A ta with low dielectric loss 2 o 5 Doped niobate-based glass-ceramic material and its preparation method and application

A glass ceramic and niobate technology, applied in glass manufacturing equipment, glass molding, hybrid/electric double layer capacitor manufacturing, etc., can solve the problem of high dielectric loss of energy storage materials, unfavorable capacitor capacitance, and low energy storage density and other problems, to achieve the effect of improving the dielectric constant, uniform and dense microscopic morphology, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The above-mentioned Ta with low dielectric loss 2 o 5 A method for preparing a doped niobate-based glass-ceramic material, comprising the following steps:

[0034] 1) with SrCO 3 、Na 2 CO 3 , Nb 2 o 5 , SiO 2 、 Ta 2 o 5 As raw material, according to 6.4Na 2 CO 3 -25.6SrCO 3 -32[(1-x)Nb 2 o 5 ,xTa 2 o 5 ]-36SiO 2 The molar ratio in the formula is prepared and mixed evenly, and then melted at a high temperature of 1450-1550 ° C for 1-2 hours to obtain a high-temperature molten slurry;

[0035] 2) Pour the high-temperature molten slurry prepared in step 1) into a preheated mold at 600-650°C for molding, and after removing residual stress at a constant temperature for 5-6 hours, slice it to obtain glass flakes;

[0036] 3) Heating the glass flakes prepared in step 2) to 750-850°C at a heating rate of 1-5°C / min, and performing controlled crystallization for 3-5 hours to obtain Ta 2 o 5 Doped niobate-based glass-ceramic materials.

[0037] The following ar...

Embodiment 1

[0039] A low dielectric loss Ta 2 o 5 Doped niobate-based glass-ceramic material, the preparation method of which comprises the following steps:

[0040] 1) SrCO with a purity greater than 99wt% 3 、Na 2 CO 3 , Nb 2 o 5 , SiO 2 、 Ta 2 o 5 As raw material, according to chemical formula 6.4Na 2 CO 3 -25.6SrCO 3 -32[(1-x)Nb 2 o 5 ,xTa 2 o 5 ]-36SiO 2 (x represents the molar ratio, x=0, 1%, 2%, 5%, 10%) is weighed in molar ratio, after ball milling and mixing for 24h (with absolute ethanol as the ball milling medium, the ball-to-material ratio is 1.5: 1) Dry at 100°C for 6 hours, and then melt at 1550°C for 2 hours to obtain a high-temperature melt;

[0041] 2) Pouring the high-temperature melt into a square metal mold, and annealing under stress at 650°C for 6 hours, and then cutting to obtain glass flakes with a thickness of 1.0-1.5mm;

