Patents

Literature

56 results about "Ferroelectric hysteresis loop" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

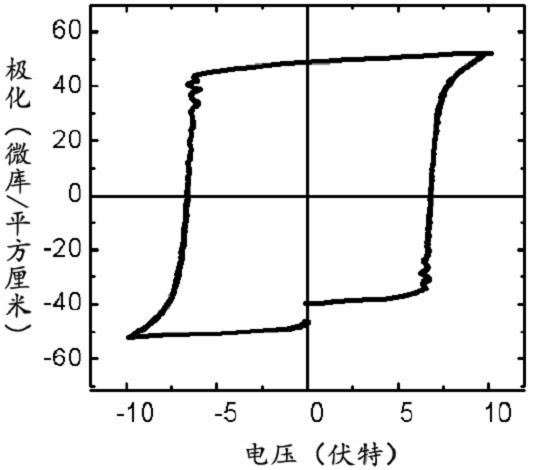

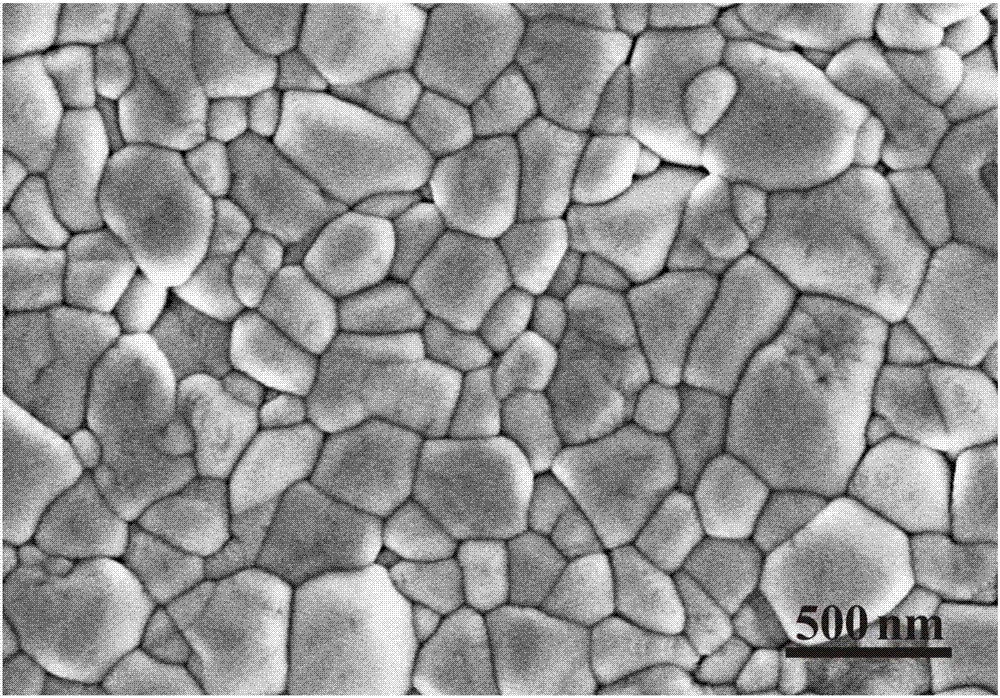

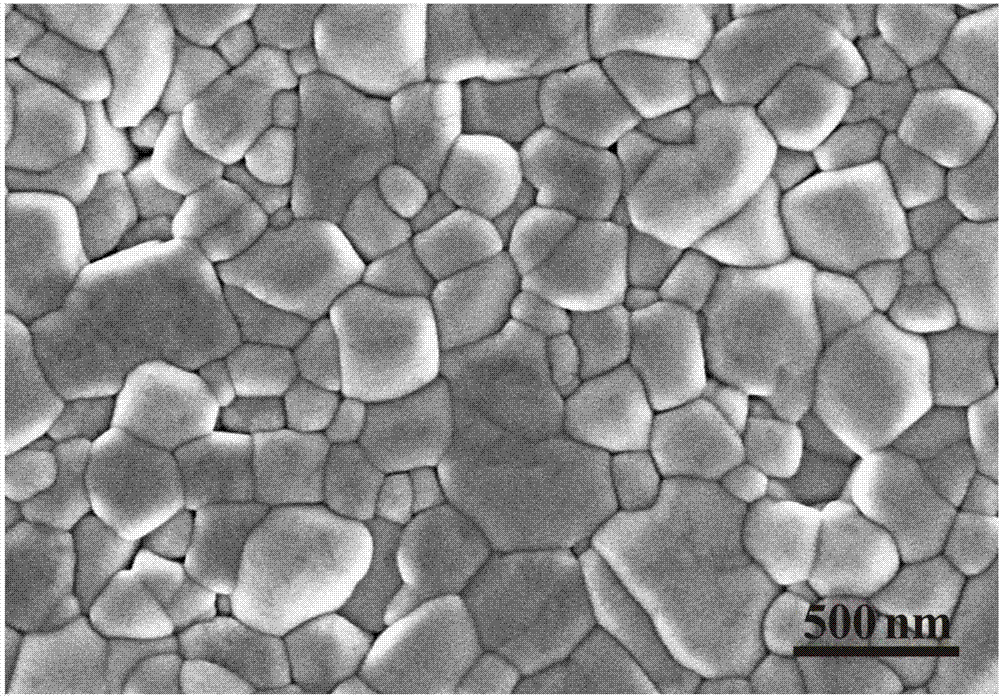

High-voltage-withstanding, low-electric-leakage and high-polarization strength bismuth ferrite thin film and preparation method thereof

ActiveCN103839928AHigh rectangularityHigh polarizationSemiconductor/solid-state device detailsSolid-state devicesMagnetizationSingle crystal

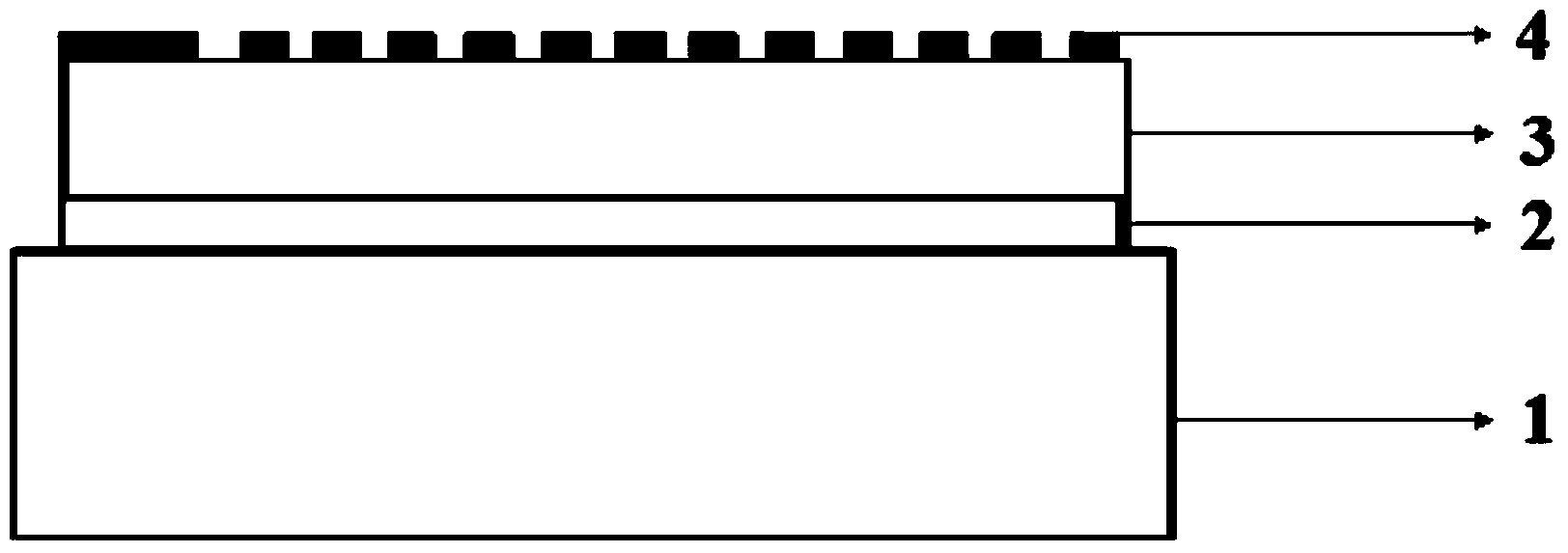

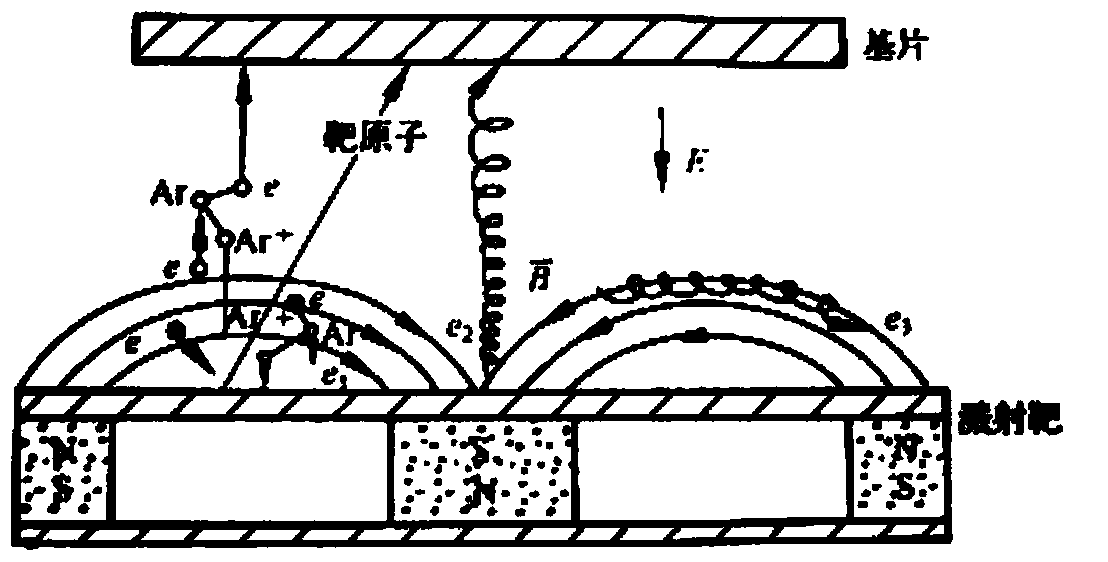

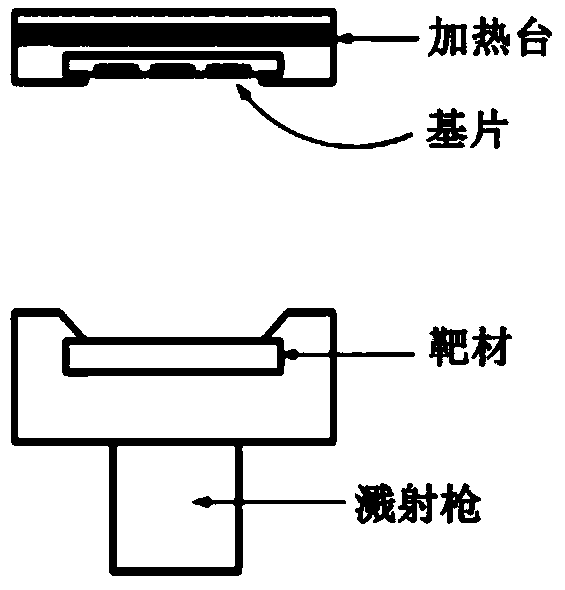

The invention relates to a high-voltage-withstanding, low-electric-leakage and high-polarization strength bismuth ferrite thin film and a preparation method thereof. The high-voltage-withstanding, low-electric-leakage and high-polarization strength bismuth ferrite thin film comprises a base body, a bottom electrode, a bismuth ferrite dielectric layer and a top electrode, a mono-crystal oxide semiconductor substrate with lattice constant close to that of the bismuth ferrite is used as the base body, the bottom electrode is a conductive oxide thin film, and the top electrode is a metal thin film point electrode. The bottom electrode is deposited on the base body in a coaxial sputtering mode, then the bismuth ferrite dielectric layer is deposited on the bottom electrode in an off-axis sputtering mode, and at last the top electrode is deposited on the bismuth ferrite dielectric layer so that the thin film can be prepared. The prepared BiFeO3 thin film is in a rhombohedral shape and achieves height orientation, a ferroelectric hysteresis loop with good rectangularity is achieved under the room temperature, the intensity of polarization is high, the intensity of magnetization can reach 100 -110 micro coulombs / cm<2>, the voltage withstanding performance is good, and the maximum withstand voltage can achieve 50 v.

