Patents

Literature

46results about How to "High breakdown field" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

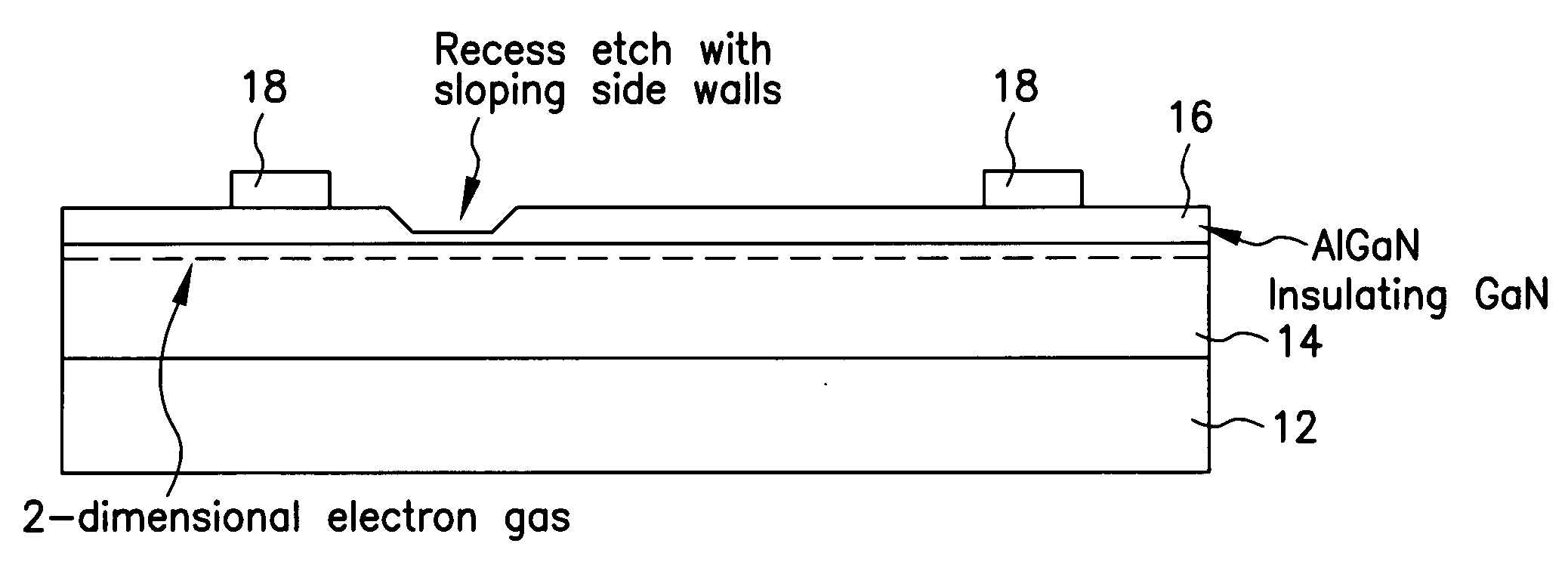

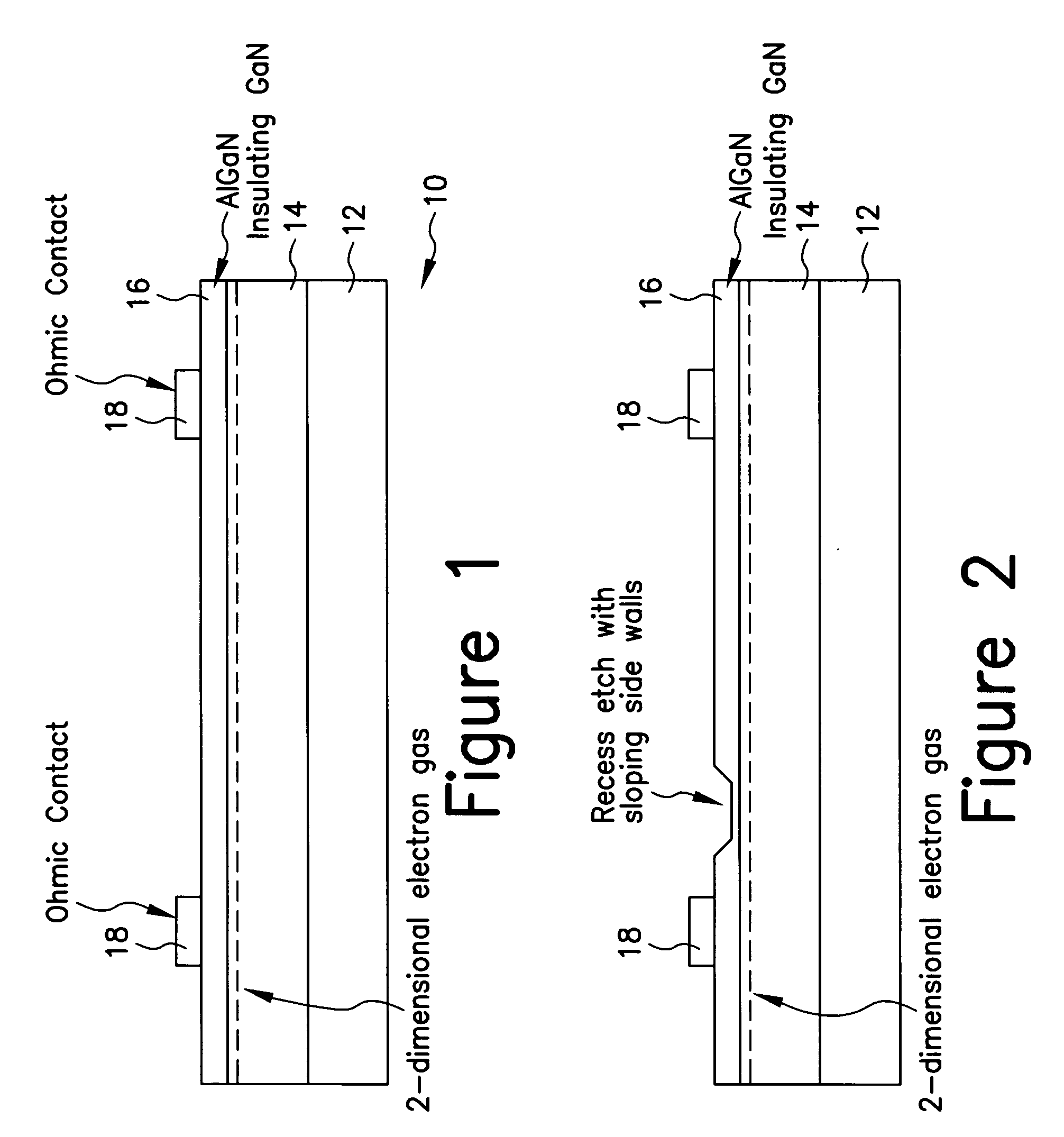

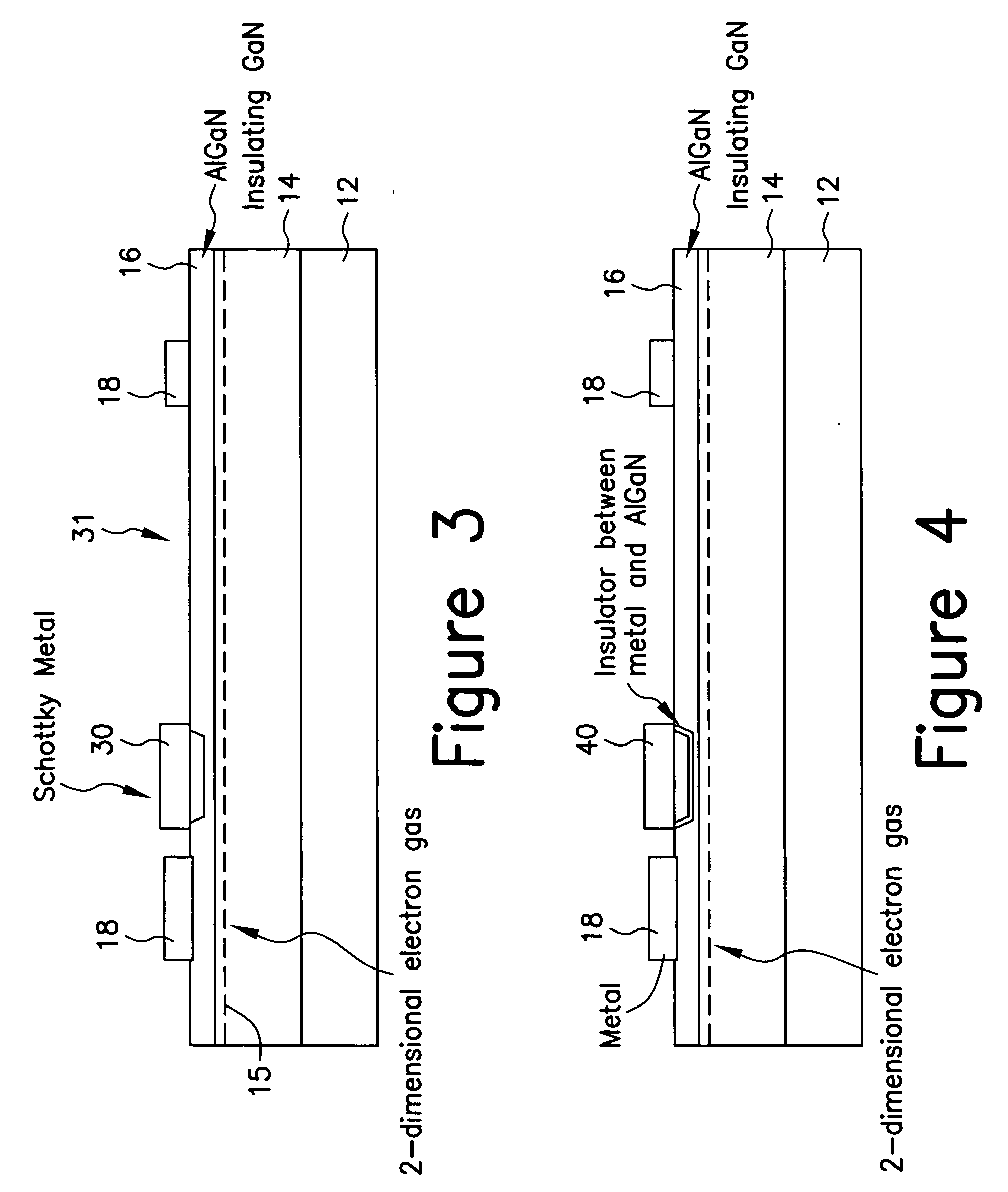

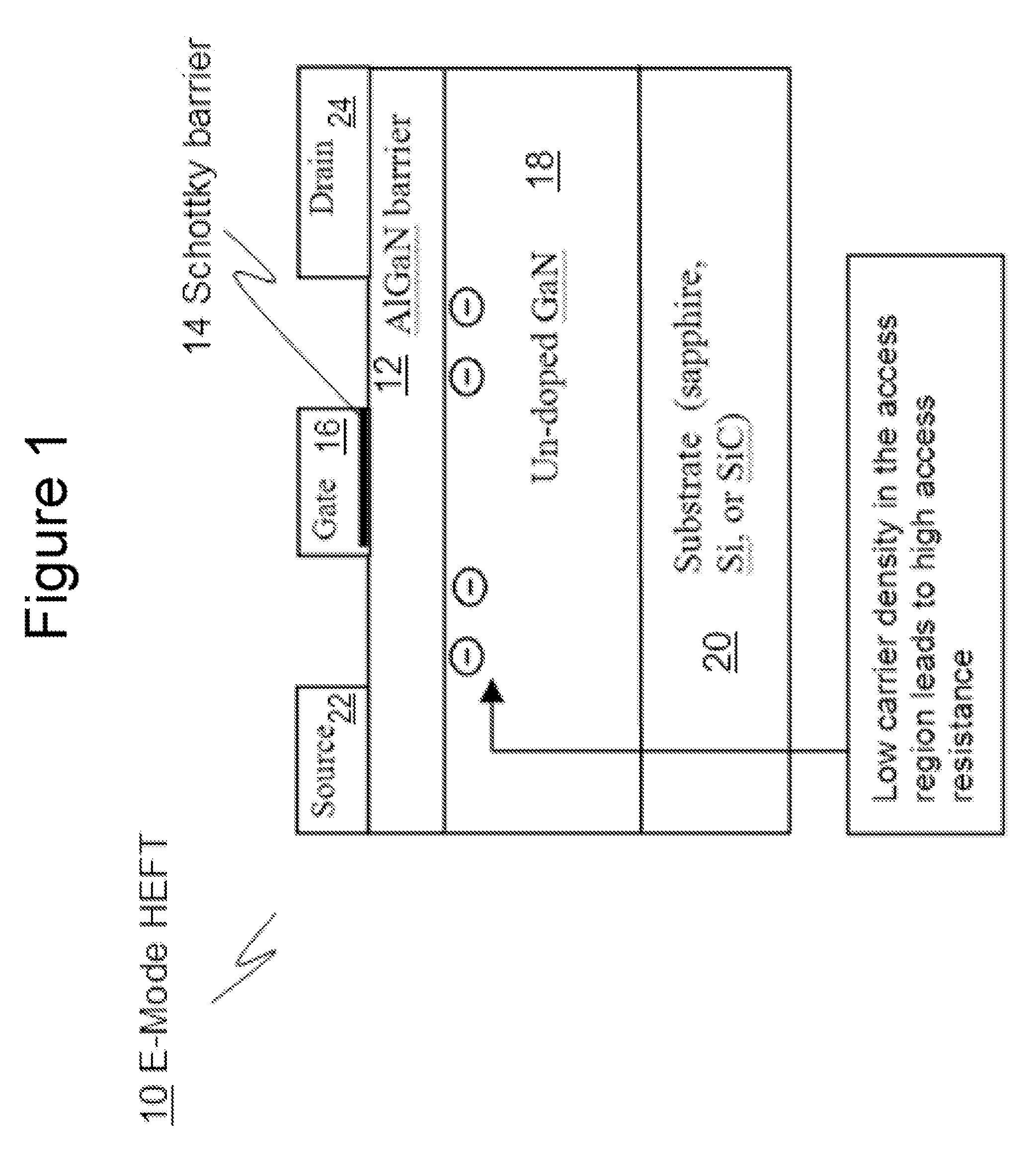

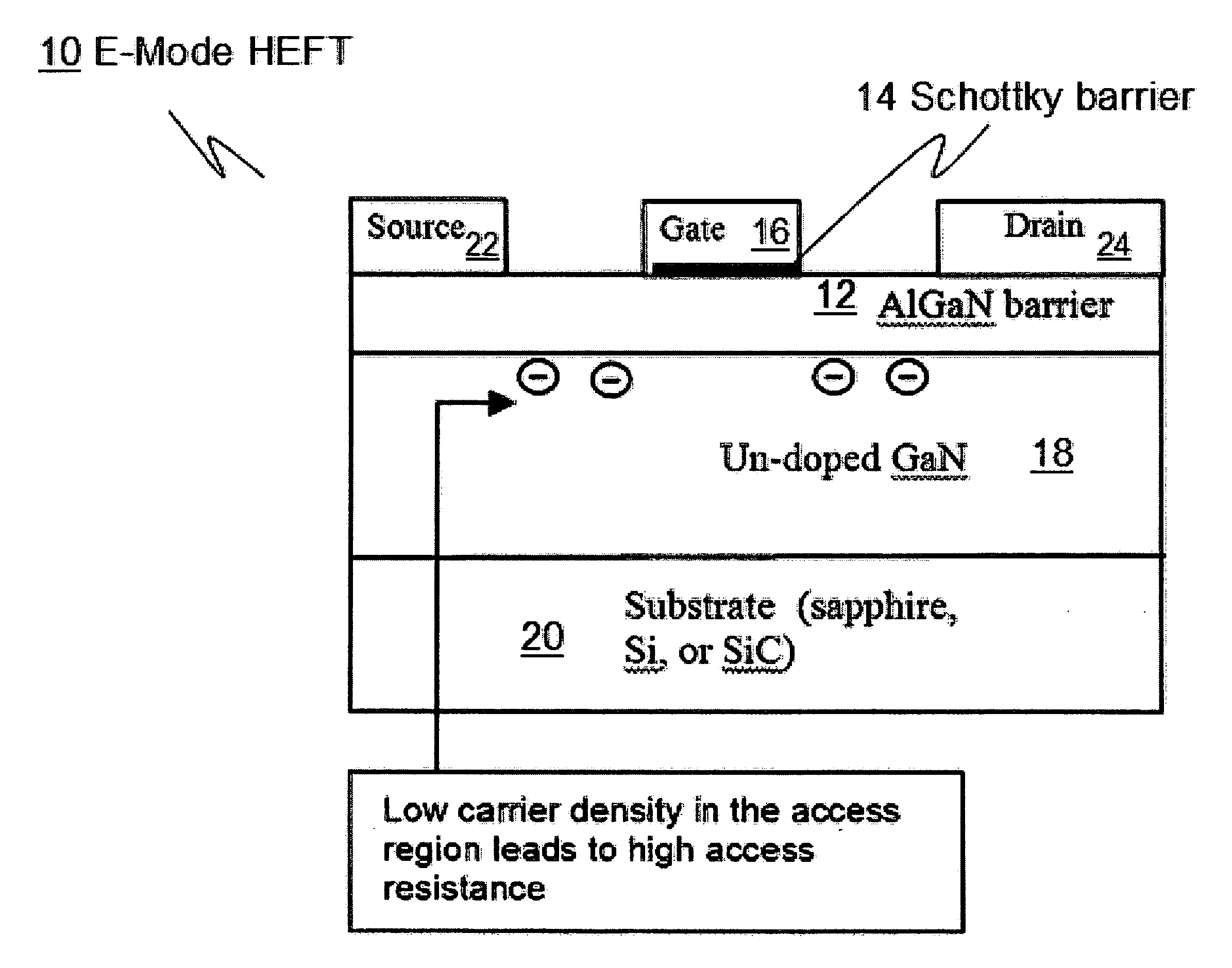

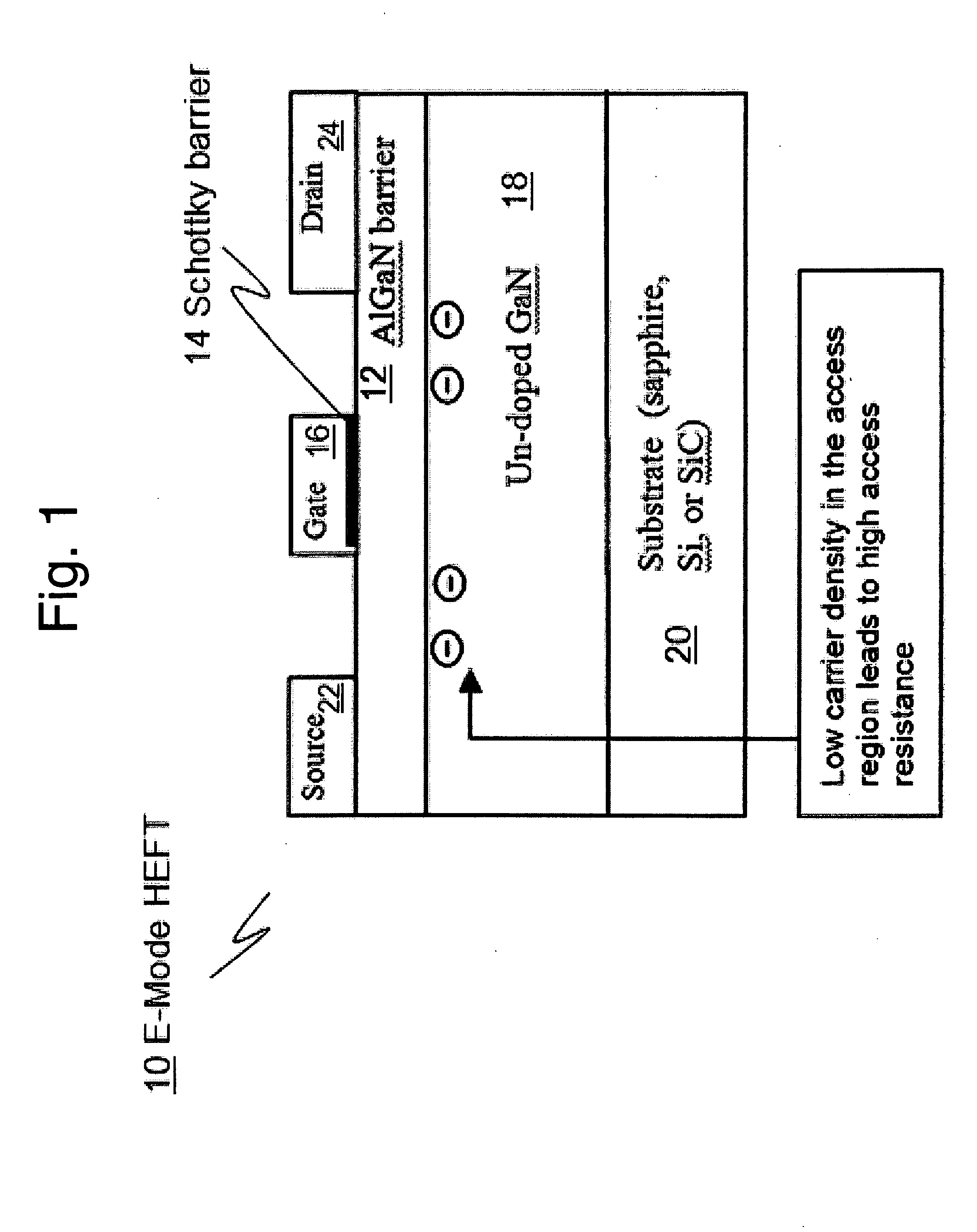

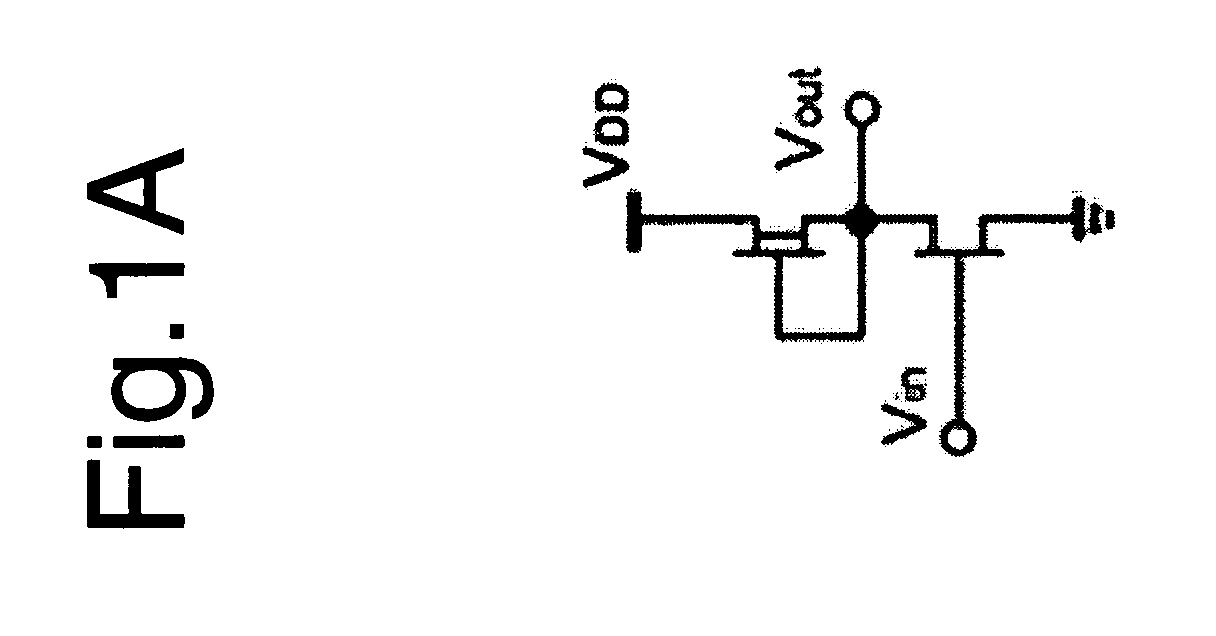

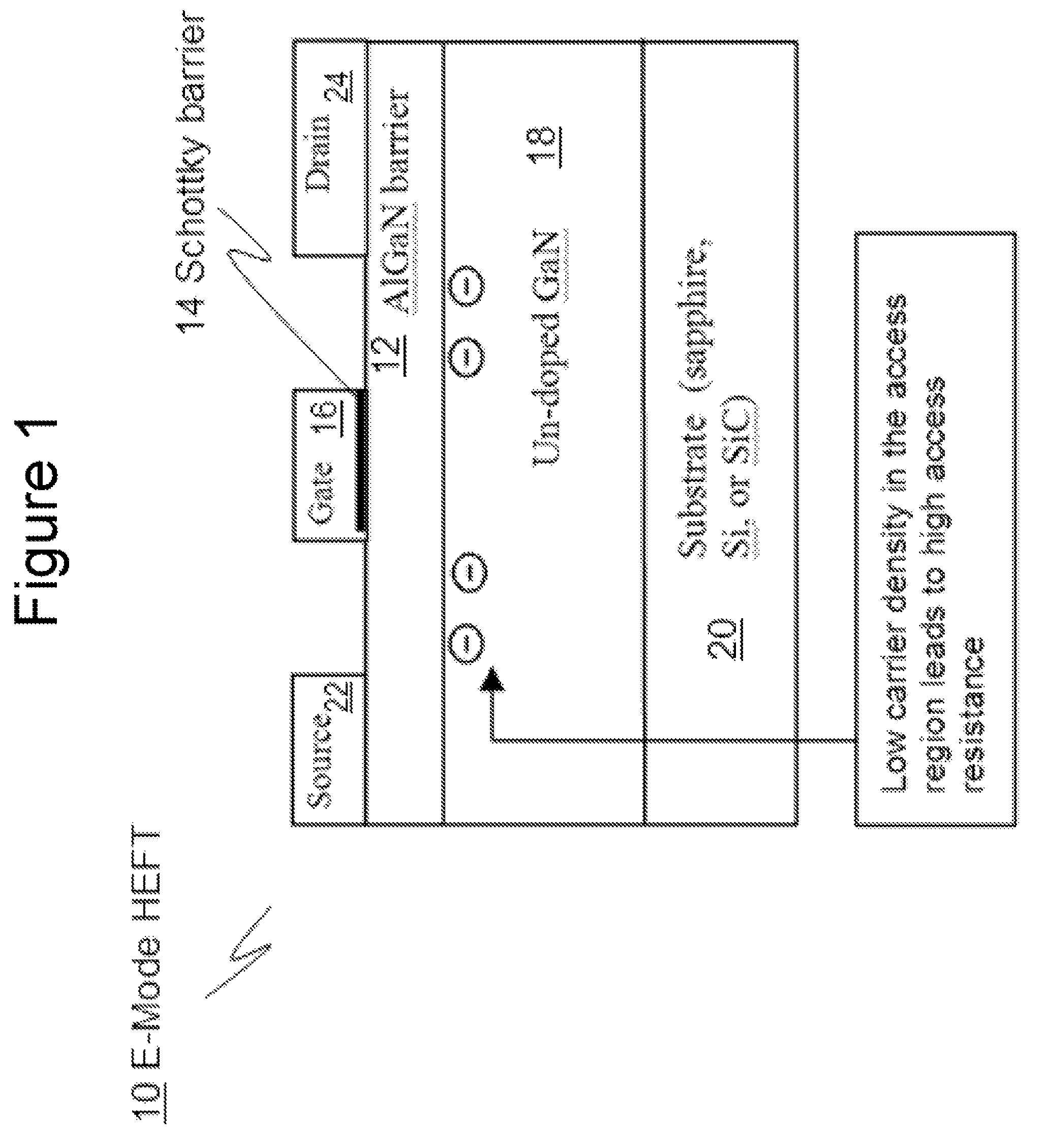

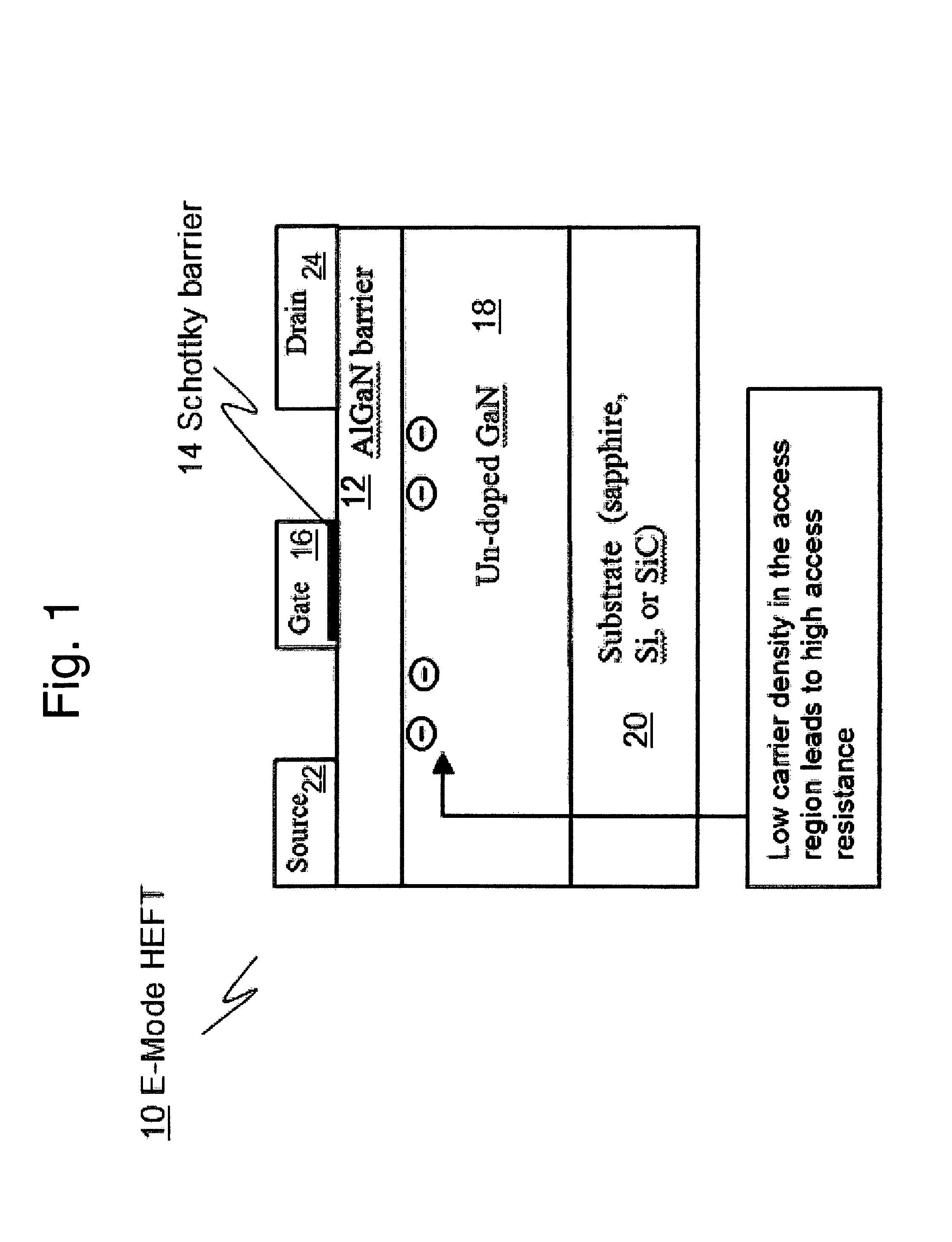

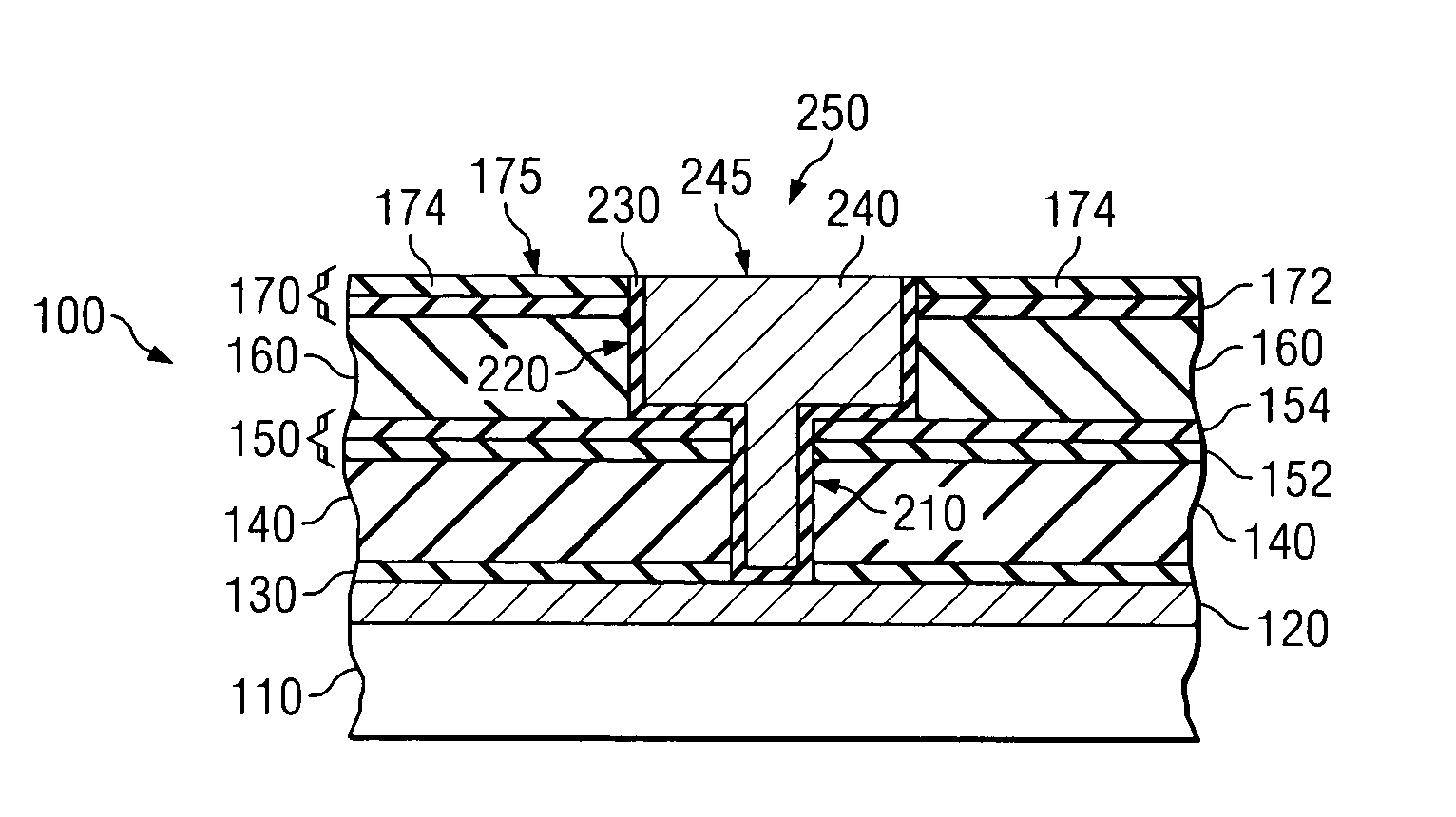

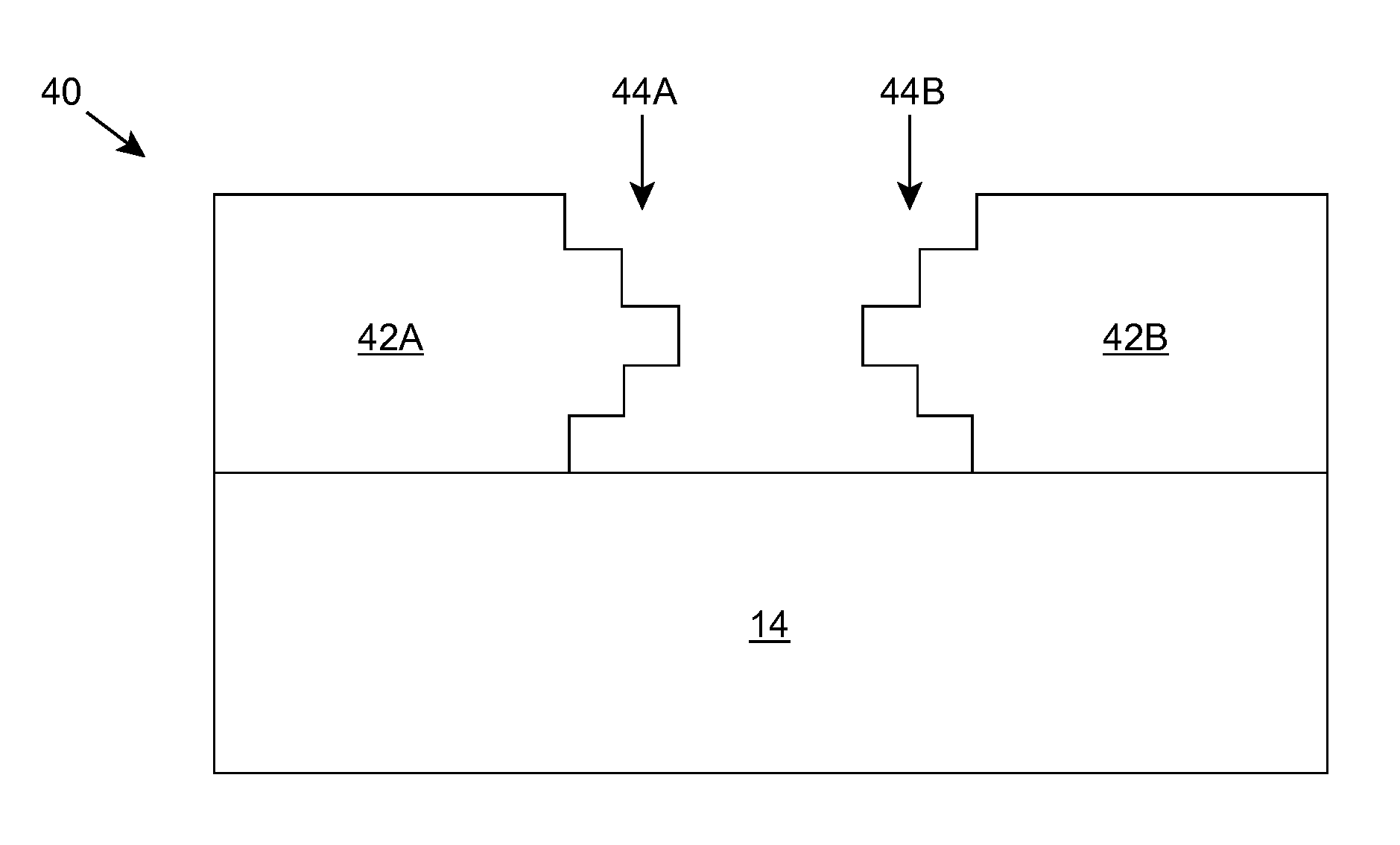

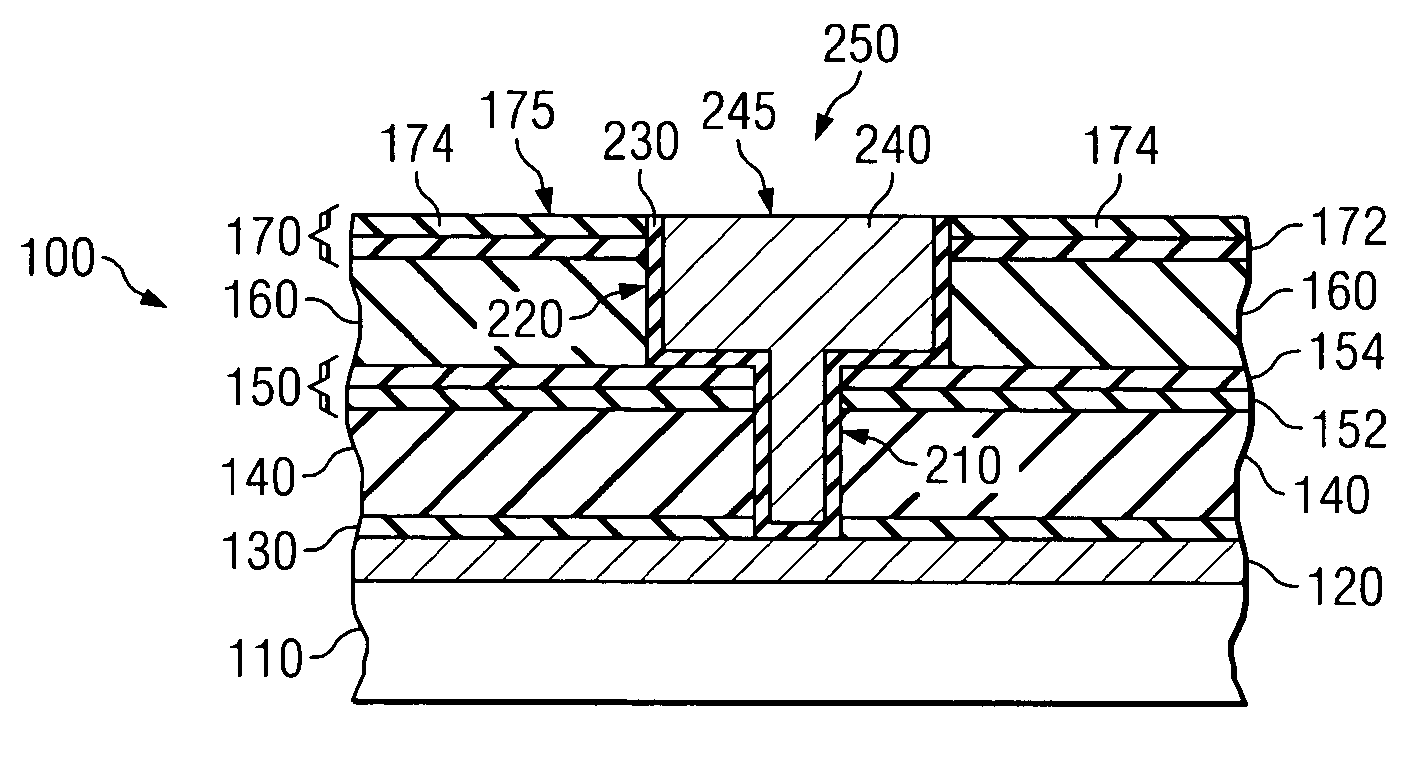

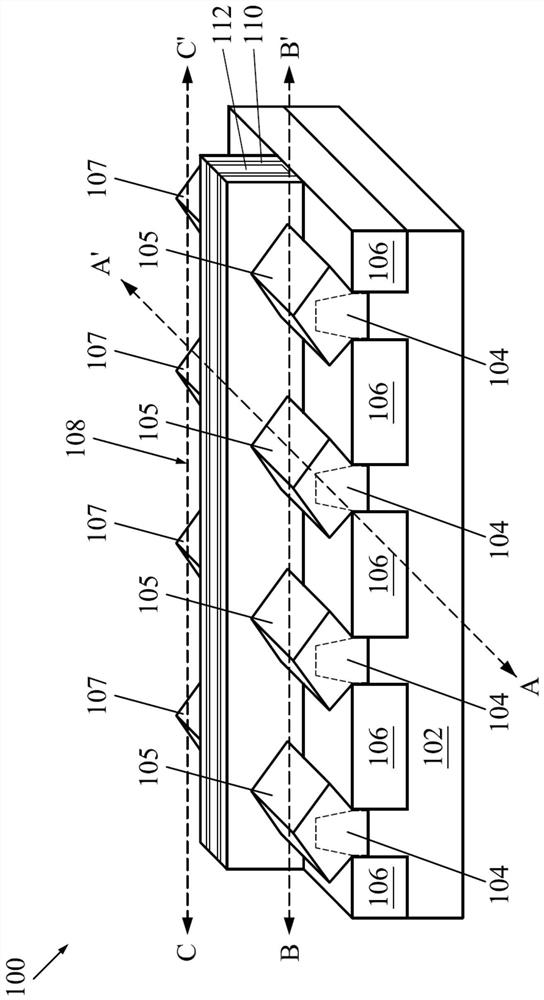

Enhancement mode III-nitride FET

ActiveUS20060060871A1Lower resistanceReduce leakageSemiconductor/solid-state device manufacturingSemiconductor devicesNitrideConduction channel

A III-nitride switch includes a recessed gate contact to produce a nominally off, or an enhancement mode, device. By providing a recessed gate contact, a conduction channel formed at the interface of two III-nitride materials is interrupted when the gate electrode is inactive to prevent current flow in the device. The gate electrode can be a schottky contact or an insulated metal contact. Two gate electrodes can be provided to form a bi-directional switch with nominally off