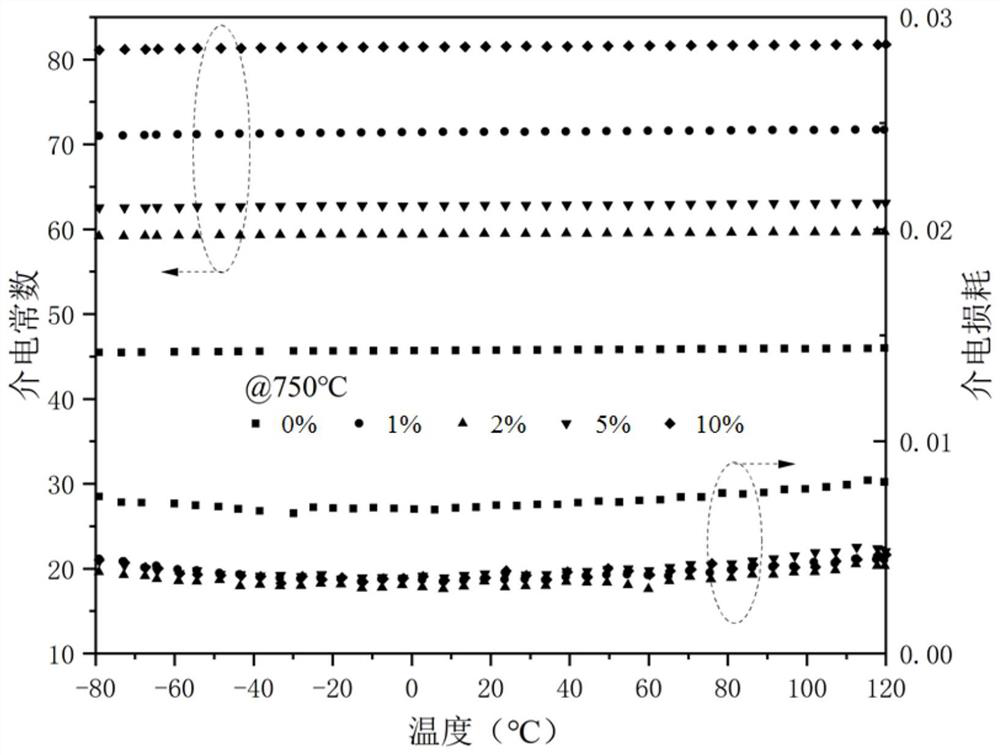

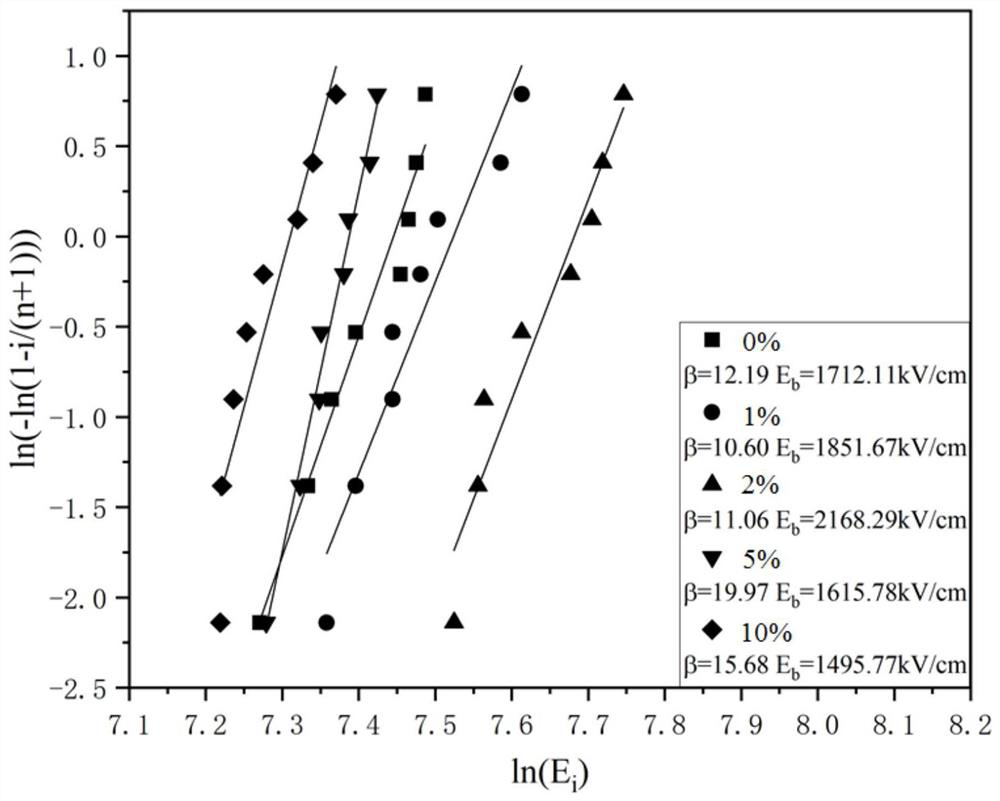

[0042] 3) Put an equal number of glass flakes into a crucible, heat to 750°C at a heating rate of 3°C / min and keep it warm for 5...

