Rare earth doped niobate-based glass ceramic material with high energy storage density and preparation method and application thereof

A technology of high energy storage density and glass ceramics, which is applied in the field of dielectric energy storage materials, can solve the problems of low energy storage density of energy storage materials, achieve the effects of simple preparation method, increase energy storage density, and reduce defect concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] A method for preparing a rare earth-doped niobate-based glass-ceramic material with high energy storage density, comprising the following steps:

[0041] 1) with BaCO 3 、 Bi 2 o 3 、Na 2 CO 3 , Nb 2 o 5 , SiO 2 , R 2 o 3 , MnO 2 As raw material, the molar ratio is 21.6BaCO 3 -2.4Bi 2 o 3 -6Na 2 CO 3 -30Nb 2 o 5 -40SiO 2 -xR 2 o 3 -yMnO 2 Ingredients, where x and y represent the molar ratio of each component, respectively 0≤x≤1, 0≤y≤1, R is one of La, Gd, Yb, after mixing evenly, control the temperature at 1450-1550 Melt at high temperature for 1-2 hours at ℃ to make high temperature molten slurry;

[0042]2) Pour the high-temperature molten slurry prepared in step 1) into a mold preheated at 600-650°C to form and maintain the preheating temperature for 5-6 hours to remove the residual stress in the glass to prepare a transparent uniform glass, and slice it to obtain glass flakes ;

[0043] 3) Perform controlled crystallization on the glass flakes p...