characteristics. The recesses formed with the gate electrode can have sloped sides. The gate electrodes can be formed in a number of geometries in conjunction with current carrying electrodes of the device.

Owner:INFINEON TECH AMERICAS CORP

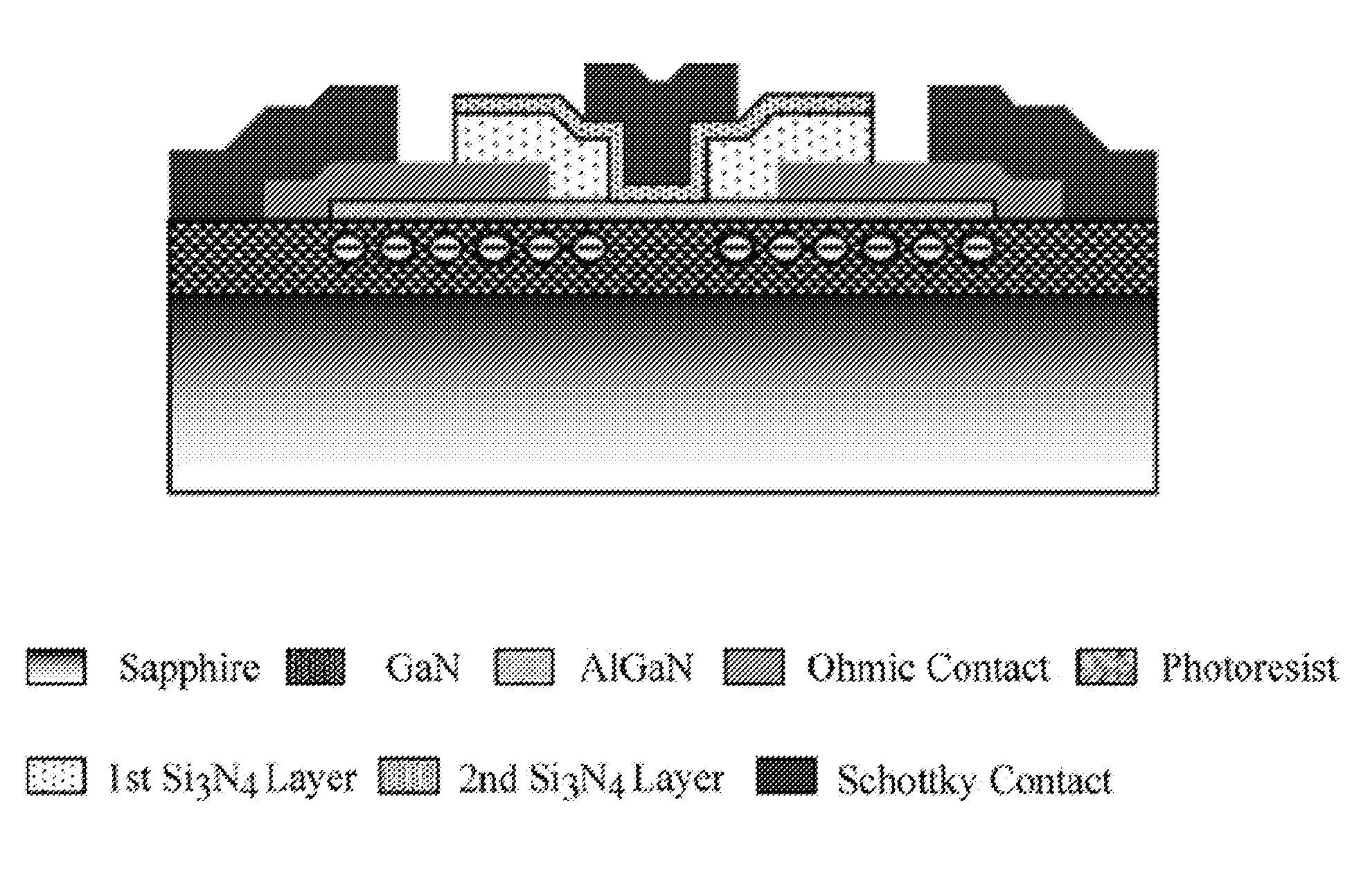

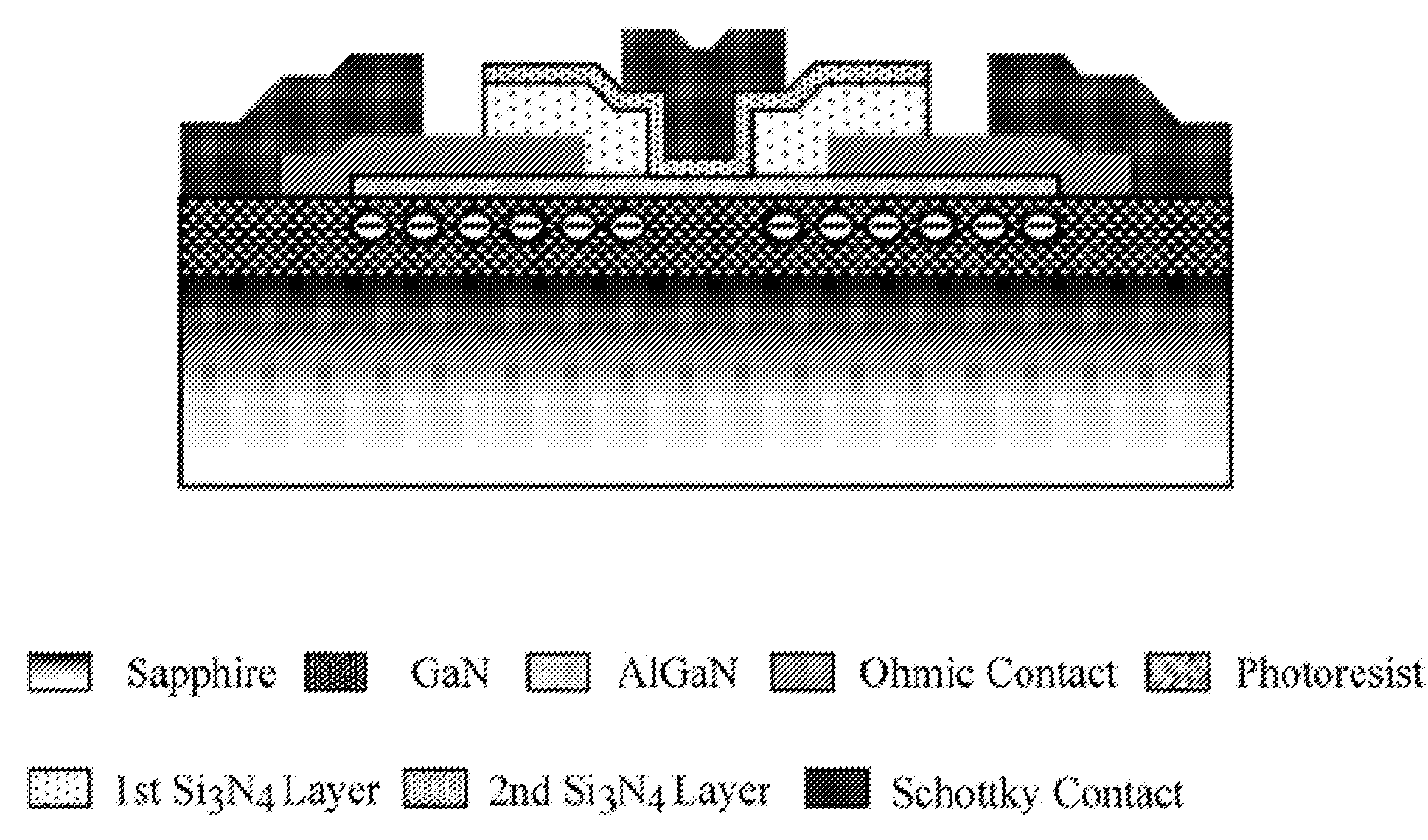

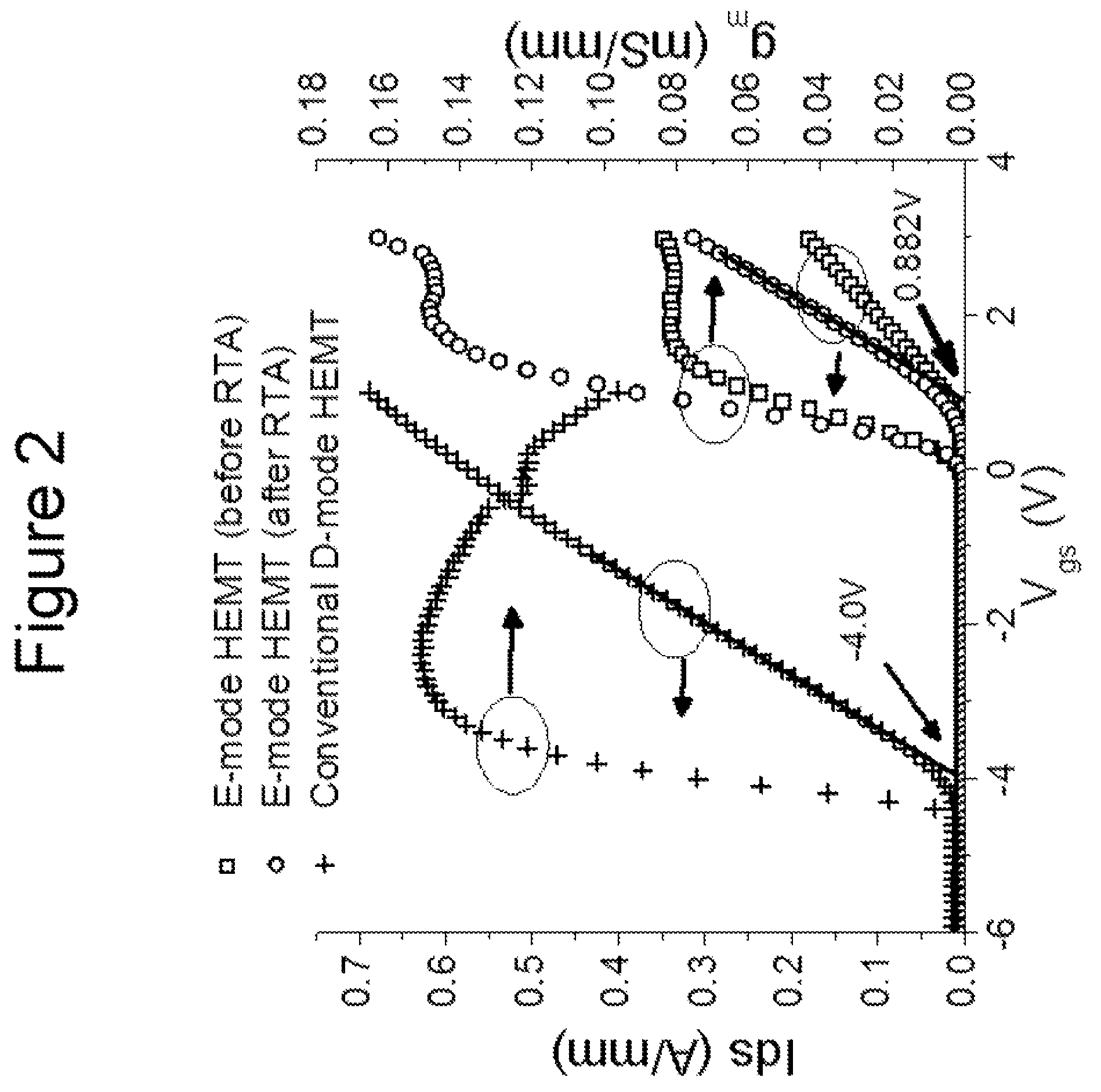

Enhancement-Mode III-N Devices, Circuits, and Methods

ActiveUS20070278518A1High breakdown fieldHigh Power Handling CapabilitySemiconductor devicesPhotoresistIon implantation

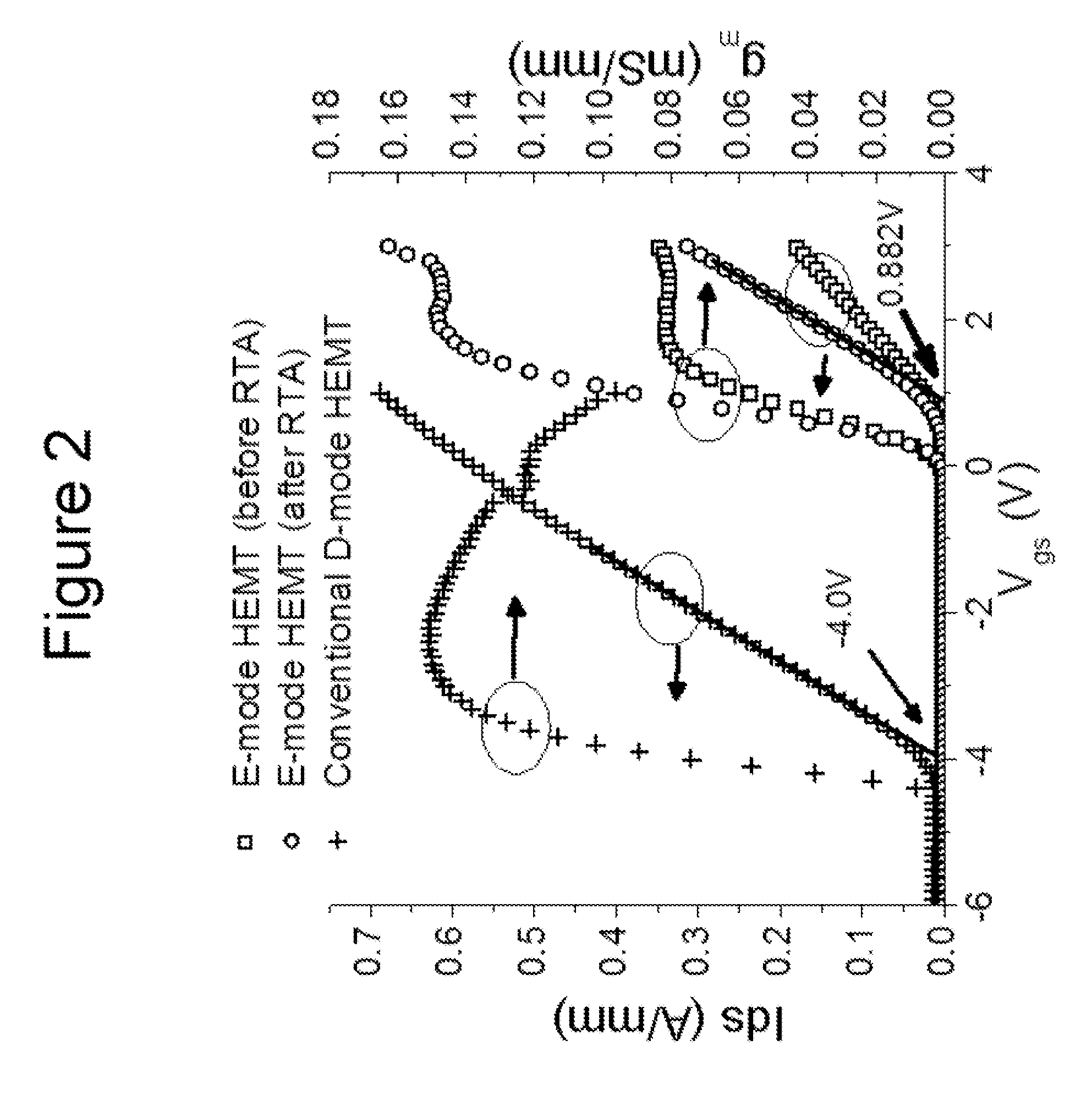

A method of fabricating AlGaN / GaN enhancement-mode heterostructure field-effect transistors (HFET) using fluorine-based plasma immersion or ion implantation. The method includes: 1) generating gate patterns; 2) exposing the AlGaN / GaN heterostructure in the gate region to fluorine-based plasma treatment with photoresist as the treatment mask in a self-aligned manner; 3) depositing the gate metal to the plasma treated AlGaN / GaN heterostructure surface; 4) lifting off the metal except the gate electrode; and 5) high temperature post-gate annealing of the sample. This method can be used to shift the threshold voltage of a HFET toward a more positive value, and ultimately convert a depletion-mode HFET to an enhancement-mode HFET (E-HFET).

