Contact-making and connection arrangement on the basis of film conductors introduced in a housing

A technology of thin-film conductors and configuration units, applied in the direction of conductive adhesive connection, connection, fixed connection, etc., can solve problems such as price and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

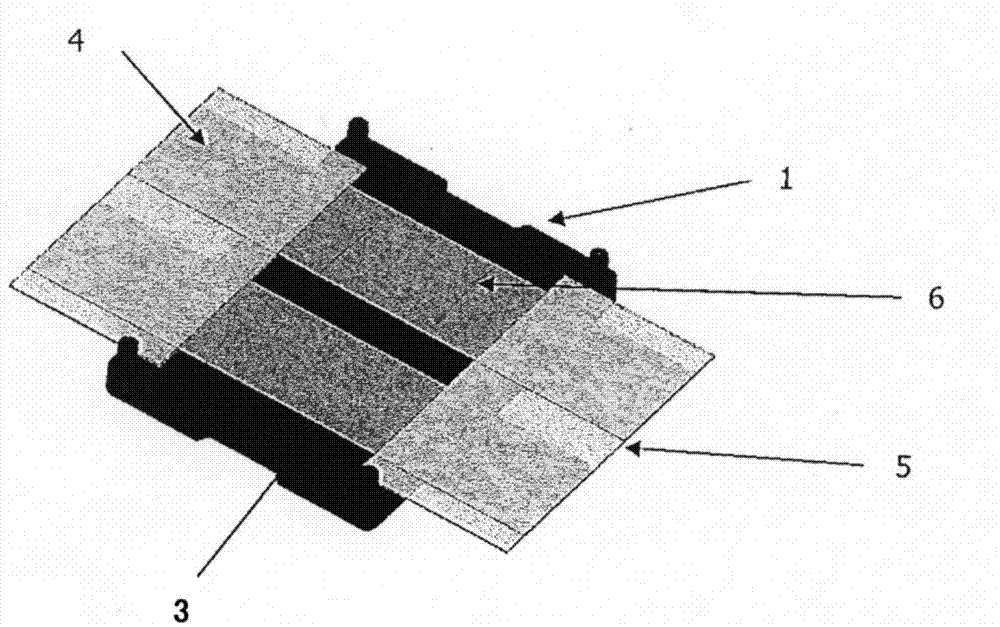

[0026] In the illustration according to the drawing, it is assumed that two housing halves 1 and 2 are formed as a lower part 1 and an upper part 2 . In the inner edge region of the housing halves 1 and 2 there is a heat-activatable glue deposit 3 .

[0027] in accordance with figure 1 In the illustration of , a first foil conductor 4 is introduced, which leads into a plate not shown in the figure. The second foil conductor 5 is connected to a connecting strand, not shown.

[0028] The individual exposed contact contact segments 6 are electrically and mechanically connected via an intermediate layer of conductive, double-sidedly bonded nonwoven material.

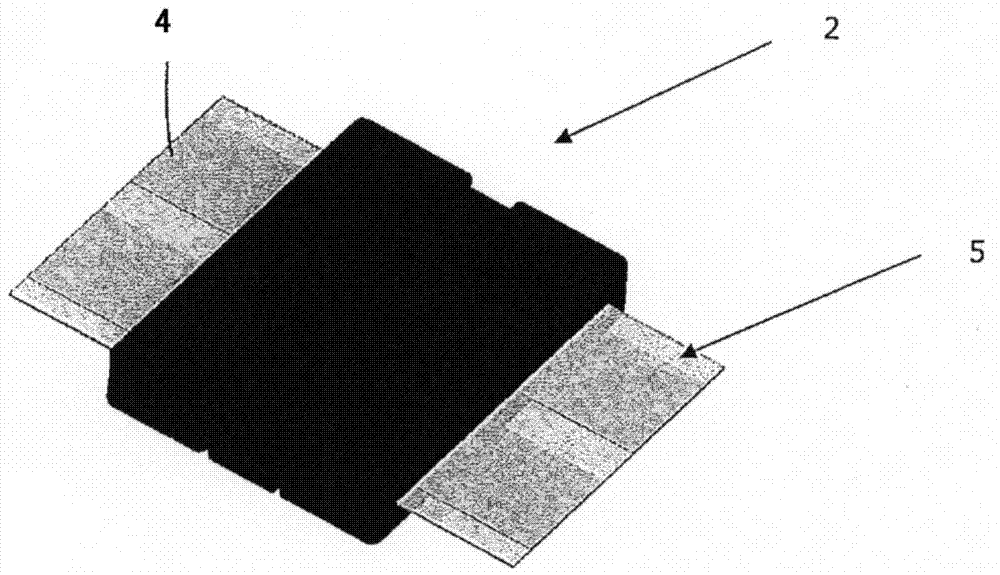

[0029] Obtained by placing the upper part of the housing 2 figure 2 The closed housing structure shown in . The deposit of heat-activatable adhesive placed in the housing halves is displaced by the action of heat into a flowable state, with the result that a tight connection of the housing halves 1 and 2 is obtained.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com