Owner:欧阳俊

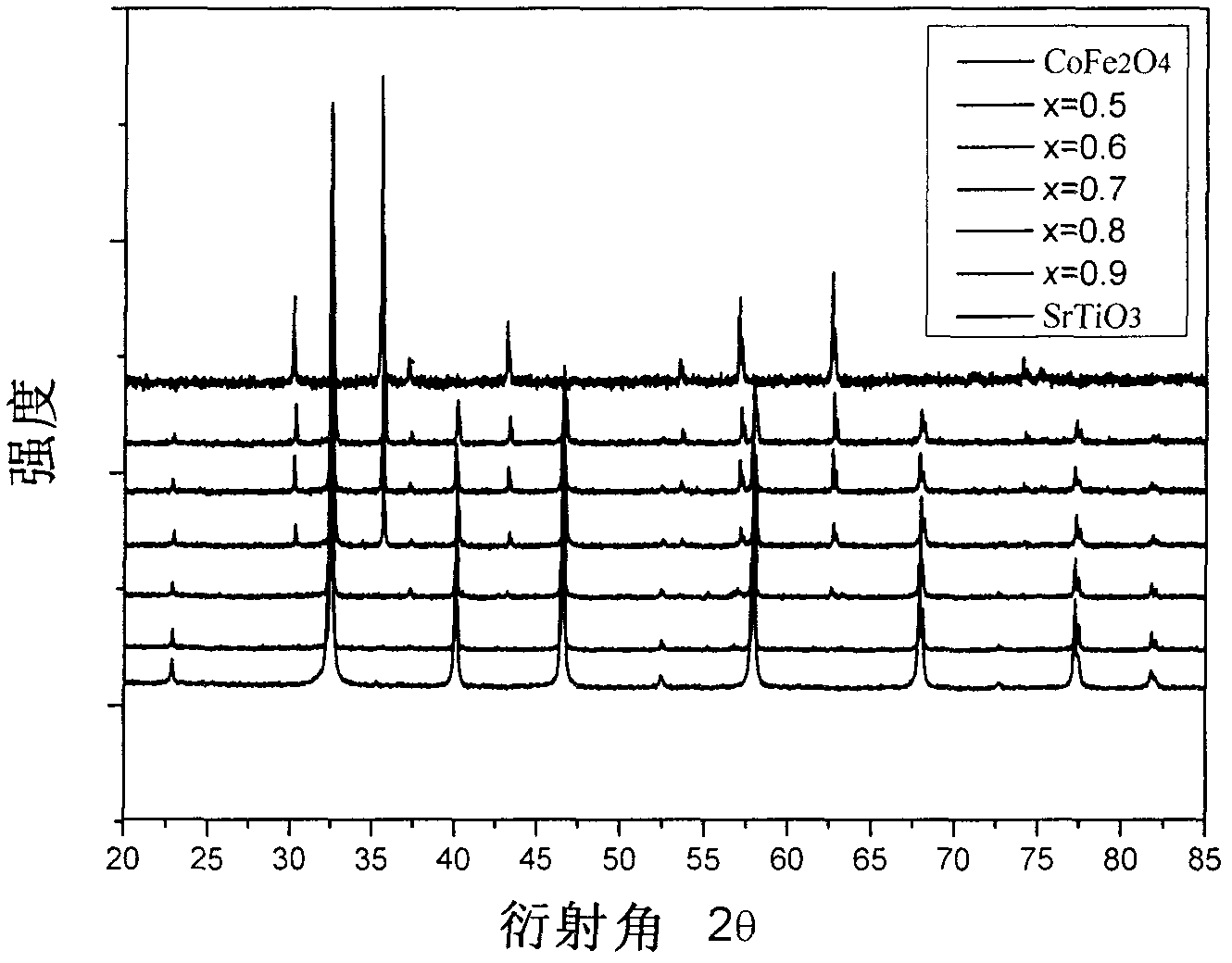

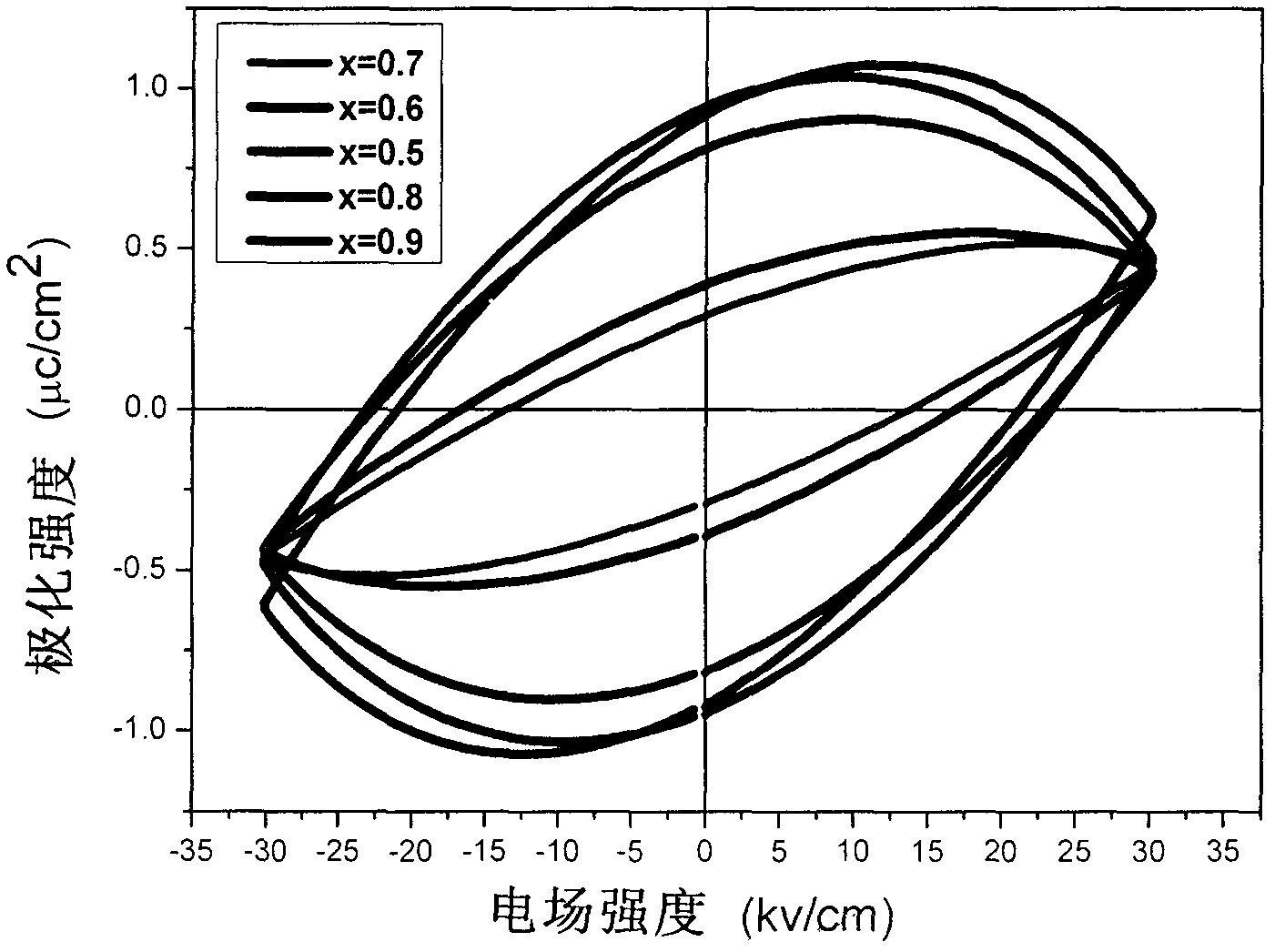

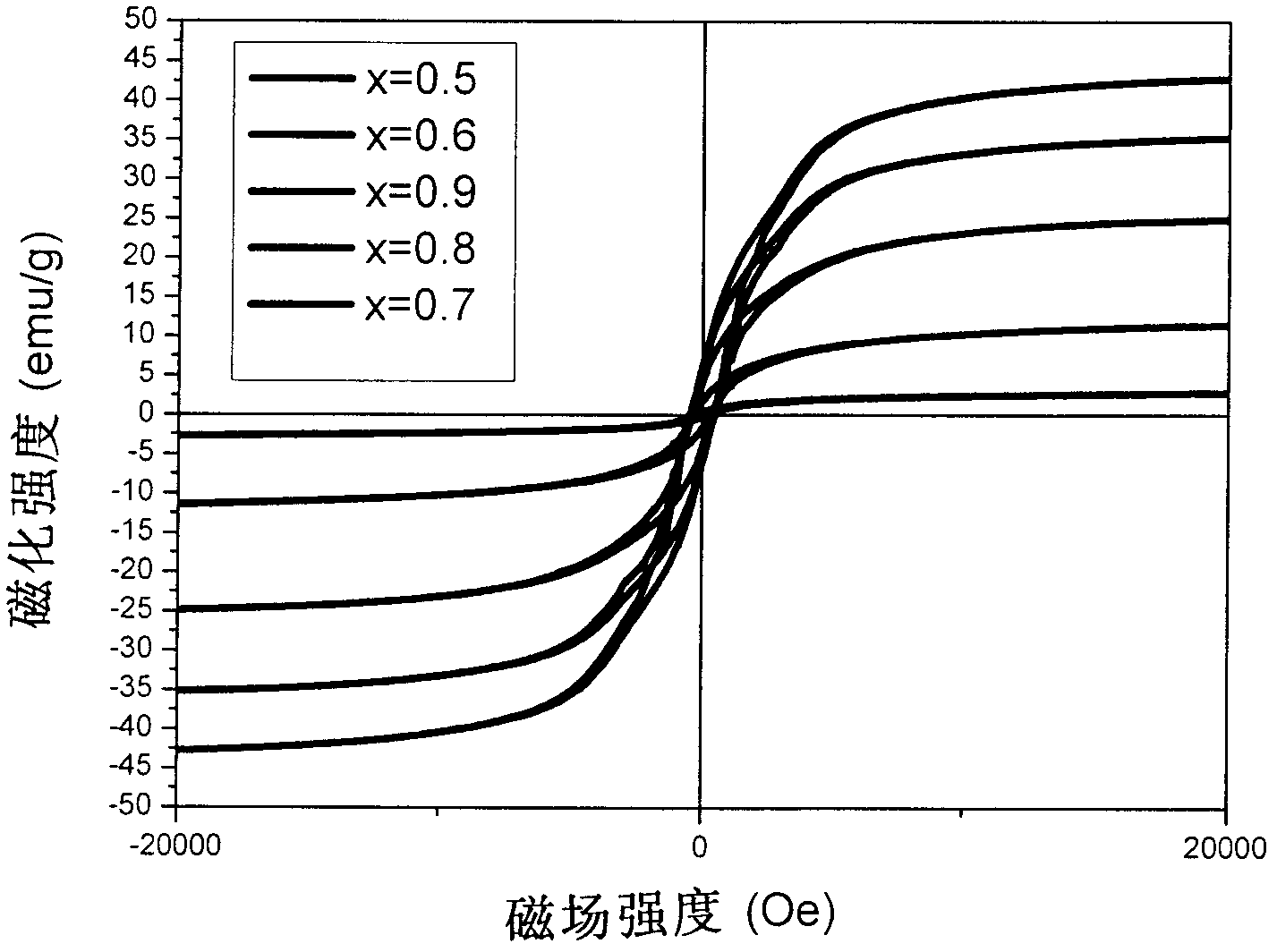

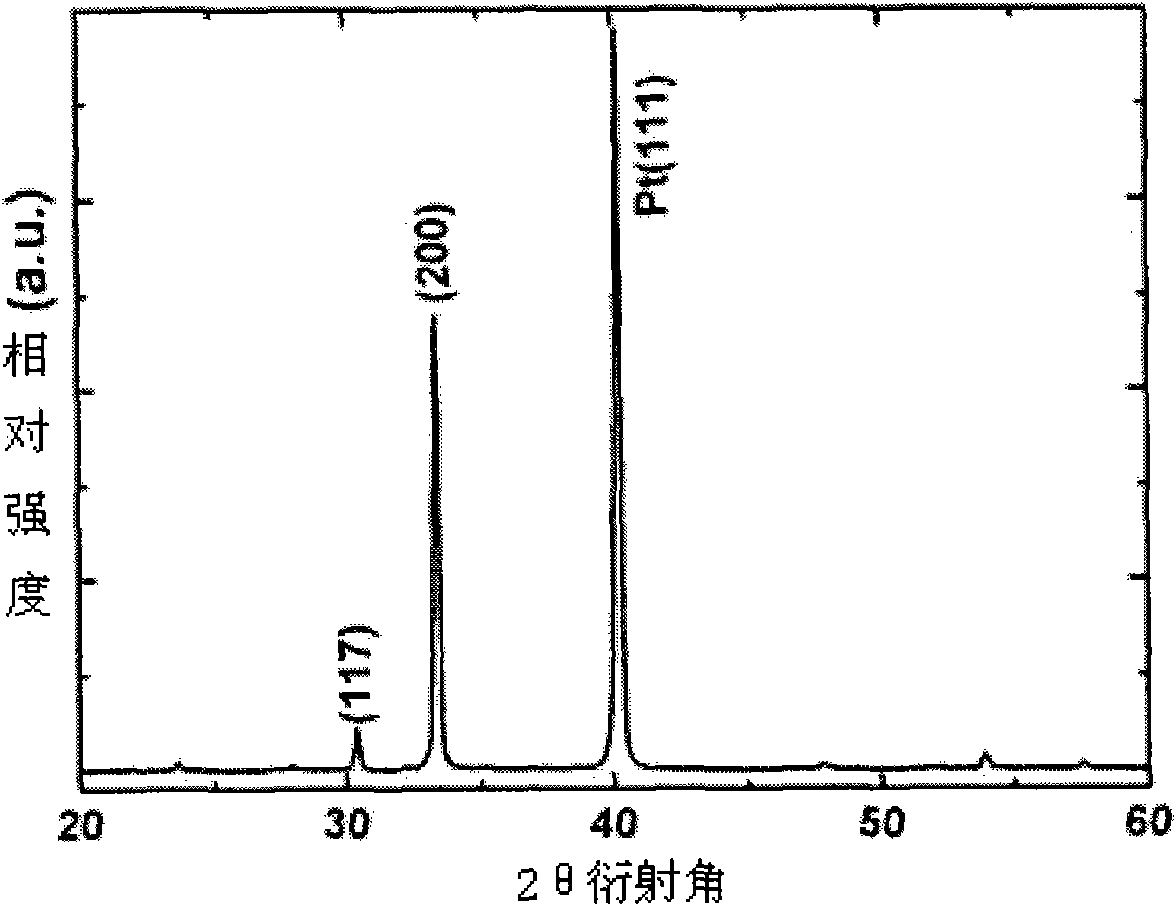

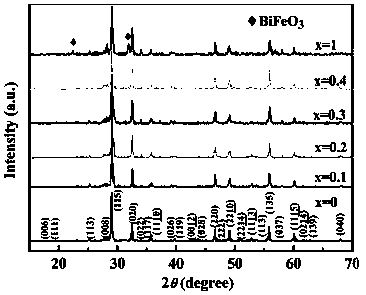

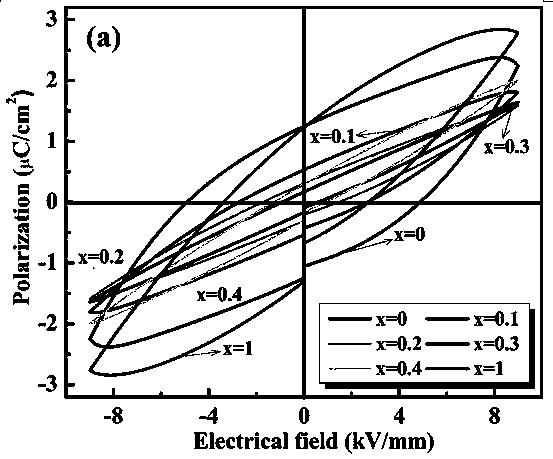

Xsrtio3-(1-x) cofe2o4 composite material and preparation method thereof

InactiveCN102643088AGood calcination temperatureHelpful for practical applicationComposite ceramicCobalt

The invention discloses an xSrTiO3-(1-x) CoFe2O4 composite material having ferromagnetism and ferroelectricity and a preparation method thereof. In the formula, x ranges from 0.5 or 0.6 or 0.7 or 0.8 or 0.9. Compared with single-phase ceramics, the composite ceramics have certain changes in ferroelectricity and ferromagnetism. The preparation method is an improved sol gel method and uses strontium nitrate, citric acid, cobalt nitrate, butyl titanate, absolute ethyl alcohol, glacial acetic acid and ferric nitrate as raw materials. The preparation method simplifies compound steps, effectively avoids outside affecting factors of particle compound, and reduces material compound temperature. The ferroelectricity of the xSrTiO3-(1-x) CoFe2O4 composite material is improved compared with single-phase SrTiO3, and a ferroelectric hysteresis loop tending to be saturated is obtained. The ferromagnetism has regularity along with increase of content of cobalt ferrite, and therefore actual application of composite materials is facilitated.

Owner:HEBEI NORMAL UNIV

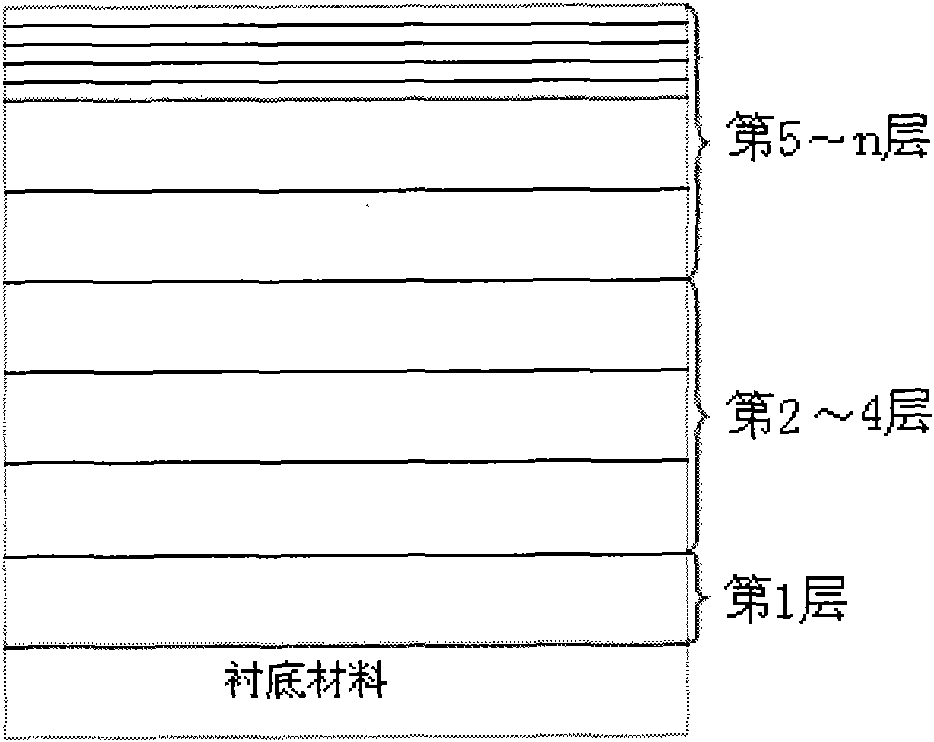

Lanthanide-doped bismuth titanate film and preparation method thereof

The invention discloses a lanthanide-doped bismuth titanate film. The film comprises at least five layers of materials, and the component of each layer of material is Bi(4-x)(1+y)LnxTi3O12, wherein Ln is one of lanthanides, x is a molar equivalent weight of the lanthanide, and x is more than or equal to 0.1 and less than or equal to 0.85; and excessive Bi element is added, y is the excessive percentage based on the weight of Bi, the y in the first layer of material is 5 to 15 percent, the y in the second to fourth layer of material is 10 to 20 percent, and the y in the fifth to over fifth layer of material is 15 to 25 percent. The invention also discloses a preparation method for the film. The preparation method of the invention has low cost and simple operation; and the prepared film (100) has high orientation preferential degree, improves the rectangular degree of polarized and ferroelectric hysteresis loops and the like, and is suitable for application.

