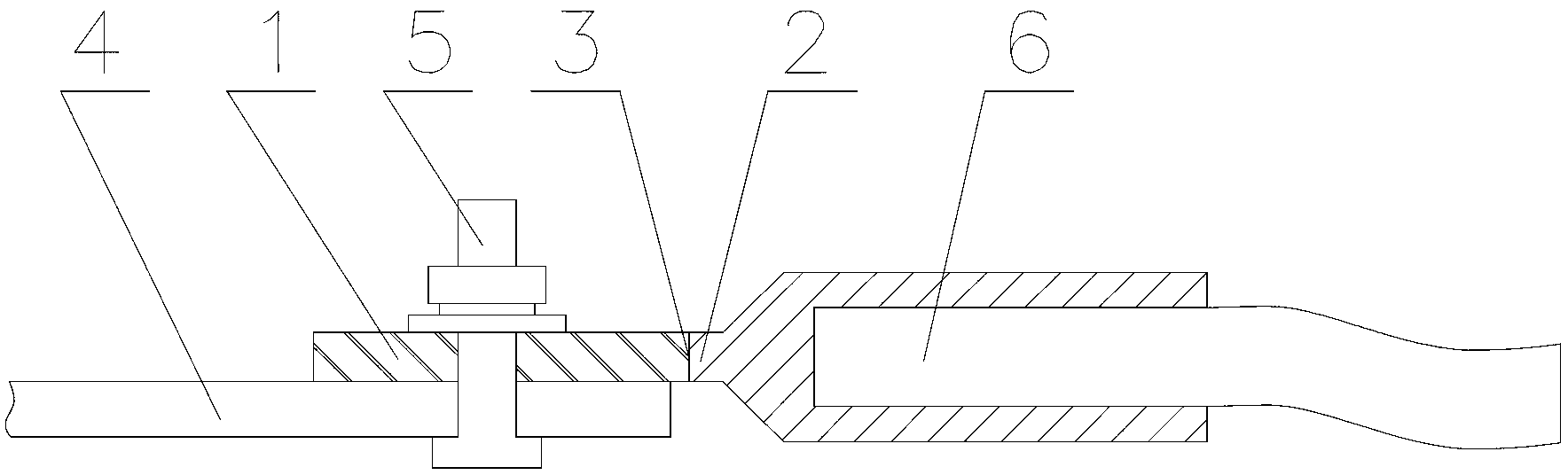

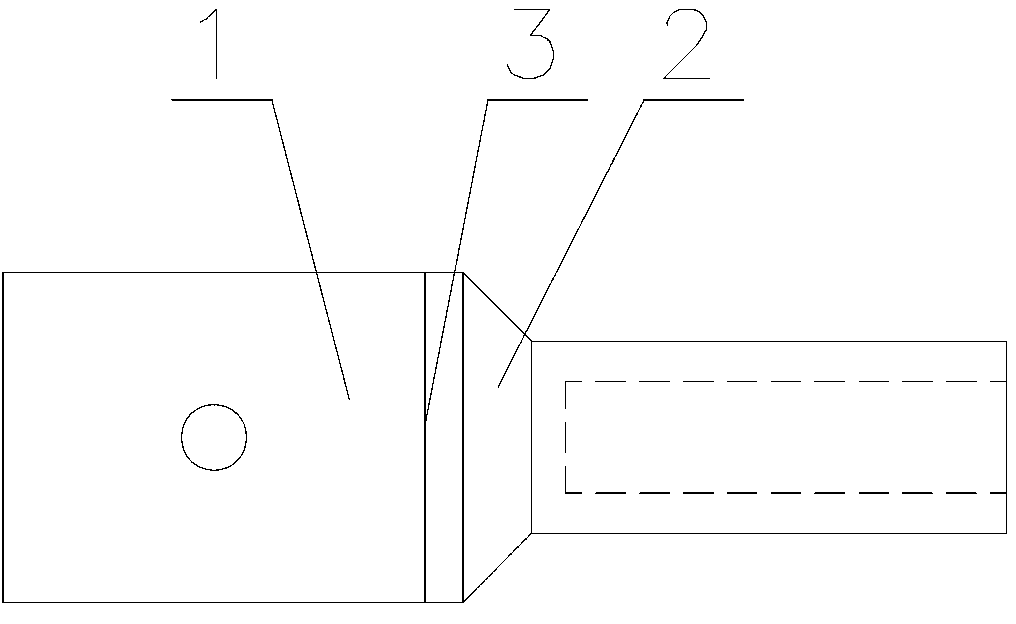

[0020] Compared figure 1 , figure 2 , the traditional transition interface 3 is only the end face, while image 3 , Figure 4 The transition interface 3 is the entire upper side of the device holder 1, and the area is increased by 5 to 7 times.

[0021] The above is only...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com