Embodiment 2

[0045] A low dielectric loss Ta 2 o 5 Doped niobate-based glass-ceramic material, the preparation method of which comprises the following steps:

[0046] 1) SrCO with a purity greater than 99wt% 3 、Na 2 CO 3 , Nb 2 o 5 , SiO 2 、 Ta 2 o 5 As raw material, according to chemical formula 6.4Na 2 CO 3 -25.6SrCO 3 -32[(1-x)Nb 2 o 5 ,xTa 2 o 5 ]-36SiO 2 (x represents the molar ratio, x=0, 1%, 2%, 5%, 10%) is weighed in molar ratio, after ball milling and mixing for 24h (with absolute ethanol as the ball milling medium, the ball-to-material ratio is 1.5: 1) Dry at 100°C for 6 hours, and then melt at 1550°C for 2 hours to obtain a high-temperature melt;

[0047] 2) Pouring the high-temperature melt into a square metal mold, and annealing under stress at 650°C for 6 hours, and then cutting to obtain glass flakes with a thickness of 1.0-1.5mm;

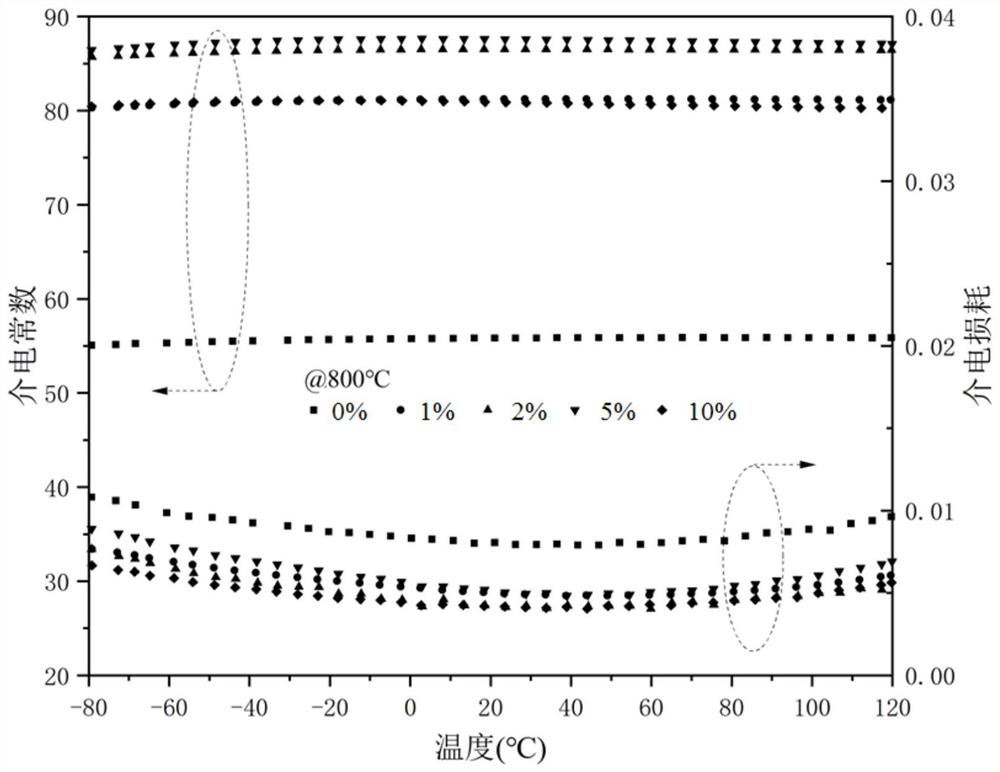

[0048] 3) Put an equal number of glass flakes into a crucible, heat to 800°C at a heating rate of 3°C / min and keep it warm for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breakdown field strength | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

| breakdown field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com