A kind of preparation method of glass/ceramic nanocomposite material

A nanocomposite material and technology of composite materials are applied in the field of preparation of glass/ceramic nanocomposite materials, which can solve the problems of reducing the uniformity of material components, unfavorable batch preparation of powder, deterioration of material properties, etc., and achieves low loss and preparation method. Simple, high breakdown field strength effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

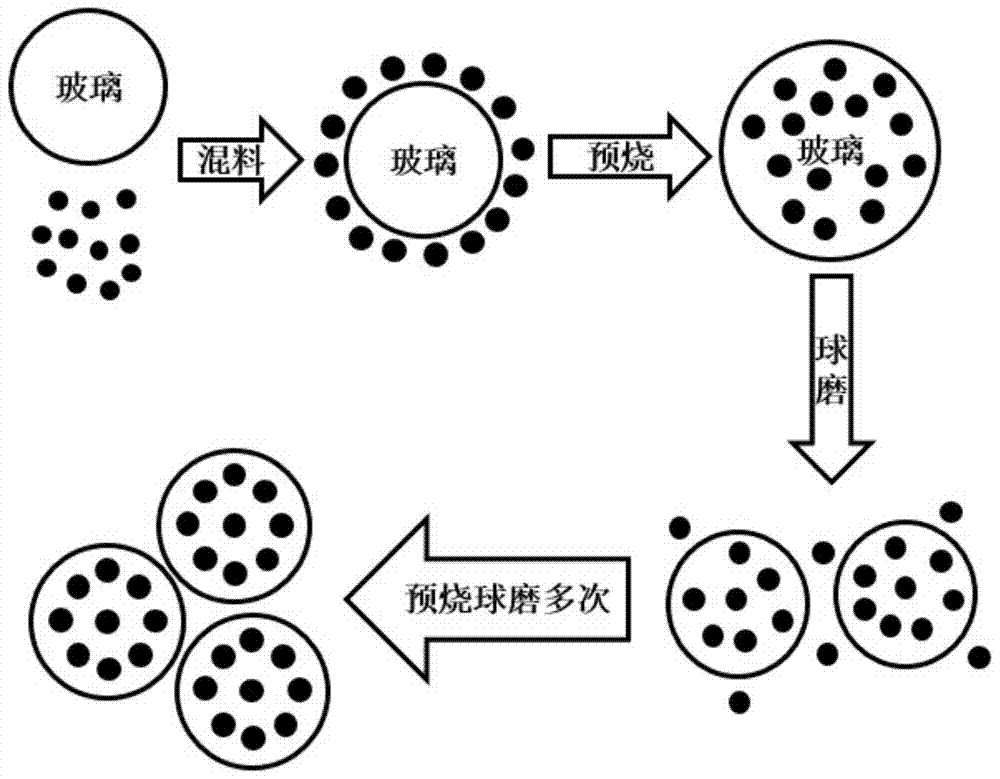

[0048] A method for preparing glass / ceramic nanocomposite material specifically includes the following steps:

[0049] Step 1: According to the glass: 21mol% BaO, 15mol% B 2 O 3 , 5mol% Al 2 O 3 , 59mol% SiO 2 The ratio of the precursor Ba(NO 3 )(99.5%), H 3 BO 3 (99.5%), Al(NO 3 ) 3 ·9H 2 O (99%) and high-purity quartz sand (99.99%), then put the above precursors into a ball mill tank containing deionized water, ball mill for 24 hours, and then discharge and dry;

[0050] Step 2: Put the powder obtained in step 1 into the crucible of the melting furnace, firstly increase the temperature from room temperature to 1200°C at a heating rate of 15°C / min, and then increase the temperature from 1200°C to 1550°C at a heating rate of 8°C / min At this time, it is the clarification temperature of the glass and quenched at a high temperature to obtain a glass block; the block is mechanically crushed, then ball milled for 72 hours, and finally passed through a 300 mesh sieve to obtain glass powde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breakdown field strength | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| breakdown field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com