Owner:THE HONG KONG UNIV OF SCI & TECH

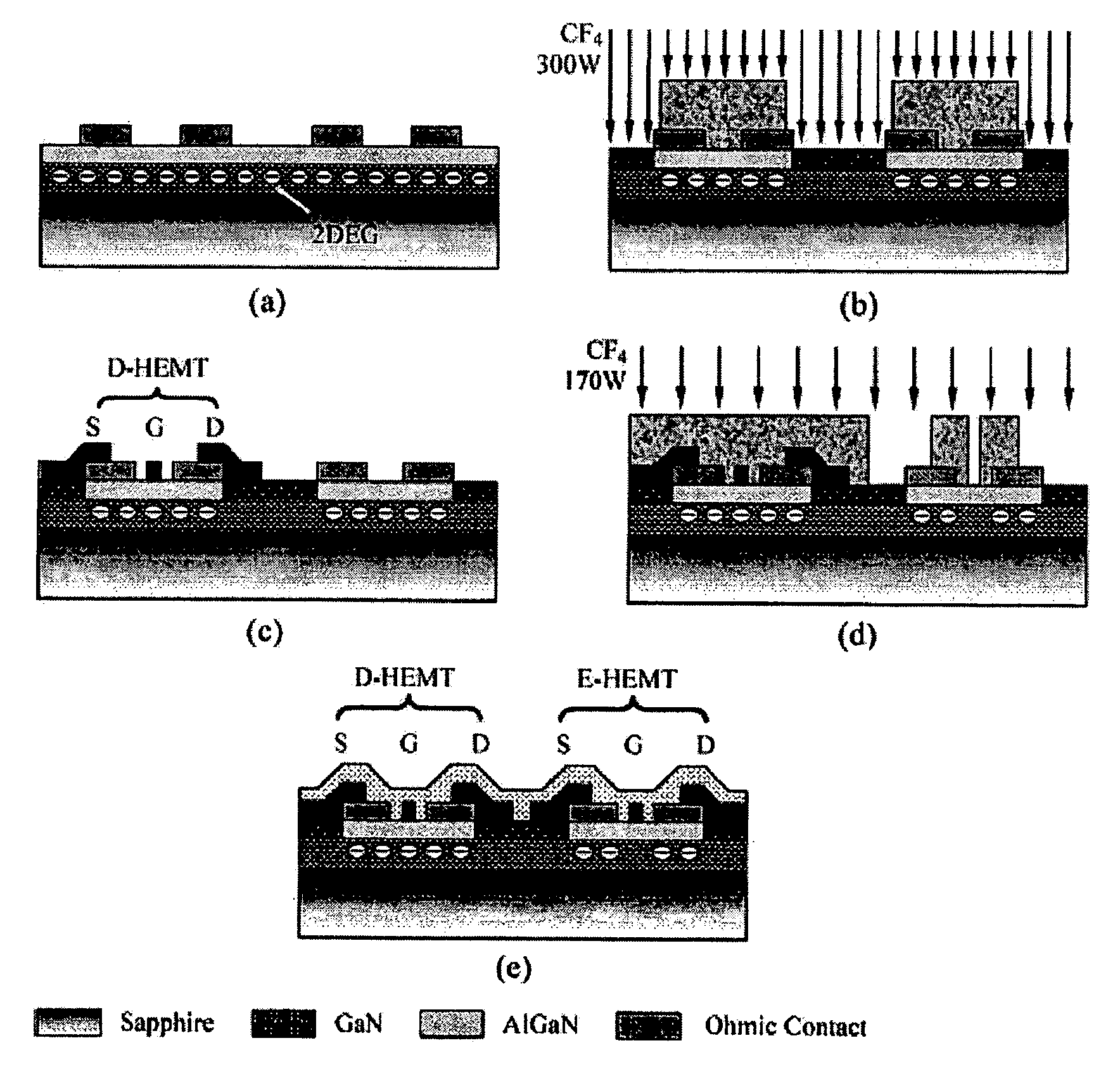

Monolithic Integration of Enhancement- and Depletion-mode AlGaN/GaN HFETs

ActiveUS20070228416A1Wide bandgapHigh breakdown fieldTransistorSolid-state devicesHeterojunctionEtching

A method for and devices utilizing monolithic integration of enhancement-mode and depletion-mode AlGaN / GaN heterojunction field-effect transistors (HFETs) is disclosed. Source and drain ohmic contacts of HFETs are first defined. Gate electrodes of the depletion-mode HFETs are then defined. Gate electrodes of the enhancement-mode HFETs are then defined using fluoride-based plasma treatment and high temperature post-gate annealing of the sample. Device isolation is achieved by either mesa etching or fluoride-based plasma treatment. This method provides a complete planar process for GaN-based integrated circuits favored in high-density and high-speed applications.

Owner:THE HONG KONG UNIV OF SCI & TECH

Enhancement-mode III-N devices, circuits, and methods

ActiveUS7932539B2High breakdown fieldHigh Power Handling CapabilitySemiconductor devicesResistPhotoresist

A method of fabricating AlGaN / GaN enhancement-mode heterostructure field-effect transistors (HFET) using fluorine-based plasma immersion or ion implantation. The method includes: 1) generating gate patterns; 2) exposing the AlGaN / GaN heterostructure in the gate region to fluorine-based plasma treatment with photoresist as the treatment mask in a self-aligned manner; 3) depositing the gate metal to the plasma treated AlGaN / GaN heterostructure surface; 4) lifting off the metal except the gate electrode; and 5) high temperature post-gate annealing of the sample. This method can be used to shift the threshold voltage of a HFET toward a more positive value, and ultimately convert a depletion-mode HFET to an enhancement-mode HFET (E-HFET).

Owner:THE HONG KONG UNIV OF SCI & TECH

Monolithic integration of enhancement- and depletion-mode AlGaN/GaN HFETs

A method for and devices utilizing monolithic integration of enhancement-mode and depletion-mode AlGaN / GaN heterojunction field-effect transistors (HFETs) is disclosed. Source and drain ohmic contacts of HFETs are first defined. Gate electrodes of the depletion-mode HFETs are then defined. Gate electrodes of the enhancement-mode HFETs are then defined using fluoride-based plasma treatment and high temperature post-gate annealing of the sample. Device isolation is achieved by either mesa etching or fluoride-based plasma treatment. This method provides a complete planar process for GaN-based integrated circuits favored in high-density and high-speed applications.

Owner:THE HONG KONG UNIV OF SCI & TECH

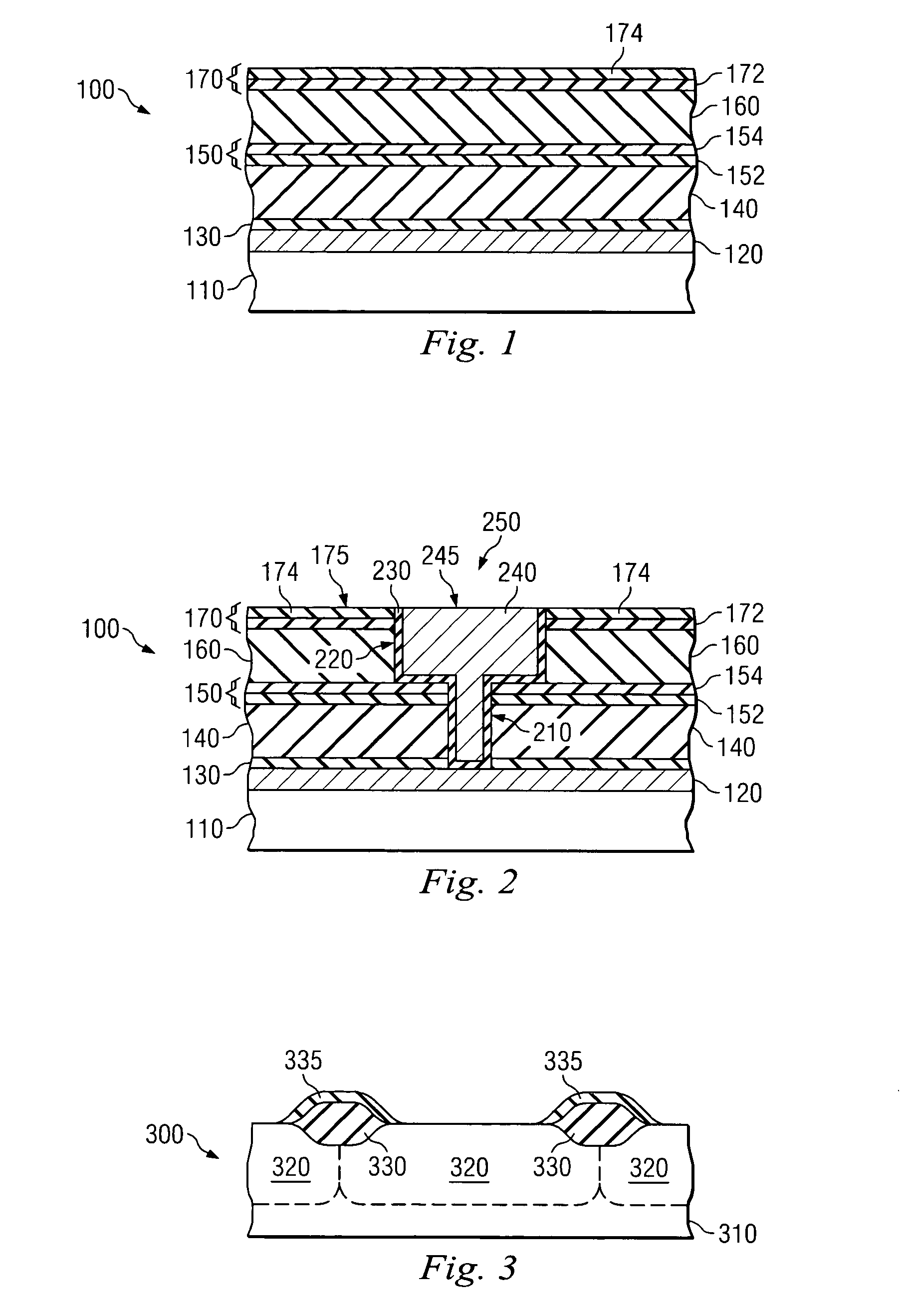

Insulating layer having decreased dielectric constant and increased hardness

InactiveUS20050093108A1High hardnessHigh thermal stabilitySemiconductor/solid-state device detailsSolid-state devicesCarbon nitrideOptoelectronics

A method of manufacturing a mechanically robust insulating layer, including forming a low-k dielectric layer having a first dielectric constant on a substrate and forming a carbon nitride cap layer on the low-k dielectric layer, the insulating layer thereby having a second dielectric constant that is less than the first dielectric constant.

Owner:TAIWAN SEMICON MFG CO LTD

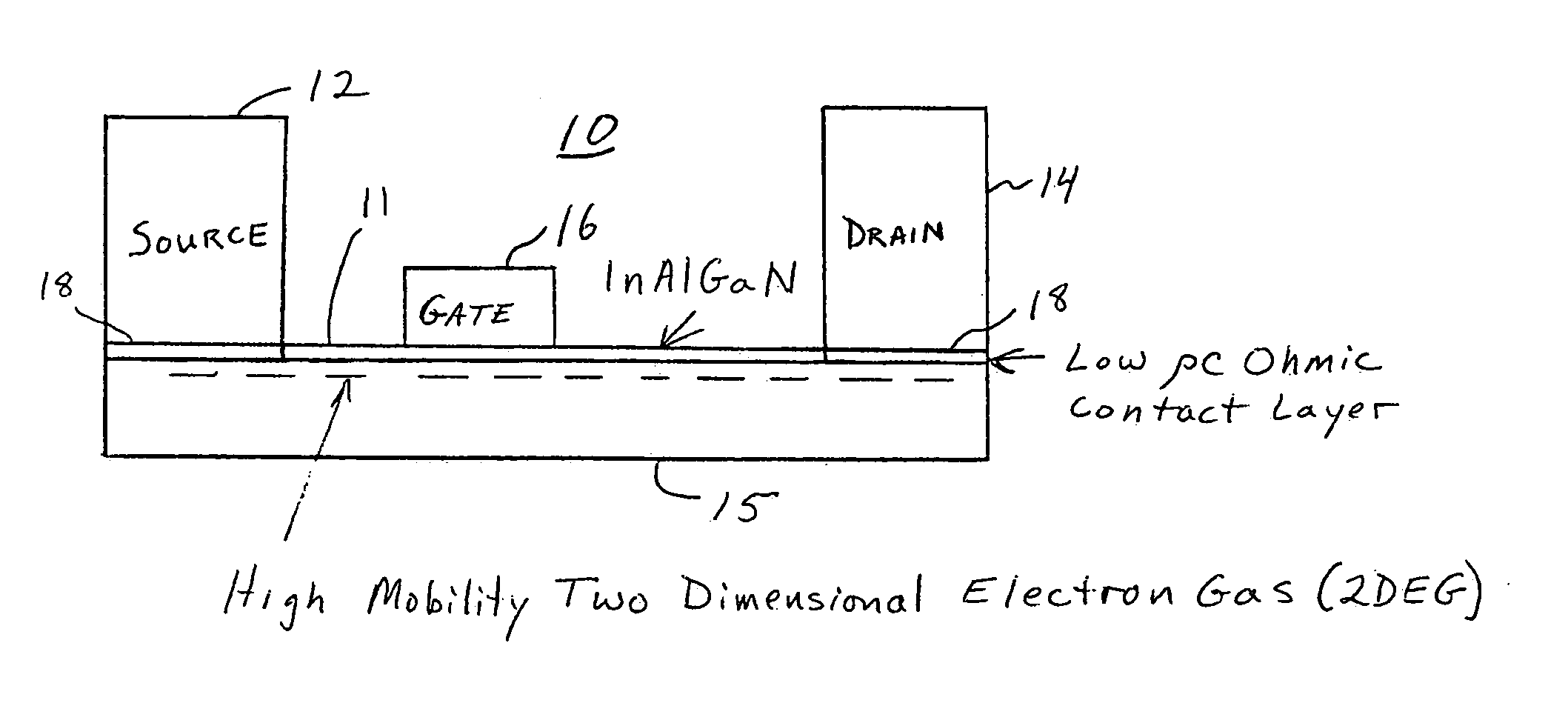

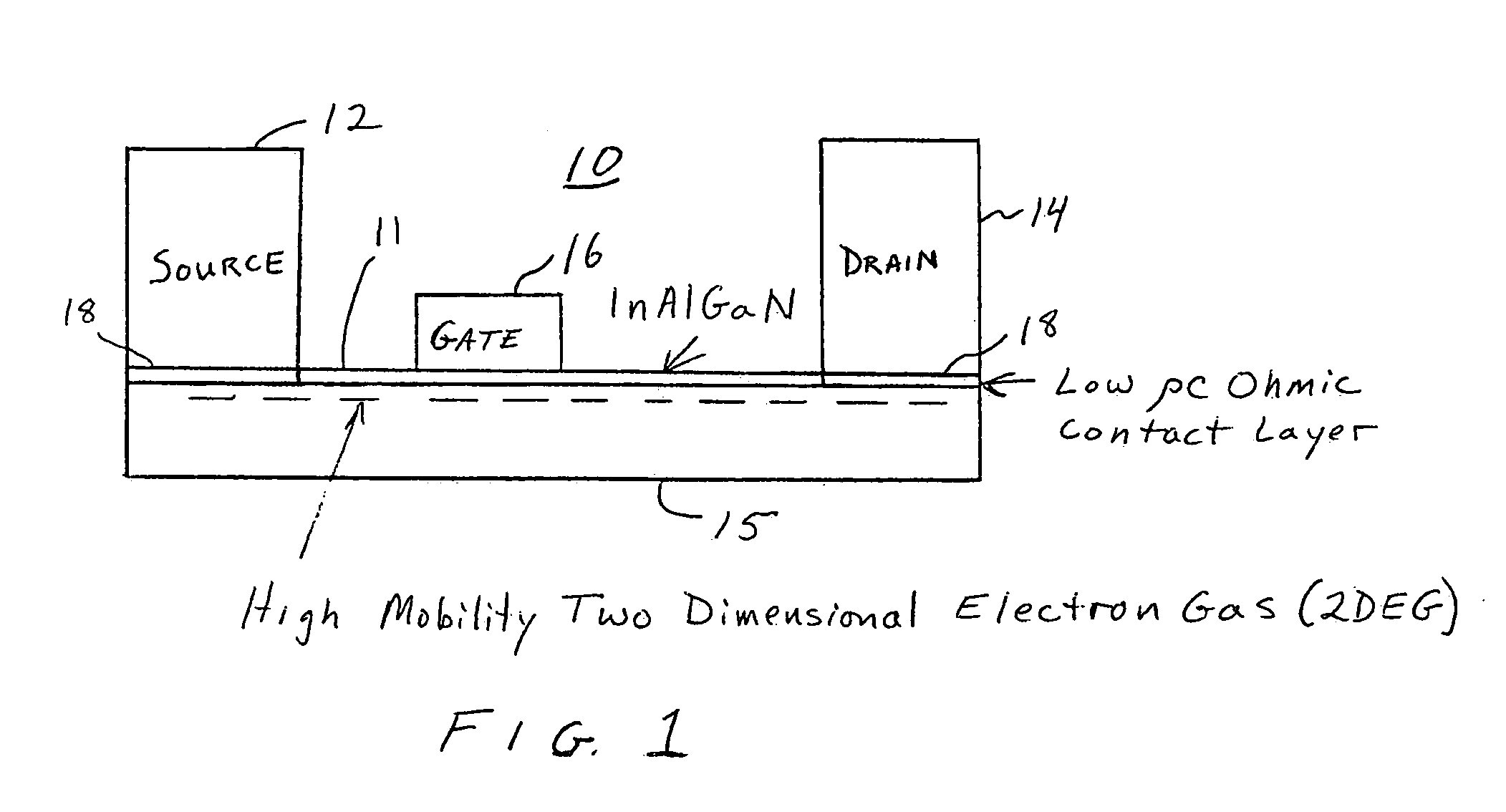

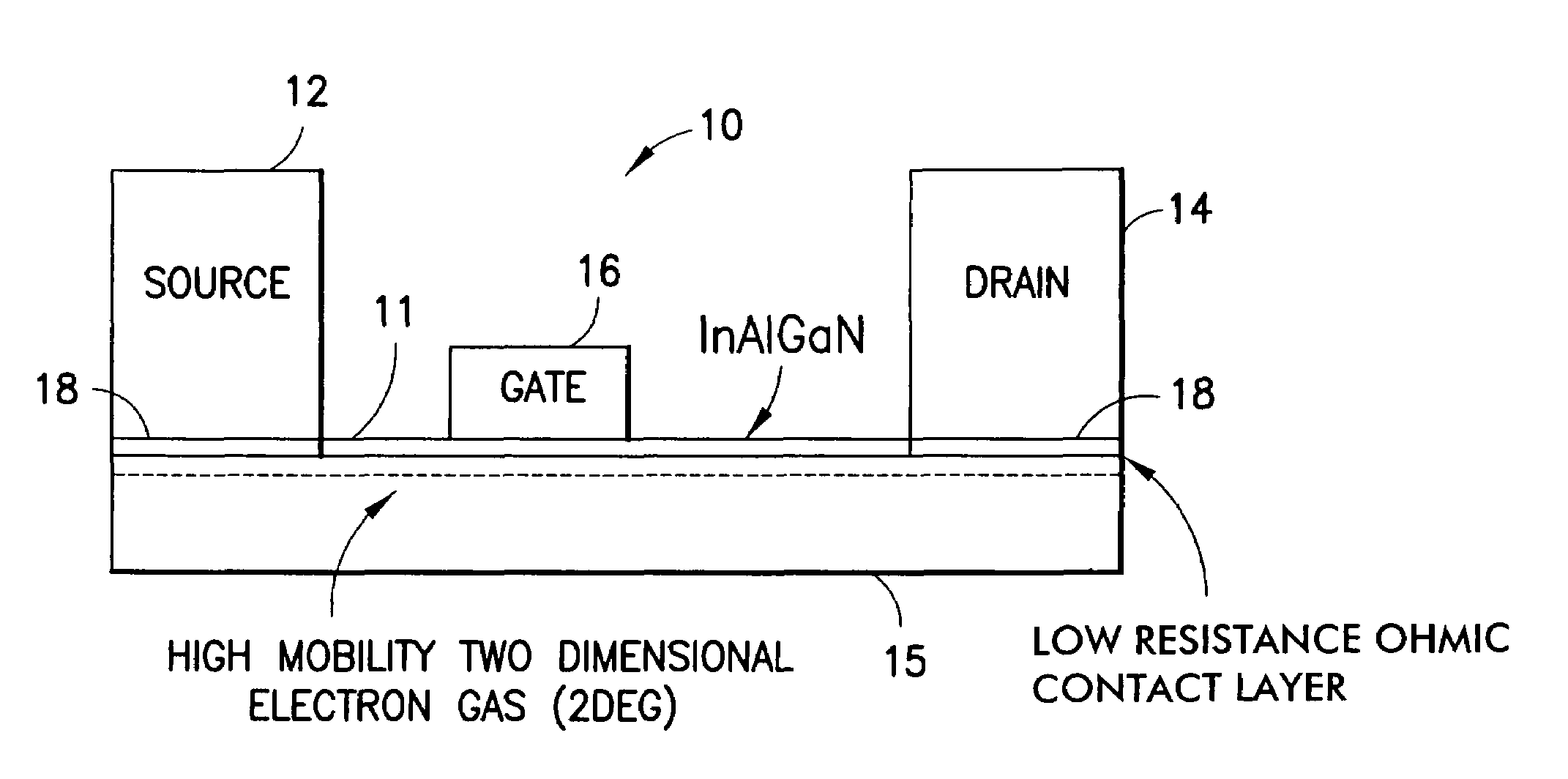

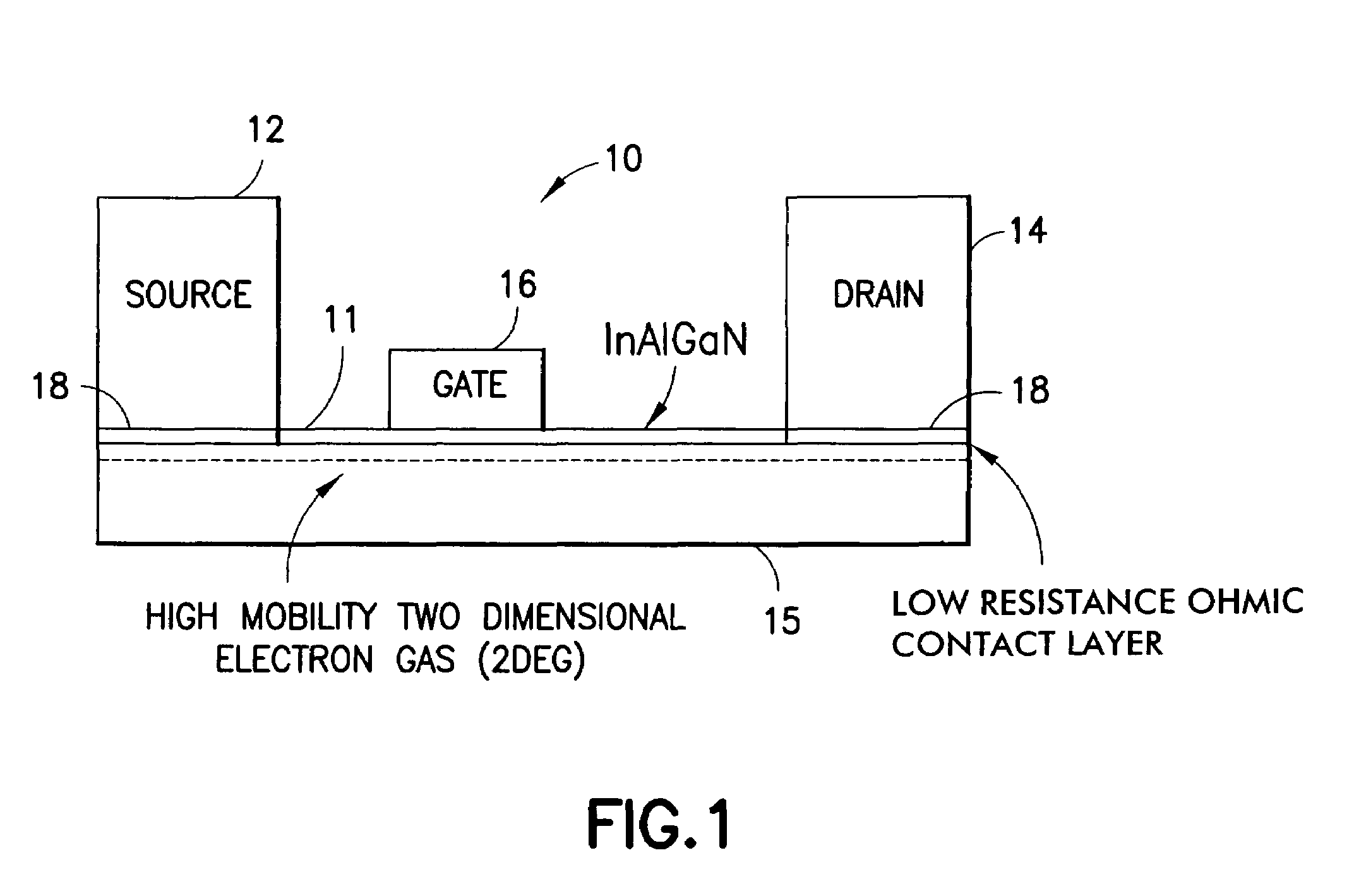

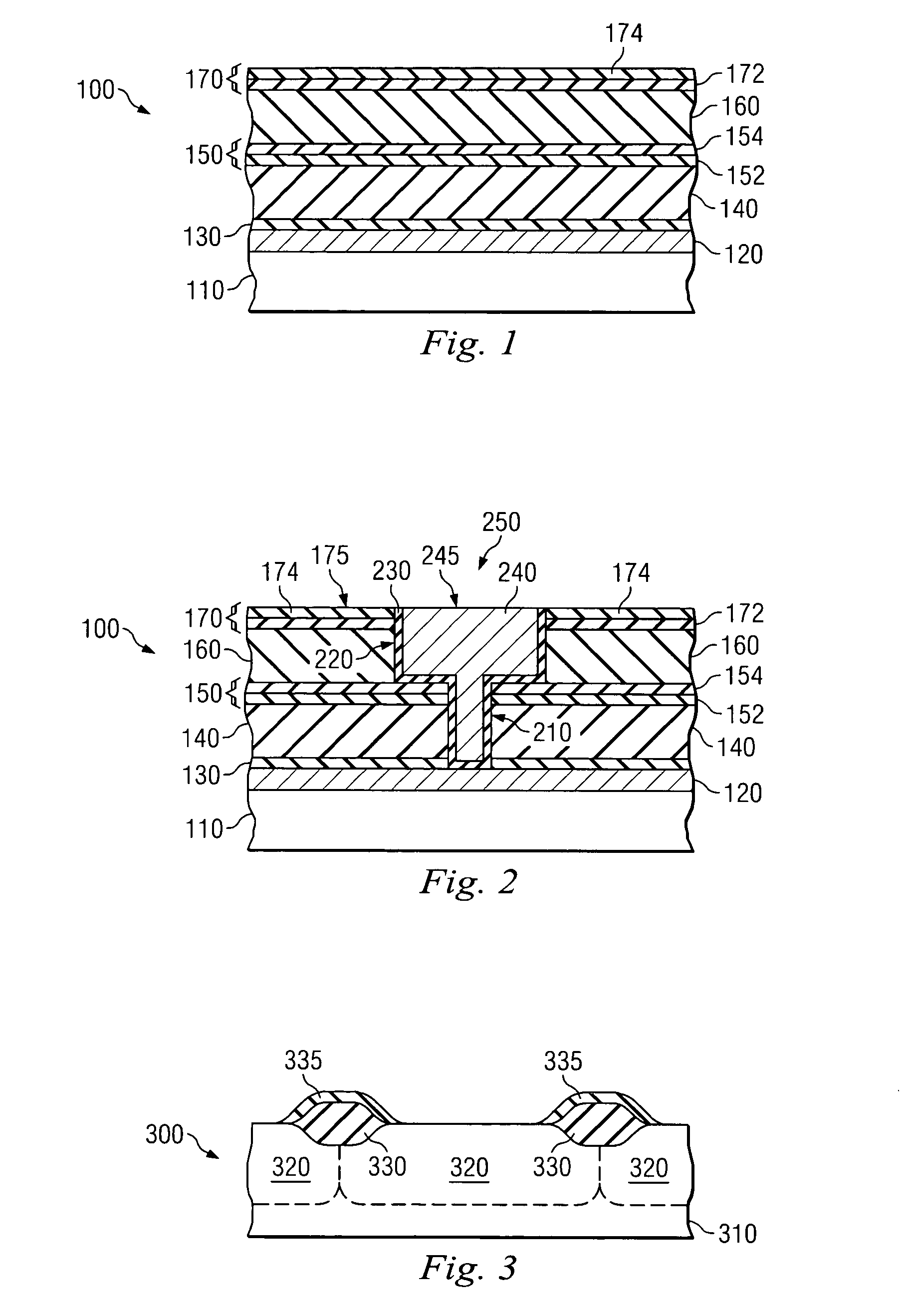

Field effect transistor with enhanced insulator structure

ActiveUS20050121661A1Reduce and eliminate strain generated fieldHigh densitySemiconductor/solid-state device manufacturingSemiconductor devicesIn planeField-effect transistor

