A kind of plywood unilateral surface reinforced profile and its preparation method and application

A plywood, side surface technology, applied in the direction of plywood press, wood heating, veneer press, etc., can solve the problems of poor stability, complex preparation process, large volume loss of modified plywood, etc., to achieve density and hardness improvement, method Simple, overcoming the effect of long processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

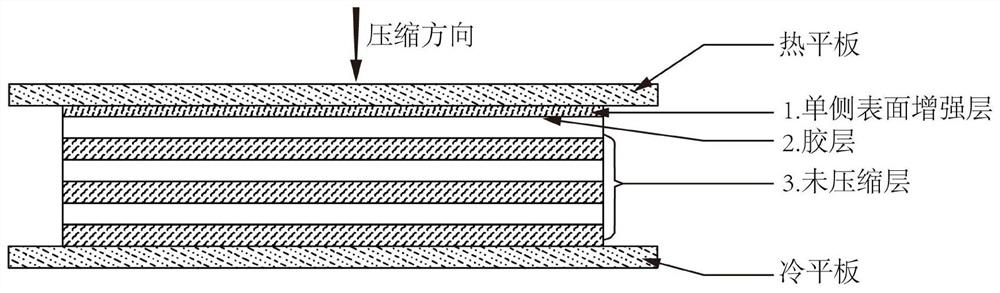

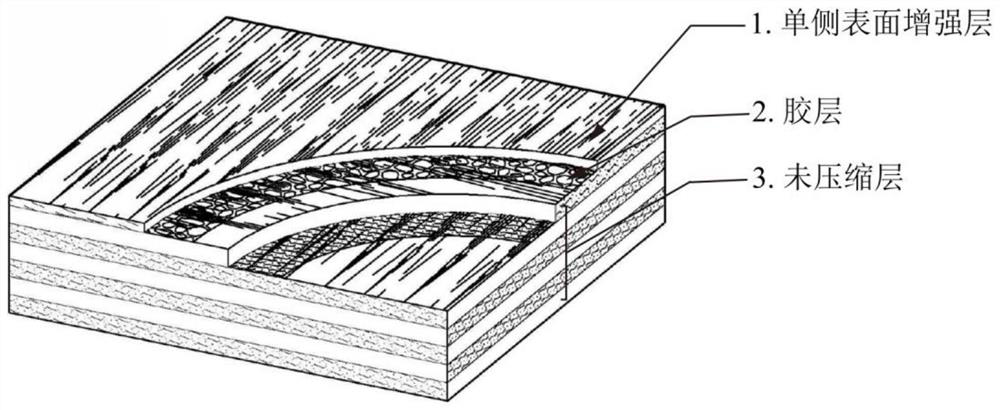

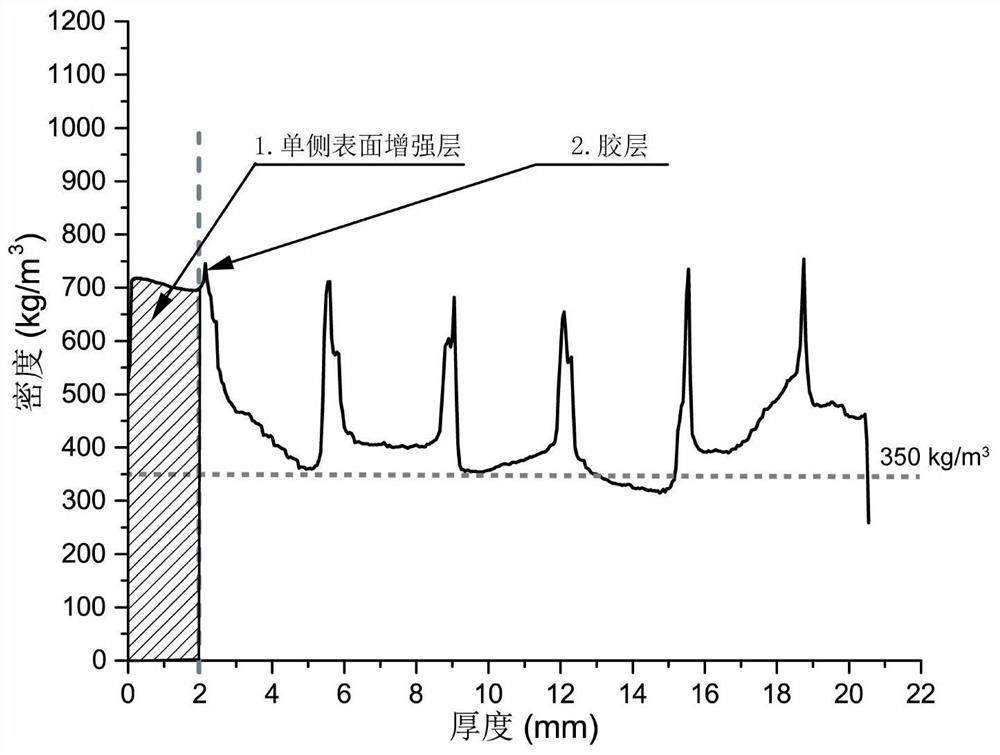

[0037] In this example, radiata pine plywood is subjected to one-side surface enhancement treatment, and the finished plywood used is composed of radiata pine veneer, and the average moisture content of each layer of veneer is 10%; the thickness of the surface layer veneer on the side that needs to be compressed and strengthened is 3mm, and the average density is 350kg / m 3 , the hardness is 1250N; the average density of the uncompressed layer is 350kg / m 3 , the hardness is 1300N. figure 1 It is a schematic diagram of the preparation method of the single-side surface reinforced profile of the plywood of the present invention, from figure 1 It can be seen that the uncompressed layer is composed of multiple layers of veneers in plywood, and each layer of veneer is connected by an adhesive layer. The specific steps are as follows:

[0038] (1) Plasticizing stage of one-side surface layer: the water vapor spray method is used to spray water on the surface layer of the plywood on ...

Embodiment 2