Owner:UNIV OF JINAN

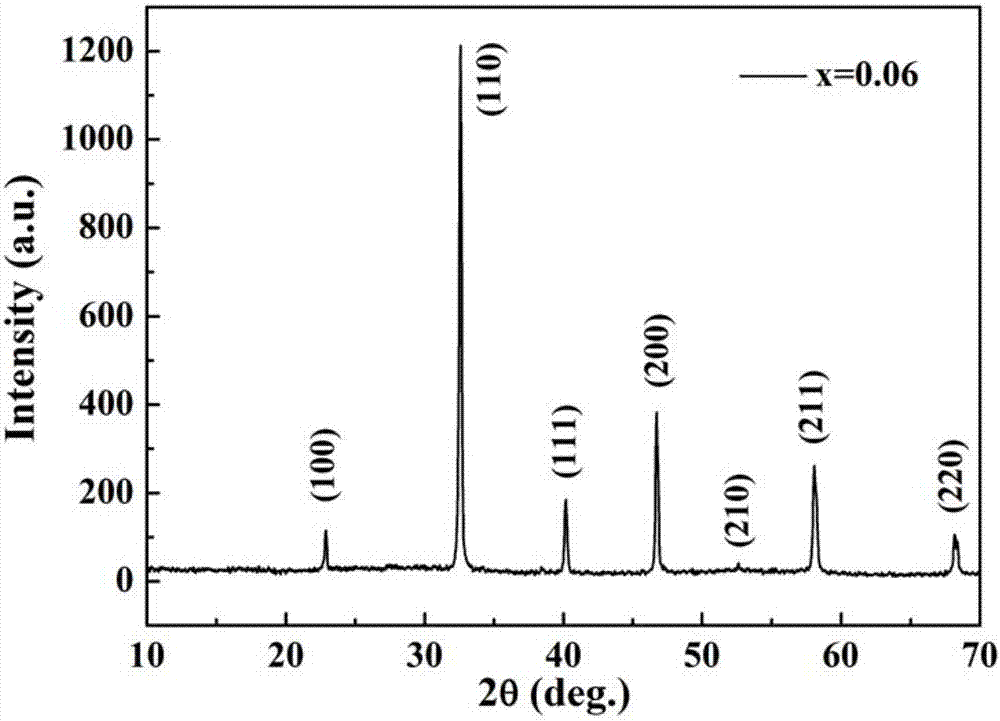

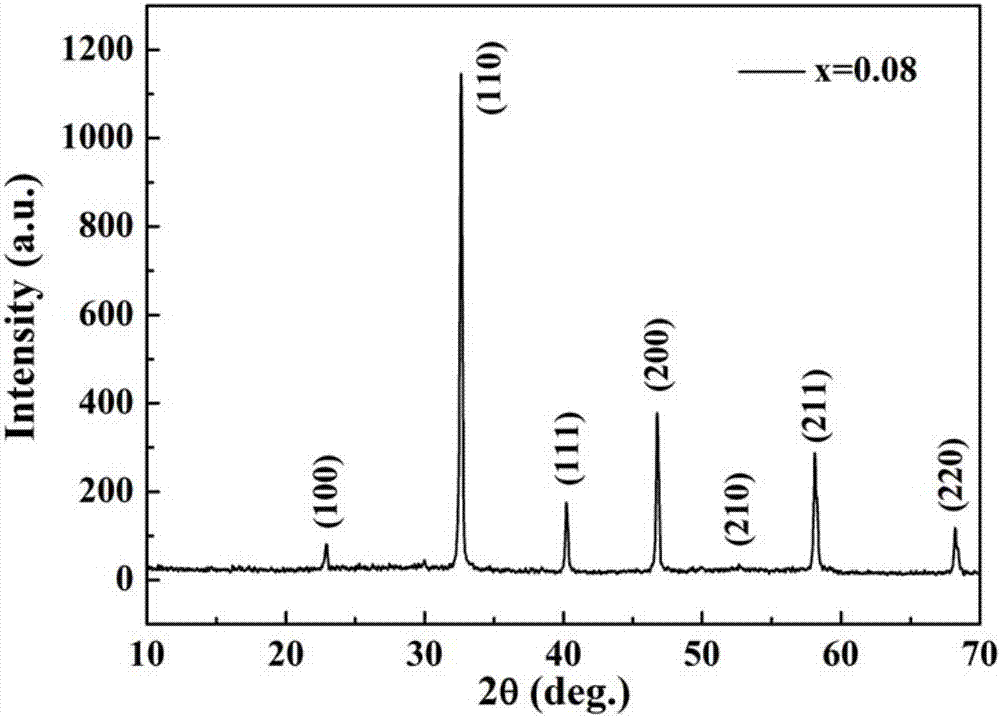

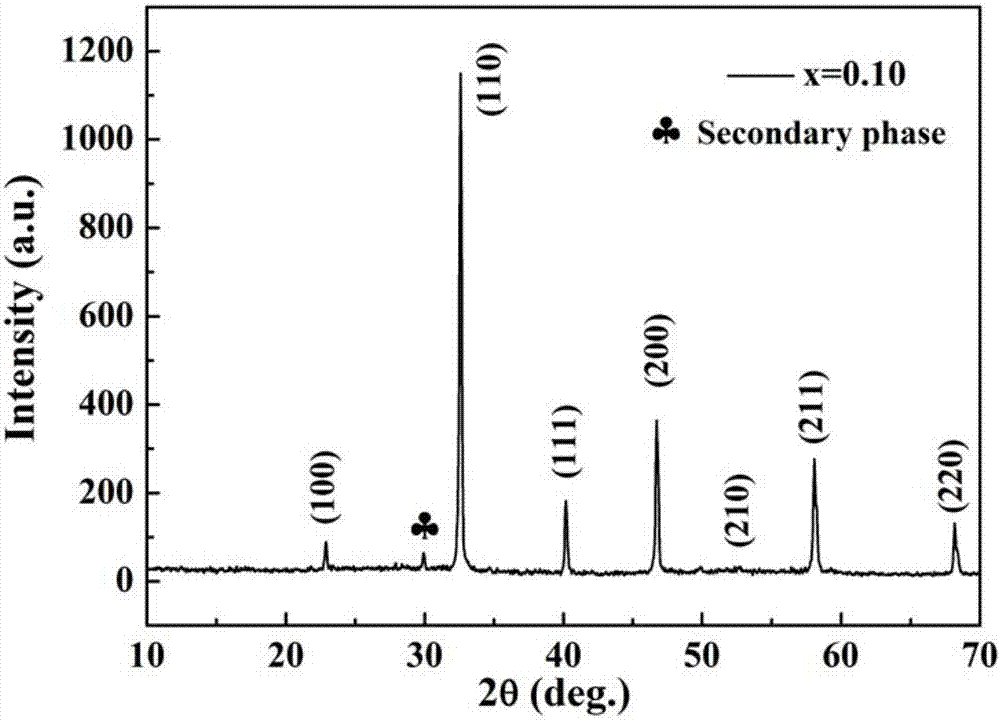

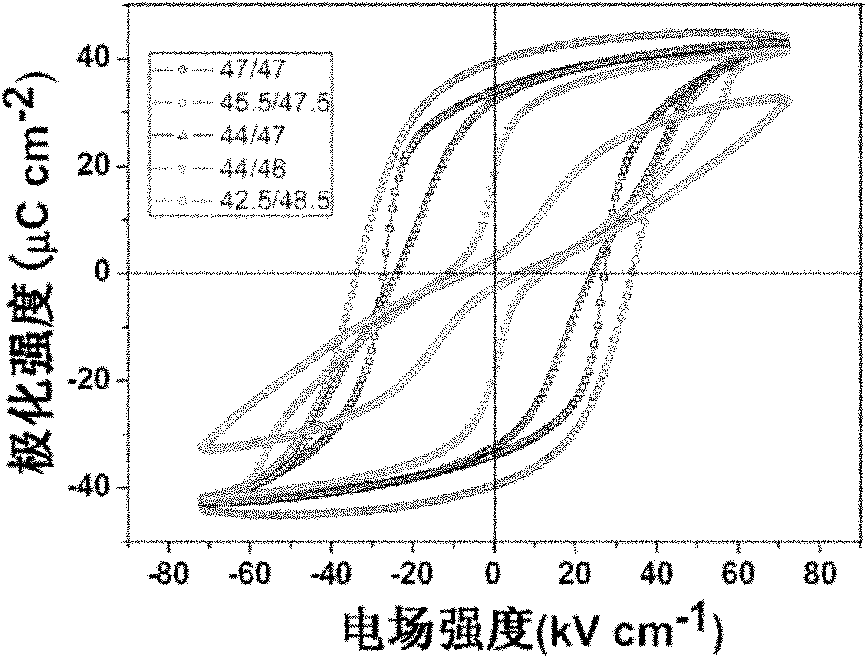

Lead-free high-energy-storage-density and high-energy-storage-efficiency ceramic material and preparation method of same

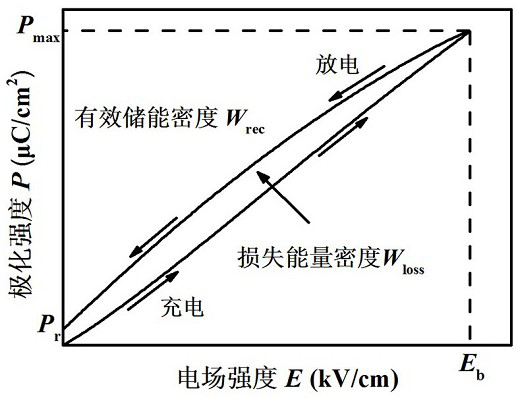

ActiveCN106915960AHigh energy storage densityImprove energy storage efficiencyHigh energyEnergy storage efficiency

