Method for preparing BCZT energy-storing ceramic material with adjustable Curie temperature

A technology of Curie temperature and ceramic materials, which is applied in fixed capacitance parts, electrical components, fixed capacitor dielectrics, etc., can solve the problem of miniaturization and light weight of unfavorable energy storage components, restrictions on the application range of dielectric capacitors, nonlinear dielectric materials Poor stability and other problems, to achieve the effect of refining the hysteresis loop, improving energy storage density and energy storage efficiency, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

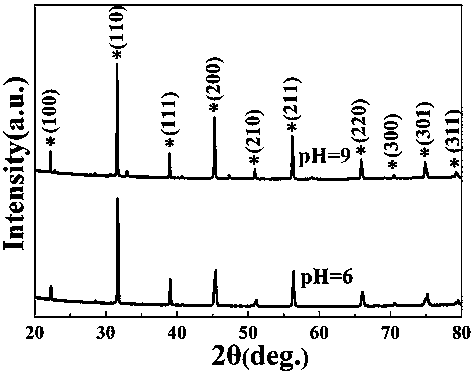

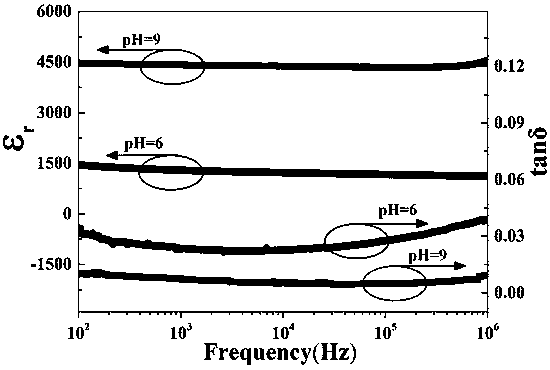

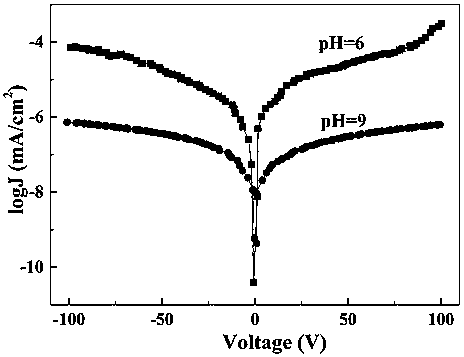

Embodiment 1

[0028] Step S1: Ba(NO 3 ) 2 , Ca(NO 3 ) 2 4H 2 O, ZrOCl 2 ·8H 2 O, tetrabutyl titanate, ammonia and citric acid are the initial raw materials, wherein according to Ba 0.85Ca 0.15 Zr 0.1 Ti 0.9 o 3 The stoichiometric ratio of the raw material Ba(NO 3 ) 2 , Ca(NO 3 ) 2 4H 2 O, ZrOCl 2 ·8H 2 O and tetrabutyl titanate;

[0029] Step S2: Dissolve tetrabutyl titanate and citric acid in 10 mL and 30 mL of ethanol respectively, stir each until completely dissolved, then drop the ethanol solution of tetrabutyl titanate into the ethanol solution of citric acid to obtain a mixed solution A, the mol ratio of citric acid and metal cation in mixed solution A is 1.25:1;

[0030] Step S3: Zr(NO 3 ) 4 ·5H 2 O, Ca(NO 3 ) 2 4H 2 O and Ba(NO 3 ) 2 Dissolve in 30mL deionized water and heat to 80°C and stir until completely dissolved to obtain mixed solution B;

[0031] Step S4: Add the mixed solution B obtained in step S3 dropwise to the mixed solution A obtained in step...

Embodiment 2

[0038] Step S1: with Ba(NO 3 ) 2 , Ca(NO 3 ) 2 4H 2 O, ZrOCl 2 ·8H 2 O, tetrabutyl titanate, ammonia and citric acid are the initial raw materials, wherein according to Ba 0.85 Ca 0.15 Zr 0.1 Ti 0.9 o 3 The stoichiometric ratio of the raw material Ba(NO 3 ) 2 , Ca(NO 3 ) 2 4H 2 O, ZrOCl 2 ·8H 2 O and tetrabutyl titanate;

[0039] Step S2: Dissolve tetrabutyl titanate and citric acid in 10 mL and 30 mL of ethanol respectively, stir each until completely dissolved, then drop the ethanol solution of tetrabutyl titanate into the ethanol solution of citric acid to obtain a mixed solution A, the mol ratio of citric acid and metal cation in mixed solution A is 1.25:1;

[0040] Step S3: Zr(NO 3 ) 4 ·5H 2 O, Ca(NO 3 ) 2 4H 2 O and Ba(NO 3 ) 2 Dissolve in deionized water and heat and stir until completely dissolved to obtain mixed solution B;

[0041] Step S4: Add the mixed solution B obtained in step S3 dropwise to the mixed solution A obtained in step S2 to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy density | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com