[0045] In this example, the poplar plywood is reinforced on one side of the surface, and the finished plywood used is composed of poplar veneer, and the average moisture content of each layer of veneer is 10%; the thickness of the surface layer veneer on the side that needs to be compressed and strengthened 4mm, the average density is 400kg / m 3 , the hardness is 1750N, and the average density of the uncompressed layer is 400kg / m 3 , the hardness is 1800N.

[0046] (1) Plasticizing stage of one-side surface layer: the water vapor spray method is used to spray water on the surface layer of the plywood on the side that needs to be compressed and reinforced. At 55°C, the plywood was sealed and wrapped with polyethylene film for 36 hours, and the moisture content of the surface layer on one side of the plywood was adjusted to 15% to obtain a plywood with a plasticized one-side surface layer;

[0047] (2) Softening stage of one-side surface layer: The plasticized surface layer of ...

Embodiment 3

[0053] In this example, one-side surface enhancement treatment is performed on the Milao row-radiata pine plywood. The finished plywood used is composed of the Milao row and the radiata pine veneer. The average moisture content of each layer is 10%. ; The thickness of the surface layer veneer on the side to be compressed and strengthened is 3mm, and the average density is 480kg / m 3 , the hardness is 2100N; the average density of the uncompressed layer is 480kg / m 3 , the hardness is 1300N.

[0054] (1) Plasticizing stage of one-side surface layer: the water vapor spray method is used to spray water on the surface layer of the plywood on the side that needs to be compressed and reinforced. At 70°C, the plywood was sealed and wrapped with polyethylene film for 48 hours, and the moisture content of the single-side surface layer of the plywood was adjusted to 17% to obtain a single-side surface layer plasticized plywood;

[0055] (2) Softening stage of one-side surface layer: The p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com