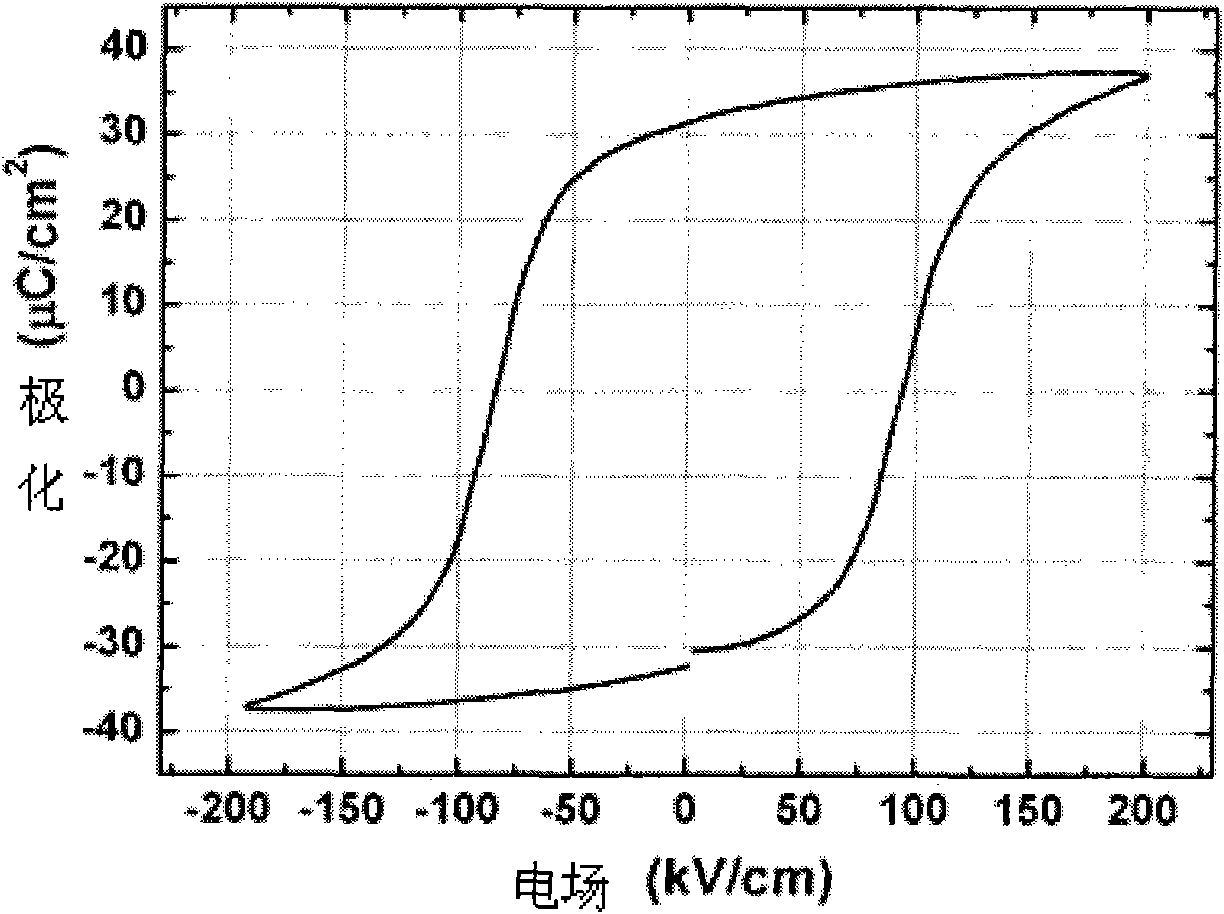

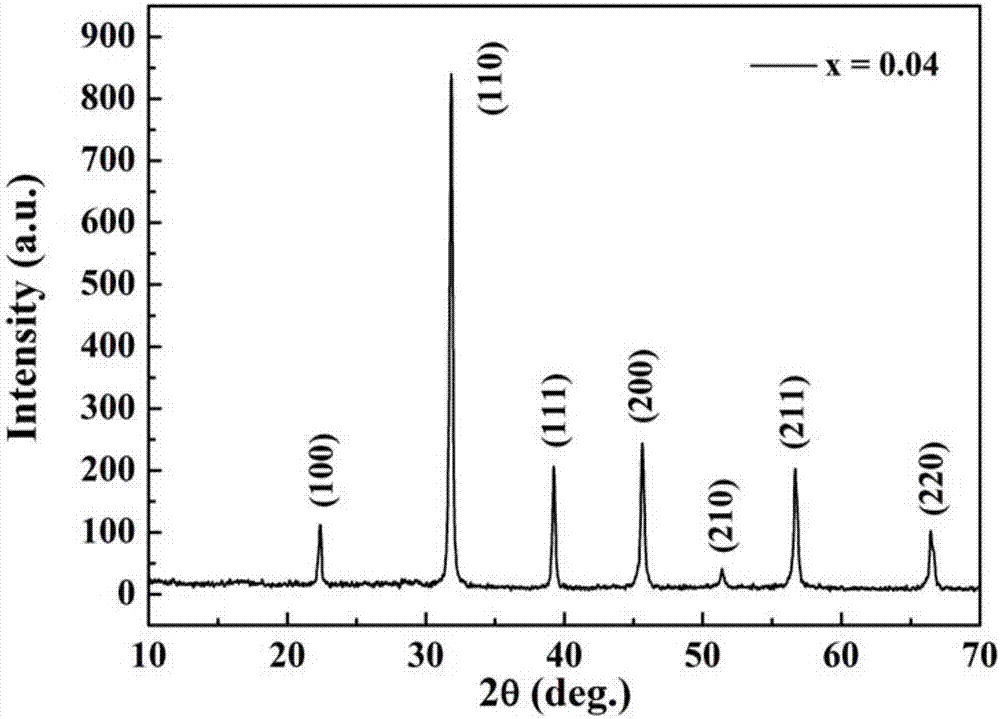

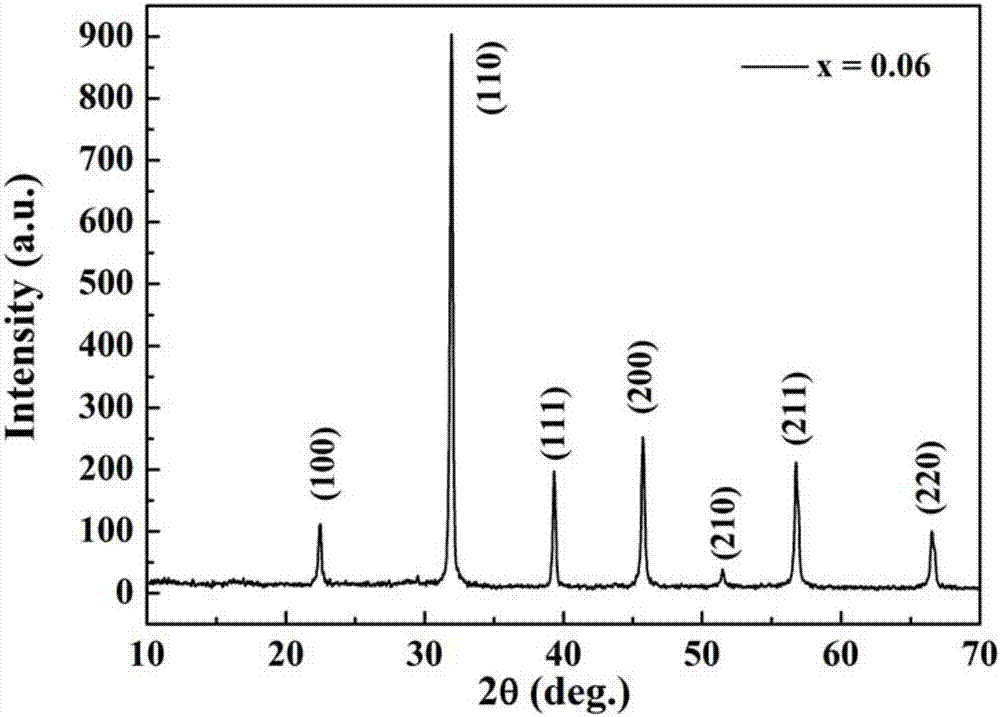

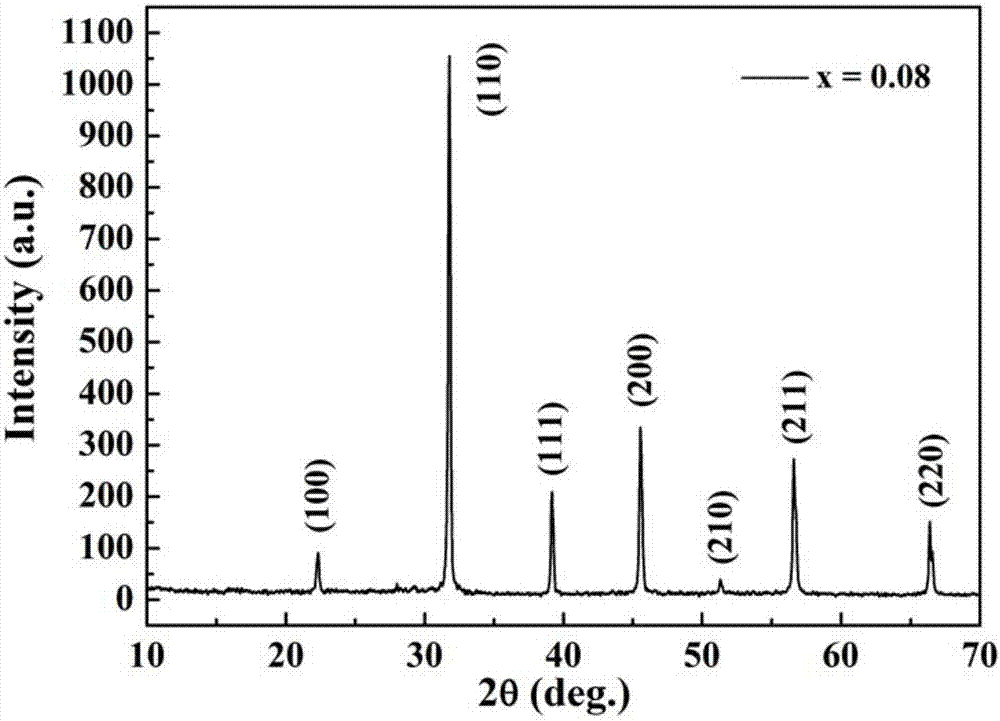

A lead-free high-energy-storage-density and high-energy-storage-efficiency ceramic material and a preparation method of same. The preparation method includes the following steps: 1) preparing raw materials according to the chemical formula (1-x)(0.65BaTiO3-0.35Bi<0.5>Na<0.5>TiO3)-xNa<0.73>Bi<0.09>NbO3, wherein x refers to molar fraction, 0.04 <= x <= 0.10; 2) performing ball-milling and drying to obtain a powder; 3) adding a binder to the powder for granulation, and aging the granules for 24-48 h, pressing the granules into sheets, performing glue removal treatment, and sintering the mixture with temperature maintained at 1100-1150 DEG C for 2-3 h to obtain ceramic, which is the lead-free high-energy-storage-density and high-energy-storage-efficiency ceramic material. The preparation method is simple and stable and is suitable for industrial production. The ceramic material has high energy-storage performance, is 1.24-1.70 J / cm<3> in energy storage density calculated on the basis of ferroelectric hysteresis loop and is 76.95-85.73% in energy storage efficiency.

Owner:SHAANXI UNIV OF SCI & TECH

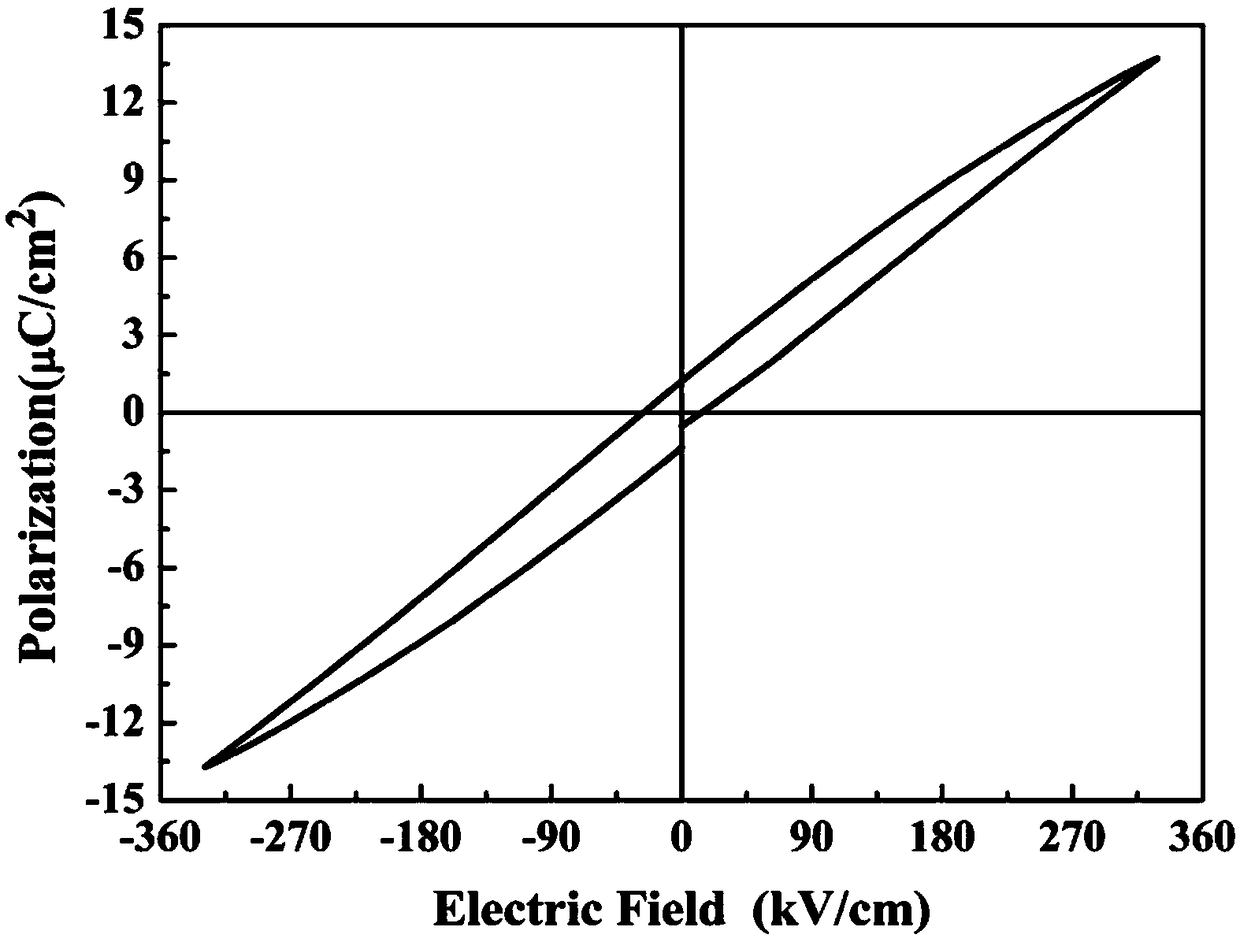

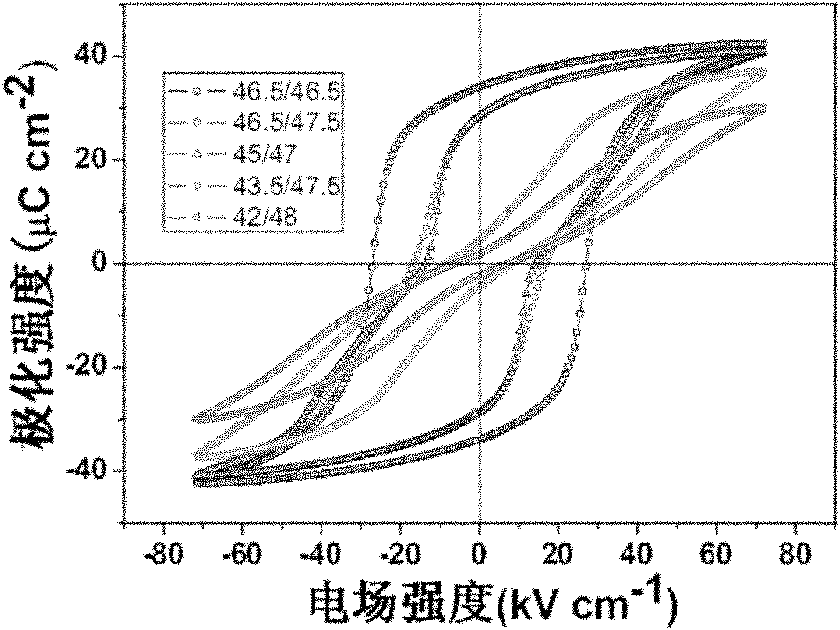

Strontium titanate-based ceramic material with high energy storage density and low dielectric loss and preparation method thereof

The invention discloses a strontium titanate-based ceramic material with high energy storage density and low dielectric loss and a preparation method thereof. The method comprises the following steps: preparing materials according to a chemical formula which is expressed as (1-x)SrTiO[3-x]Bi0.48La0.02Na0.48Li0.02Ti0.98Zr0.02O3, mixing uniformly to obtain raw material powder, uniformly mixing organic solvents and emulsifiers, then adding the raw material powder, adhesives, dispersants and plasticizers, mixing uniformly, carrying out tape casting, then cutting and stacking, then pressurizing, discharging glue and sintering to obtain the strontium titanate-based ceramic material with high energy storage density and low dielectric loss. The ceramic material is simple in preparation process and mature in preparation technique, and is suitable for industrial production; the energy storage density calculated on the basis of ferroelectric hysteresis loop is 1.98-2.59j / cm<3>, the energy storage efficiency is 69-87%, and the electric field intensity is 200kV / cm or more; the ceramic material is excellent in energy storage characteristic and low in dielectric loss.

Owner:SHAANXI UNIV OF SCI & TECH

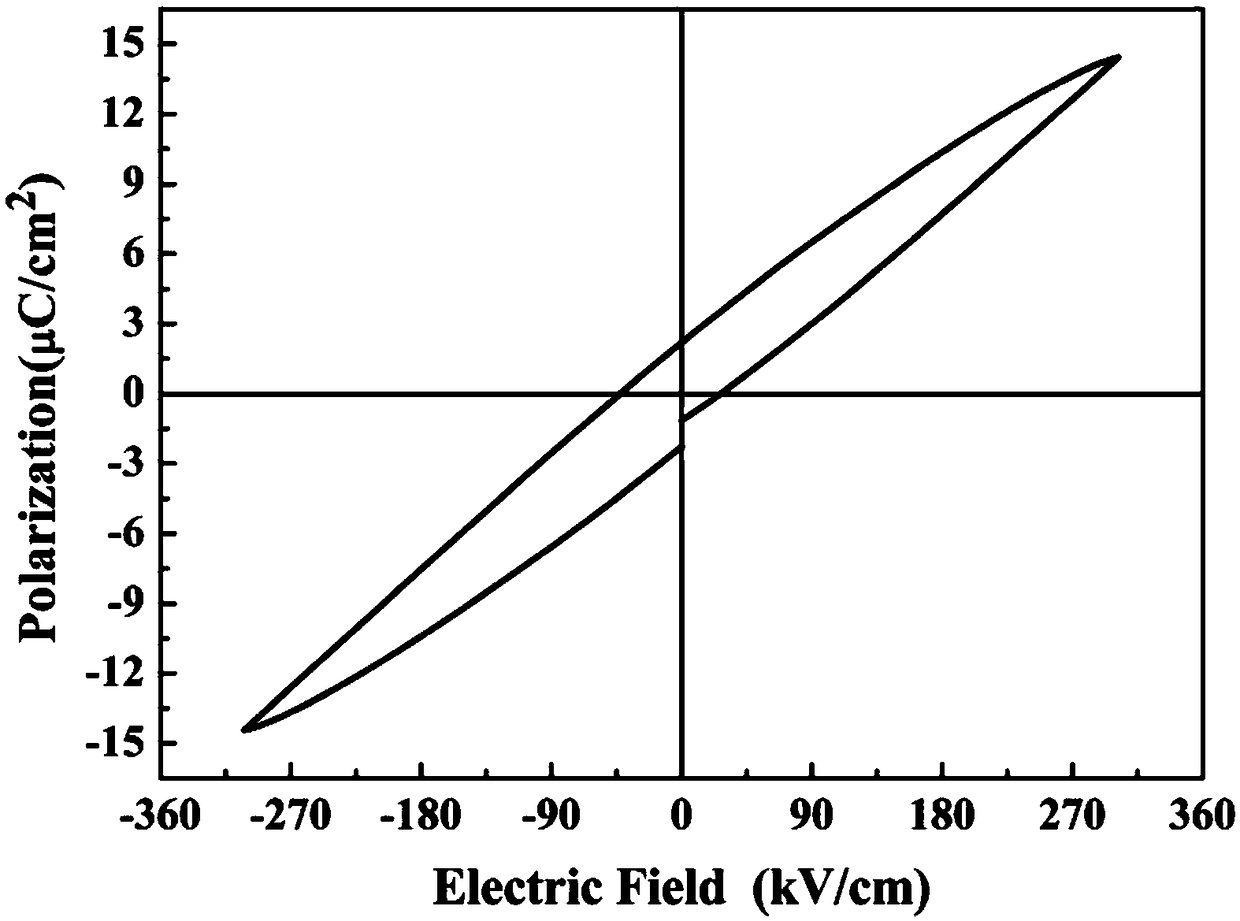

Sandwich-structured lead-free ceramic with low dielectric loss and high energy storage density and preparation method thereof

The invention discloses sandwich structured lead-free ceramic with low dielectric loss and high energy storage density and a preparation method thereof. The preparation method comprises the followingsteps: uniformly mixing an organic solvent and an emulsifier, then adding SrTiO3 powder, a binder, a dispersant and a plasticizer, and uniformly mixing to obtain SrTiO3 tape casting slurry; preparing(1-x)SrTiO3-xBaFe0.5Nb0.5O3 casting slurry with the same tape casting method; respectively carrying out tape casting on the two tape casting slurry in the manner of tape casting to obtain two kinds oftape casting film; and carrying out superposition, pressurization, rubber discharging and sintering to obtain the sandwich-structured lead-free ceramic. The ceramic has the advantages that the preparation process is simple and the technology is mature, is suitable for industrial production, has excellent energy storage characteristics, has the discharge energy density between 1.67 and 1.90 J / cm<3> calculated based on ferroelectric hysteresis loop, the energy storage efficiency of 86% and the electric field strength of 300kV / cm or above, and can exhibit a lower dielectric loss value.