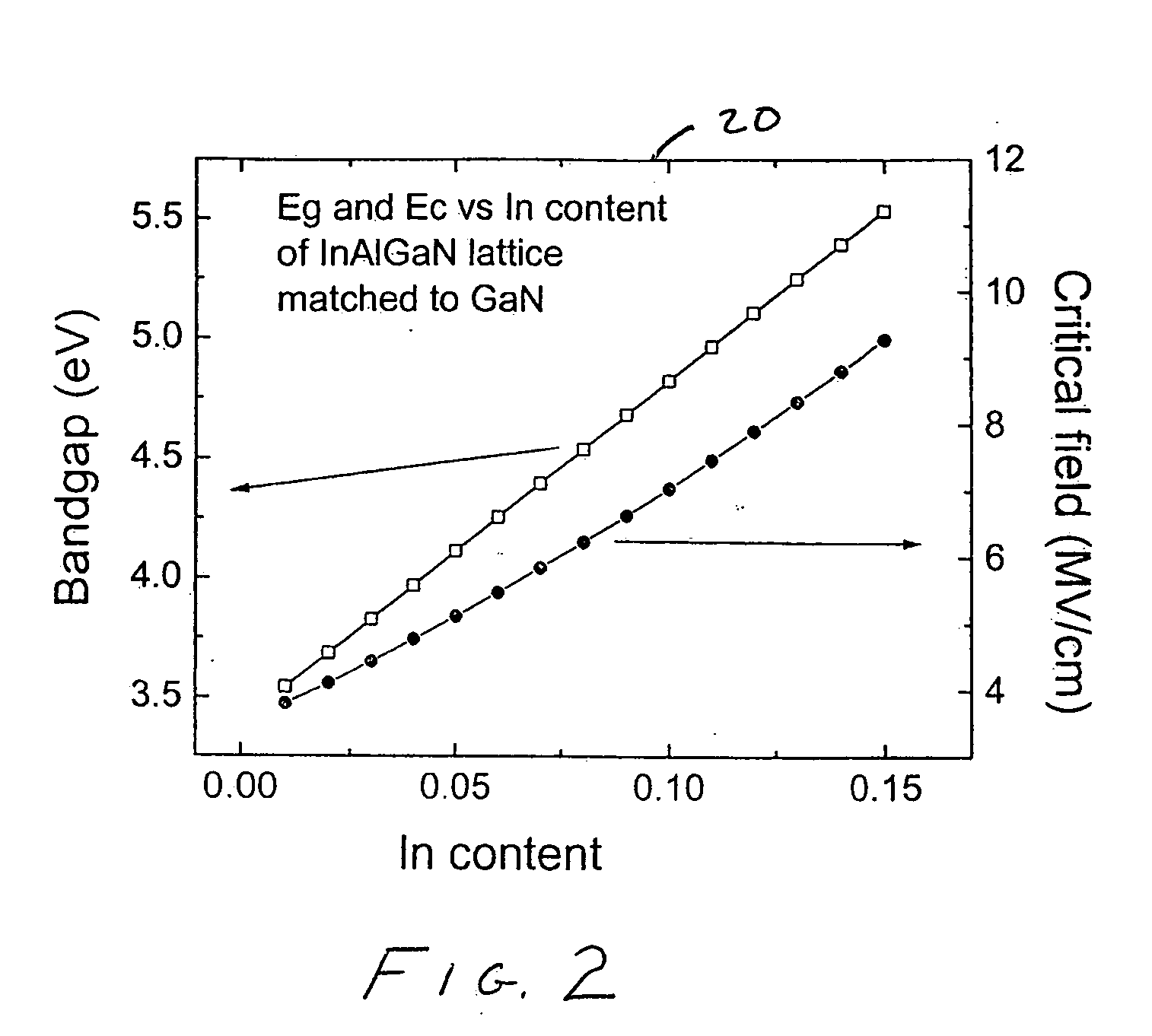

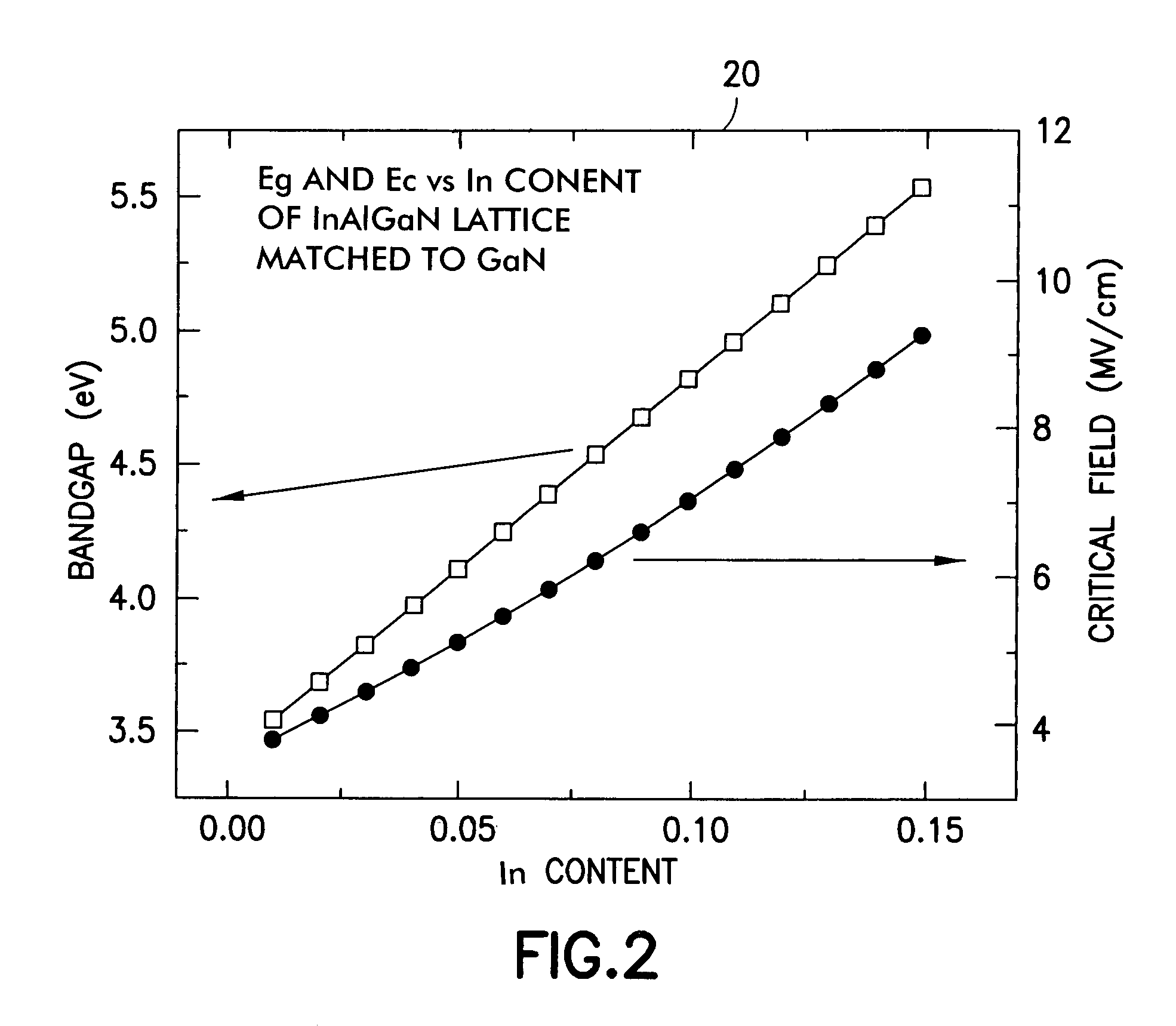

A III-nitride based field effect transistor obtains improved performance characteristics through manipulation of the relationship between the in-plane lattice constant of the interface of material layers. A high mobility two dimensional electron gas generated at the interface of the III-nitride materials permits high current conduction with low ON resistance, and is controllable through the manipulation of spontaneous polarization fields obtained according to the characteristics of the III-nitride material. The field effect transistor produced can be made to be a nominally on device where the in-plane lattice constants of the material forming the interface match. A nominally off device may be produced where one of the material layers has an in-plane lattice constant that is larger than that of the other layer material. The layer materials are preferably InAlGaN / GaN layers that are particularly tailored to the characteristics of the present invention.

Owner:INFINEON TECH AMERICAS CORP

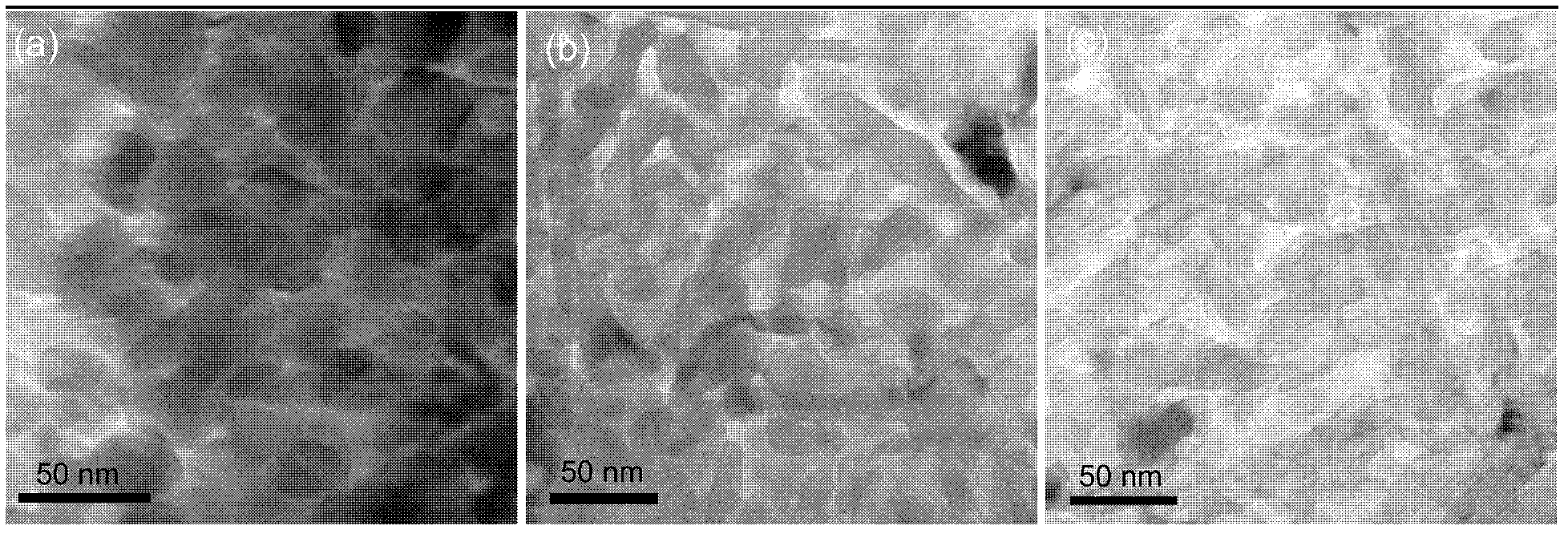

High Electric Energy Density Polymer Capacitors With Fast Discharge Speed and High Efficiency Based On Unique Poly (Vinylidene Fluoride) Copolymers and Terpolymers as Dielectric Materials

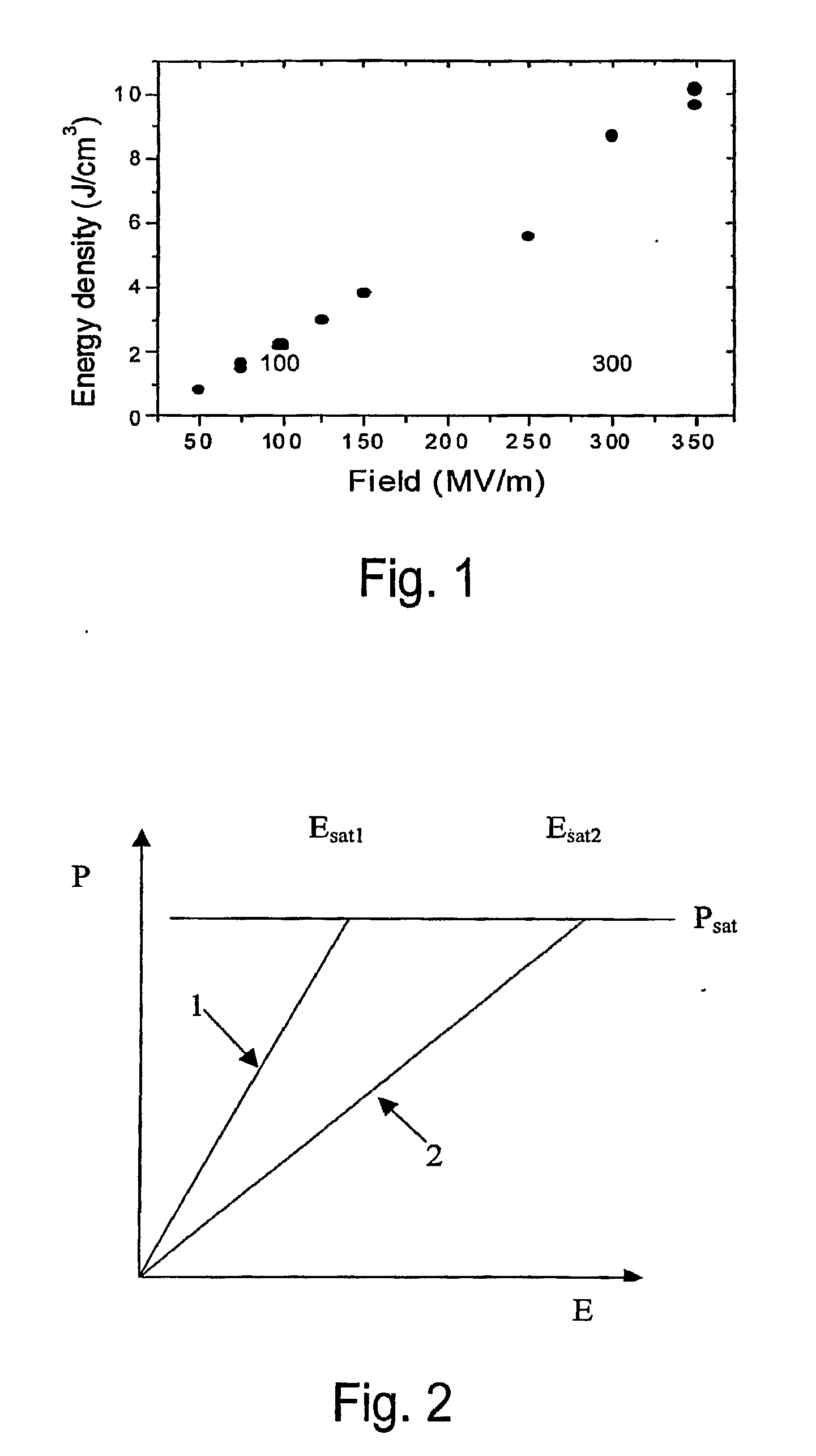

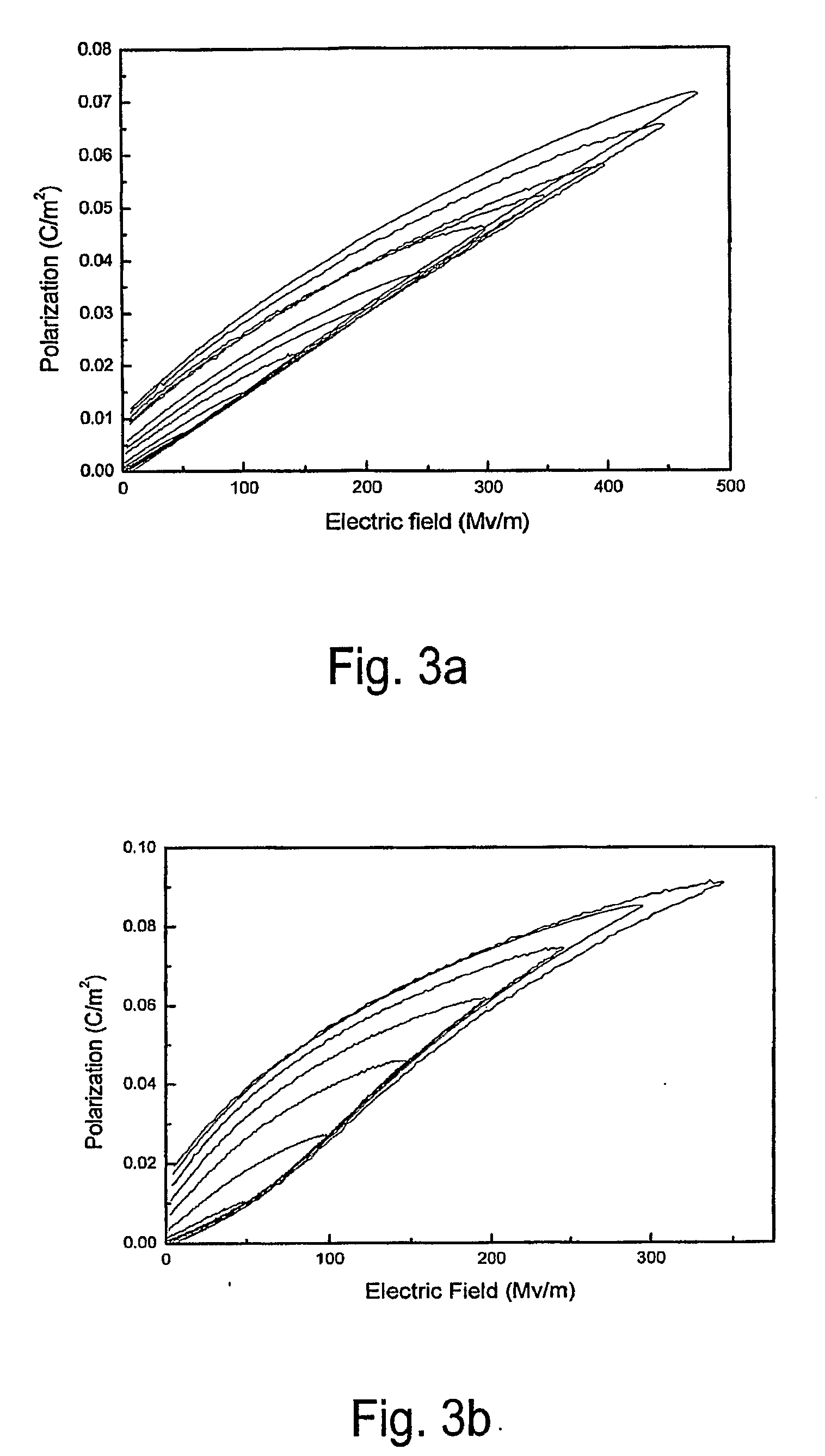

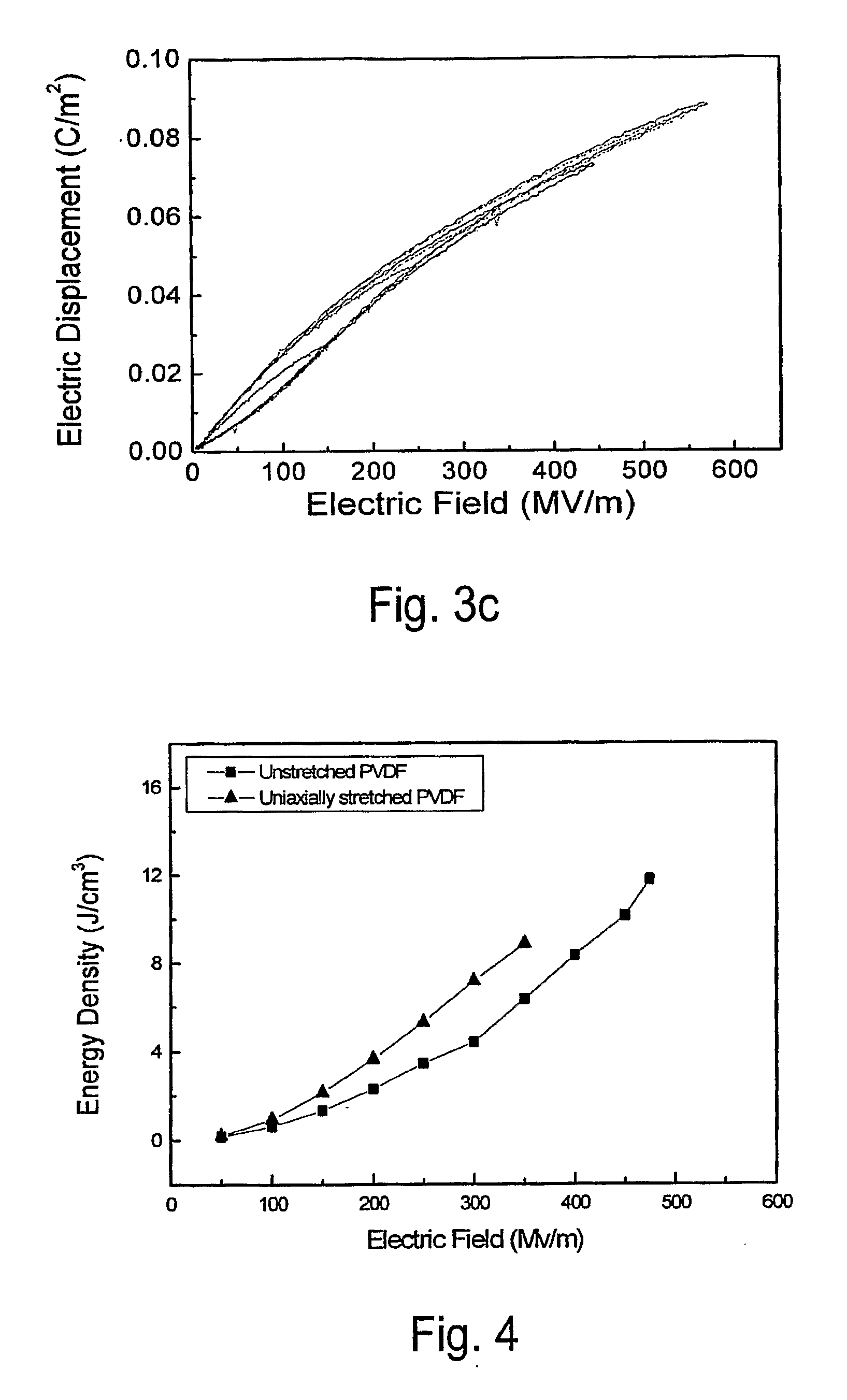

InactiveUS20090030152A1High electric energy densityFast dischargeFixed capacitor dielectricVehicular energy storagePolymer capacitorEthylene Homopolymers

An improved charge or energy storage device having a dielectric charge or energy storage layer including:(i) a copolymer or terpolymer selected from P(VDF-CTFE), P(VDF-CFE), P(VDF-HFP), P(VDF-CDFE), P(VDF-TrFE-CTFE), P(VDF-TrFE-CFE), P(VDF-TrFE-HFP), P(VDF-TrFE-CDFE), P(VDF-TFE-CTFE), P(VDF-TFE-CFE), P(VDF-TFE-HFP), and P(VDF-TFE-CDFE); or(ii) a polymer blend of PVDF homopolymer with a copolymer selected from P(VDF-CTFE); P(VDF-CFE); P(VDF-HFP); and P(VDF-CDFE); or(iii) a polymer blend of a PVDF homopolymer with a terpolymer selected from P(VDF-TrFE-CTFE); P(VDF-TrFE-CFE); P(VDF-TrFE-HFP); P(VDF-TrFE-CDFE); P(VDF-TFE-CTFE); P(VDF-TFE-CFE); P(VDF-TFE-HFP); and P(VDF-TFE-CDFE); or(iv) a polymer blend of copolymer selected from P(VDF-CTFE); P(VDF-CFE); P(VDF-HFP); and P(VDF-CDFE); with a terpolymer selected from P(VDF-TrFE-CTFE); P(VDF-TrFE-CFE); P(VDF-TrFE-HFP); P(VDF-TrFE-CDFE); P(VDF-TFE-CTFE); P(VDF-TFE-CFE); P(VDF-TFE-HFP); and P(VDF-TFE-CDFE).

Owner:PENN STATE RES FOUND

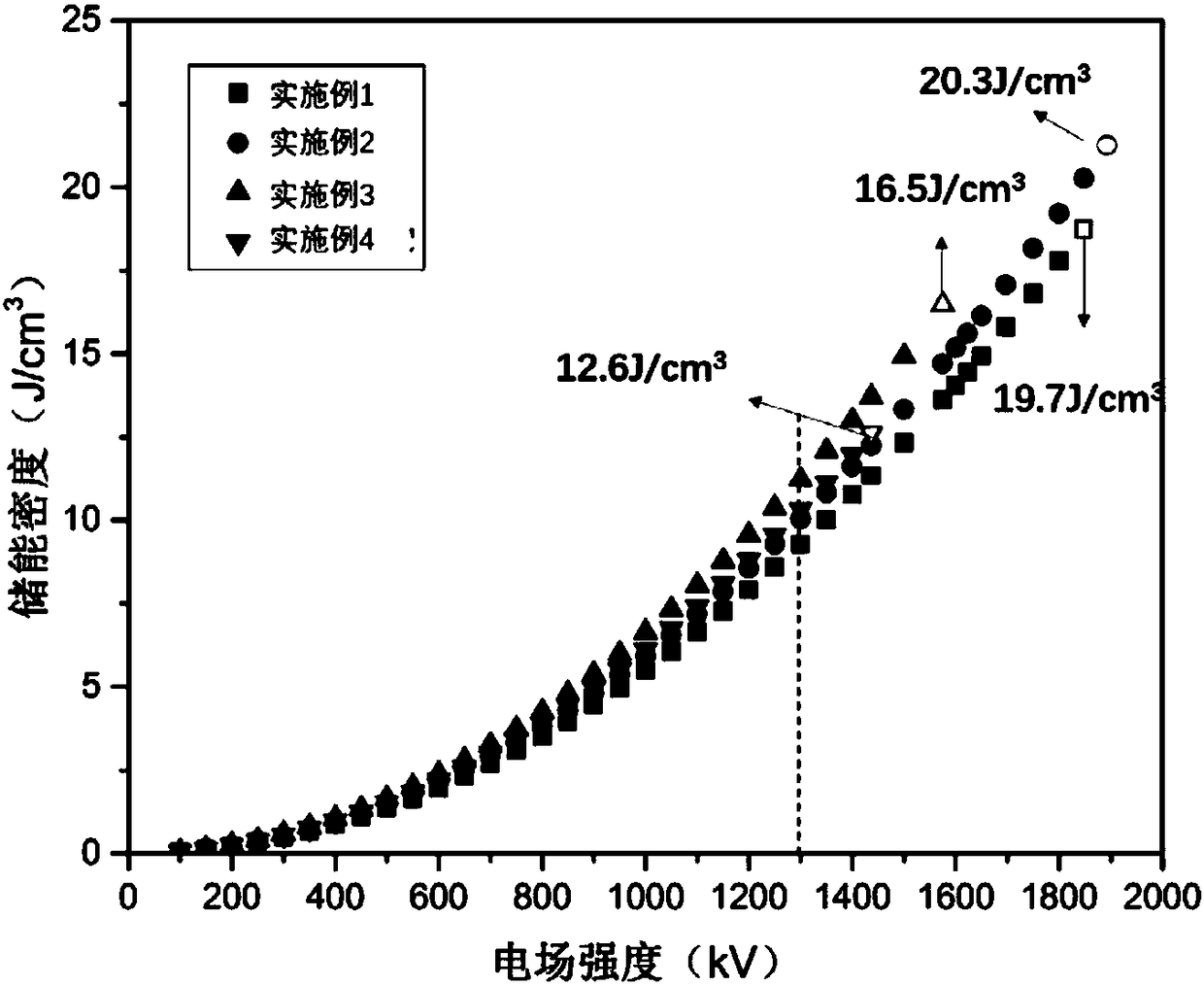

Lead barium niobate sodium-based glass ceramic material with high energy density, and preparation method thereof

ActiveCN108395106AHigh breakdown fieldHigh dielectric constantGlass shaping apparatusTungstenCeramic particle

The invention relates to a lead barium niobate sodium-based glass ceramic material with high energy density, and a preparation method thereof. The ceramic particles are mainly prepared from the components: perovskite-phase NaNbO3 and tungsten bronze-phase Ba2NaNb5O15. The glass ceramic energy storage material is prepared from the chemical components meeting a chemical general formula of 6.4Na2CO3-23.04BaCO3-2.56PbO-32Nb2O5-36SiO2. The preparation method comprises the steps of adopting Na2CO3, BaCO3, PbO, Nb2O5 and SiO2 as raw materials, rolling and mixing, drying, then melting at high temperature to obtain a glass melt; quickly pouring the high-temperature melt into a preheating mold, preserving heat for multiple hours in a constant-temperature furnace body so as to remove residual stressin quenching glass, and then cutting a glass block into glass slices with equal sizes and thicknesses; carrying out controlled crystallization on the glass slices, and obtaining the glass ceramic energy storage material. The lead barium niobate sodium-based glass ceramic energy-storage material is applied to an energy-storage capacitor material. Compared with the prior art, the ceramic energy-storage material prepared by the invention has the advantages of high dielectric constant and energy density, wide heat treatment temperature range and the like.