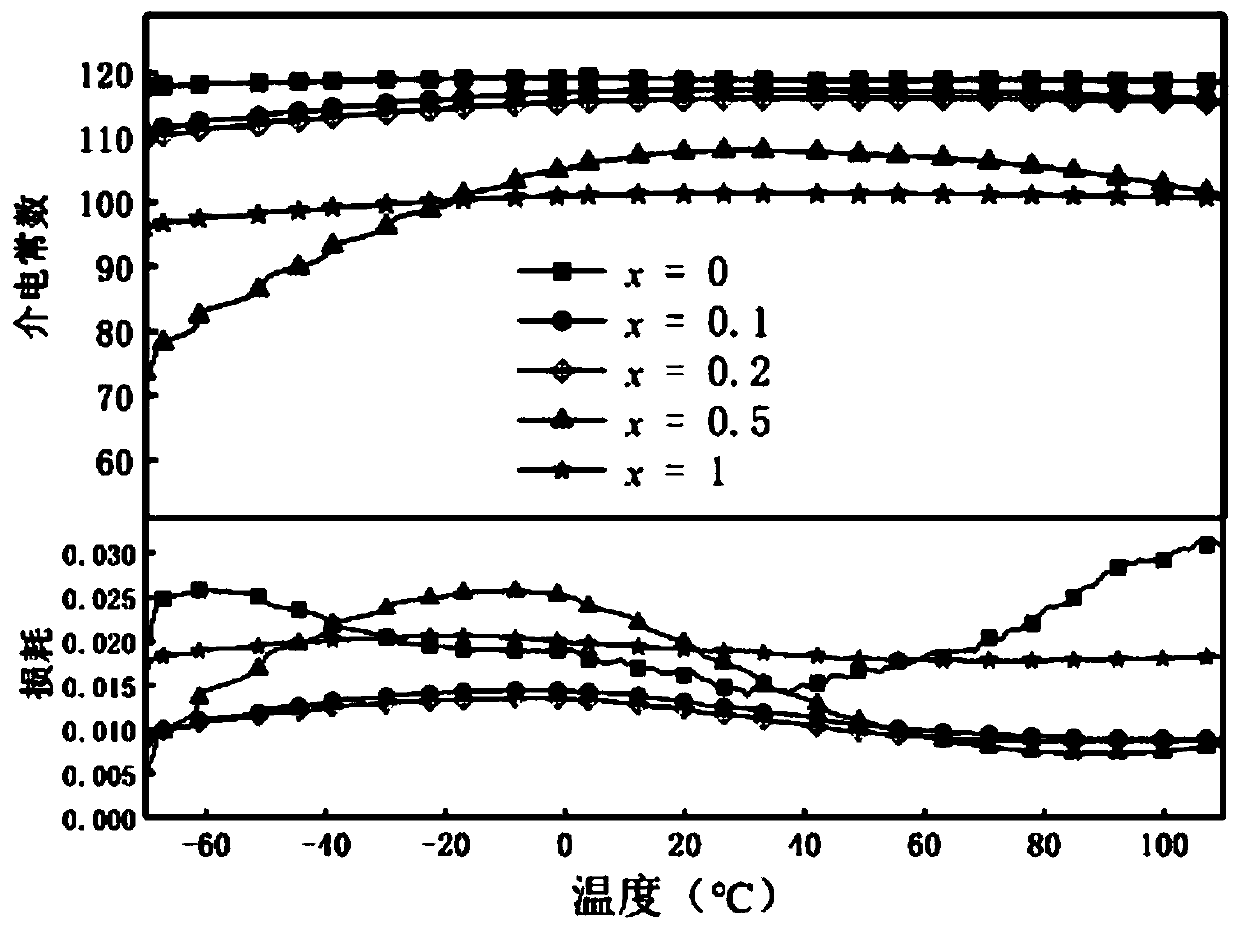

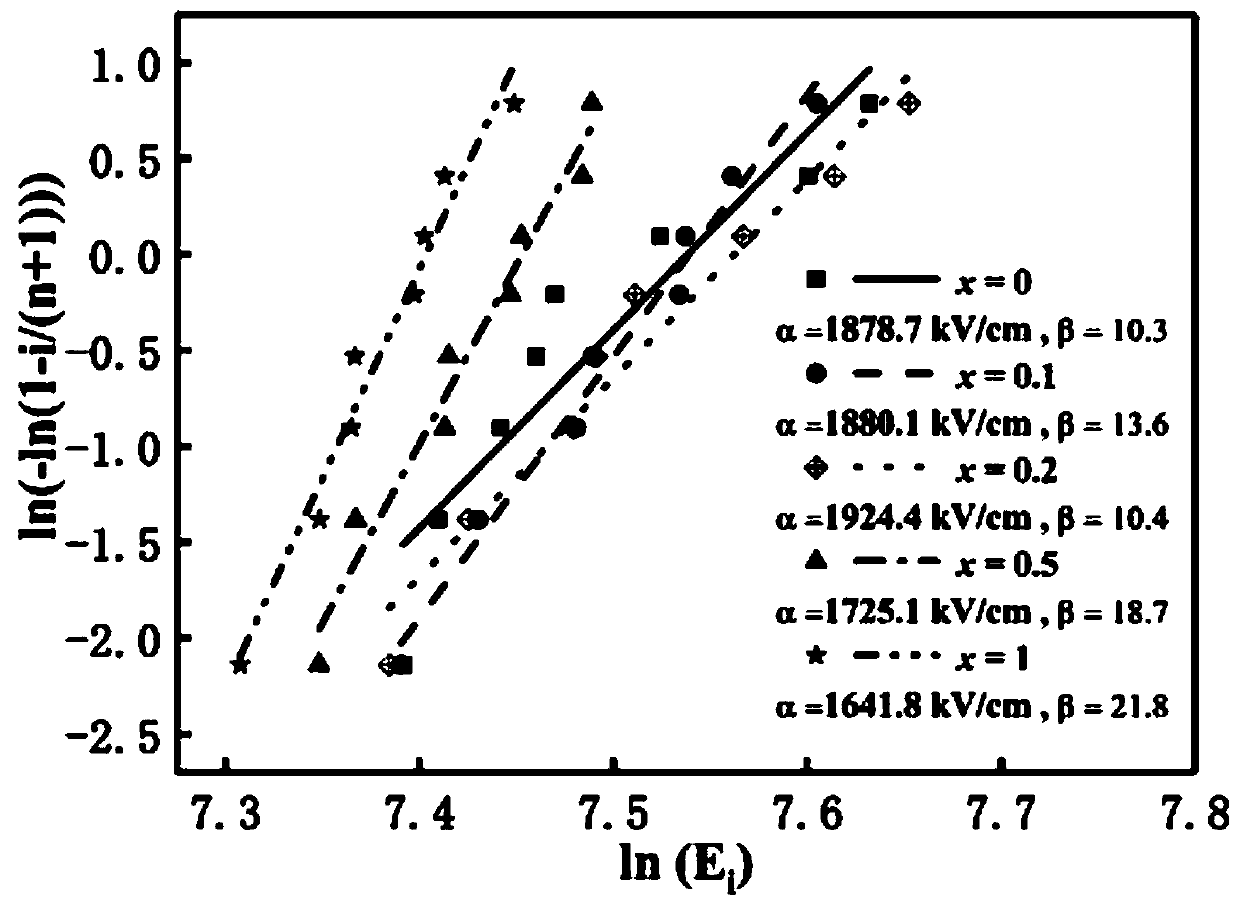

Embodiment 1

[0046] A rare earth-doped niobate-based glass-ceramic material with high energy storage density is prepared by the following steps:

[0047] 1) BaCO with a purity greater than 99wt% 3 、 Bi 2 o 3 、Na 2 CO 3 , Nb 2 o 5 , SiO 2 , La 2 o 3 For raw material ingredients, the molar ratio between the components is 21.6:2.4:6:30:40:x, after ball milling for 24 hours, drying at 100°C for 6 hours, melting at 1550°C for 2 hours , obtain high-temperature molten slurry; Wherein x=0,0.1,0.2,0.5,1, above-mentioned ball milling process is medium with absolute ethanol, and ball-to-material ratio is 1.5:1;

[0048] 2) pouring the high-temperature molten slurry prepared in step 1) into a square metal mold, annealing under stress at 650° C. for 6 hours, and then cutting to obtain glass flakes with a thickness of 1.0-1.5 mm;

[0049] 3) Put an equal amount of the glass flakes prepared in step 2) into a crucible, heat to 950°C at a heating rate of 3°C / min, and keep warm for 5h to obtain a ...