Owner:SHAANXI UNIV OF SCI & TECH

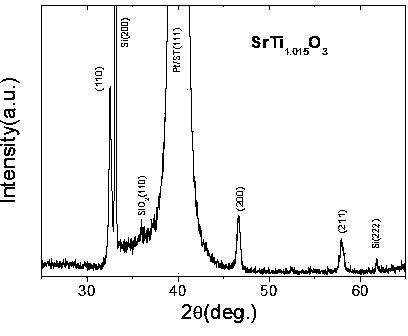

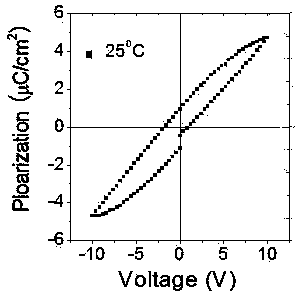

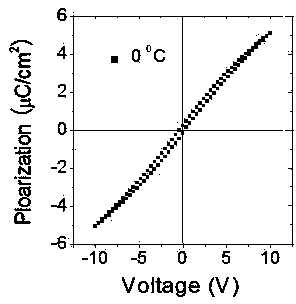

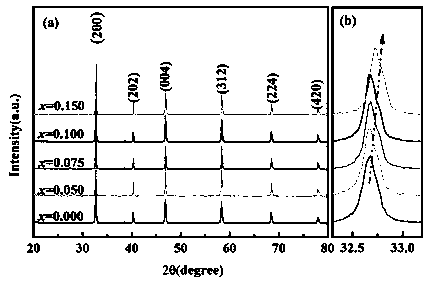

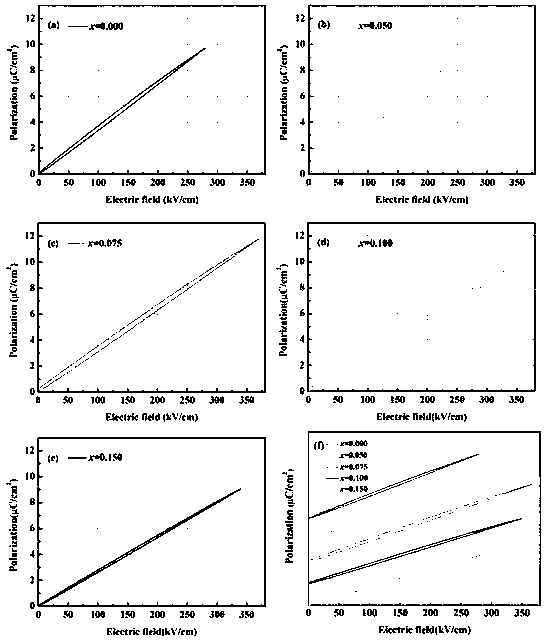

Self-doped strontium titanate ferroelectric film and preparation method thereof

A self-doped strontium titanate ferroelectric film and a preparation method thereof. The self-doped strontium titanate ferroelectric film is composed of a material with a molecular formula of SrTi1+xO3, wherein the value range of x is 0.015-0.02. The preparation method of the film comprises the following steps: weighing strontium acetate, tetrabutyl titanate, and acetylacetone according to a mole ratio of 1:(1.015-1.02):0.7, completely dissolving strontium acetate in acetic acid, then adding ethylene glycol monomethyl ether, tetrabutyl titanate, and acetylacetone, diluting the solution with ethylene glycol monomethyl ether to obtain a mole concentration of strontium acetate of 0.3 mol / L, stirring to obtain a solution C; dropping the solution C on a substrate in a spin coater, performing spin coating, drying and thermolysis till the thickness of the SrTi1+xO3 dry film reaches 300 nm, and performing annealing to obtain the SrTi1+xO3 film. According to the invention, ferroelectricity is induced by excessive Ti and in an anoxic atmosphere, and ferroelectric hysteresis loops are measured at a temperature above zero or even at room temperature; no introduction of other element is necessary, and the method is simple.

Owner:HENAN UNIV OF SCI & TECH

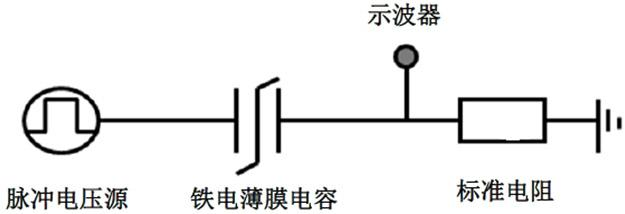

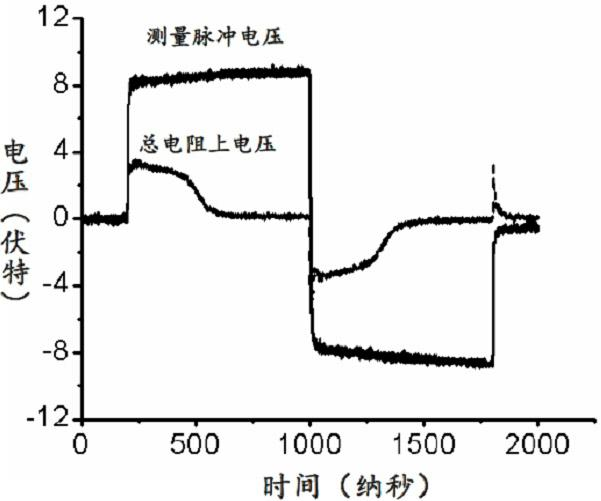

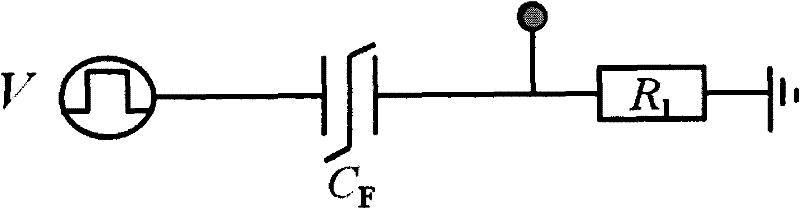

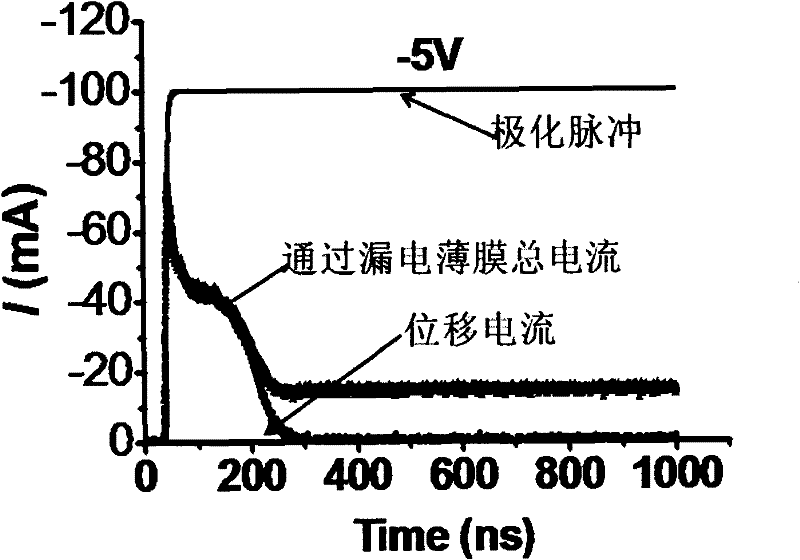

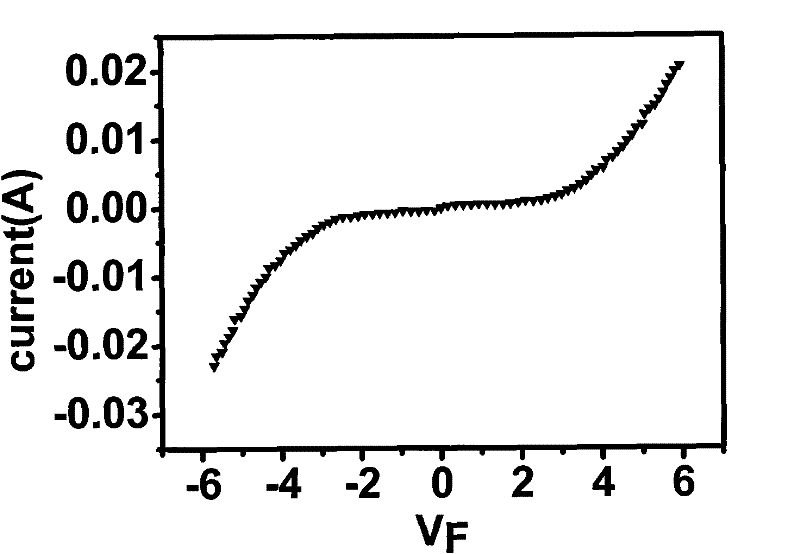

A Method for Measuring and Converting Domain Reversal Current of Insulated/Leakage Ferroelectric Thin Film into Hysteresis Loop

InactiveCN102279308AFast measurementCurrent/voltage measurementShort-circuit testingCapacitanceHysteresis

Provided are a method, a device, and a program product for testing the performance of a ferroelectric film. The method comprises: testing, based on a test circuit (110) formed by a ferroelectric capacitor (111) and a resistor (113) connected in series, a ferroelectric hysteresis loop of a ferroelectric film by using a square voltage pulse with a pulse width comparative to an electric domain inversion time. By means of the method, the test is accurate and reliable and the range of the test frequency is wide. The method can be used to test the performance of an insulative ferroelectric film and an electric leakage ferroelectric film.

Owner:FUDAN UNIV

Sodium-bismuth-titanate-based transparent ceramic material and preparing method and application thereof