Owner:TONGJI UNIV

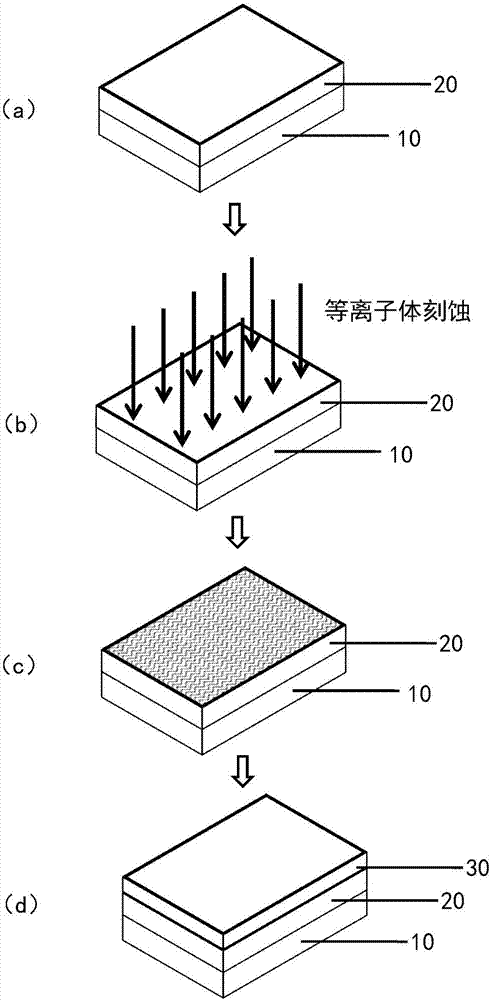

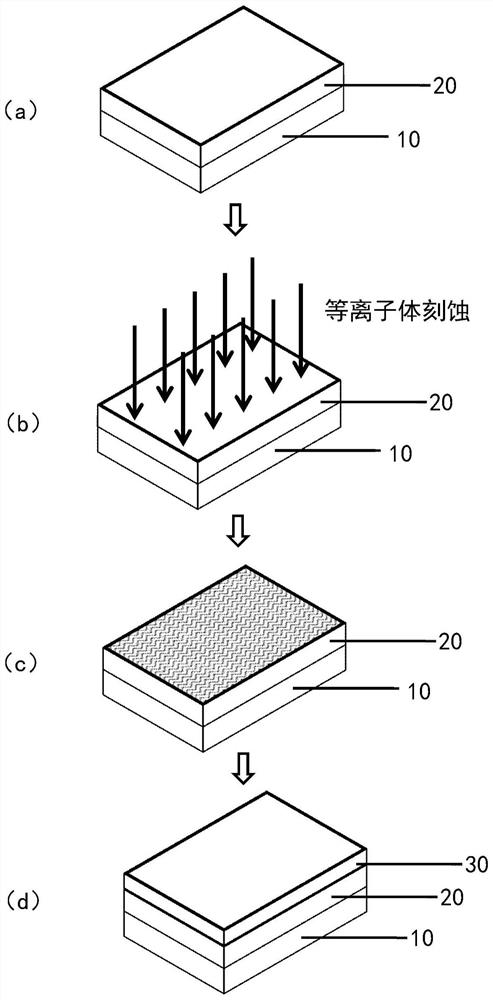

Method for improving gallium oxide semiconductor device ohmic contact

ActiveCN107993934ALower the barrierReduce the impact of exposureSemiconductor devicesOhmic contactMicrometer

The invention provides a method for improving gallium oxide semiconductor device ohmic contact. The method comprises the steps of conducting plasma etching surface treatment on a gallium oxide semiconductor and adjusting the roughness and oxygen vacancy on the surface of the gallium oxide semiconductor by controlling an etching technology, so that the surface roughness is within 1 micrometer, andthe oxygen vacancy is improved; growing a metal layer with a corresponding power function on the gallium oxide semiconductor after being subjected to the plasma etching surface treatment to form a semiconductor device with the ohmic contact. By means of the method, application and popularization of a gallium oxide material are facilitated; besides, according to a plasma etching method, the ohmic contact is improved to be not limited to the gallium oxide material, and the method can also be expanded and applied to other semiconductor devices.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Strontium titanate-based lead-free high-energy storage density and high-energy storage efficiency ceramic material and preparation method thereof

ActiveCN106699170ALow dielectric lossImprove energy storage density and energy storage efficiencyStorage efficiencyHigh energy

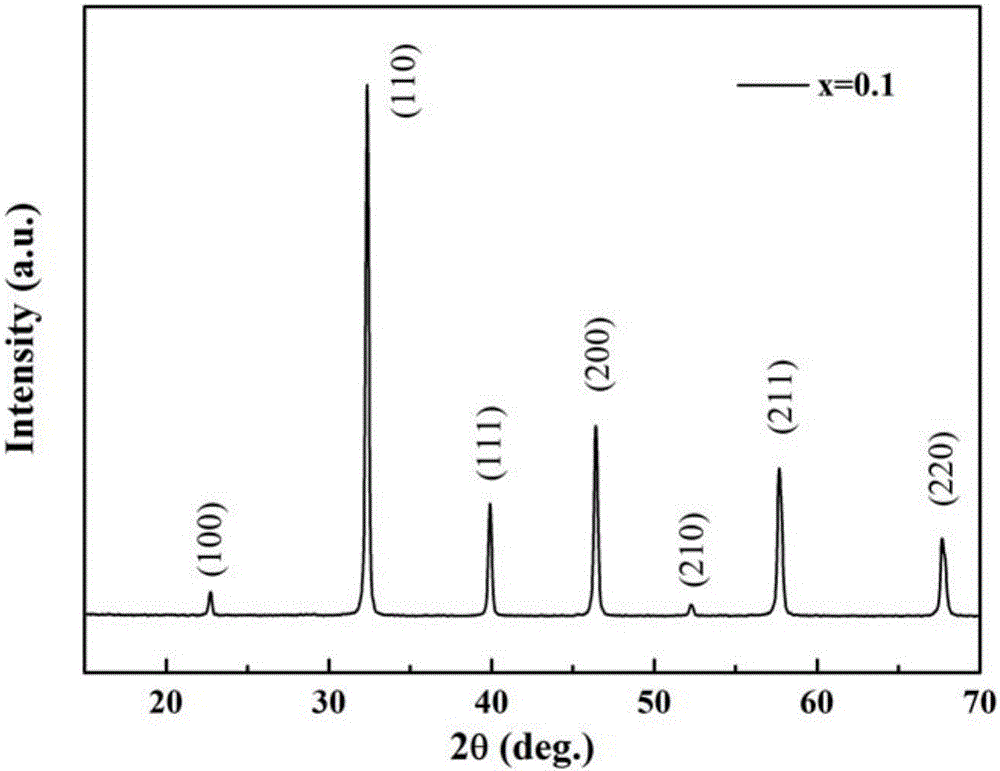

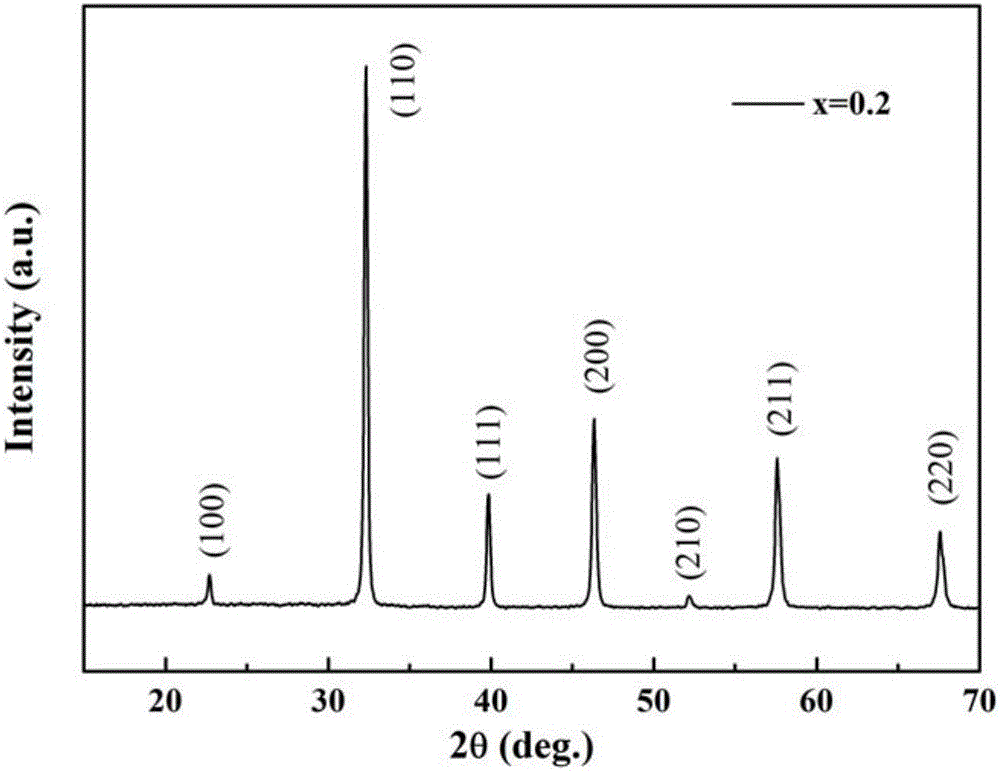

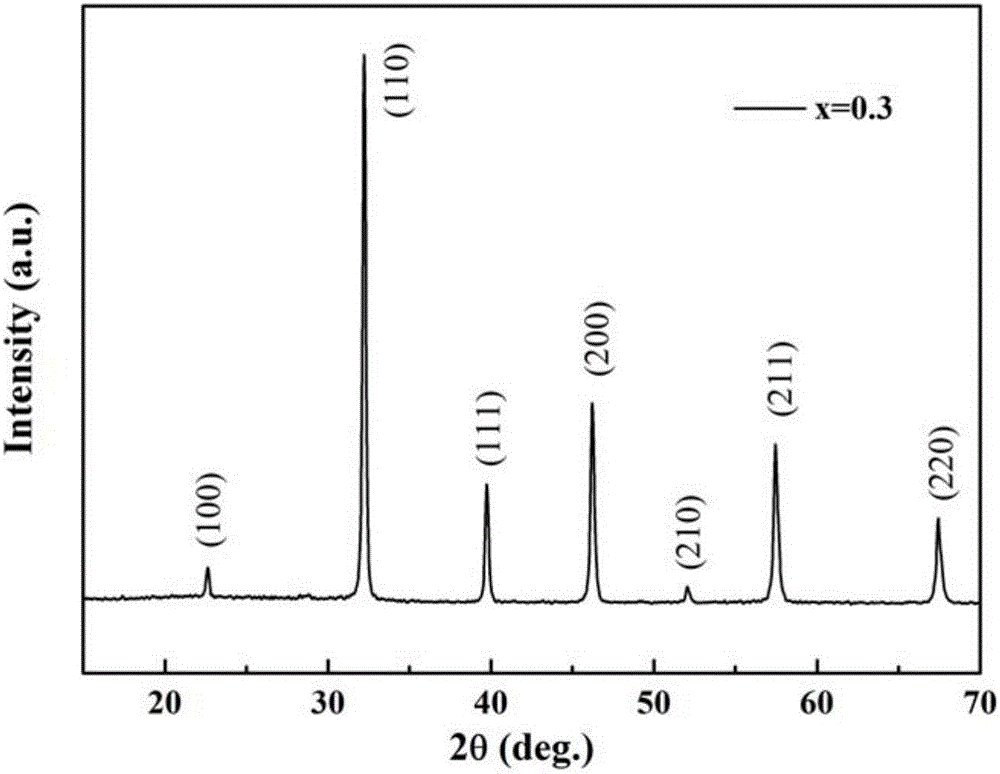

The invention relates to a strontium titanate-based lead-free high-energy storage density and high-energy storage efficiency ceramic material and a preparation method thereof. The preparation method comprises the following steps: firstly batching according to a chemical formula (1-x)SrTiO3-x(0.65BaTiO3-0.35Bi0.5Na0.5TiO3), wherein x represents a molar fraction and is greater than or equal to 0.1 but less than or equal to 0.6; ball-milling and drying to obtain a raw material powder body; adding the obtained raw material powder body into a bonding agent for pelleting, decaying for 24-48 hours, pressing into a sheet, performing glue removal treatment and sintering at a temperature of 1250-1350 DEG C to obtain the strontium titanate-based lead-free high-energy storage density and high-energy storage efficiency ceramic material. The ceramic material provided by the invention is simple and stable in preparation process, suitable for industrial production and excellent in energy storage characteristics, the energy storage density calculated based on a ferroelectric hysteresis loop is 0.961-1.403 J / cm<3>, and the energy storage efficiency is 84.77-91.63 percent.