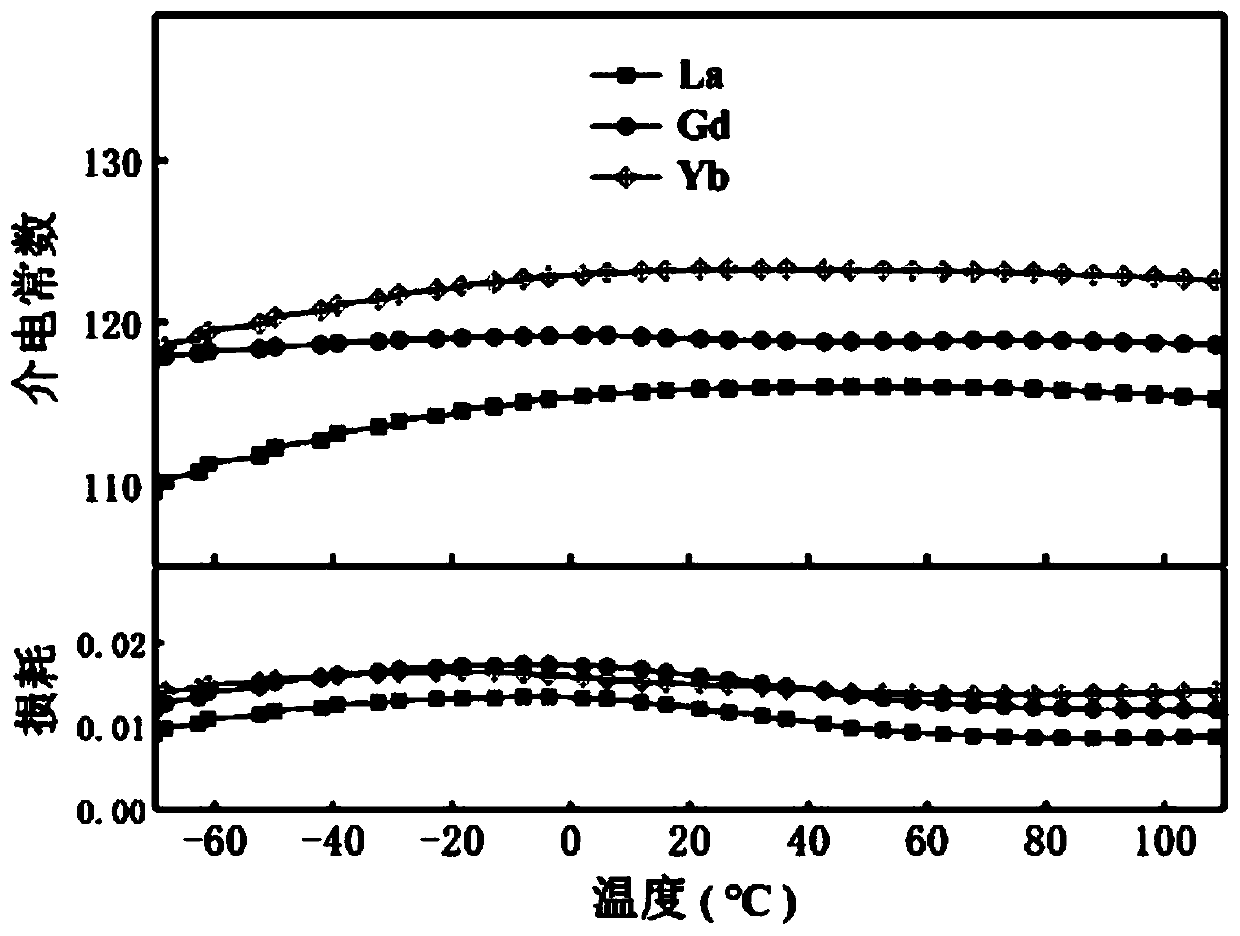

Embodiment 2

[0052] A rare earth-doped niobate-based glass-ceramic material with high energy storage density is prepared by the following steps:

[0053] 1) BaCO with a purity greater than 99wt% 3 、 Bi 2 o 3 、Na 2 CO 3 , Nb 2 o 5 , SiO 2 、Gd 2 o 3 For raw material ingredients, the molar ratio between the components is 21.6:2.4:6:30:40:0.2. After ball milling for 24 hours, dry at 100°C for 6 hours, and melt at 1550°C for 2 hours. , to obtain a high-temperature molten slurry; wherein the above-mentioned ball milling process takes absolute ethanol as a medium, and the ball-to-material ratio is 1.5:1;

[0054] 2) pouring the high-temperature molten slurry prepared in step 1) into a square metal mold, annealing under stress at 650° C. for 6 hours, and then cutting to obtain glass flakes with a thickness of 1.0-1.5 mm;

[0055] 3) Put an equal amount of the glass flakes prepared in step 2) into a crucible, heat to 950°C at a heating rate of 3°C / min, and keep warm for 5h to obtain a nio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy density | aaaaa | aaaaa |

| breakdown field strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com