Electric connecting equipment and method for manufacturing same

An electrical connection and equipment technology, applied in the field of electrical connection equipment, can solve problems such as difficult costs, and achieve the effects of high mechanical strength, low transition resistance, and high current carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

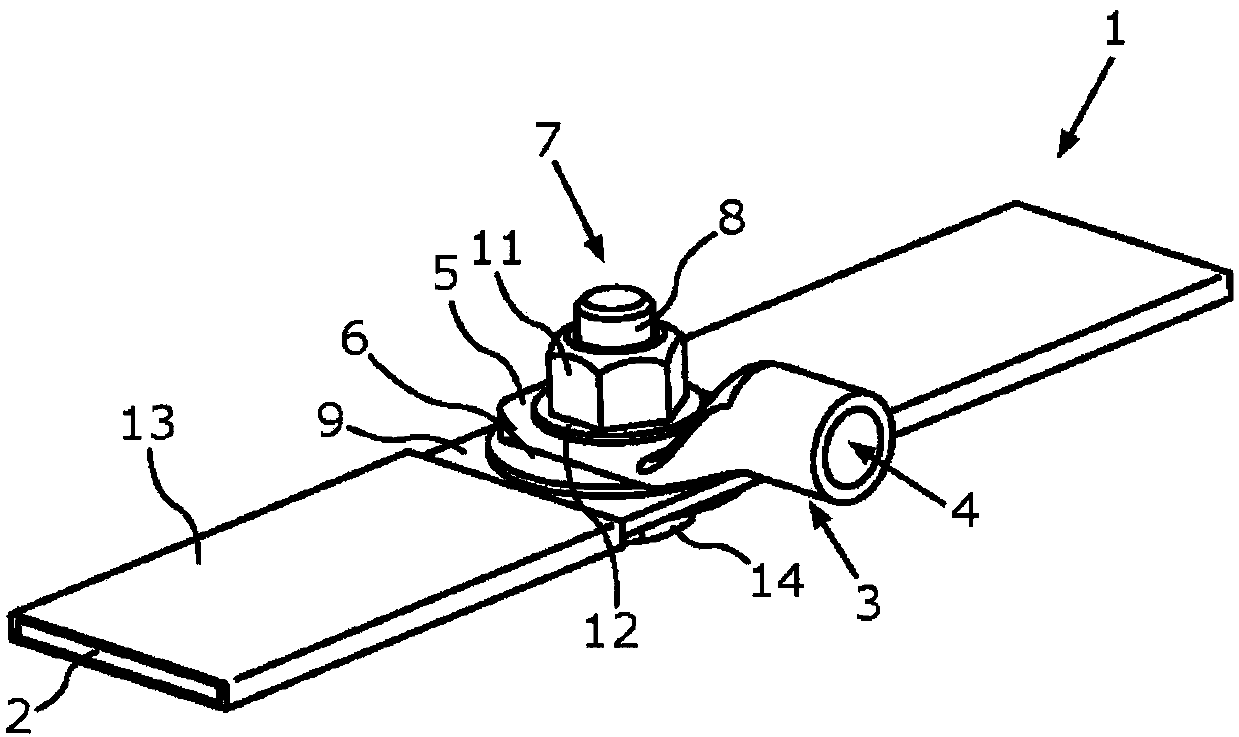

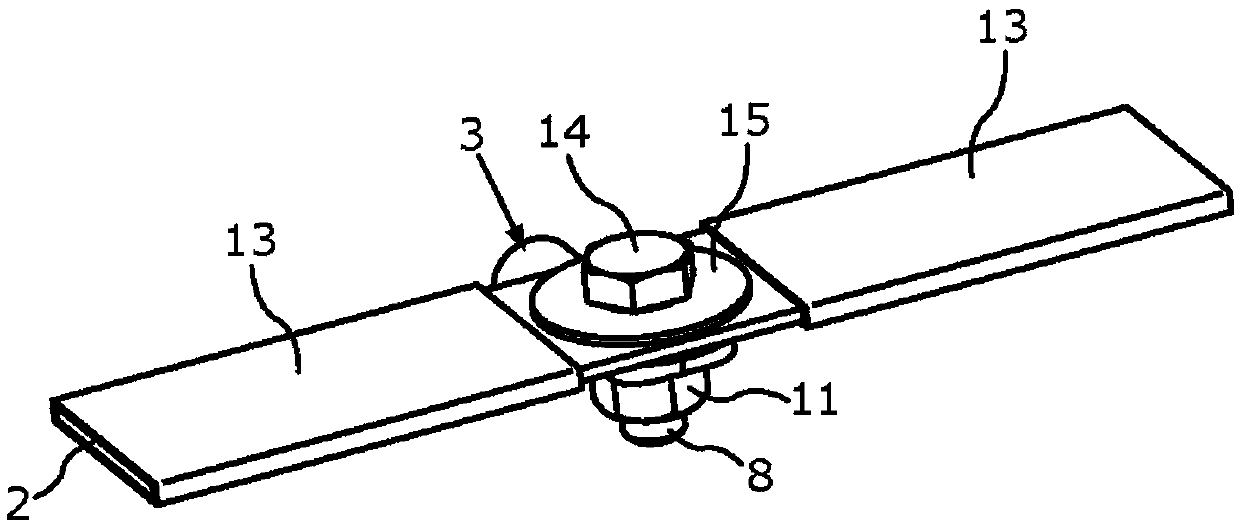

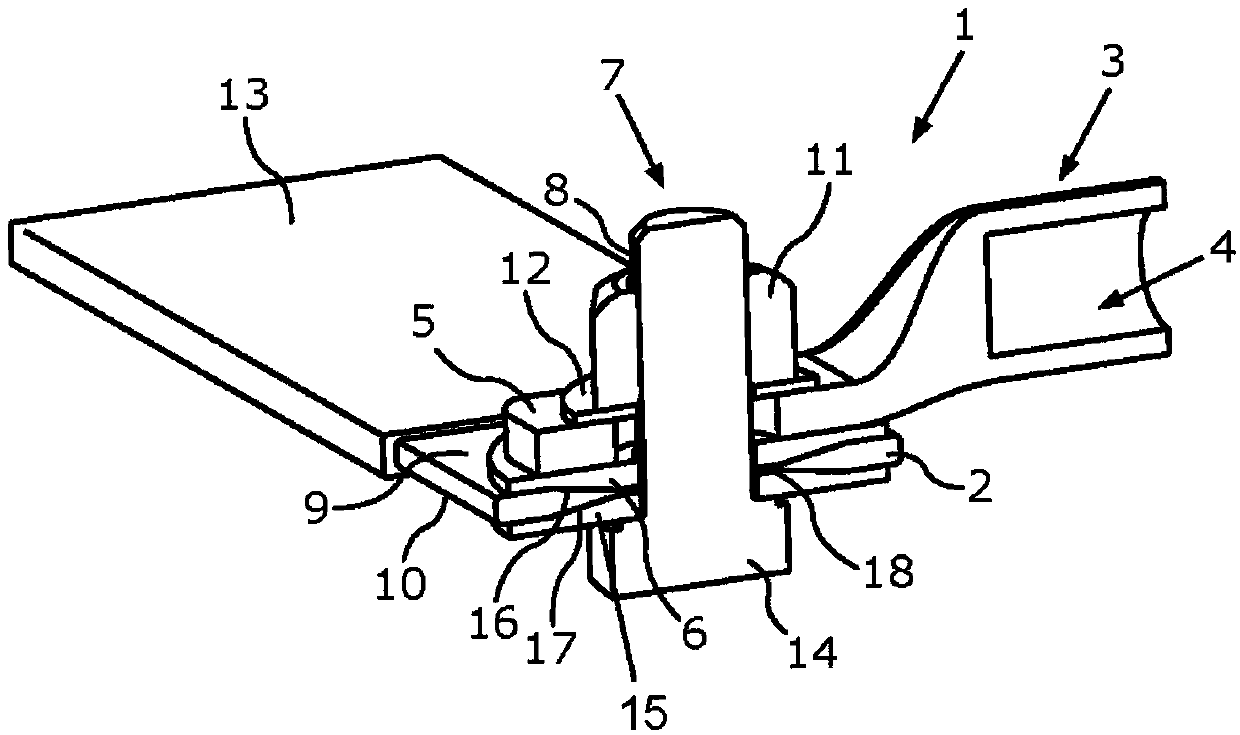

[0049] exist figure 1 The first embodiment of the electrical connection device 1 is shown obliquely from above in a perspective view. The electrical connection device 1 comprises a flat bus bar 2 made of aluminum, on which a cable shoe 3 is fastened. The cable shoe 3 serves as a cable receiving element for electrically conductively connecting a cable (not shown here) to the flat busbar 2 . For receiving cables, the cable boot 3 comprises a cylindrical receiving area 4 . For example, cables formed as flexible round conductors or stranded conductors can be received via the receiving area 4 . The cable shoe 3 is electrically conductively connected with the flattened contact area 5 by means of the contact element 6 to the flat bus bar 2 . The flat bus bar 2 can be specially built in the vehicle for power supply or grounding.

[0050] The flat bus bar 2 includes through-openings, not visible here, through which the screws 7 are guided with their shafts. The through-opening ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com