Owner:SHAANXI UNIV OF SCI & TECH

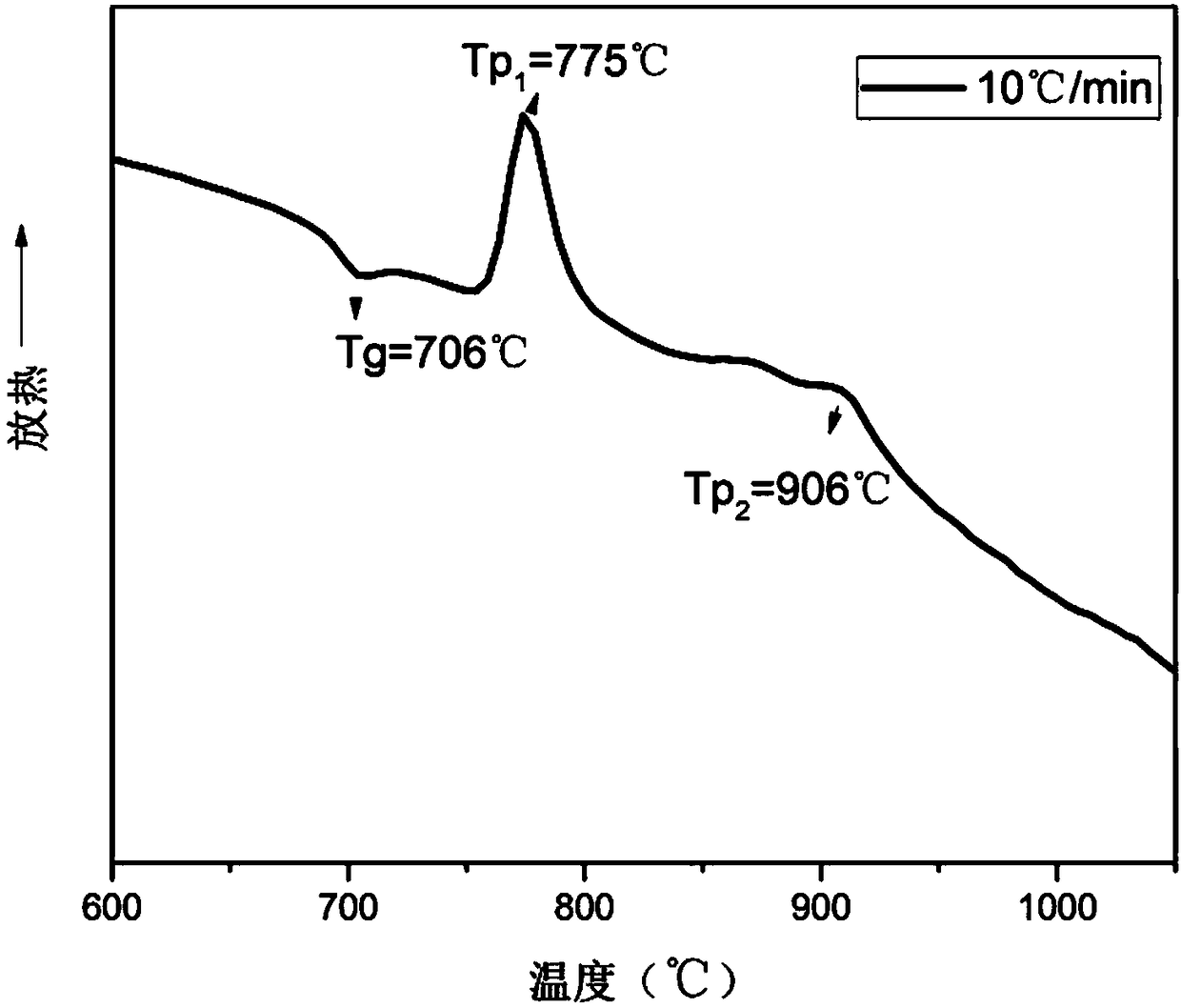

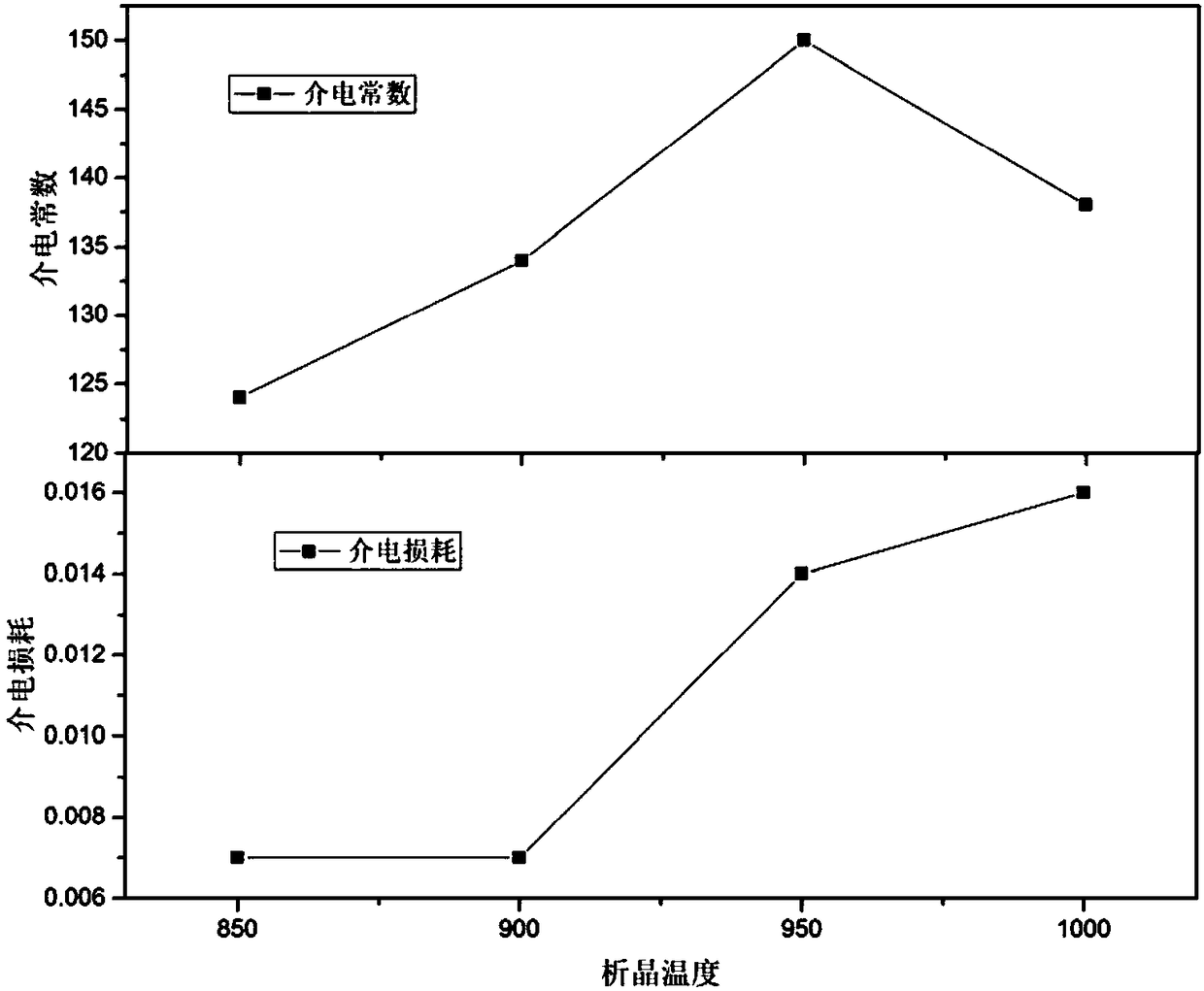

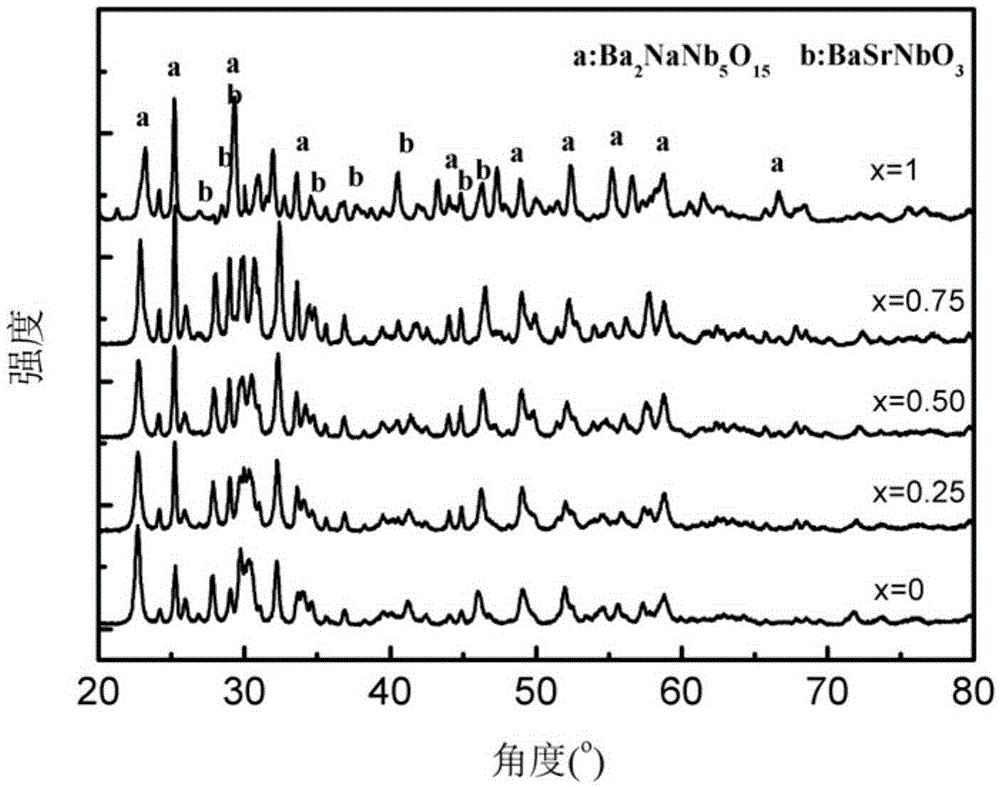

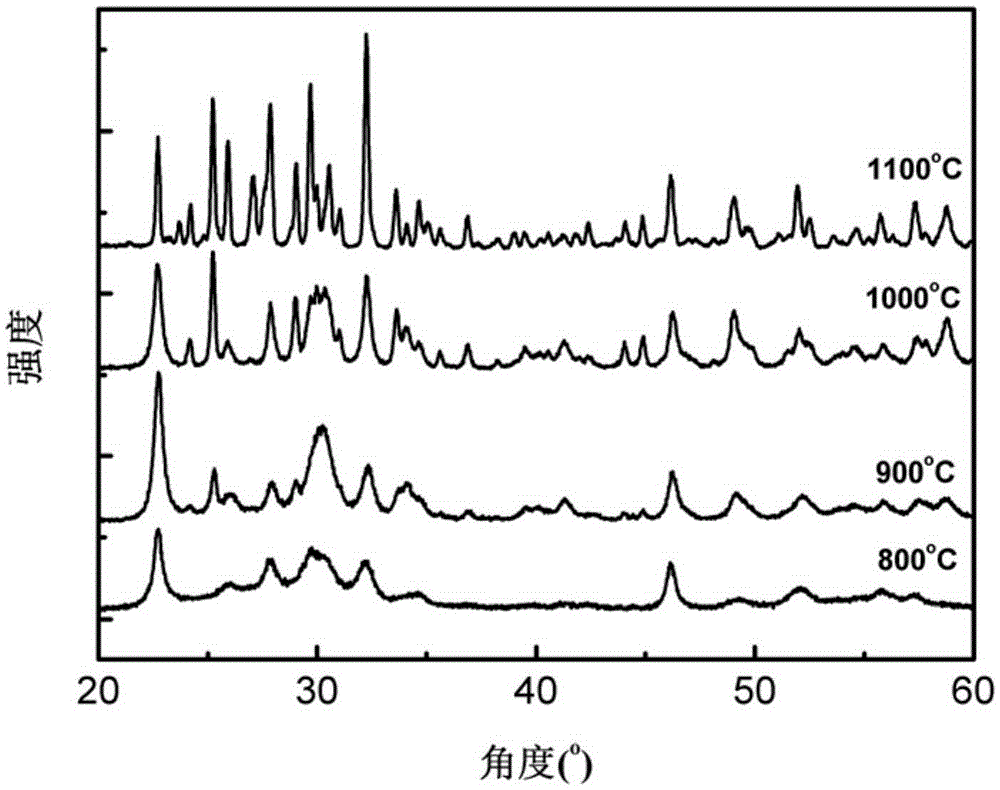

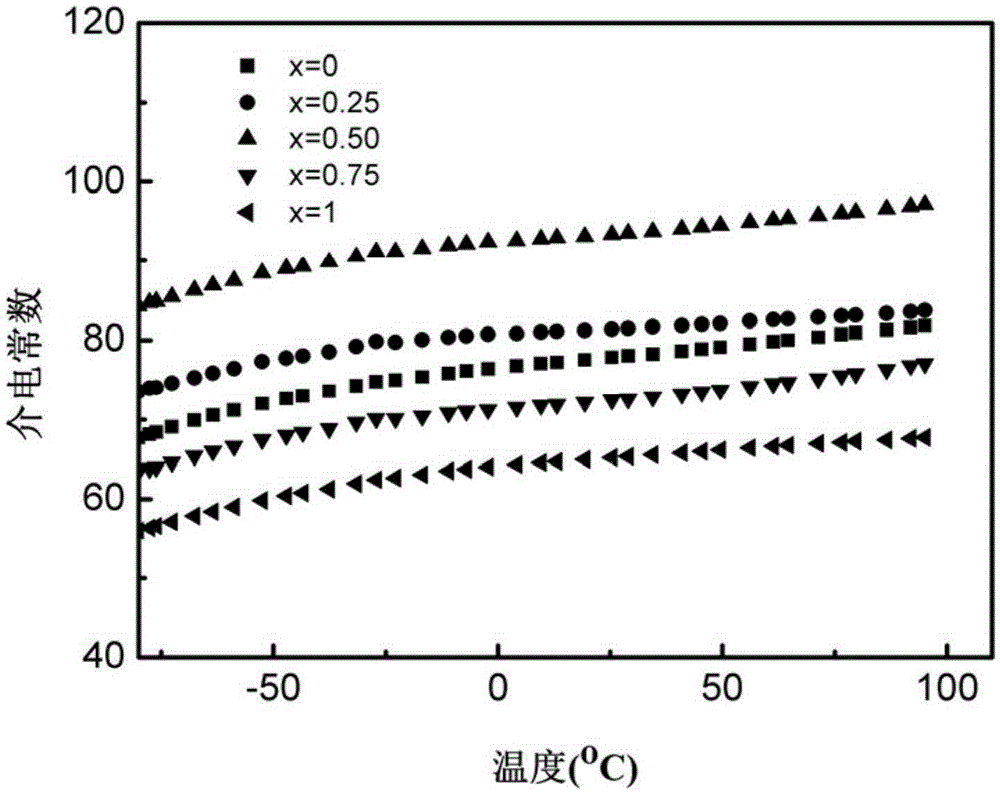

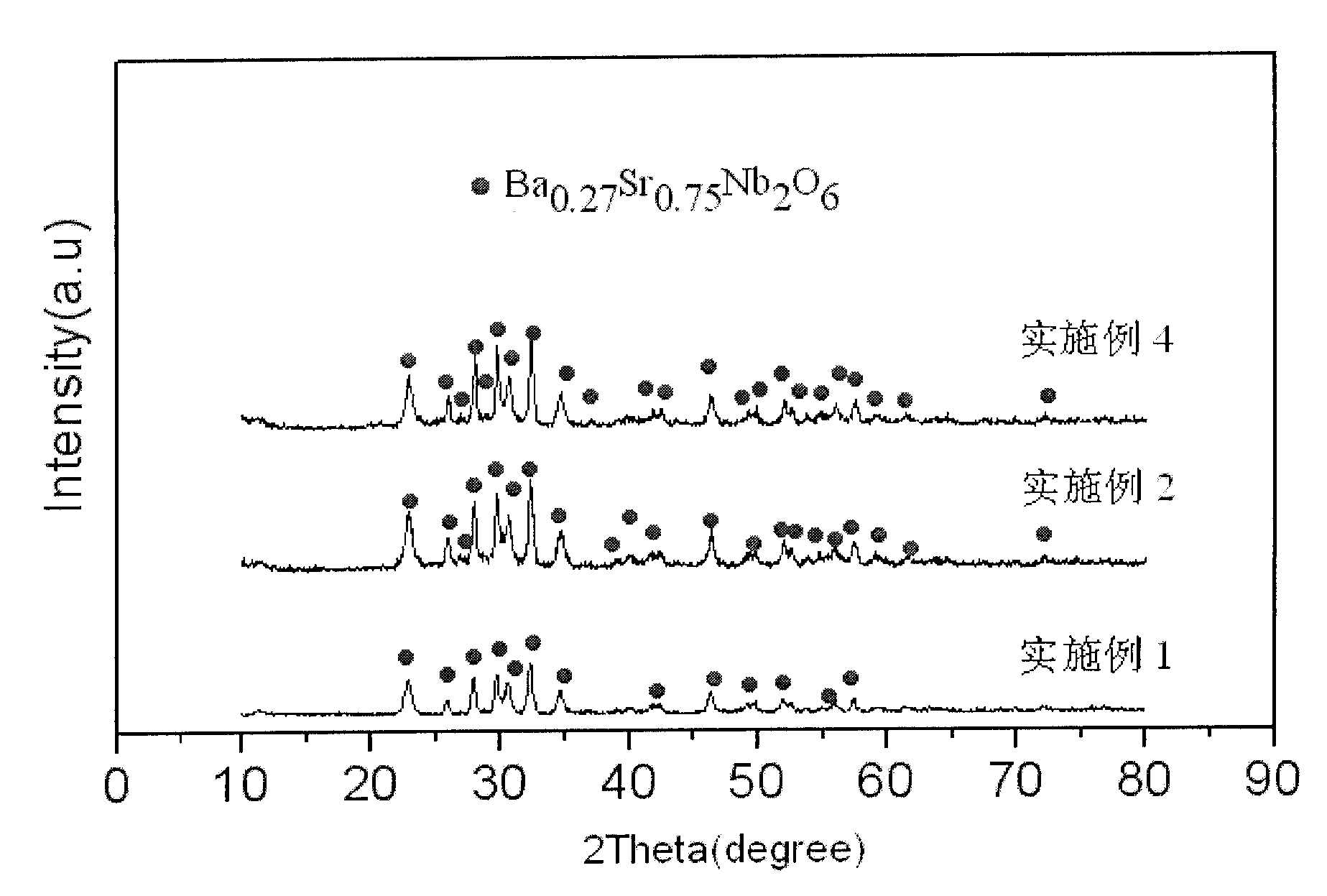

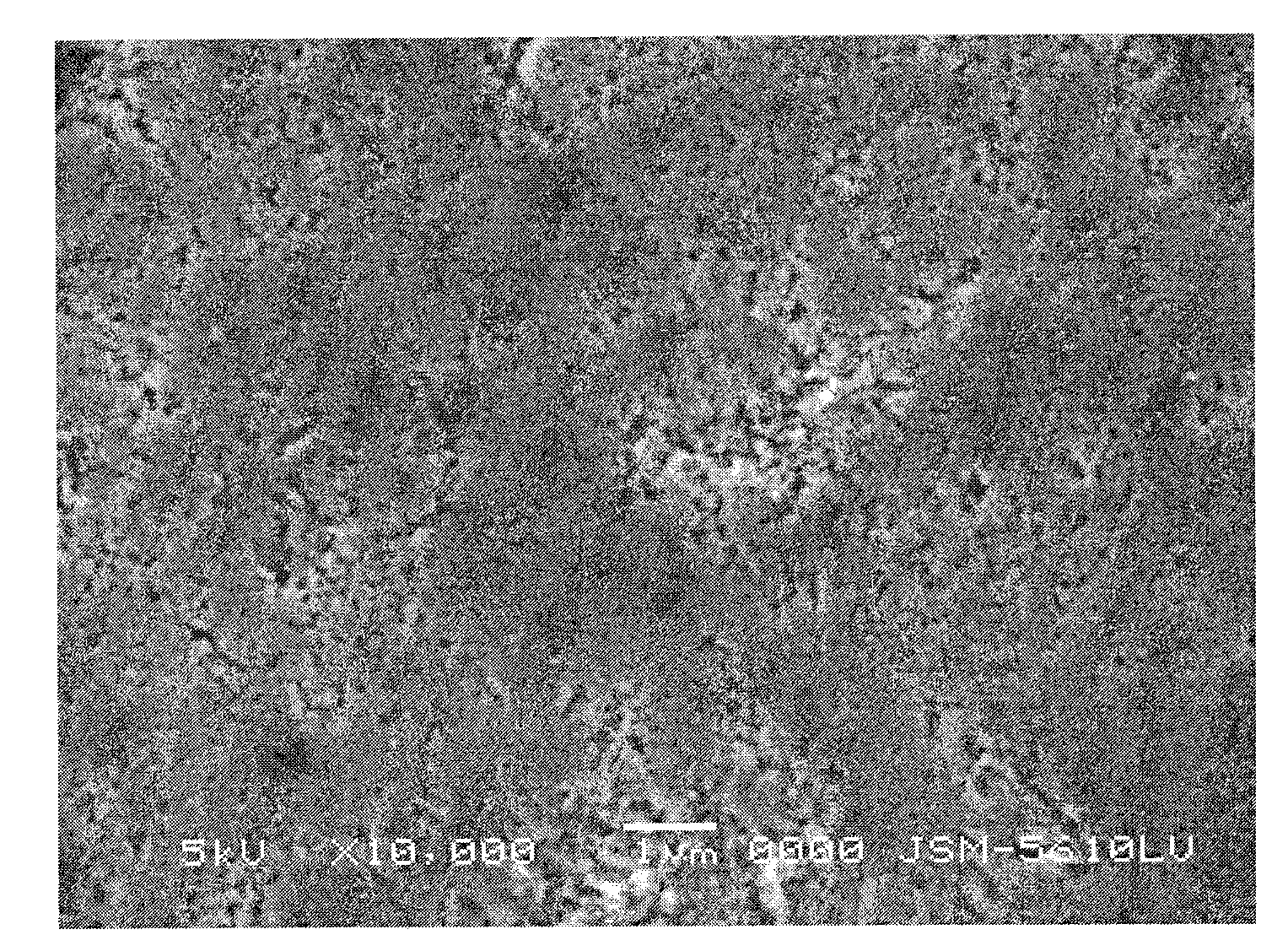

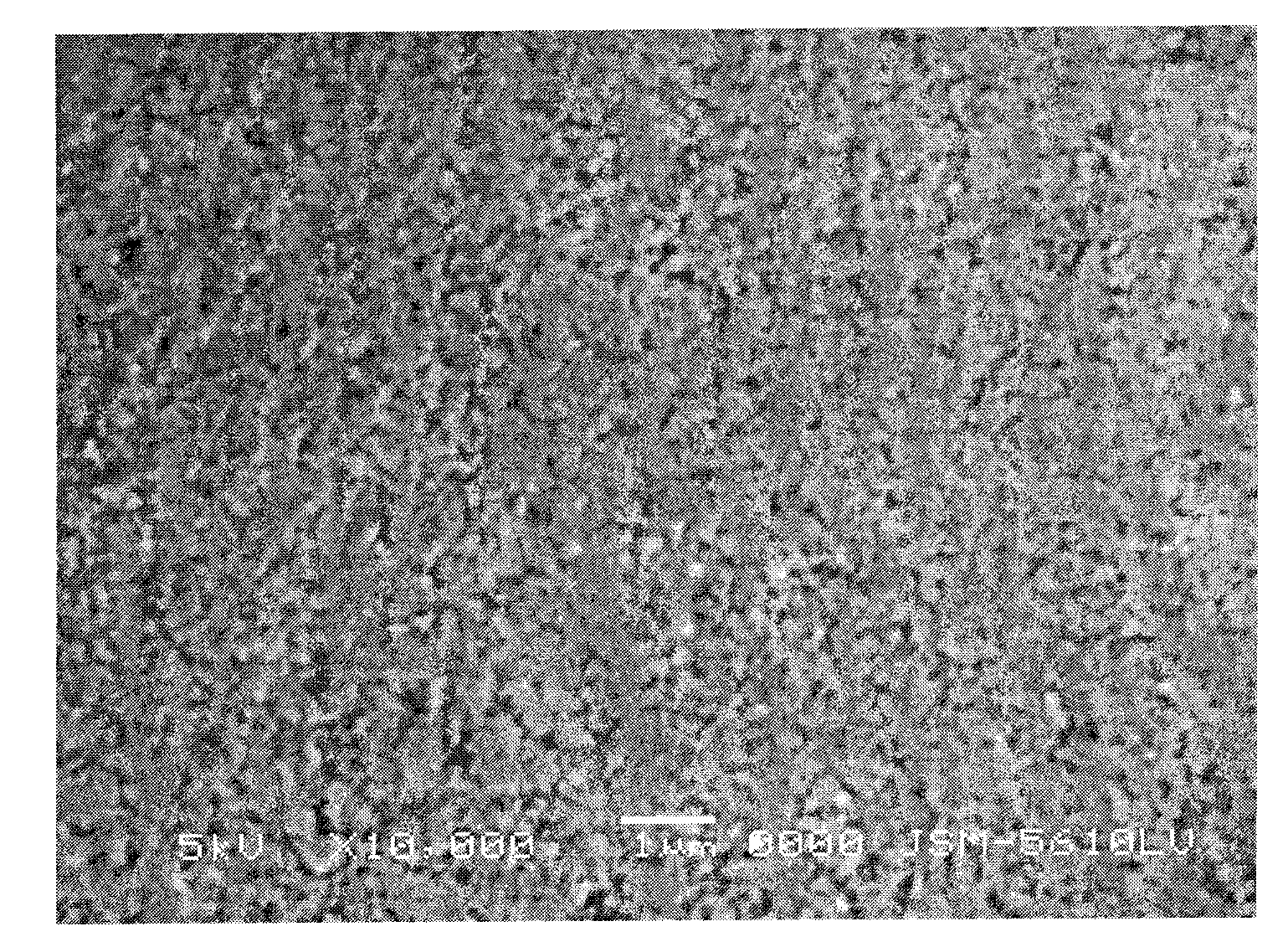

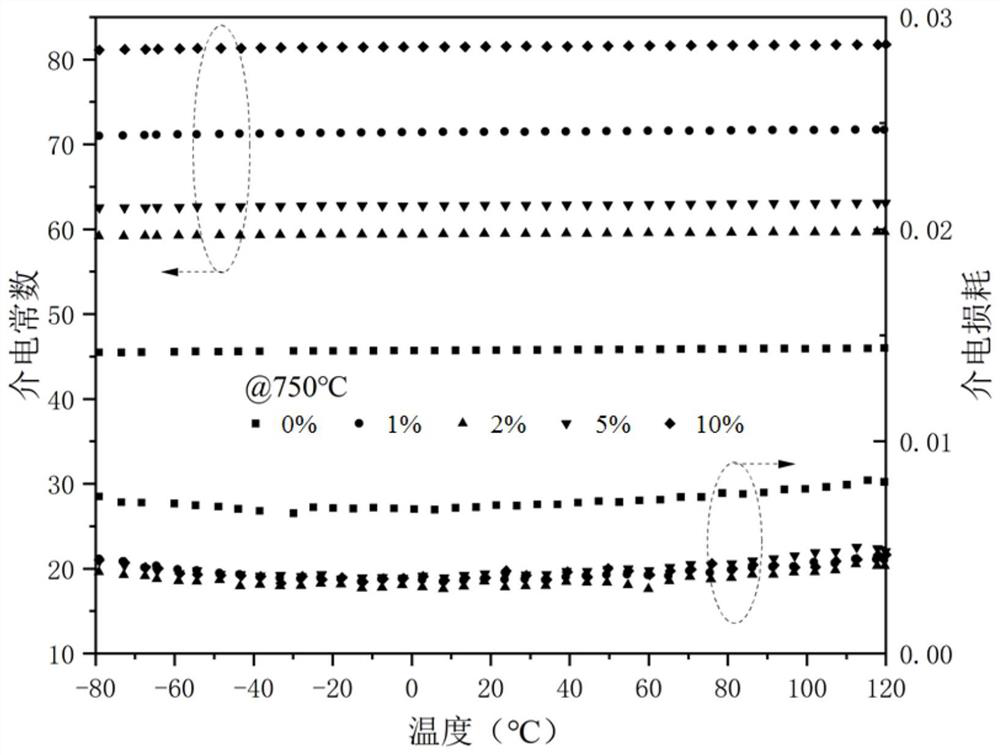

Novel niobate-base glass ceramic energy-storing material and preparation method and application thereof

InactiveCN105418068AHigh breakdown fieldHigh breakdown field strength breakdown fieldChemical compositionHigh energy

The invention relates to a novel niobate-base glass ceramic energy-storing material and a preparation method and application thereof. The chemical composition of the material is [(Ba<1-x>Sr<x>) <2>NaNb<5>O<15>] <0.6>-[SiO<2>] <0.4>, wherein 0<=x<=1. With BaCO3, SrCO3, NaCO3, Nb2O5 and SiO2 powder being raw materials, the mass of each component is weighed according to the designed chemical composition, the components are subjected to ball milling and even mixing and then added into a crucible to be molten at high temperature, and high-temperature melt is rapidly poured into a preheated copper mold for stress removal and then cut into slices with the thickness of 1.0 mm; the glass slices are placed into an annealing furnace to be subjected to controlled crystallization, and through controlling ingredients of the glass raw materials and optimizing a crystallization technology, the prepared niobate glass ceramic has high energy-storing density and reliability. Compared with the prior art, the method is simple, and through testing of experiments, the prepared glass ceramic material has high energy-storing density and charging and discharging efficiency and is expected to be used as a novel energy-storing capacitor material.

Owner:TONGJI UNIV

Field effect transistor with enhanced insulator structure

ActiveUS7279697B2Improve current carrying capacityLower resistanceSemiconductor/solid-state device manufacturingSemiconductor devicesIn planeField-effect transistor

Owner:INFINEON TECH AMERICAS CORP

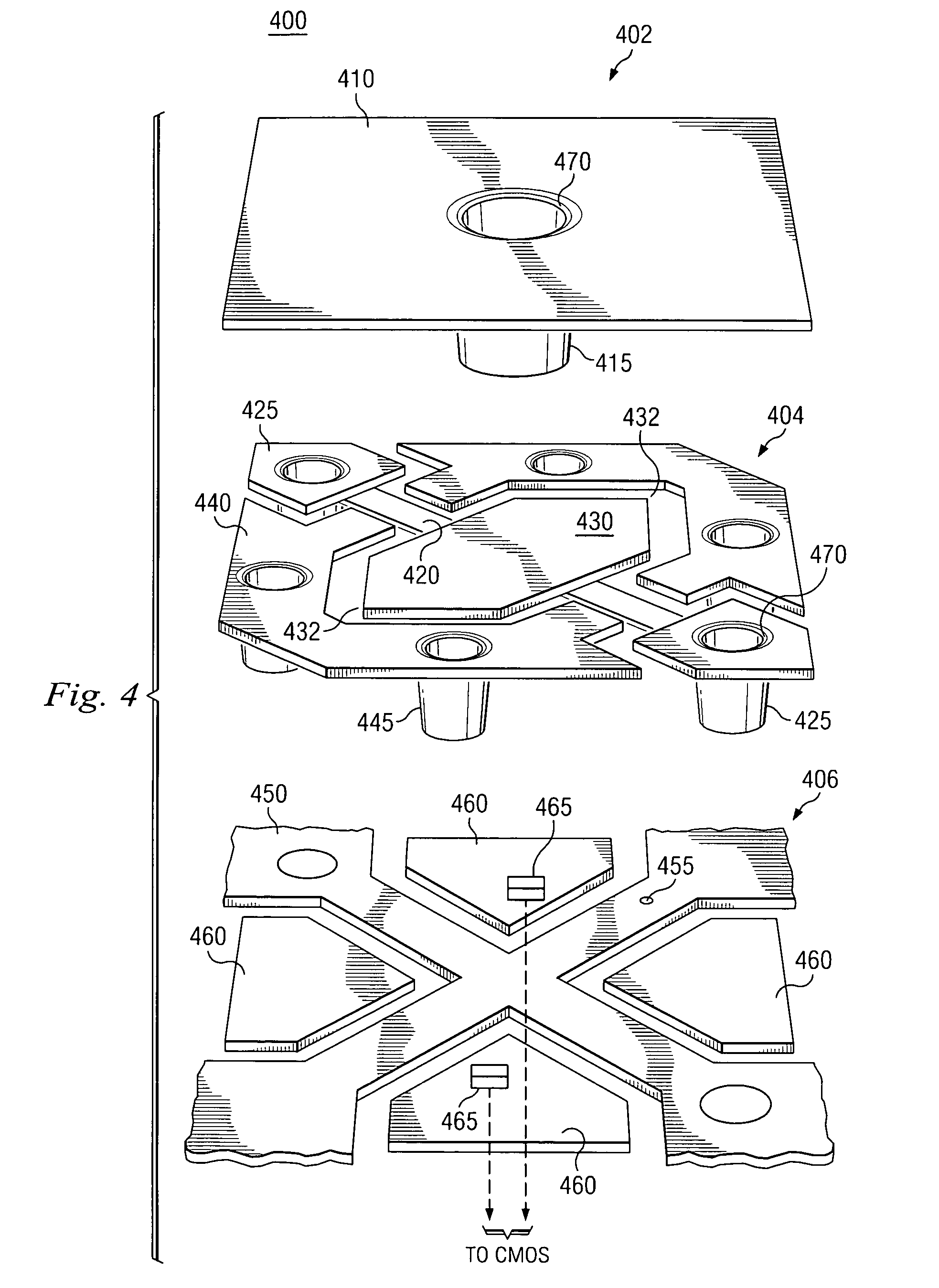

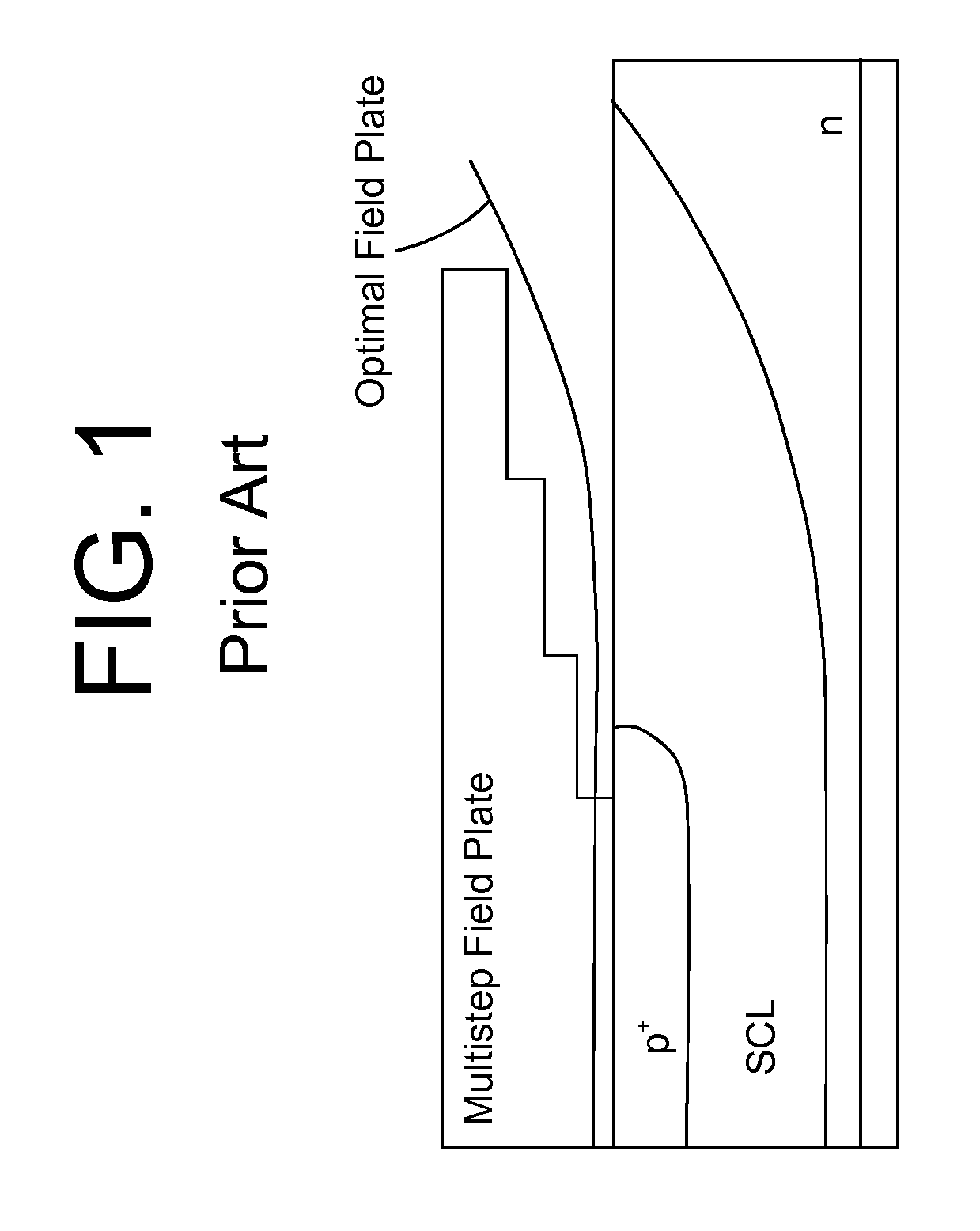

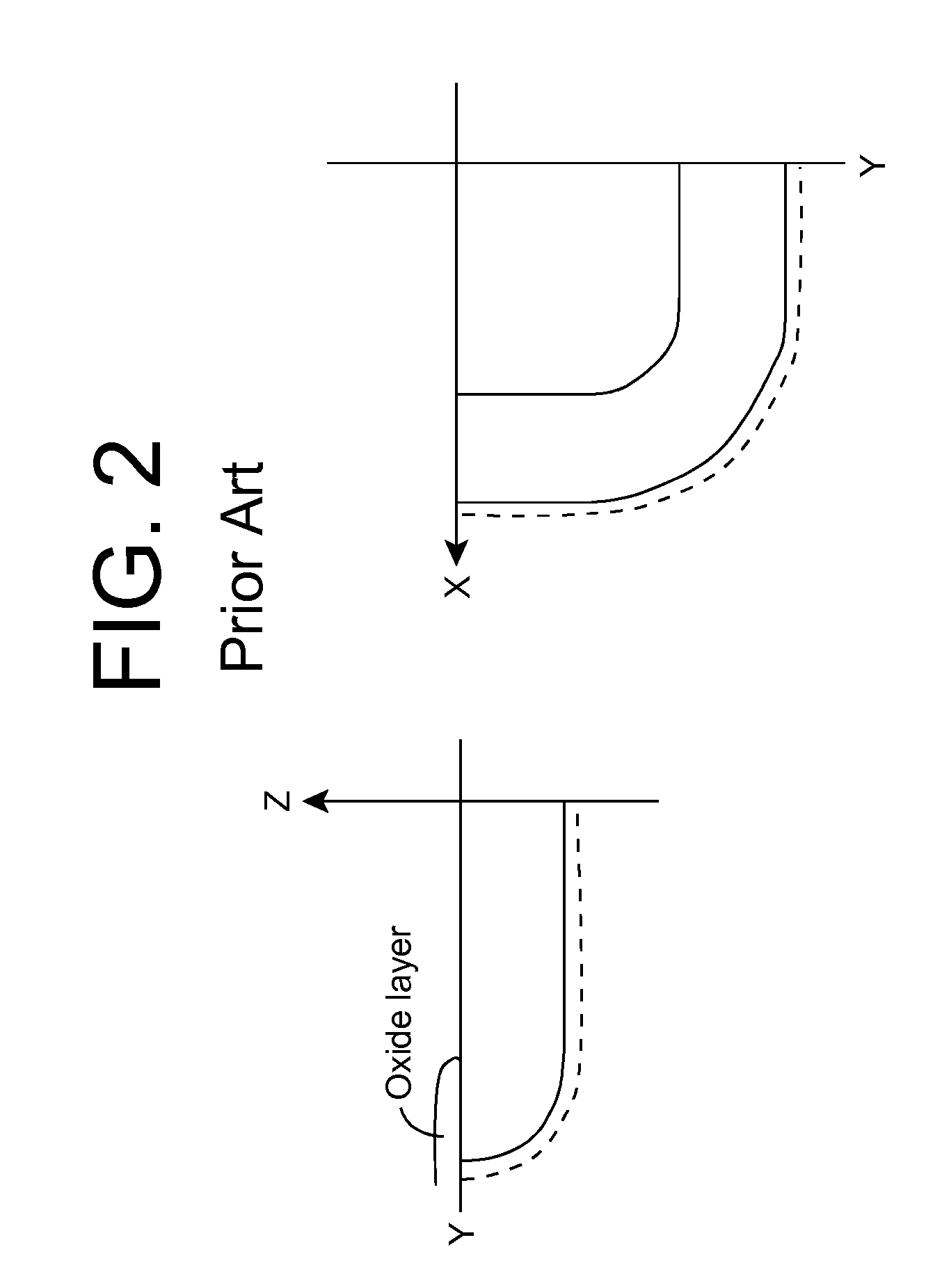

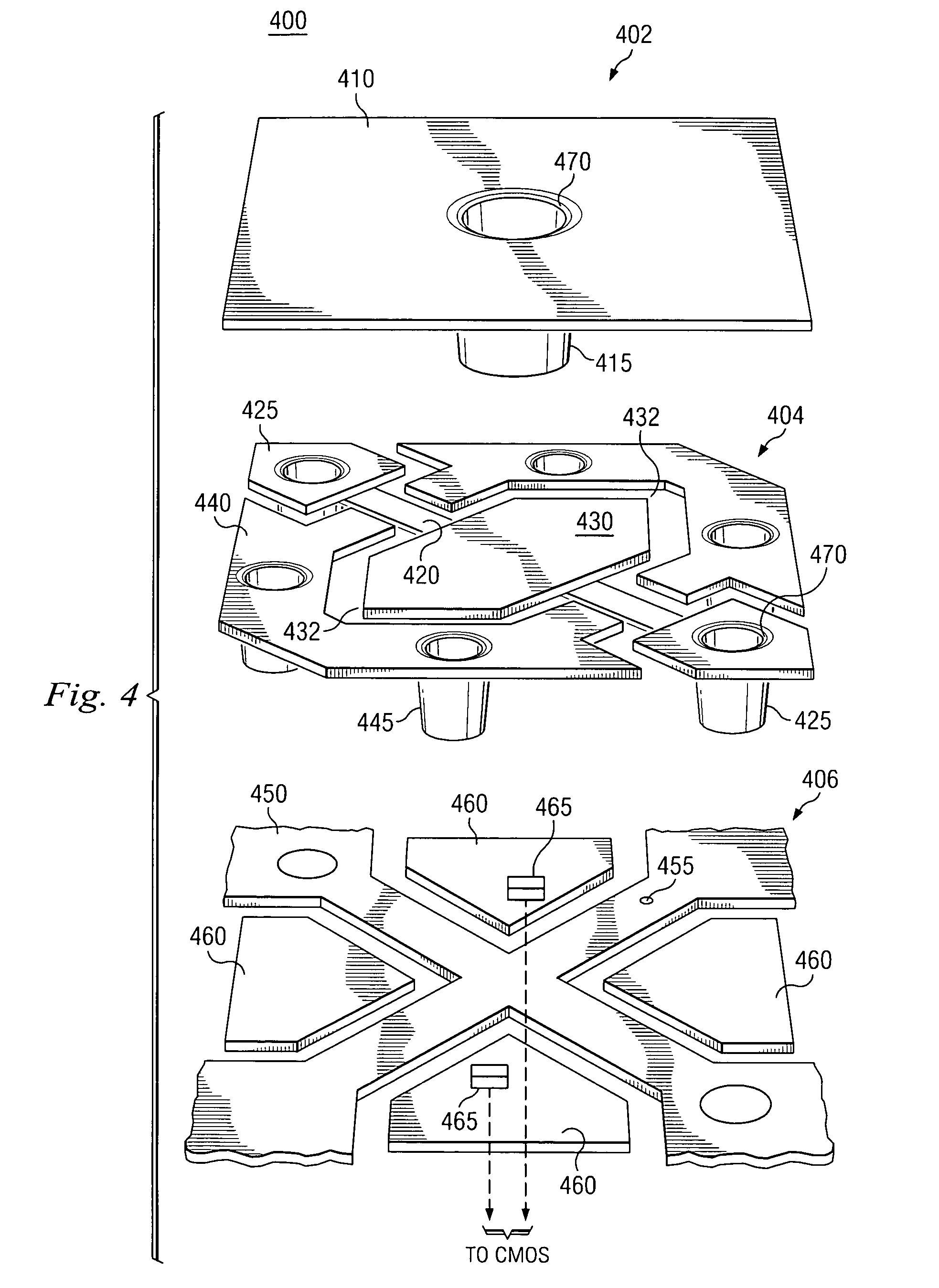

Profiled contact for semiconductor device

ActiveUS20100301490A1Improve breakdown voltageEliminate direct inter-electrode breakdownThyristorSemiconductor/solid-state device detailsPower semiconductor deviceSemiconductor structure

A profiled contact for a device, such as a high power semiconductor device is provided. The contact is profiled in both a direction substantially parallel to a surface of a semiconductor structure of the device and a direction substantially perpendicular to the surface of the semiconductor structure. The profiling can limit the peak electric field between two electrodes to approximately the same as the average electrical field between the electrodes, as well as limit the electric field perpendicular to the semiconductor structure both within and outside the semiconductor structure.

Owner:SENSOR ELECTRONICS TECH

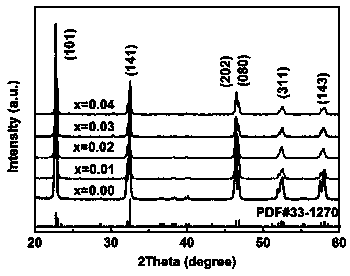

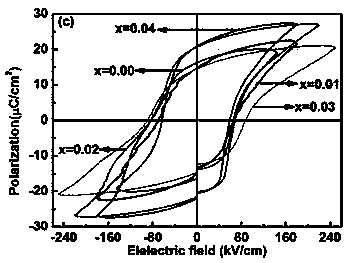

High-breakdown ferroelectric ceramic and preparation method thereof

The intention discloses a high- breakdown ferroelectric ceramic. The stoichiometric formula of the ferroelectric ceramic is Na1-2xMgxNbO3. The invention also discloses a preparation method of the ceramic material, and the method comprises the following steps: adding MgO into NaNbO3, and carrying out ball milling, drying, briquetting, screening, isostatic cool pressing and sintering to obtain a Na1-2xMgxNbO3 ceramic sample. The high-breakdown Na1-2xMgxNbO3 ceramic material provided by the invention is simple in preparation process, low in material cost, green and environment-friendly, and a high-breakdown ferroelectric ceramic matrix is provided.

Owner:SHAANXI UNIV OF SCI & TECH

Insulating layer having decreased dielectric constant and increased hardness

InactiveUS7352053B2High hardnessHigh thermal stabilitySemiconductor/solid-state device detailsSolid-state devicesCarbon nitrideOptoelectronics

A method of manufacturing a mechanically robust insulating layer, including forming a low-k dielectric layer having a first dielectric constant on a substrate and forming a carbon nitride cap layer on the low-k dielectric layer, the insulating layer thereby having a second dielectric constant that is less than the first dielectric constant.

Owner:TAIWAN SEMICON MFG CO LTD

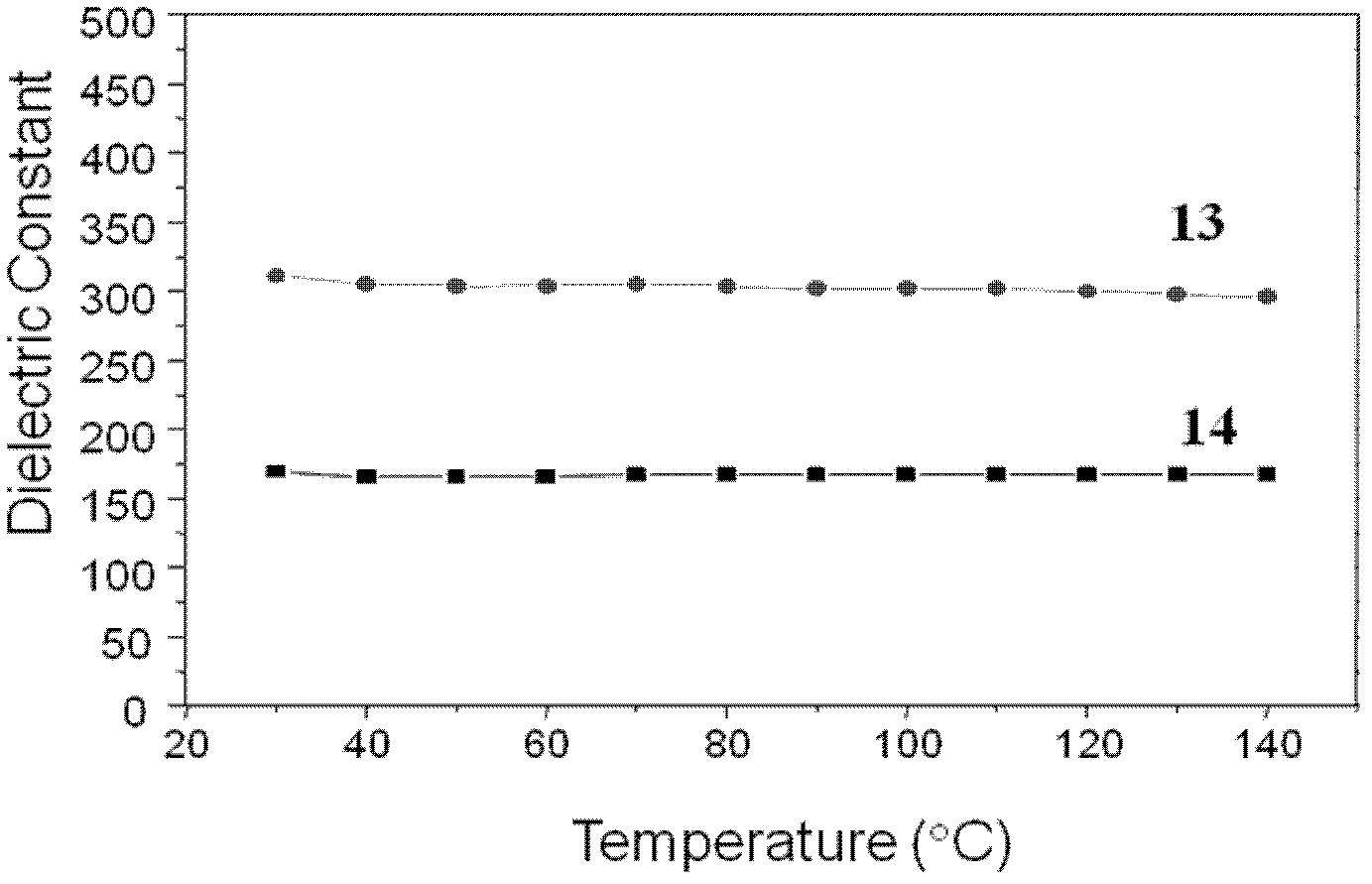

Glass ceramic dielectric with high breakdown strength and preparation method thereof