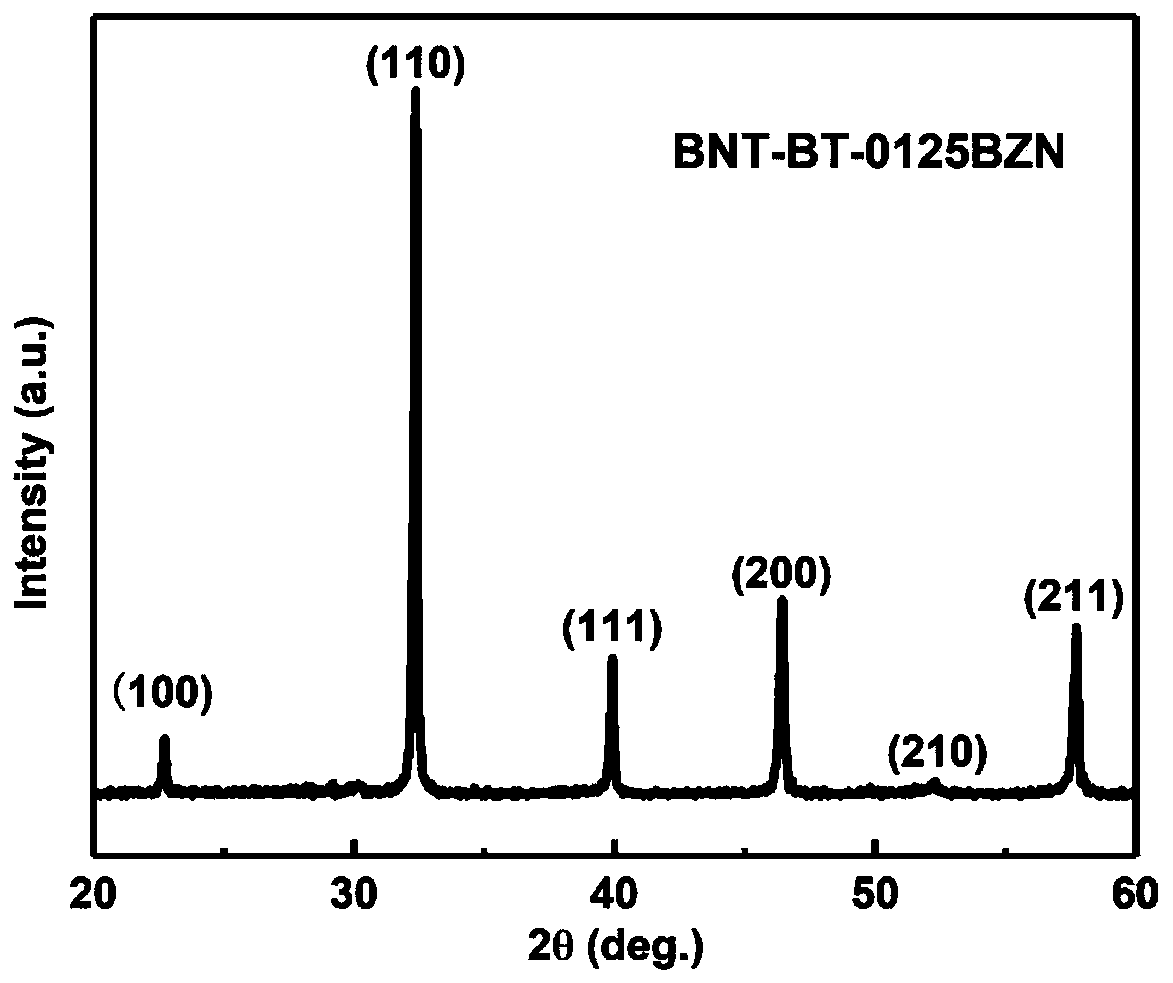

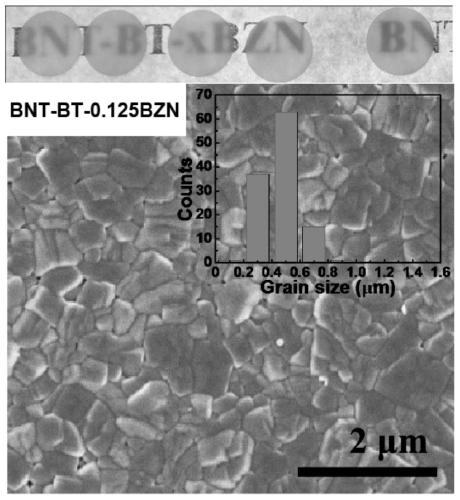

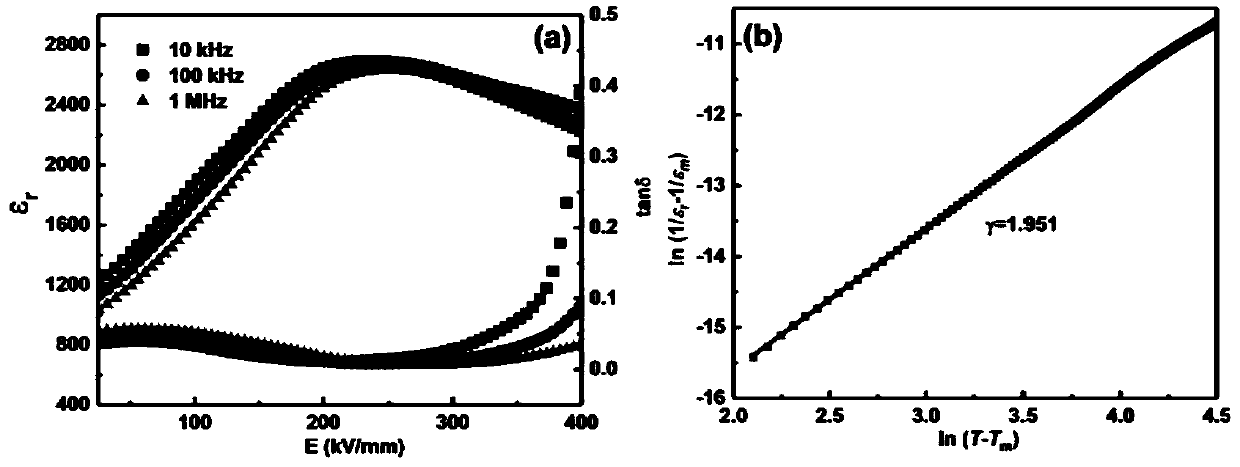

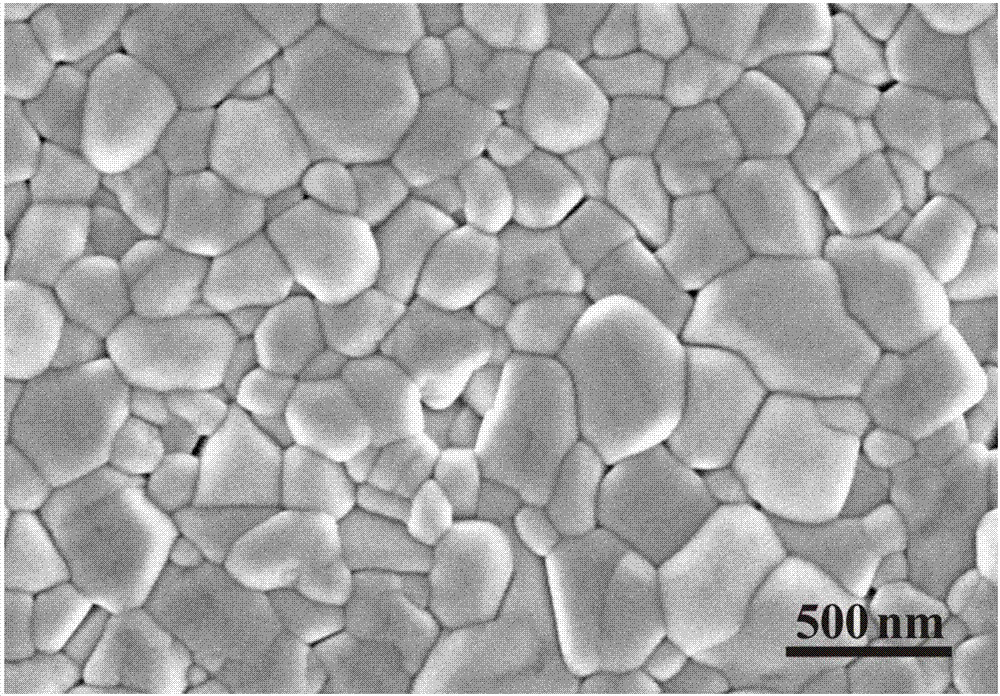

ActiveCN109942292AImprove the electric field against breakdownThin hysteresis loopEnergy storage efficiencySodium bismuth titanate

The invention discloses a sodium-bismuth-titanate-based transparent ceramic material and a preparing method. The chemical general formula of the sodium-bismuth-titanate-based transparent ceramic material is (0.95-x)Bi0.5Na0.5TiO3-0.05BaTiO3-xBi(Zn2 / 3Nb1 / 3)O3, wherein x is equal to 0.05 to 0.15 (abbreviated as (0.95-x)BNT-BT-xBZN). A traditional solid phase method is adopted, and through primary presintering and primary sintering, the sodium-bismuth-titanate-based transparent ceramic material is prepared; a sintering additive is added, a sintering technology is adjusted, a transparent fine crystal ceramic is successfully prepared at the low sintering temperature, and the average crystallite size is about 400 nm. A ceramic chip prepared with the method shows the high dielectric relaxation performance, a long-and-thin ferroelectric hysteresis loop and a high-impact breakdown electric field, and is an excellent dielectric energy-storage ceramic material. The highest discharge energy density 2.83 J / cm<3> is obtained under an 18kV / mm external electric field, and at this moment, the energy storage density is 4.23 J / cm<3>, and the energy storage efficiency is 67%. In addition, the cyclingstability of the energy storage performance is also quite excellent, and through 105 times of loop tests, loss of the discharge energy density is lower than 2%.

Owner:CENT SOUTH UNIV

Method for measuring ferroelectric hysteresis loop of leakage ferroelectric film

The invention belongs to the technical field of solid dielectric performance testing, and in particular discloses a method for measuring a ferroelectric hysteresis loop of a leakage ferroelectric film. The method of the invention comprises the following steps: firstly, applying external voltages of the same polarity onto the polarized leakage ferroelectric film, testing and recording the leakage currents at the two ends of the film passing through the ferroelectric film under the different voltages and performing curve fitting to obtain a functional equation of the leakage currents and the applied voltages; performing calculation to obtain the change relationships of polarization currents of reversed electric domains and time; finally integrating the displacement currents with respect to the time to calculate the density of displacement charges generated by the ferroelectric film under the applied voltages; and repeating the measurement and calculation processes to obtain electric displacement corresponding to the ferroelectric film under the different voltage so as to measure the ferroelectric hysteresis loop of the whole leakage ferroelectric film. The method has the advantages of overcoming the difficulty in the electric characteristics of the leakage ferroelectric film and specifically providing powerful means for study on the electric characteristics of the ultra-thin leakage ferroelectric film.

Owner:FUDAN UNIV

Lead-free ceramic material with high energy storage density and high energy storage efficiency and preparation method thereof

The invention relates to a lead-free ceramic material with high energy storage density and high energy storage efficiency and a preparation method thereof. According to the method, firstly, proportioning is performed according to a chemical formula of Ba0.4Sr0.6TiO3-x(Bi2O3-B2O3-SiO2), wherein the x is the mass percent of Bi2O3-B2O3-SiO2, and the x is greater than or equal to 3 weight percent and is smaller than or equal to 12 weight percent; through ball milling and drying, raw material powder is obtained; the obtained raw material powder is pressed into sheets; sintering is performed at 1300 to 1350 DEG C; the lead-free ceramic material with high energy storage density and high energy storage efficiency can be obtained. The lead-free ceramic material has the advantages that the preparation process is simple and stable, and is suitable for industrial production; the energy storage characteristic is excellent; the energy storage density calculated based on a ferroelectric hysteresis loop is 1.73 to 1.98J / cm<3>; the energy storage efficiency is 90 percent or higher.

Owner:SHAANXI UNIV OF SCI & TECH

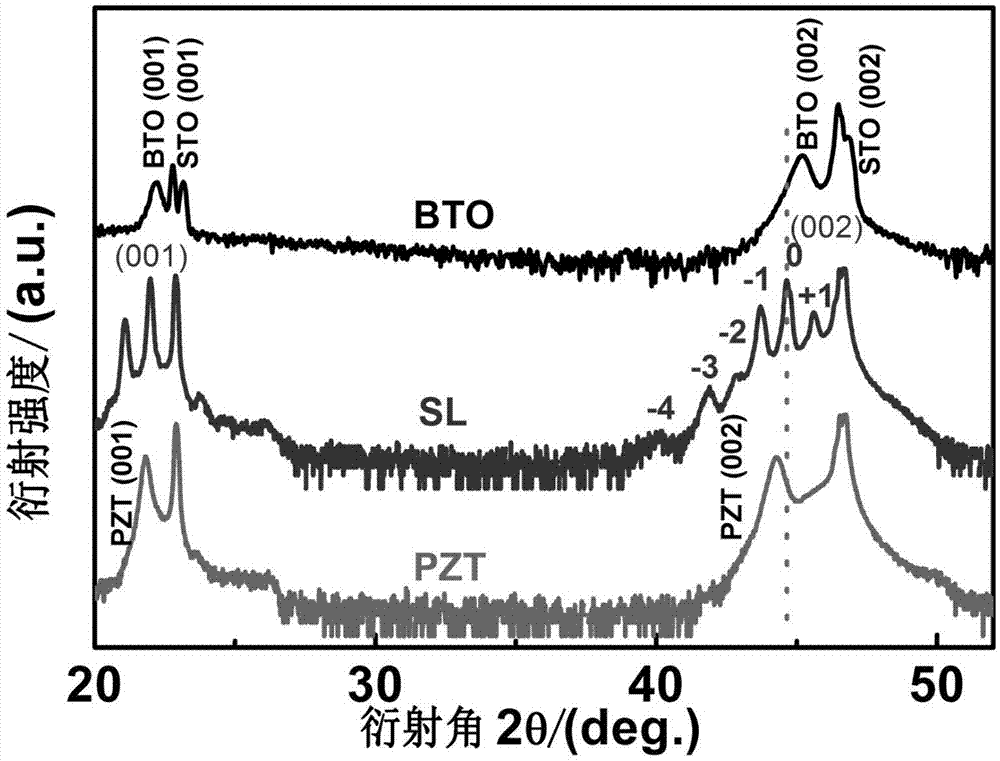

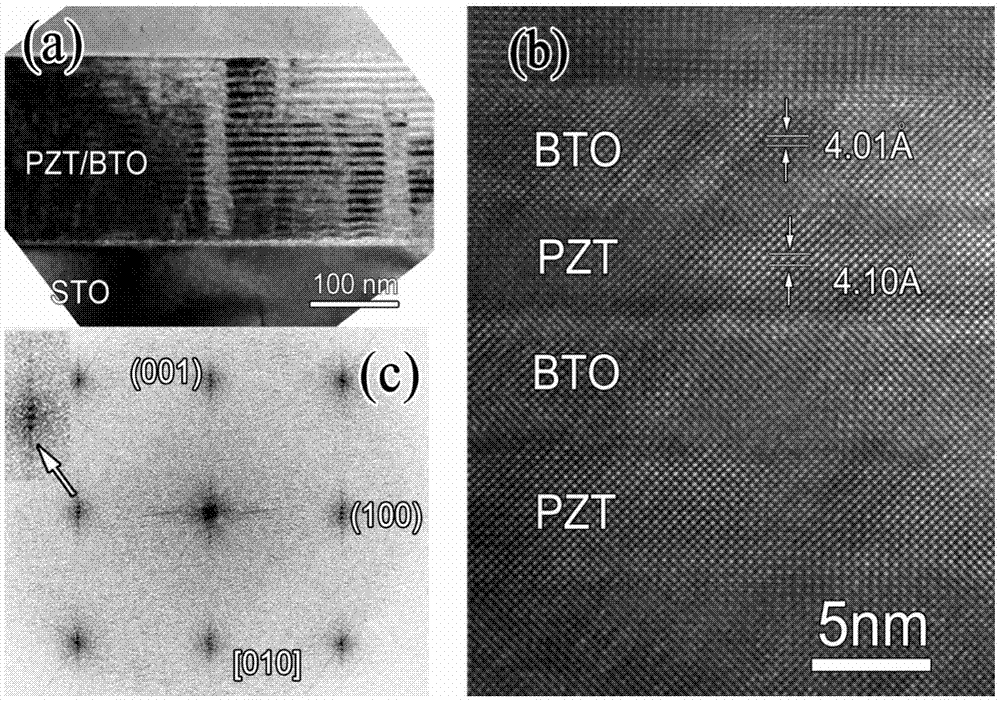

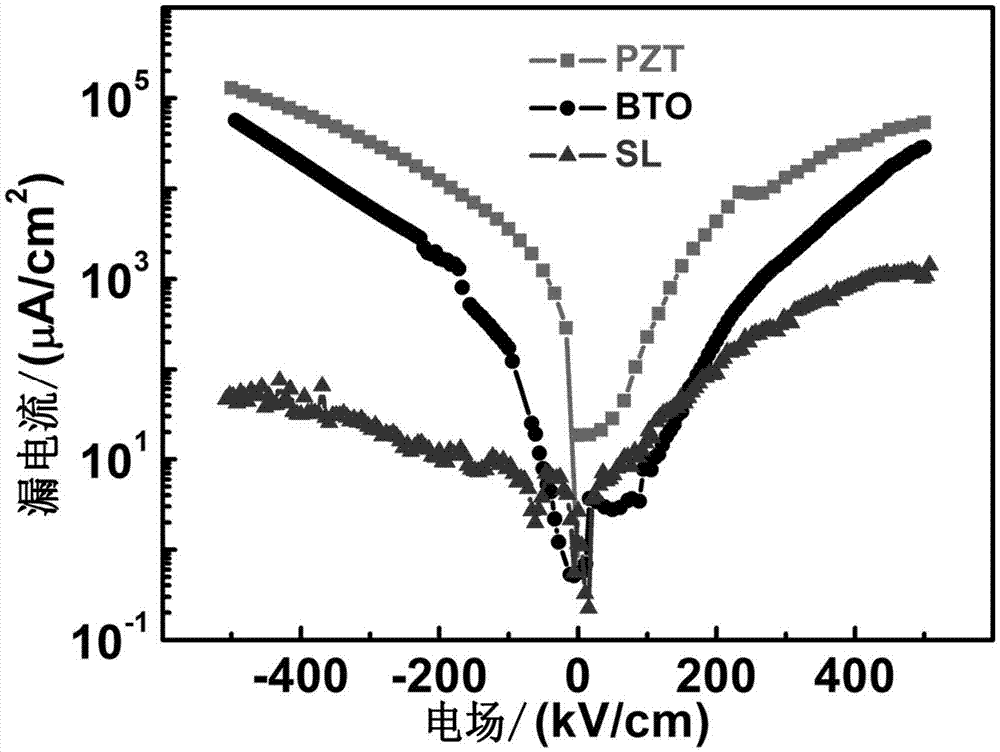

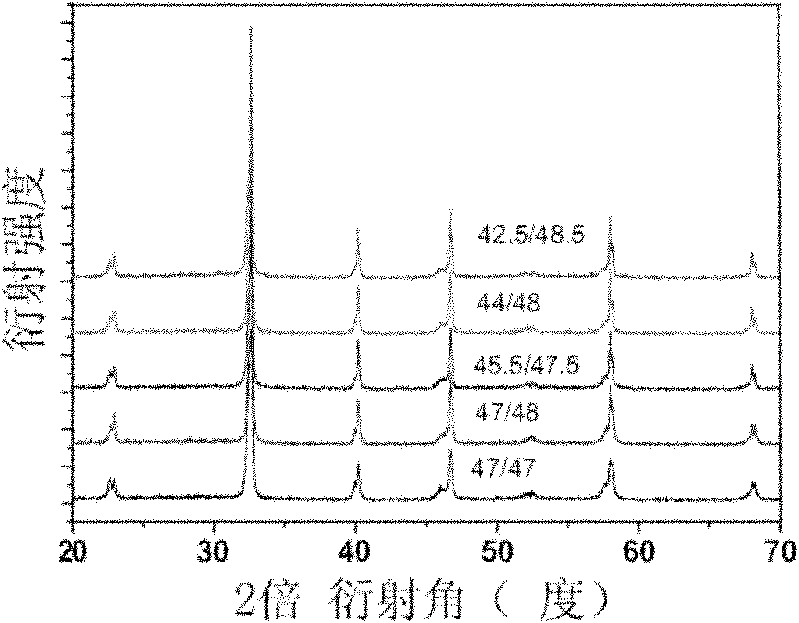

Lead zirconate titanate/barium titanate ferroelectric superlattice material, and preparation method thereof

