A kind of preparation method of micron flaky lead zirconate titanate crystal

A lead zirconate titanate, flake-shaped technology, applied in the field of piezoelectric ceramics, can solve the problems of high success rate and strong stability, and achieve the effect of high orientation degree and large diameter-thickness ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

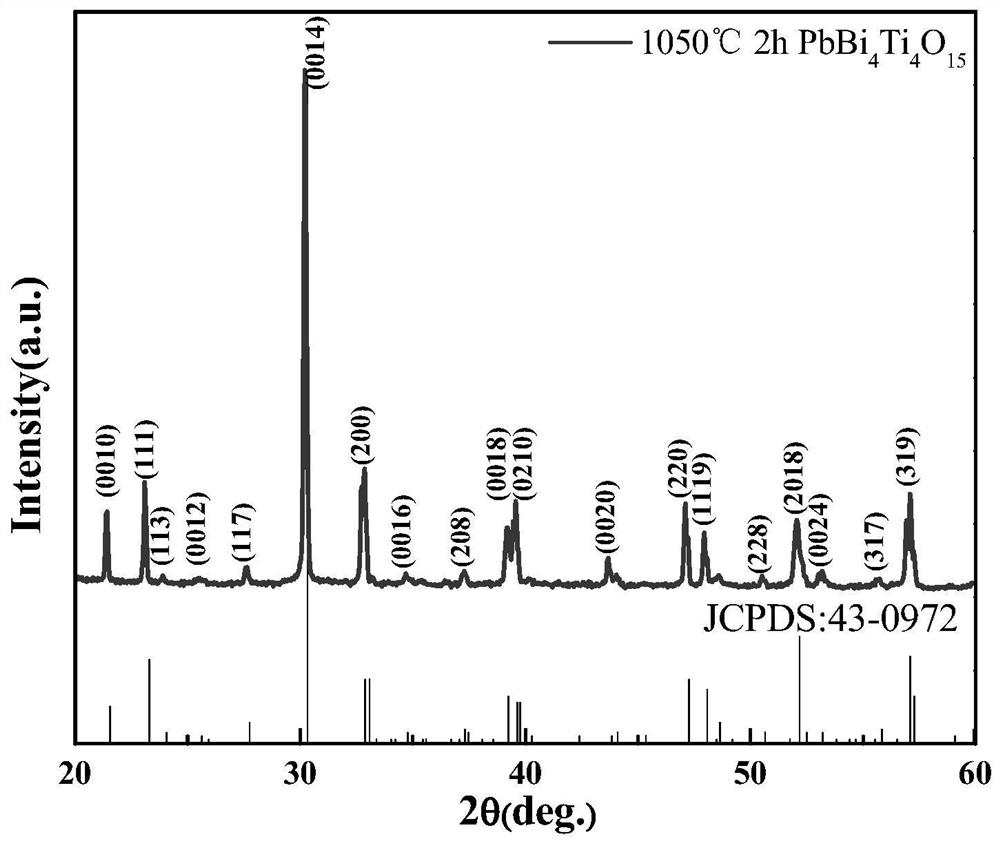

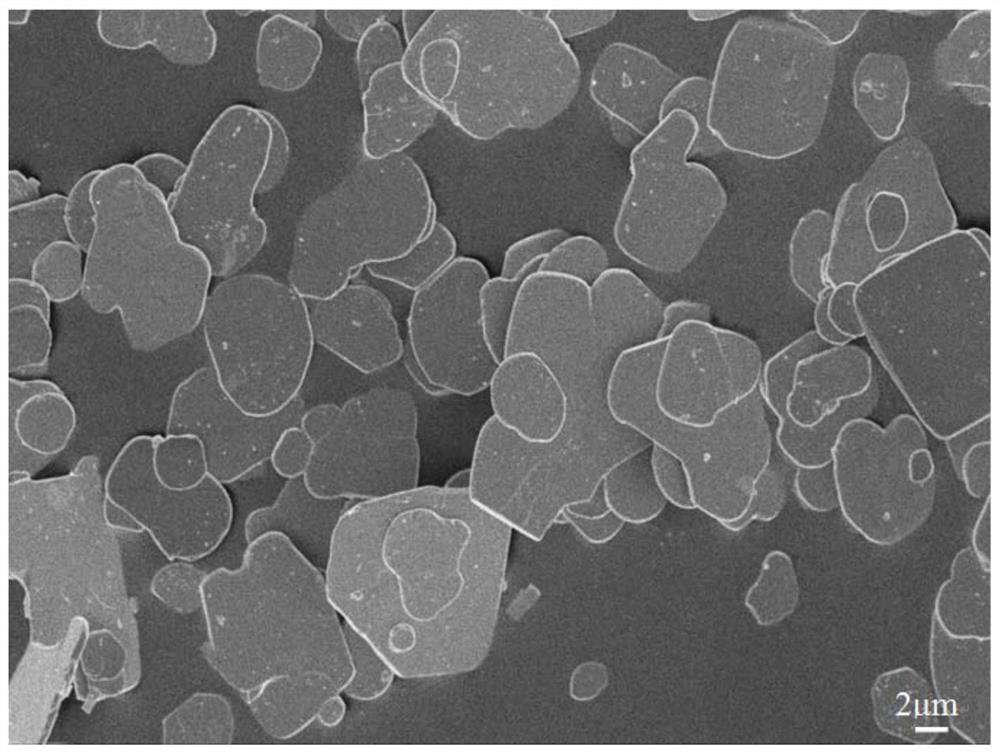

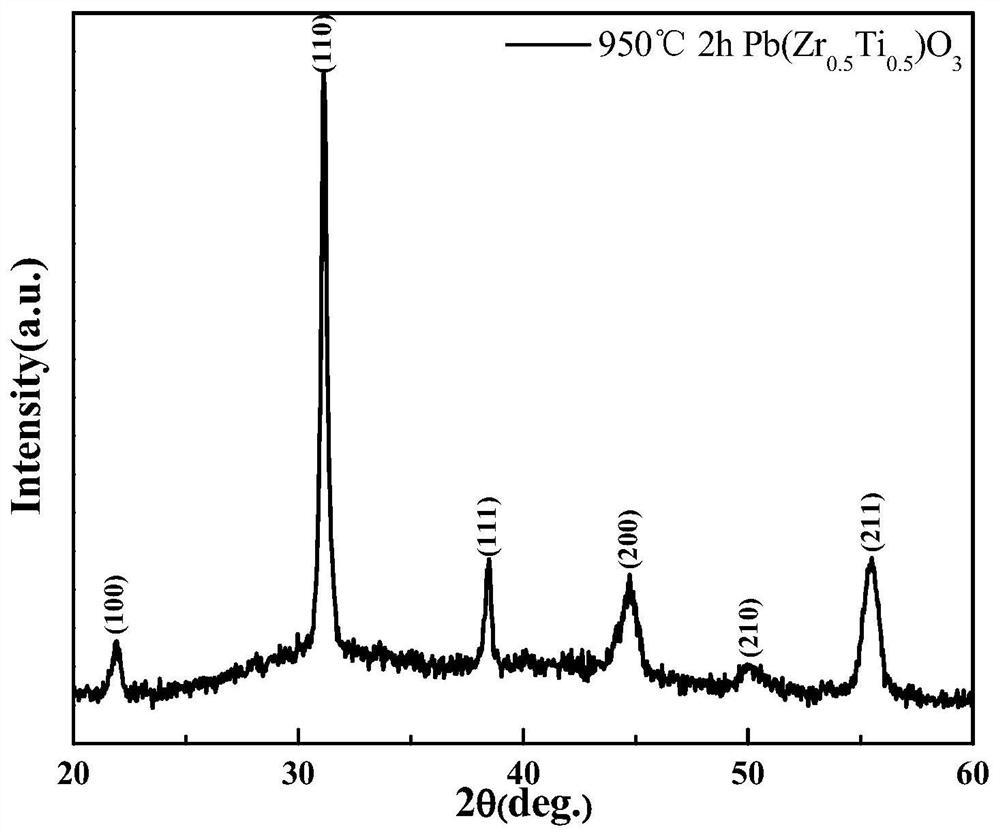

[0029] Preparation of flake PbBi 4 Ti 4 o 15 Precursor.

[0030] Strictly according to PbO: Bi 2 o 3 : TiO 2 =1:2:4 molar ratio ingredients, weigh PbO (purity: 99.9%) 2.2342g, Bi 2 o 3 (Purity: 99%) 9.4133g, TiO 2 (purity: 99.8%) 3.2024g, dry after ball milling and mixing 12h under dehydrated ethanol medium; Add flux KCl (purity: 99.5%) 14.9245g in the mixed material after drying again, under dehydrated ethanol medium Dry after magnetic stirring for 4 hours; then put the material after the second drying in Al 2 o 3 In the crucible, cover it, keep it warm at 1050°C for 2h, and then lower it to room temperature, with a heating rate of 2°C / min and a cooling rate of 2°C / min; the burnt product after the reaction is repeatedly washed and filtered in hot deionized water until it is used AgNO 3 The reagent detects the filtrate, and Cl cannot be detected in the filtrate - , the washing is completed; finally, the cleaned powder is dried to obtain the required PbBi 4 Ti 4 o...

Embodiment 2

[0033] Preparation of flake PbBi 4 Ti 4 o 15 Precursor.

[0034] Strictly according to PbO: Bi 2 o 3 : TiO 2 =1:2:4 molar ratio ingredients, weigh PbO (purity: 99.9%) 2.2342g, Bi 2 o 3 (Purity: 99%) 9.4133g, TiO 2 (purity: 99.8%) 3.2024g, dry after ball milling and mixing 12h under dehydrated ethanol medium; Add flux KCl (purity: 99.5%) 14.9245g in the mixed material after drying again, under dehydrated ethanol medium Dry after magnetic stirring for 4 hours; then put the material after the second drying in Al 2 o 3 In the crucible, cover it, keep it warm at 1000°C for 2h, and then lower it to room temperature with a heating rate of 2°C / min and a cooling rate of 2°C / min; the burnt product after the reaction is repeatedly washed and filtered in hot deionized water until it is used AgNO 3 The reagent detects the filtrate, and Cl cannot be detected in the filtrate — , the washing is completed; finally, the cleaned powder is dried to obtain the required PbBi 4 Ti 4 o ...

Embodiment 3

[0036] Preparation of flake PbBi 4 Ti 4 o 15 Precursor.

[0037] Strictly according to PbO: Bi 2 o 3 : TiO 2 =1:2:4 molar ratio ingredients, weigh PbO (purity: 99.9%) 2.2342g, Bi 2 o 3 (Purity: 99%) 9.4133g, TiO 2 (purity: 99.8%) 3.2024g, dry after ball milling and mixing 12h under dehydrated ethanol medium; Add flux KCl (purity: 99.5%) 14.9245g in the mixed material after drying again, under dehydrated ethanol medium Dry after magnetic stirring for 4 hours; then put the material after the second drying in Al 2 o 3 In the crucible, cover it, keep it warm at 1100°C for 2h, then lower it to room temperature, the heating rate is 2°C / min, the cooling rate is 2°C / min; the burnt product after the reaction is repeatedly washed and filtered in hot deionized water until it is used AgNO 3 The reagent detects the filtrate, and Cl cannot be detected in the filtrate — , the washing is completed; finally, the cleaned powder is dried to obtain the required PbBi 4 Ti 4 o 15 cry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com