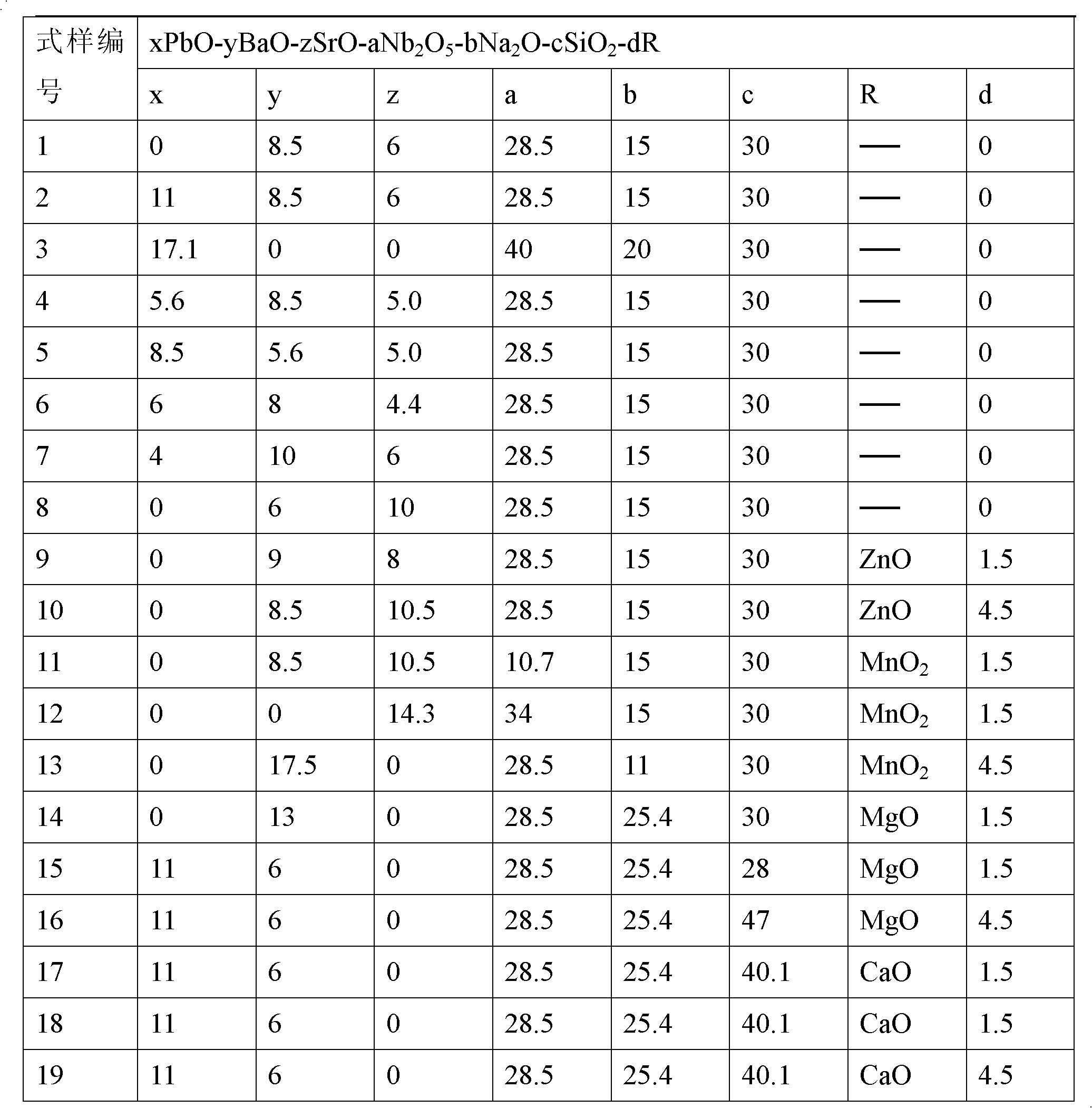

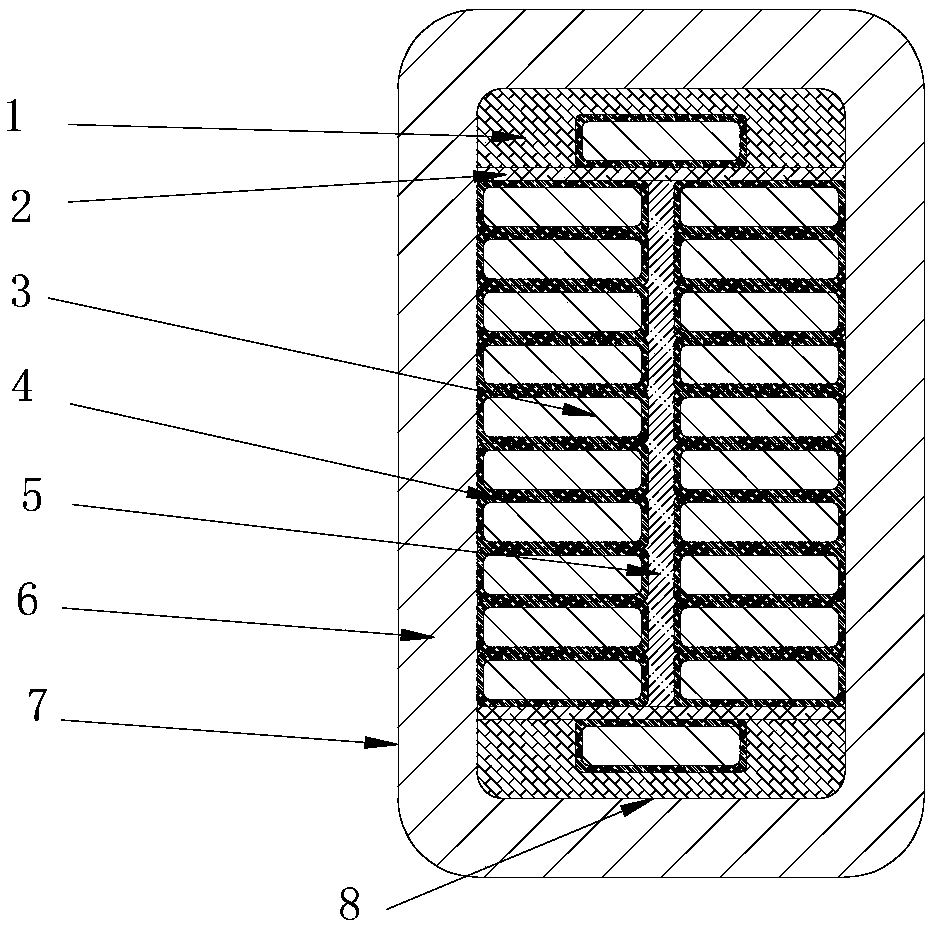

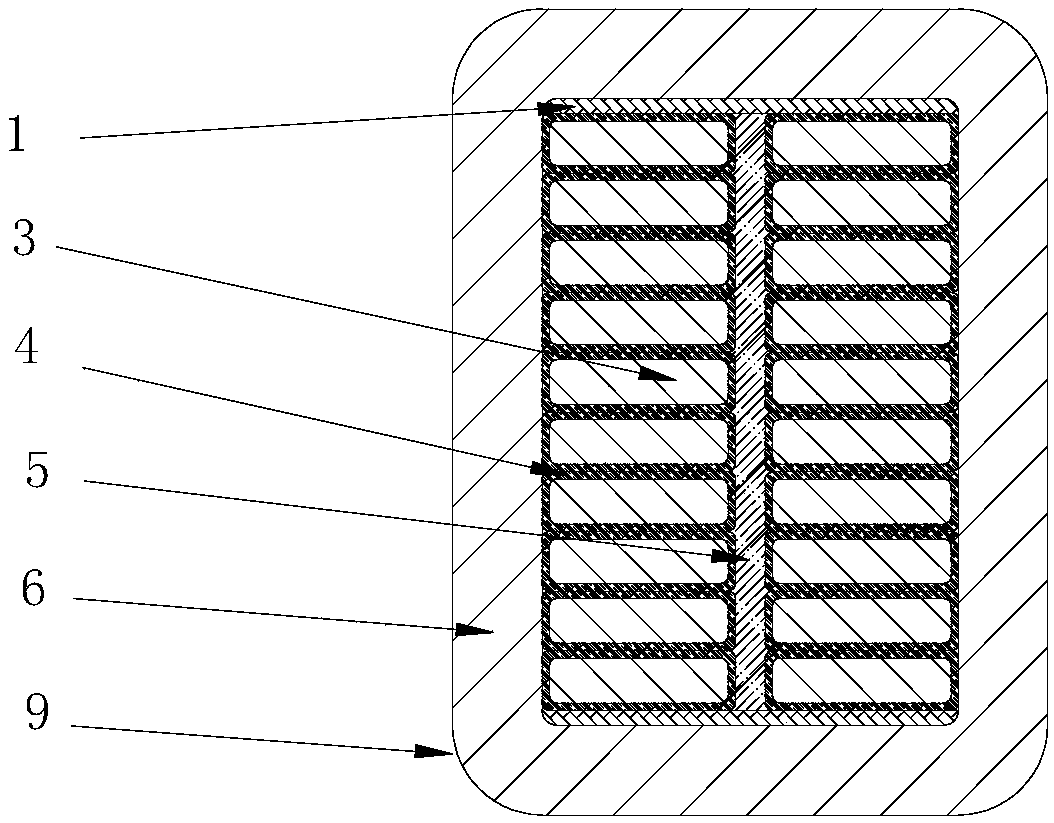

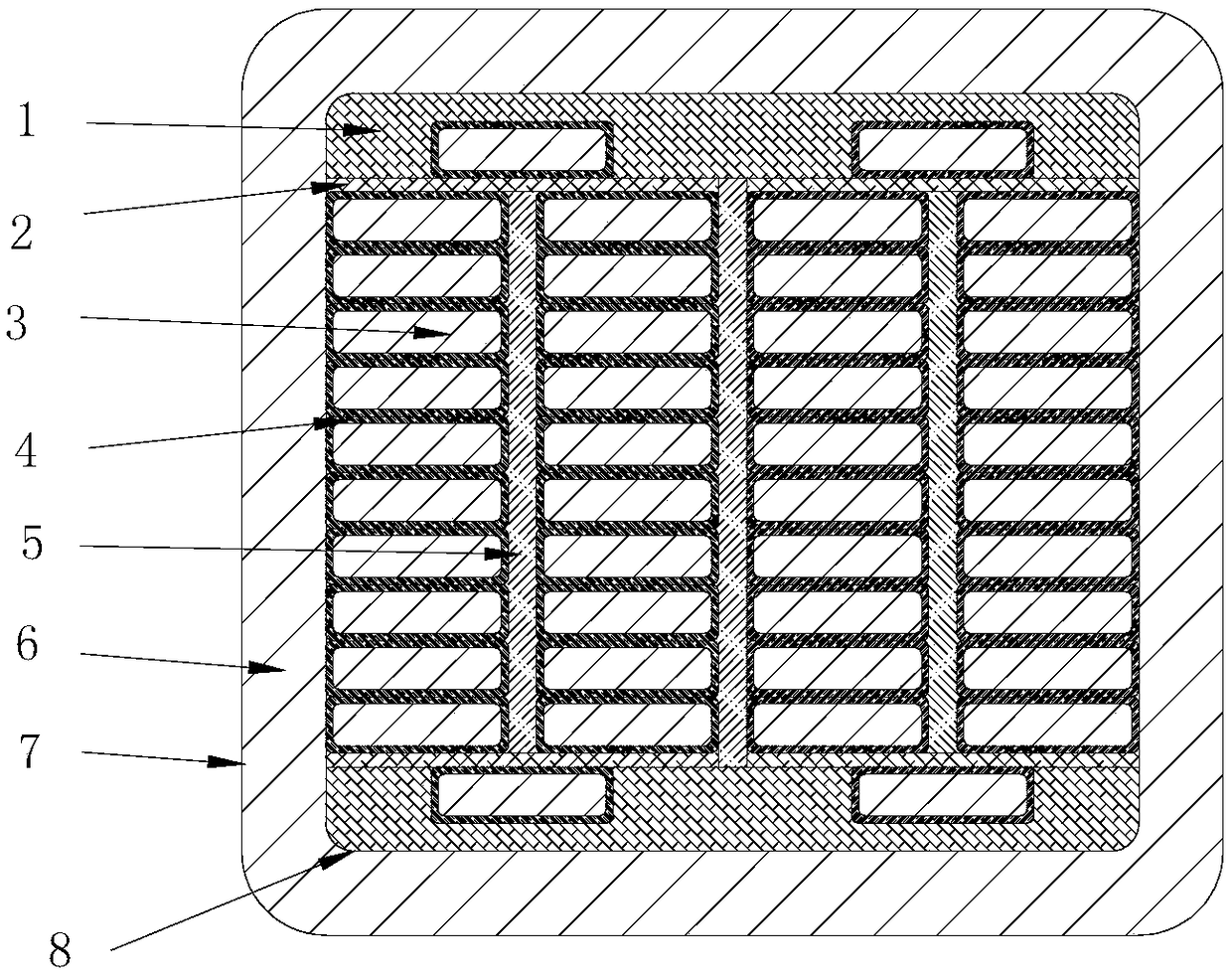

The invention discloses a glass ceramic dielectric with high breakdown strength suitable for usage in high voltage direct current environment and a preparation method thereof, and belongs to the technical field of glass ceramic dielectric. The glass ceramic dielectric comprises a composition of xPbO-yBaO-zSrO-aNb2O5-bNa2O-cSiO2-dR, and x, y, z, a, b, c and d satisfy the relations of: 0<=x<=17.1, 0<=y<=17.5, 0<=z<=14.3, 10.7<=a<=34, 11<=b<=25.4, 28<=c<=47, and 0<=d<=4.5; R represents an auxiliary component, which is at least one selected from MnO2, MgO, CaO and ZnO; and x, y, z, a, b, c and d represent molar ratios. The glass ceramic dielectric provided by the invention has advantages of high breakdown strength, high dielectric constant and good dielectric constant temperature stability, and realizes no pore and direct current breakdown strength higher than 50kV / mm.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Manufacturing method of air-cooled hydrogenerator VPI (Vacuum Pressure Impregnating) stator coil bar

The invention relates to a manufacturing method of an air-cooled unit capacity hydrogenerator VPI (Vacuum Pressure Impregnating) stator coil bar. An inner shielding layer on the surface of a wire canreduce an internal local discharge probability of the wire. After the coil bar is bound with a VPI main insulation layer, a straight-line segment is bound in a half-lapping mode with a layer of low-resistance anti-corona material, then VPI of epoxy anhydride resin is carried out, after impregnation is ended, the end part is respectively bound in a half-lapping mode with medium resistance, medium-high resistance and high resistance segments, and the surface of an anti-corona segment of the end part is bound with two layers of additional insulation layers; after an anti-corona layer is processedwell, the coil bar is assembled into a hot-pressing die, pressurization is carried out, and the coil bar is placed into a baking oven to carry out heating, curing and forming; and after the main insulation layer is cured and formed, a protection layer is brushed with a high-resistance anti-corona paint and a surface coating varnish so as to obtain the finished product VPI stator coil bar. The air-cooled unit capacity hydrogenerator VPI stator coil bar has the main technical performance indexes that: (1) a breakdown voltage of the finished product coil bar is greater than or equal to 5.5UN; and (2) an electrical aging resistance experiment of the coil bar shows that the service life under a voltage of 3.0UN is greater than 40H, and the service life under a voltage of 2.0UN is greater than1,100h.

Owner:HARBIN ELECTRIC MASCH CO LTD

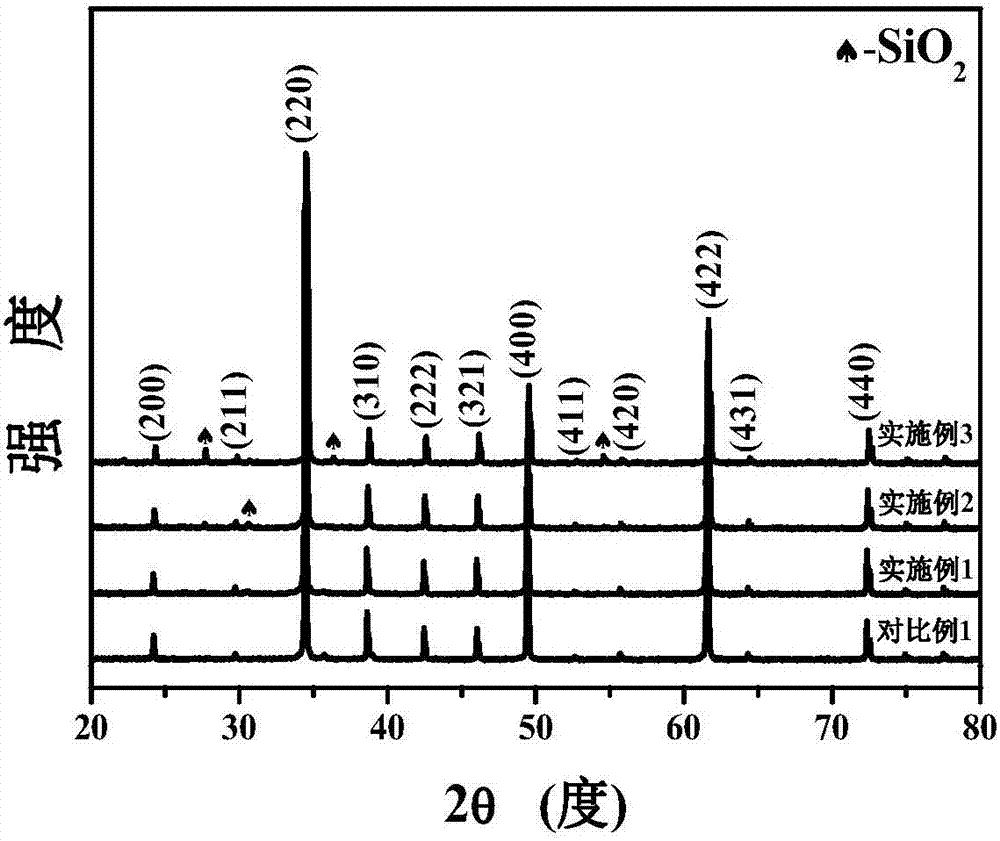

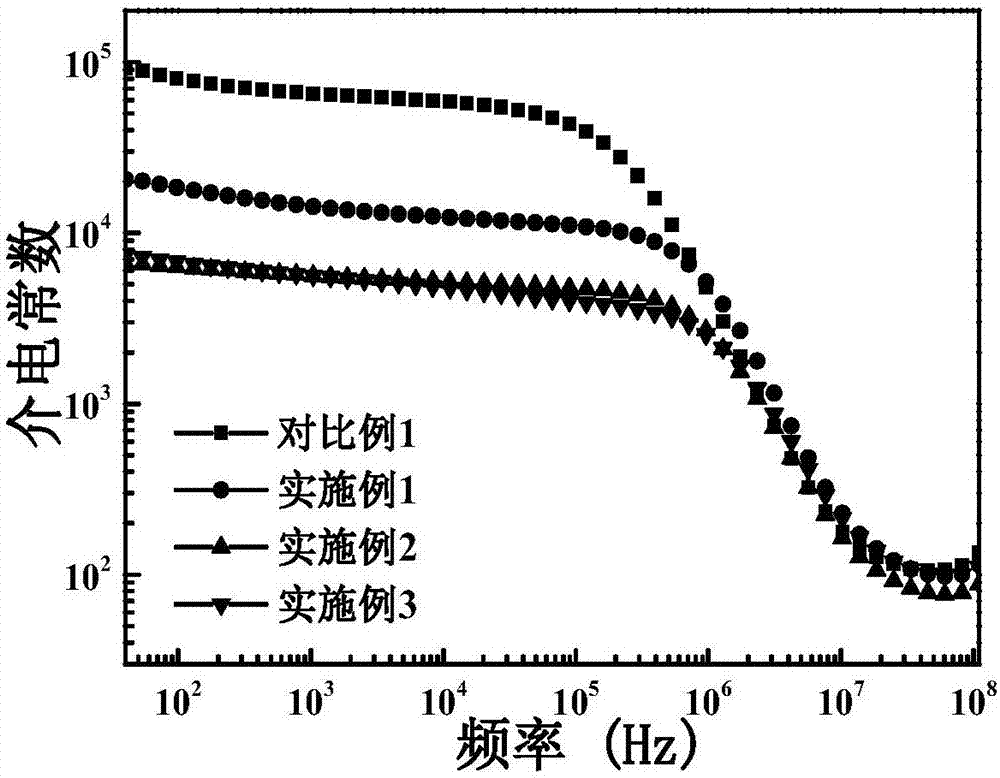

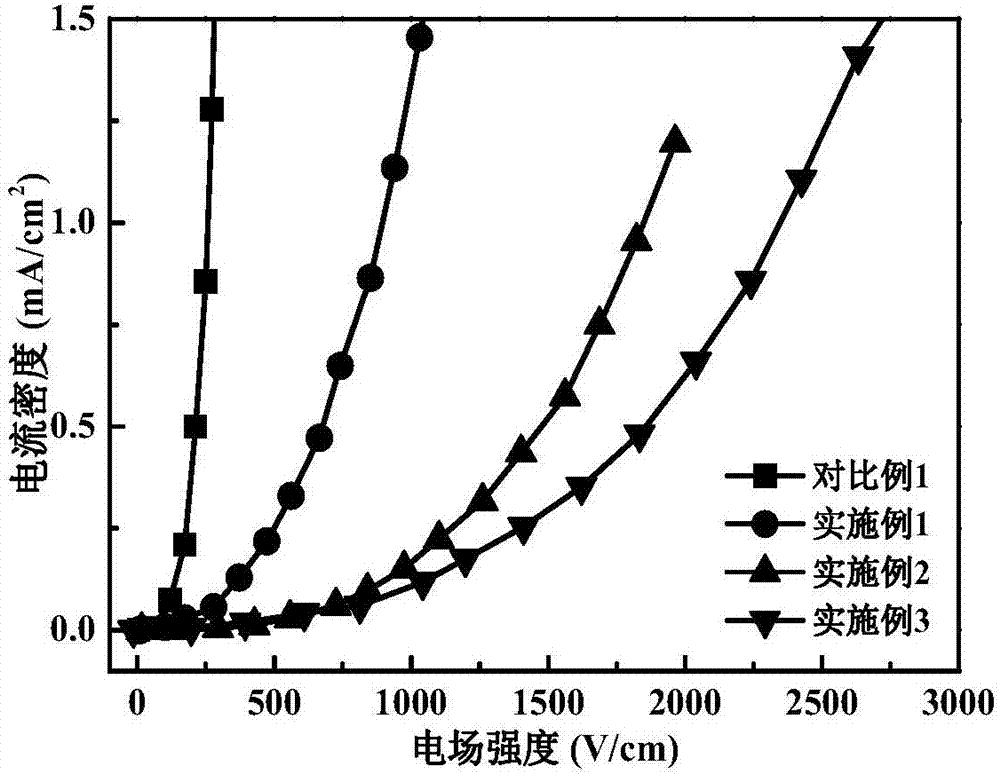

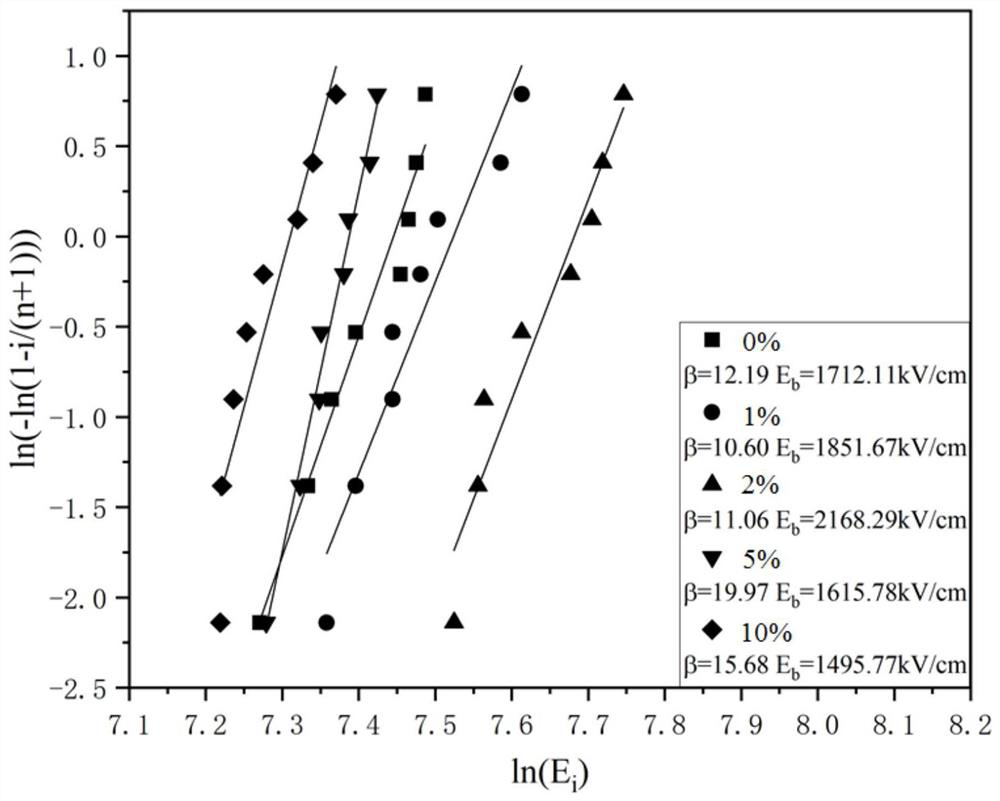

High breakdown field strength and energy storage density silicon dioxide doped cadmium copper titanate giant dielectric ceramic material and preparation method

ActiveCN107188559AEasy to prepareLow reaction temperatureFixed capacitor dielectricStacked capacitorsDielectricReaction temperature

The invention discloses a high breakdown field strength and energy storage density silicon dioxide doped cadmium copper titanate giant dielectric ceramic material and a preparation method. The ceramic material is prepared from materials shown in CdCu3Ti4O12-x wt%SiO2, wherein x ranges from 1.0 to 4.0, Cd(NO3)2.4H2O, Cu(NO3)2.3H2O and Ti(C4H9O)4 serve as raw materials, glacial acetic acid serves as a chelating agent, precursor powder is prepared through a sol-gel method firstly, the precursor powder is calcined at low temperature, CdCu3Ti4O12 ceramic powder which can be mixed on the molecular level and has good uniformity and high activity is obtained, then silicon dioxide powder is added into the ceramic powder, and the silicon dioxide doped cadmium copper titanate giant dielectric ceramic material can be obtained after ball milling, prilling, tableting, glue discharging and sintering. The ceramic material is simple in preparation method, low in reaction temperature, good in repeatability, high in yield and excellent in dielectric performance. The breakdown field strength can reach up to 895-2,353 V / cm, the energy storage density can reach up to 0.712-1.77 mJ / cm<3>, and wide application prospects are achieved.

Owner:SHAANXI NORMAL UNIV

Pulse-direct current alternate mixed anodizing method for anode foil for aluminum electrolytic capacitor

ActiveCN110670105AReduce thermal dissolutionAchieving Alternate AnodizingAnodisationPulse electric fieldMaterials science

The invention discloses a pulse-direct current alternate mixed anodizing method for an anode foil for an aluminum electrolytic capacitor. An aluminum oxide dielectric layer which is compact and higherin breakdown field strength resistance is obtained by arranging aluminum oxide atoms tightly by means of a pulse electric field. Polarization of an electrode caused by rapid changes of upper and lower edges of a current pulse in a pulse process can be eliminated under the direct current electric field, so that the withstand voltage of the anode foil is improved and the leak current of the anode foil is reduced. Compared with a direct current or pulse sample, the specific capacity of the anode foil is increased by 1-10%, the leak current is decreased by 10-50% and the production efficiency isincreased by 10-110% in a same voltage resistant condition.

Owner:XI AN JIAOTONG UNIV

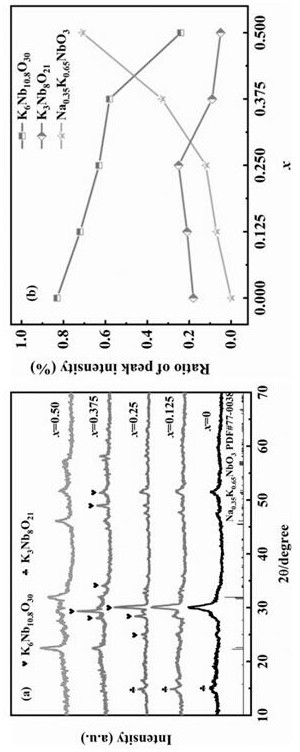

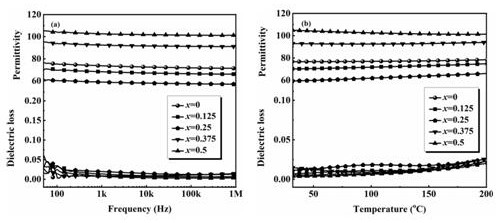

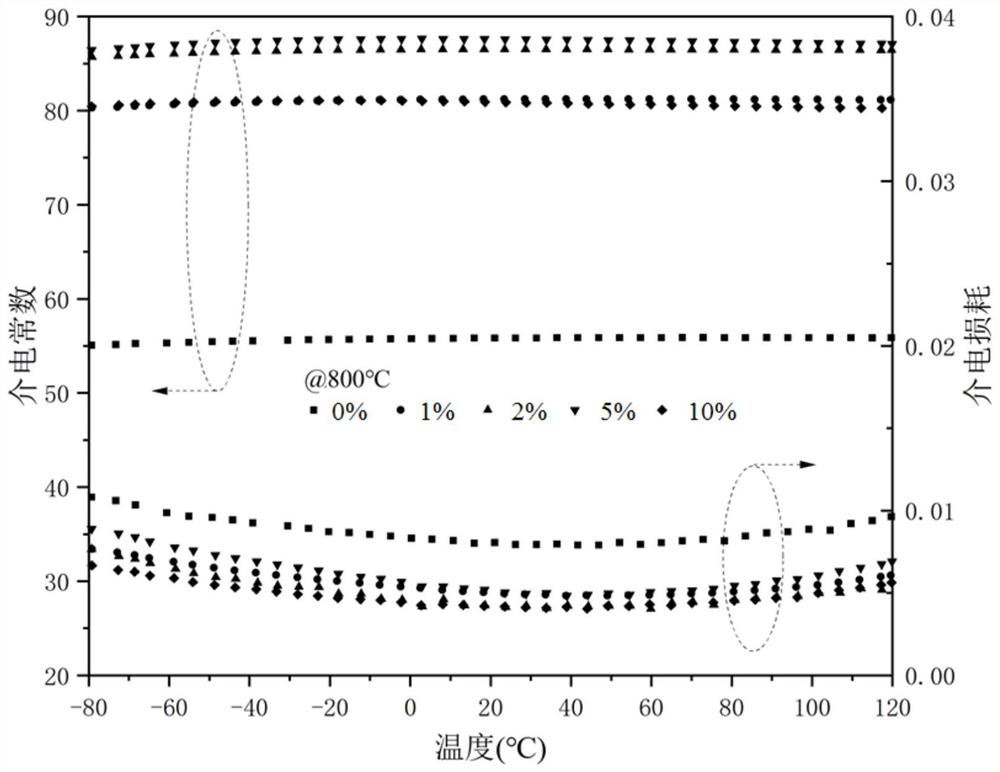

Niobate glass ceramic with alkali metal oxide substitute, low dielectric loss and high energy storage density as well as preparation method and application thereof

ActiveCN112225460AImprove compactnessReduce porosityGlass shaping apparatusAlkali metal oxideHigh energy

The invention relates to a glass ceramic material which substitutes K2ONb2O5SiO2 with alkali metal oxide Na2O and has low dielectric loss and high energy storage density. A preparation method of the material comprises the following steps: firstly, taking K2CO3, Na2CO3, Nb2O5 and SiO2 as raw materials according to a chemical formula of 40[(1-x)K2O-xNa2O]-40Nb2O5-20SiO2 (the x is less than or equalto 0.500), uniformly mixing the powder through mechanical ball milling, and performing annealing; and performing melting, cooling molding and annealing to obtain a glass block, and performing heat preservation at 800 DEG C for 2 h, and performing crystallization treatment to obtain the glass ceramic material. The method is simple in preparation process, the raw materials are low in price, the manufacturing cost is low, a linear hysteresis loop can be obtained at the room temperature, the energy storage density reaches 2.44 J / cm<3> to the maximum, the dielectric loss is lower than 0.02, and theenergy storage efficiency is guaranteed to be 94% or above at the high temperature of 200 DEG C.