InactiveCN106854748AHigh dielectric constantLow dielectric lossVacuum evaporation coatingSputtering coatingLead zirconate titanateBarium titanate

The invention provides a lead zirconate titanate / barium titanate ferroelectric superlattice material, and a preparation method thereof. The lead zirconate titanate / barium titanate ferroelectric superlattice material is composed of lead zirconate titanate and barium titanate which are obtained via periodic growth, wherein the periodic thickness of the lead zirconate titanate and barium titanate ranges from 5 to 72nm. Compared with single-layer lead zirconate titanate and barium titanate ferroelectric film, the lead zirconate titanate / barium titanate ferroelectric superlattice material possesses following advantages: leakage current is reduced by 2 to 3 orders of magnitude, dielectric loss is reduced by one order of magnitude, and dielectric constant is increased by nearly 100%; and ferroelectric superlattice possesses more symmetrical ferroelectric hysteresis loop. According to the preparation method, deposition of lead zirconate titanate and barium titanate obtained via periodic alternative growth on a 0.7% Nb-SrTiO3(001) base plate provided with a buffer layer is carried out via pulsed laser deposition, and the periodic thickness superlattice is adjusted accurately via controlling laser irradiation time. The application prospect of the lead zirconate titanate / barium titanate ferroelectric superlattice material as a high-performance ferroelectric substance in the fields of integrated ferroelectric microelectronic devices such as sensors and memorizers is promising.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

