Method for improving gallium oxide semiconductor device ohmic contact

A technology of ohmic contact and semiconductor, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of large power loss of gallium oxide power devices, large ohmic contact resistance, and inability to realize industrialization, etc., to achieve popularization and use, high impact The effect of strong field penetration and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

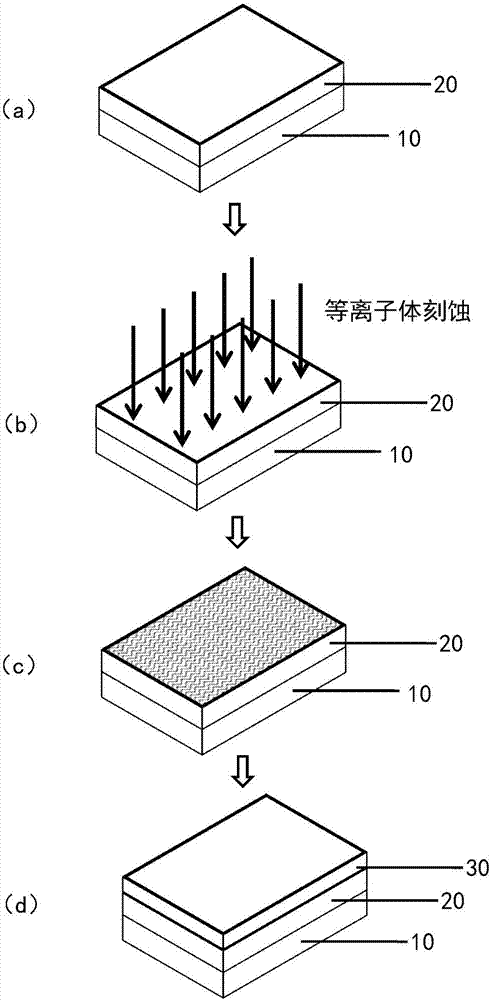

[0027] The present disclosure provides a method for enhancing the ohmic contact of a gallium oxide semiconductor device. The plasma etching technology is used to treat the surface of the gallium oxide semiconductor device, and the roughness, oxygen dangling bonds, Oxygen vacancies and other parameters make the subsequent metal deposited on the gallium oxide semiconductor form a very thin tunnel oxide layer, reduce the Schottky barrier, weaken the influence of the Schottky contact, enhance the ohmic contact, and reduce the Contact resistance. This method is helpful to promote the use of gallium oxide materials. In addition, the use of plasma etching to improve ohmic contacts is not limited to gallium oxide materials, and can also be extended to other semiconductor devices.

[0028] In order to make the purpose, technical solutions and advantages of the present disclosure clearer, the present disclosure will be further described in detail below in conjunction with specific embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com