Owner:SHAANXI UNIV OF SCI & TECH

Method for preparing BCZT energy-storing ceramic material with adjustable Curie temperature

InactiveCN110600266ALow Curie temperatureHigh energy storage densityFixed capacitor dielectricSilver pasteSilver electrode

The invention discloses a method for preparing a BCZT energy-storing ceramic material with adjustable Curie temperature, comprising: preparing a solution in which the ratio of metal ions to Ba0.85Ca0.15Zr0.1Ti0.93 is 1.25: 1, and adjusting a pH value, and preparing a sol by heating; drying the sol in a blast drying box and grinding the sol into powders; calcining the prepared powders in a muffle furnace into BCZT oxide powders; grinding and granulating the BCZT oxide powders, and then sintering the BCZT oxide powders in the muffle furnace; finally, coating the sintered ceramic material with silver paste on both sides, and sintering and solidifying the ceramic material at a certain temperature to form a metal silver electrode. The method, by using the Ba0.85Ca0.15Zr0.1Ti0.9O3 ceramic material prepared by a sol-gel method, effectively regulates the Curie temperature of the BCZT ferroelectric ceramic material to the vicinity of room temperature, and is simple in process, low in cost, andhigh in energy storage density and efficiency.

Owner:HENAN NORMAL UNIV

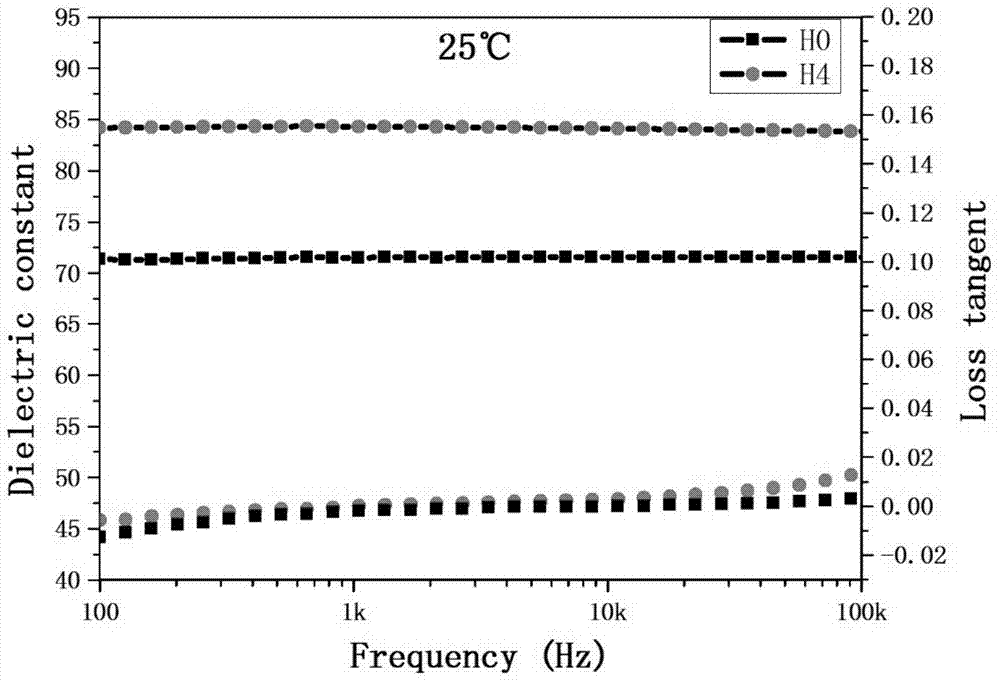

Energy storage niobate microcrystalline glass dielectric material and preparation method thereof

The invention relates to an energy storage niobate microcrystalline glass dielectric material and a preparation method thereof. The preparation method comprises the following steps of: preparing BaCO3, SrCO3, Na2CO3, Nb2O5, SiO2, B2O3, TiO2 and BaF2 serving as initial raw materials in a ratio of aNa2O3, bSrO, cBaO, dNb2O5, eSiO2, fB2O3 and gXY2 (X is Ti or Ba, and Y is O or F), ball-milling and mixing for 6 hours, drying, melting at the high temperature of between 1,530 and 1,550 DEG C for 2 to 3 hours, quickly cooling, annealing to obtain high-density uniform glass, and performing controlled crystallization at a certain temperature to obtain the microcrystalline glass dielectric material. The relative dielectric constant of the microcrystalline glass dielectric prepared by the method is adjustable in the range of 30 to 100, and the maximum direct-current breakdown field strength is 1,500kV / cm.

Owner:GUILIN UNIV OF ELECTRONIC TECH

A ta with low dielectric loss 2 o 5 Doped niobate-based glass-ceramic material and its preparation method and application

ActiveCN112390535BHigh dielectric constantHigh breakdown strengthHybrid capacitor separatorsGlass shaping apparatusBreakdown strengthCeramic composite

Owner:TONGJI UNIV

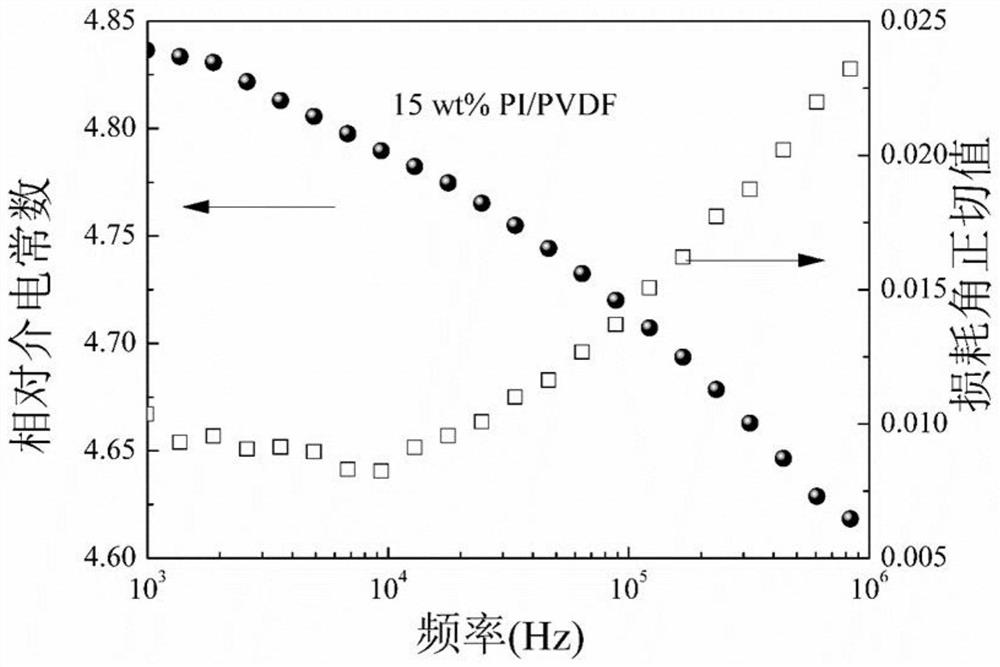

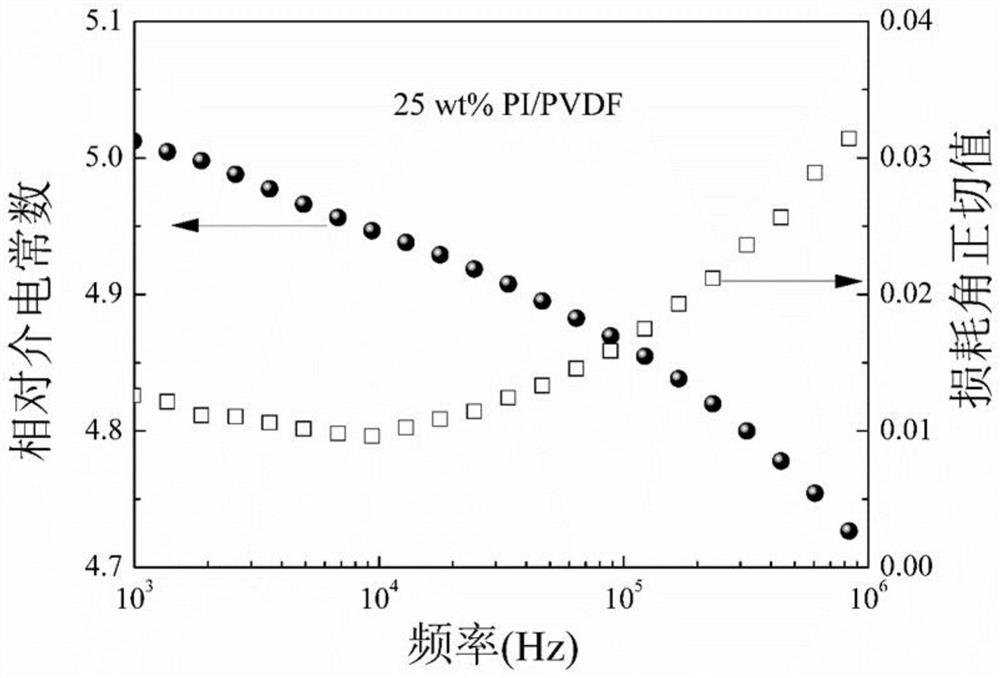

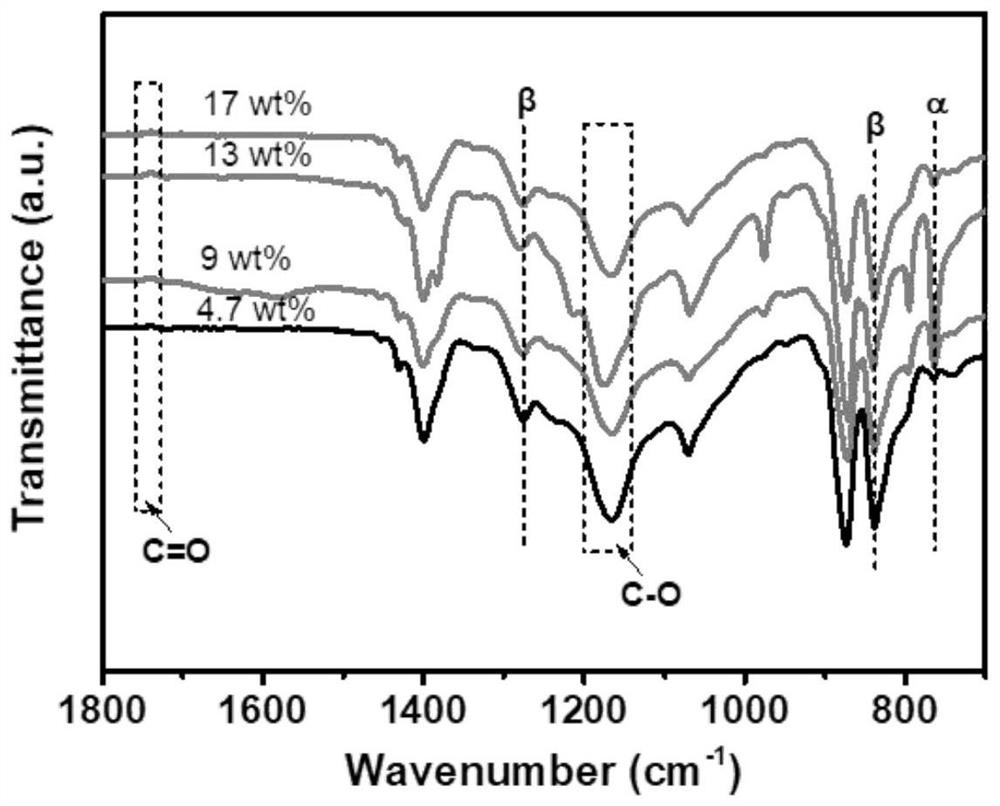

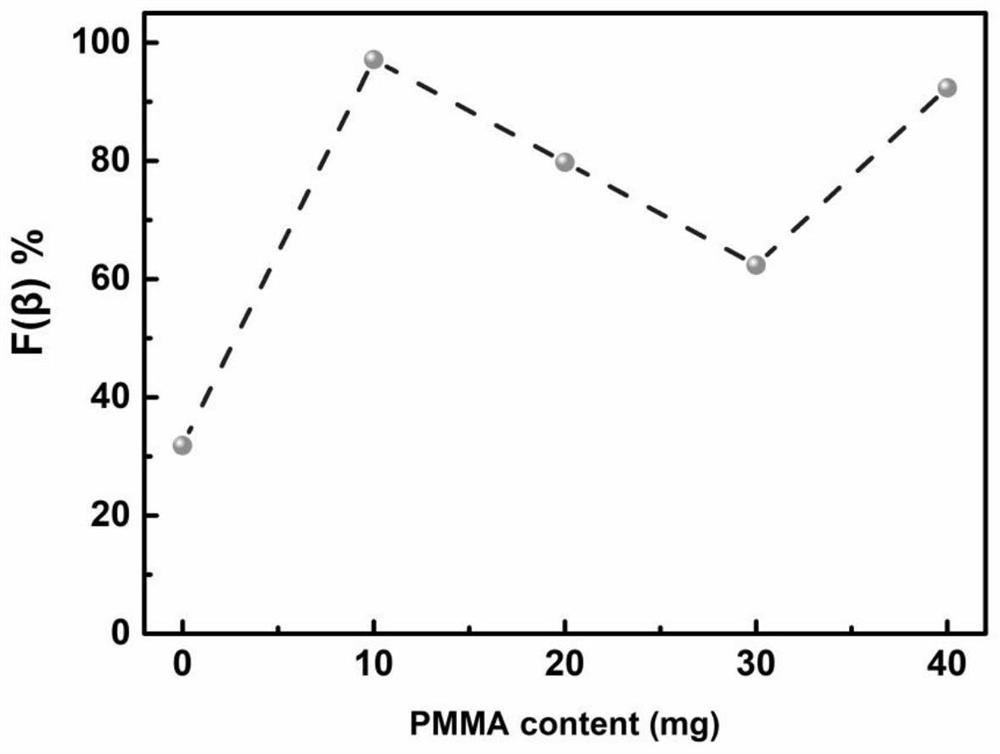

Preparation method of high-dielectric PI/PVDF composite film

PendingCN114736408ASimple preparation processAvoid energy consumptionPolyvinylidene fluorideThin membrane

The invention discloses a preparation method of a high-dielectric polyimide / polyvinylidene fluoride (PI / PVDF) composite film. The preparation method comprises the following steps: firstly, preparing a PI precursor from 4, 4 '-diaminodiphenyl ether and pyromellitic dianhydride, then adding PVDF into the PI precursor in batches, and carrying out low-temperature thermal imidization in a temperature range of 80-200 DEG C; the method can avoid introduction of holes caused by separation of PI and PVDF due to high-temperature treatment, and is an effective method for preparing the PI / PVDF composite film with high dielectric constant and high dielectric strength. Compared with a traditional pure PI film prepared through high-temperature (200 DEG C or above) thermal imidization, when the test frequency is 1000 Hz, the relative dielectric constant of the PI / PVDF composite film with the mass fraction of 15% can reach 4.68 and is 1.51 times that of pure PI; and the energy storage density is 2.68 Joules / cubic centimeter and is 1.49 times of that of pure PI.

Owner:HARBIN UNIV OF SCI & TECH

Method for enhancing ohmic contact of gallium oxide semiconductor device

ActiveCN107993934BLower the barrierReduce the impact of exposureSemiconductor devicesDevice materialOxygen vacancy

The invention provides a method for improving gallium oxide semiconductor device ohmic contact. The method comprises the steps of conducting plasma etching surface treatment on a gallium oxide semiconductor and adjusting the roughness and oxygen vacancy on the surface of the gallium oxide semiconductor by controlling an etching technology, so that the surface roughness is within 1 micrometer, andthe oxygen vacancy is improved; growing a metal layer with a corresponding power function on the gallium oxide semiconductor after being subjected to the plasma etching surface treatment to form a semiconductor device with the ohmic contact. By means of the method, application and popularization of a gallium oxide material are facilitated; besides, according to a plasma etching method, the ohmic contact is improved to be not limited to the gallium oxide material, and the method can also be expanded and applied to other semiconductor devices.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

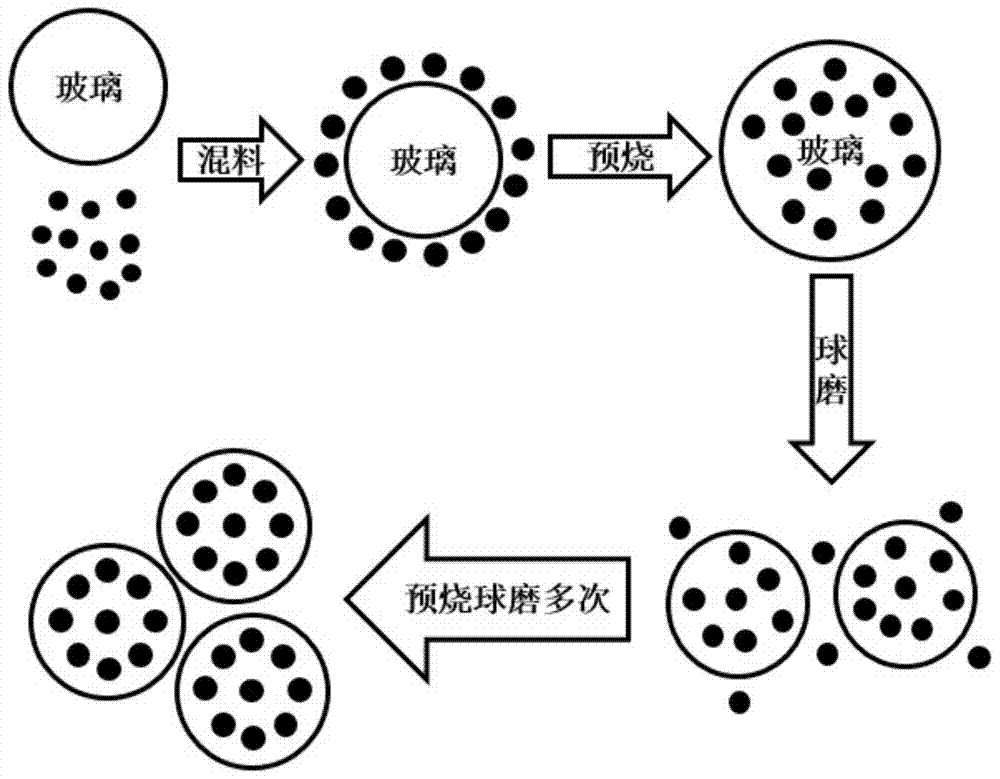

A kind of preparation method of glass/ceramic nanocomposite material

ActiveCN105174972BOvercome the disadvantage of high costHigh breakdown fieldDielectricMaterials preparation

The invention discloses a method for preparing a glass / ceramic nanocomposite material, which belongs to the field of material preparation. After mixing the glass powder with the nano-ceramic dielectric powder, ball-milling and drying, and then going through at least one "pre-firing, ball-milling" process, the glass powder can be evenly coated with the nano-ceramic dielectric powder, and the breakdown field strength of the composite material can be improved; Wherein, the pre-firing temperature is higher than the glass softening point temperature and lower than the sintering temperature of the nano-ceramic medium powder. The glass in the composite material prepared by the method of the invention can evenly cover ceramic particles, and the composite material has low loss and high breakdown field strength, and can be used as a high-voltage high-energy storage density capacitor; the preparation method is simple and pollution-free; the sol is overcome The disadvantage of the high cost of the gel method is suitable for industrialized mass production.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

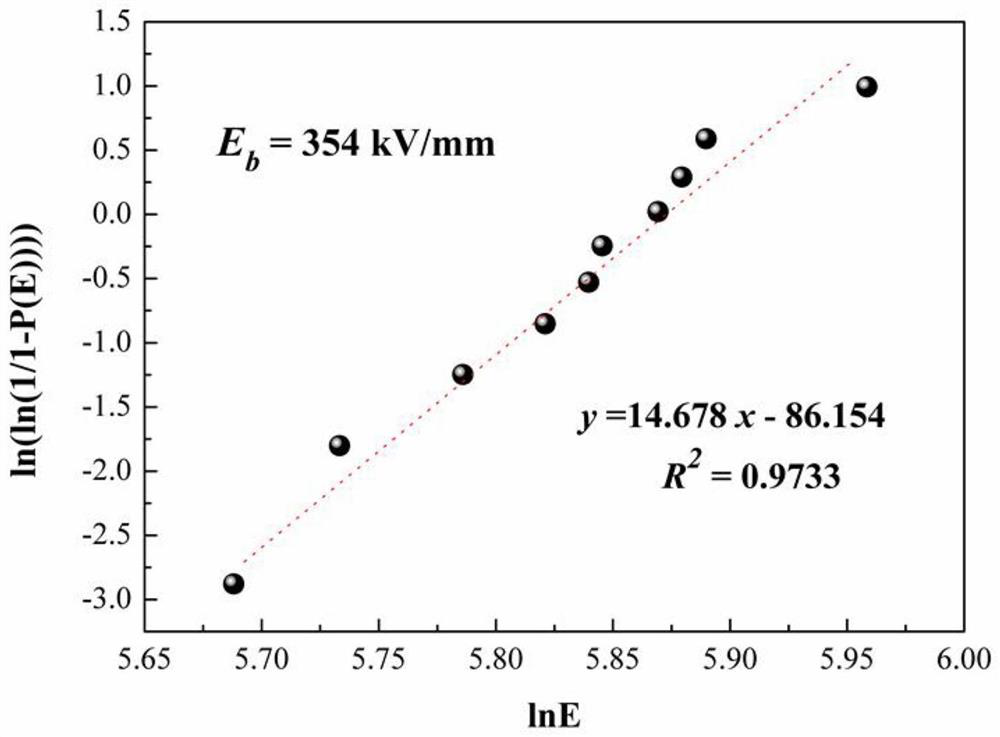

Rare earth doped niobate-based glass ceramic material with high energy storage density and preparation method and application thereof

InactiveCN111410426AHigh dielectric constantHigh energy storage densityHigh energyDielectric permittivity

The invention relates to a rare earth doped niobate-based glass ceramic material with high energy storage density and a preparation method and application thereof. The material is 21.6BaCO3-2.4Bi2O3-6Na2CO3-30Nb2O5-40SiO2-xR2O3-yMnO2, the preparation method comprises the following steps: uniformly mixing the raw materials, and sequentially carrying out high-temperature melting, slicing and controlled crystallization to obtain the niobate-based glass ceramic material. The prepared material can be used as an energy storage capacitor material. Compared with the prior art, the glass ceramic energystorage material prepared by the invention has the advantages of high dielectric constant (-107), high breakdown field strength (-2158.14 kV / cm), high energy storage density (-22.06 J / cm <3>), low loss (-0.003), good temperature stability and the like.

Owner:TONGJI UNIV

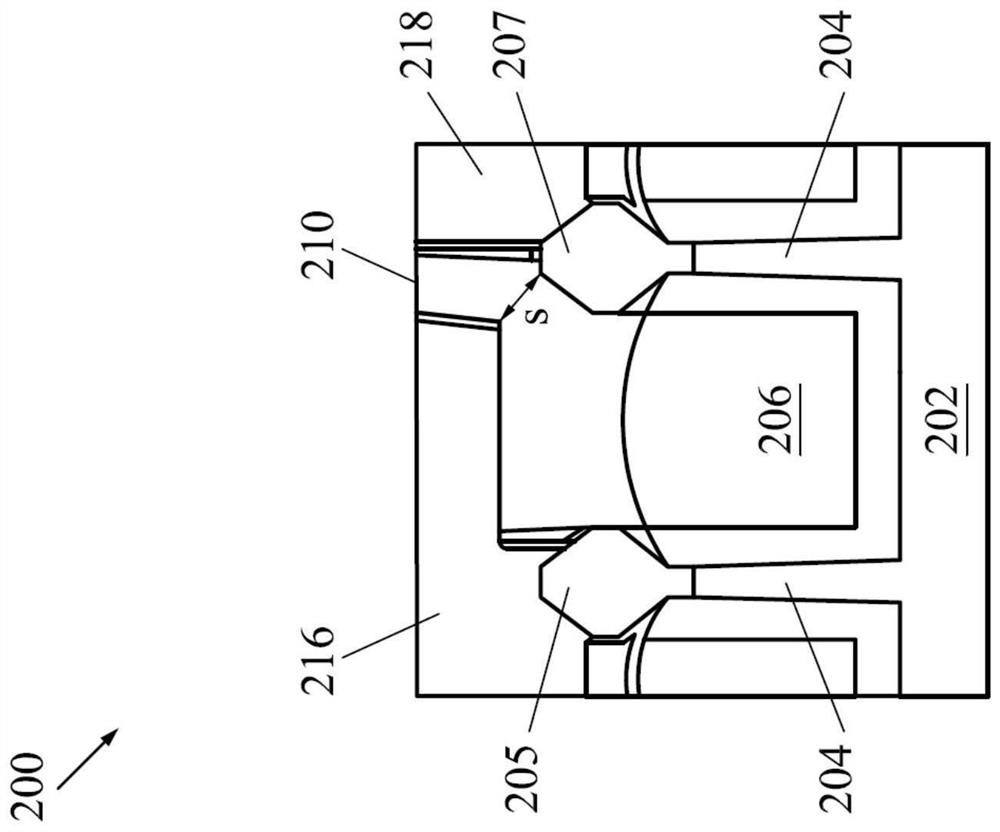

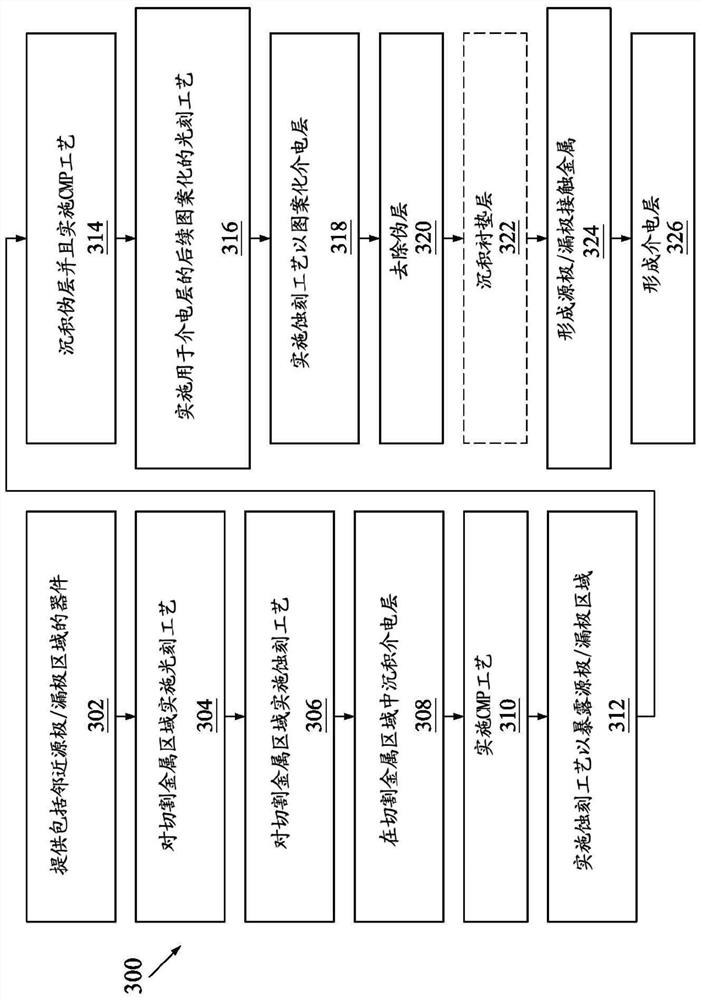

Semiconductor device and method for manufacturing the same

ActiveCN112018035AIncrease distanceHigh breakdown fieldTransistorSolid-state devicesDevice materialMaterials science

A method and structure directed to providing a source / drain isolation structure. The method includes providing a device having a first source / drain region adjacent to a second source / drain region. A masking layer is deposited between the first and second source / drain regions and over an exposed first part of the second source / drain region. After depositing the masking layer, a first portion of anILD layer disposed on either side of the masking layer is etched, without substantial etching of the masking layer, to expose a second part of the second source / drain region and to expose the first source / drain region. After etching the first portion of the ILD layer, the masking layer is etched to form an L-shaped masking layer. After forming the L-shaped masking layer, a first metal layer is formed over the exposed first source / drain region and a second metal layer is formed over the exposed second part of the second source / drain region. Embodiments also relate to a semiconductor device anda method for manufacturing the same.

Owner:TAIWAN SEMICON MFG CO LTD

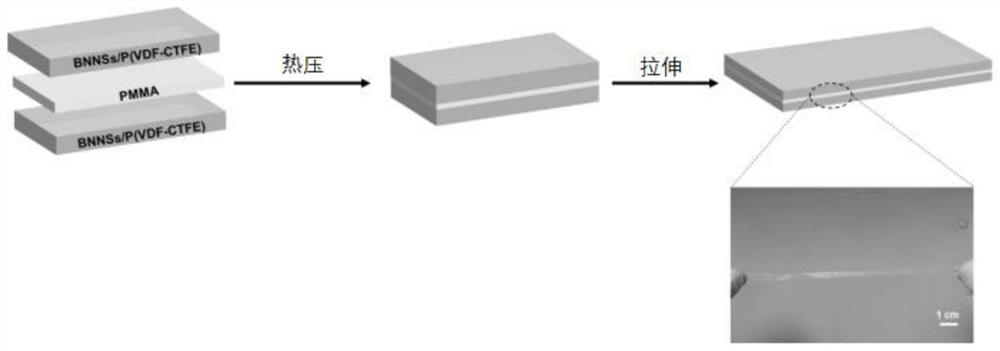

Sandwich structure P (VDF-CTFE) composite film and preparation method thereof

PendingCN114103336AActs as a surface modifying fillerGood dispersionSynthetic resin layered productsFlat articlesPolymer scienceComposite film

The invention discloses a P (VDF-CTFE) composite film with a sandwich structure and a preparation method of the P (VDF-CTFE) composite film. The P (VDF-CTFE) composite film with the sandwich structure comprises two BNNSs / P (VDF-CTFE) film layers and a PMMA (Polymethyl Methacrylate) layer clamped between the two film layers; in the BNNSs / P (VDF-CTFE) thin film layer, a copolymer HBPE-g-PMMA is adsorbed on the surfaces of the BNNSs through electrostatic force, and the BNNSs are uniformly dispersed in the P (VDF-CTFE) and are arranged in an oriented manner; the mass ratio of the BNNSs to the P (VDF-CTFE) is 0.1 to 1 percent by weight; the thickness of the BNNSs / P (VDF-CTFE) thin film layer ranges from 5 micrometers to 20 micrometers, and the thickness of the PMMA layer ranges from 0.5 micrometer to 5 micrometers. The sandwich structure P (VDF-CTFE) composite film prepared by the invention has the advantages of higher dielectric constant, low dielectric loss and high breakdown field strength, and keeps good flexibility at the same time.

Owner:ZHEJIANG UNIV OF TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com