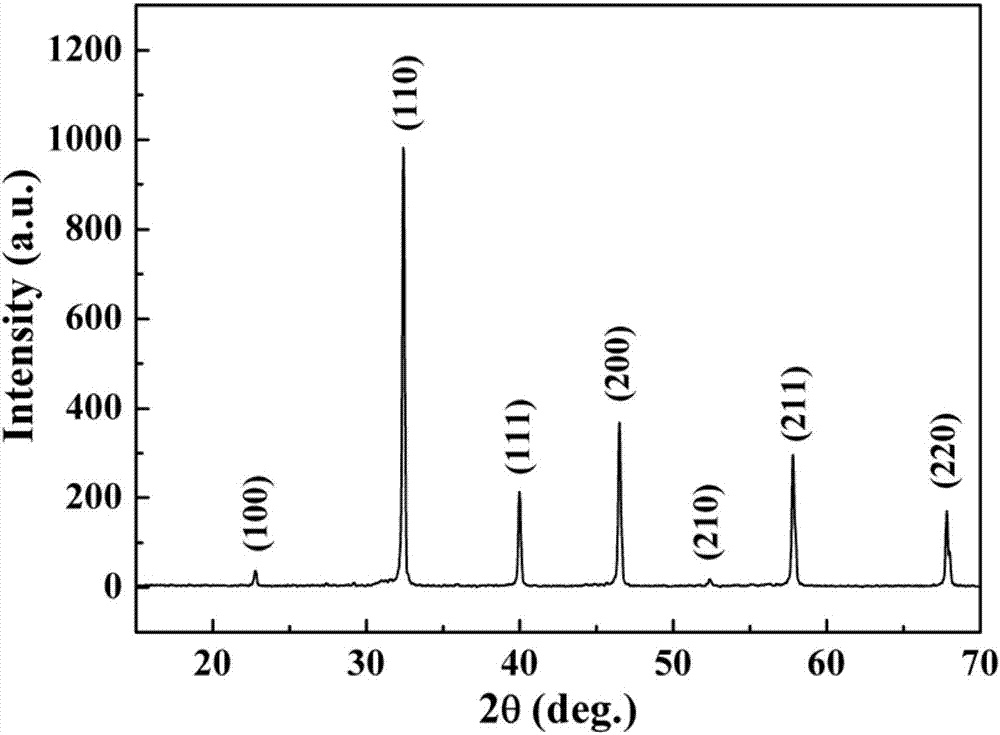

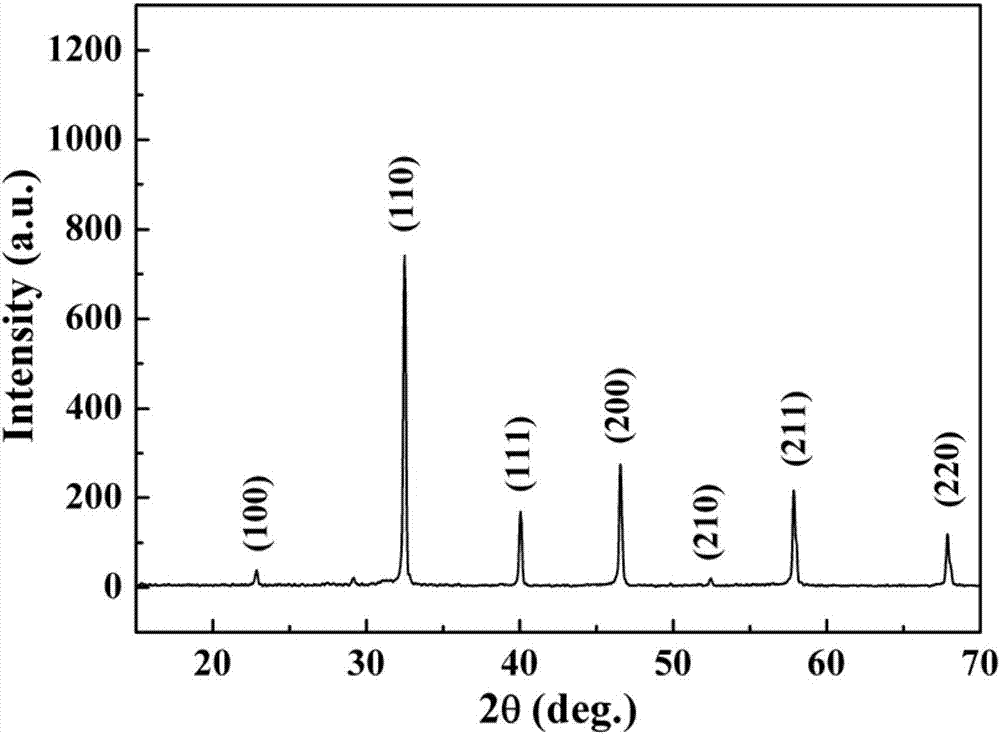

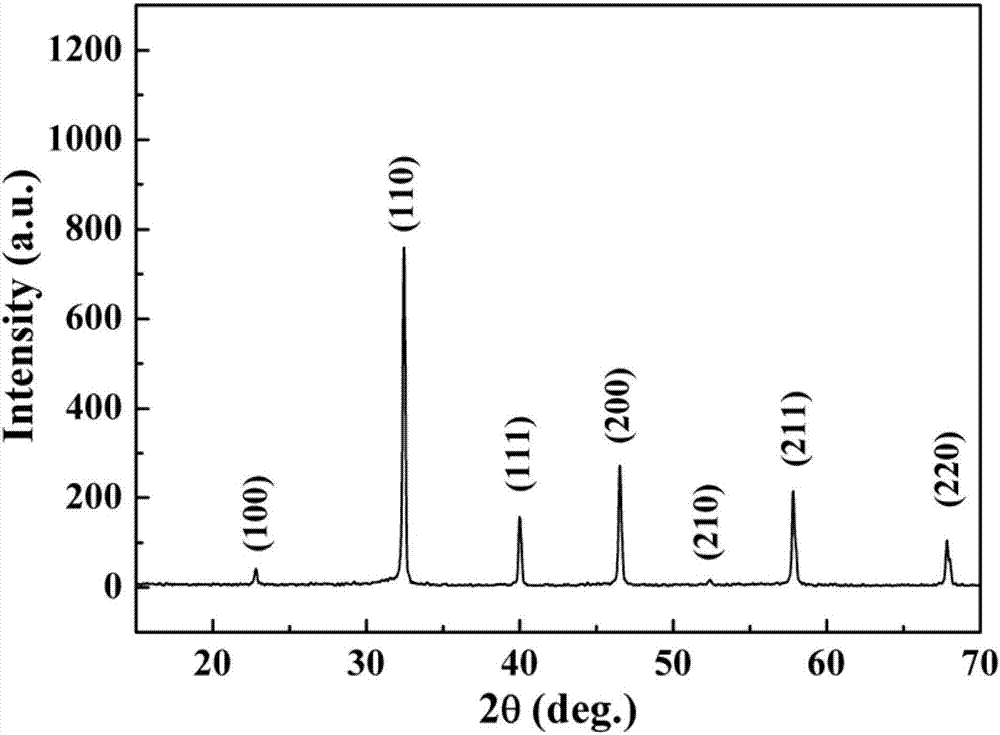

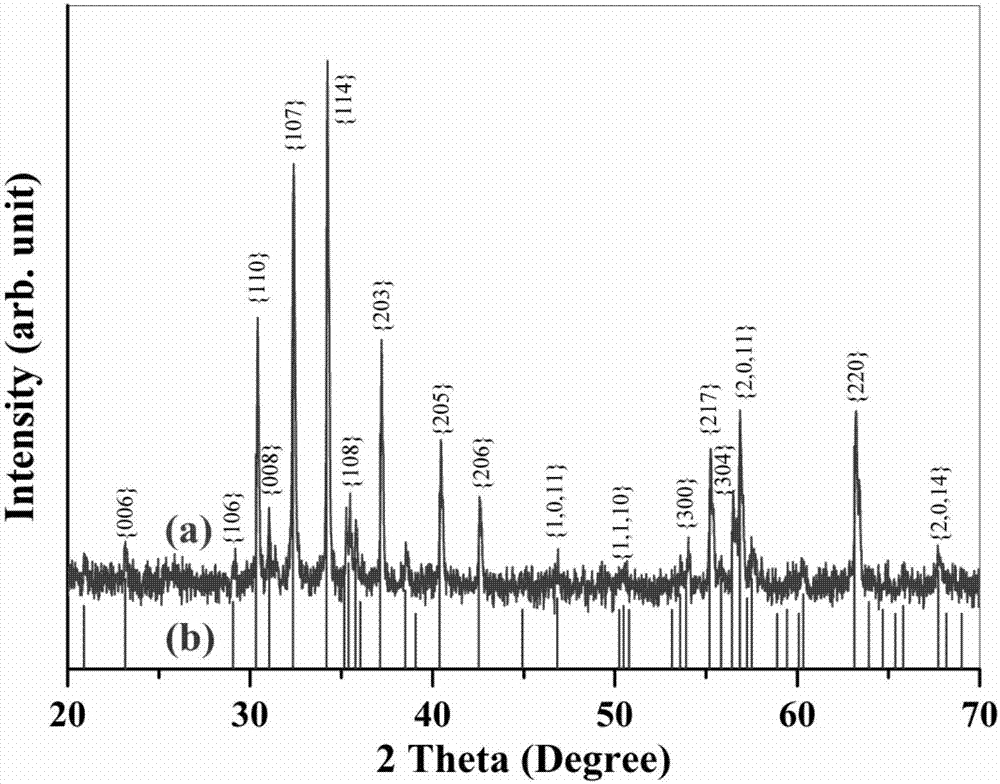

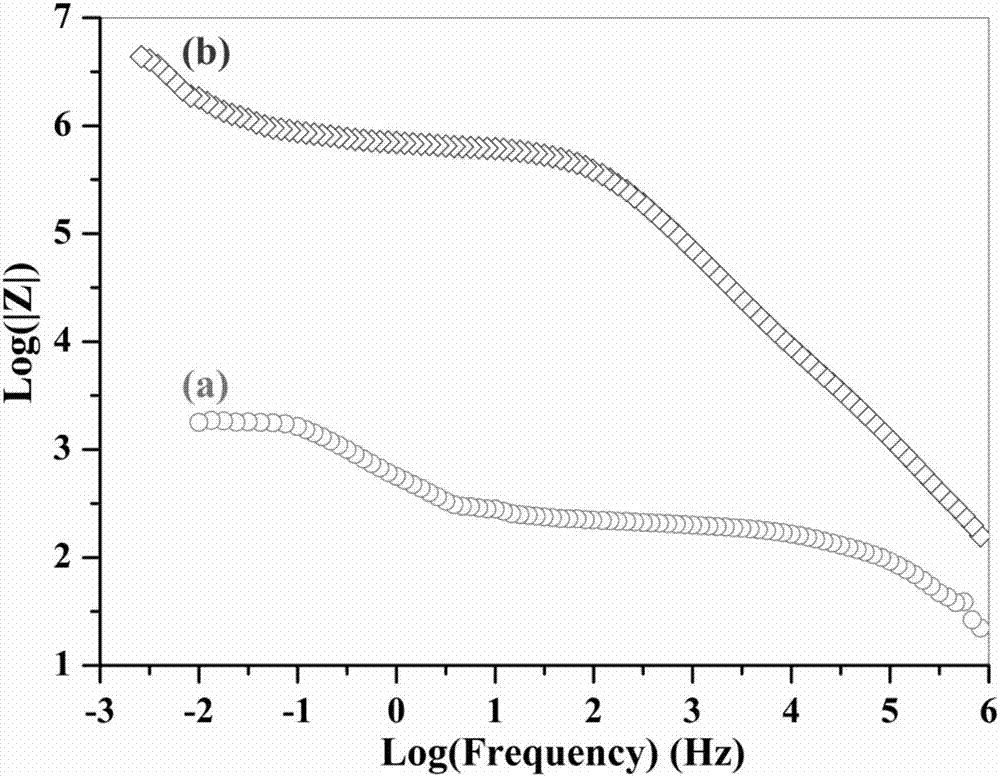

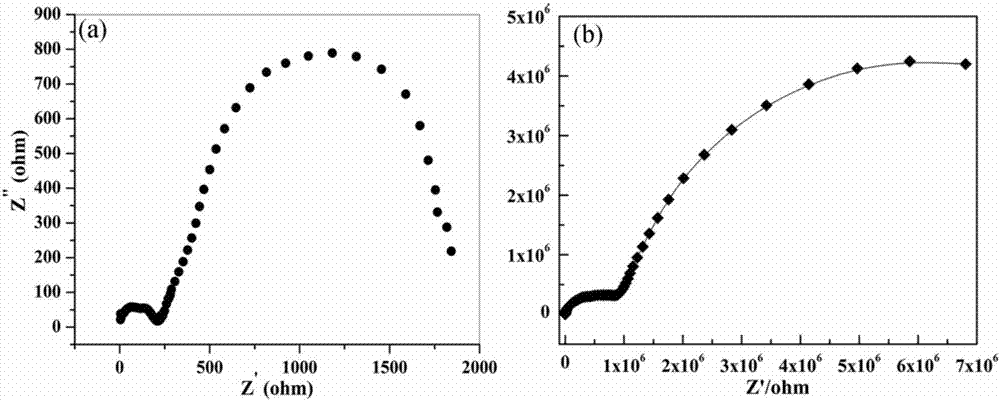

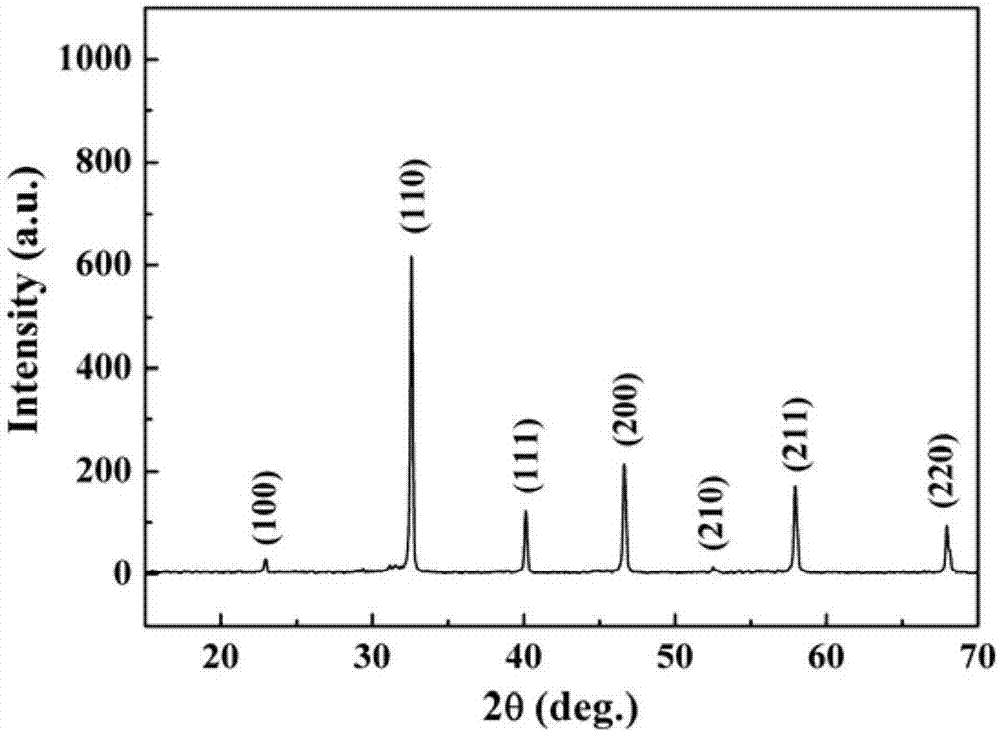

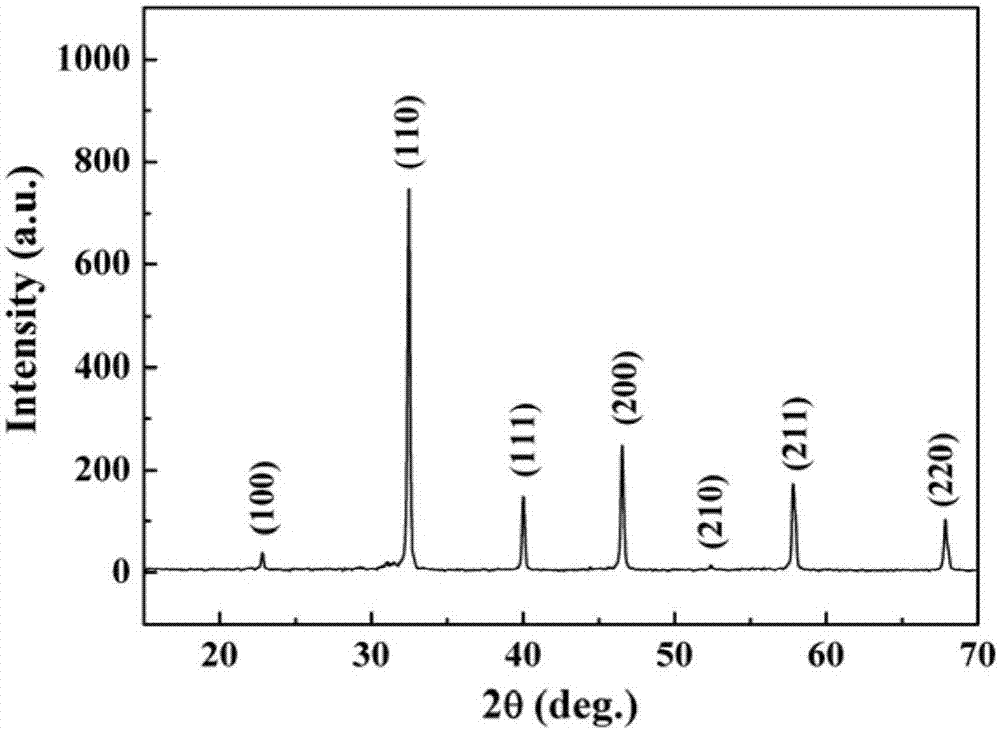

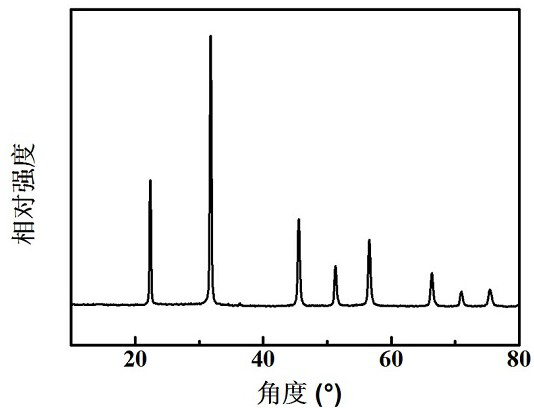

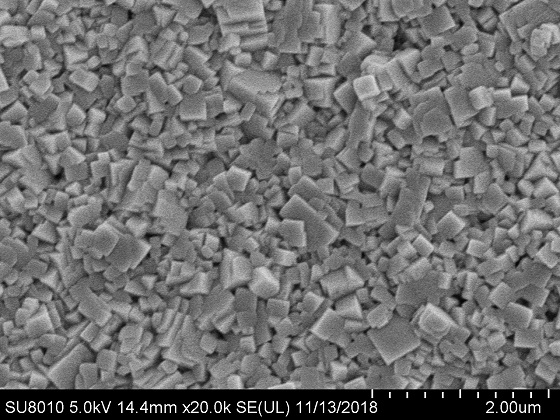

Single-phase multiferroic M-type strontium ferrite ceramic and preparation method thereof

InactiveCN107032776AMultiferroicCoercivity of large magnetic fieldHexagonal crystal systemSpace group

The invention relates to a single-phase multiferroic M-type strontium ferrite ceramic material and a preparation method thereof. The chemical formula of the ceramic material is SrFe12O19 and belongs to a hexagonal crystal system, the space group is P63 / mmc, crystal grains are uniformly distributed, the average crystal grain is 0.5-5 mu m, and the ceramic material is in dark red and has good ferroelectricity and ferromagnetism simultaneously at the room temperature. The single-phase multiferroic M-type strontium ferrite ceramic material and the preparation method have the beneficial effects that the prepared M-type strontium ferrite ceramic material has multiferroic performance, has saturated ferroelectric hysteresis loop and larger magnetic field coercivity at the room temperature, thereby being capable of having quite good ferroelectricity and ferromagnetism simultaneously. Meanwhile, tests prove that the remanent polarization of the M-type strontium ferrite ceramic material is 126.98 mu C / cm<2>, the coercive electric field is 8.28 kV / m, the remanent magnetization is 35.8 emu / g, and the coercive field is 6192Oe.

Owner:WUHAN UNIV OF TECH

Lead-free low-loss high-energy-density ceramic material and preparation method thereof

ActiveCN107445611AHigh energy storage densityHigh energy storage density and high energy storage efficiencyElectricityAdhesive

The invention relates to a lead-free low-loss high-energy-density ceramic material and a preparation method thereof. The preparation method comprises the steps of compounding according to a chemical formula (1-x)SrTiO3-x(0.95Bi0.5Na0.5TiO3-0.05BaAl0.5Nb0.5O3), wherein x is a mole fraction, and is larger than or equal to 0.1 and less than or equal to 0.8; ball-milling and drying to obtain raw material powder; adding an adhesion agent into the obtained raw material powder, pelleting, after ageing for 24 to 48 hours, pressing into tablets, after discharging adhesives, sintering at 1225 to 1350 DEG C, and obtaining the lead-free low-loss high-energy-density ceramic material. The ceramic material provided by the invention is simple and stable in preparation process, suitable for industrial production, low in dielectric loss, and excellent in energy storage property, and has the energy storage density being between 1.40 to 1.89J / cm<3> and the energy storage efficiency being between 72 to 97 percent calculated based on a ferroelectric hysteresis loop.

Owner:SHAANXI UNIV OF SCI & TECH

Re2x/3(Ba0.06Bi0.47Na0.47)1-xMeyTi1-yO3 leadless antiferroelectric high-energy density ceramic and preparation method thereof

The invention relates to Re2x / 3(Ba0.06Bi0.47Na0.47)1-xMeyTi1-yO3 leadless antiferroelectric high-energy density ceramic and a preparation method thereof. x is greater than or equal to 0.02 and is less than or equal to 0.2, y is greater than or equal to 0 and is less than or equal to 0.1, Re represents one of La, Sm, Nd, Gd, Dy and Er and Me represents one of Zr and Sn. The preparation method comprises synthesizing Re2x / 3(Ba0.06Bi0.47Na0.47)1-xMeyTi1-yO3 powder by a traditional powder synthesis technology, and preparing the Re2x / 3(Ba0.06Bi0.47Na0.47)1-xMeyTi1-yO3 leadless antiferroelectric high-energy density ceramic by a spark plasma sintering (SPS) technology. The preparation method is simple and efficient and has energy density of 0.7-1.6J / cm<3> calculated based on a ferroelectric hysteresis loop.

Owner:GUILIN UNIV OF ELECTRONIC TECH

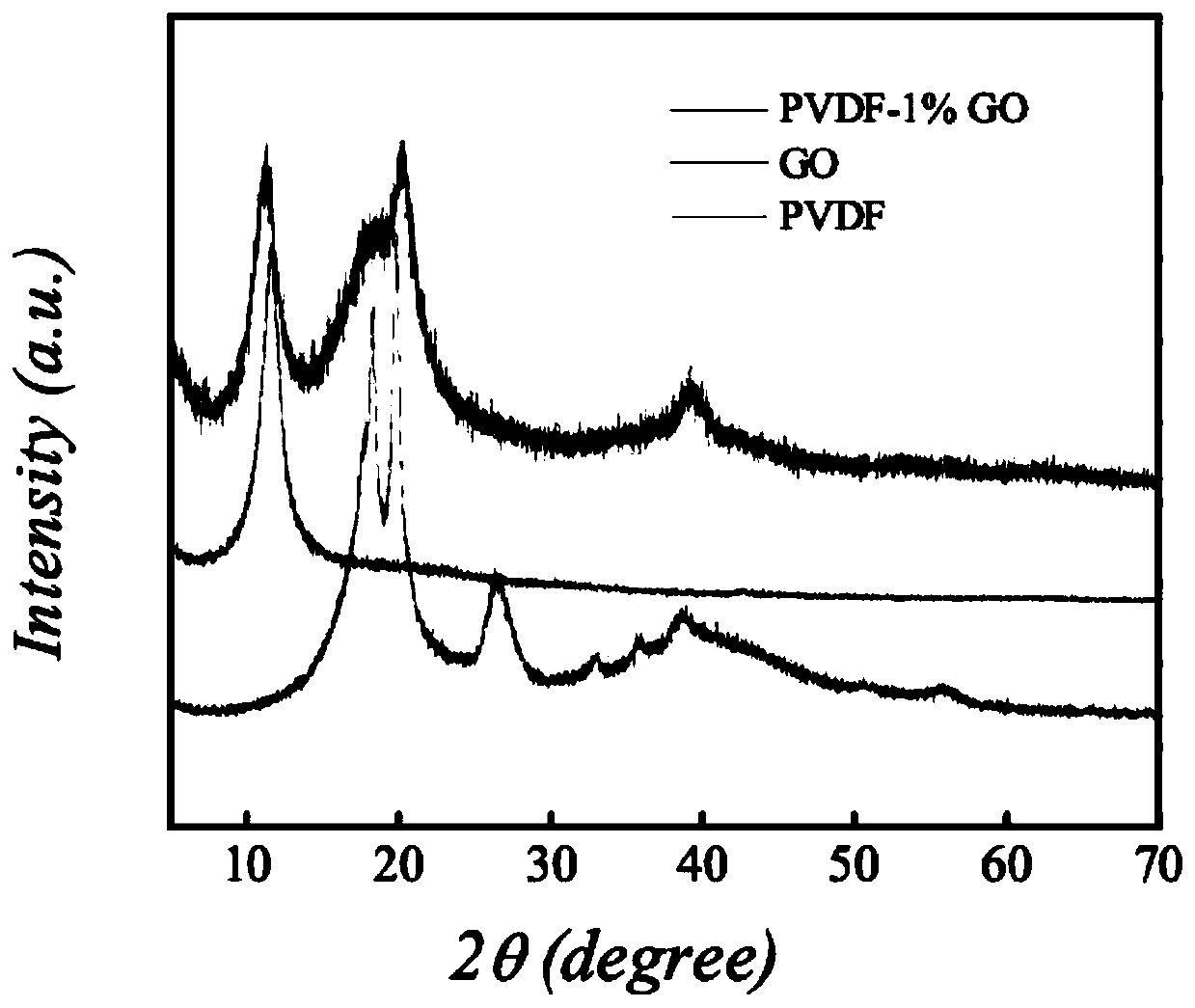

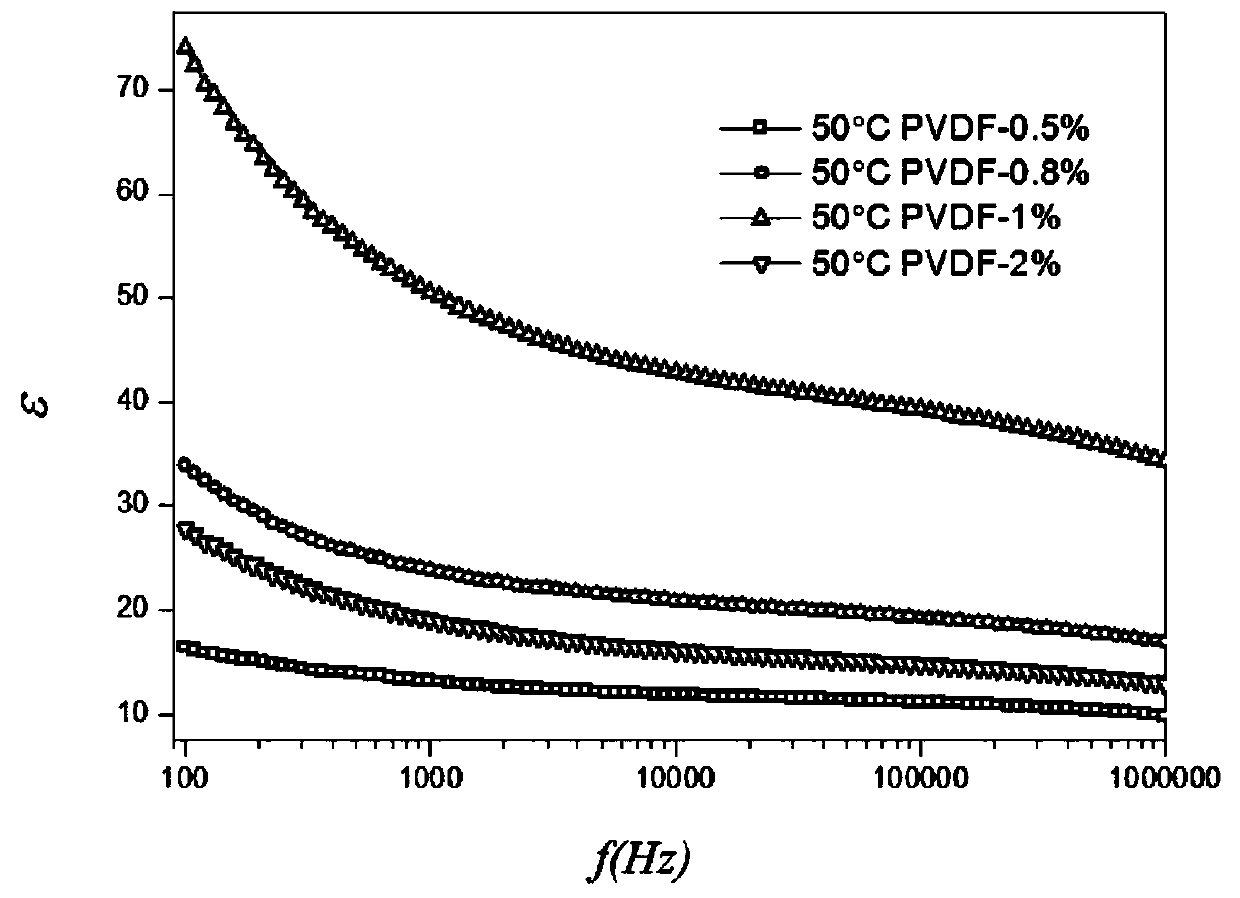

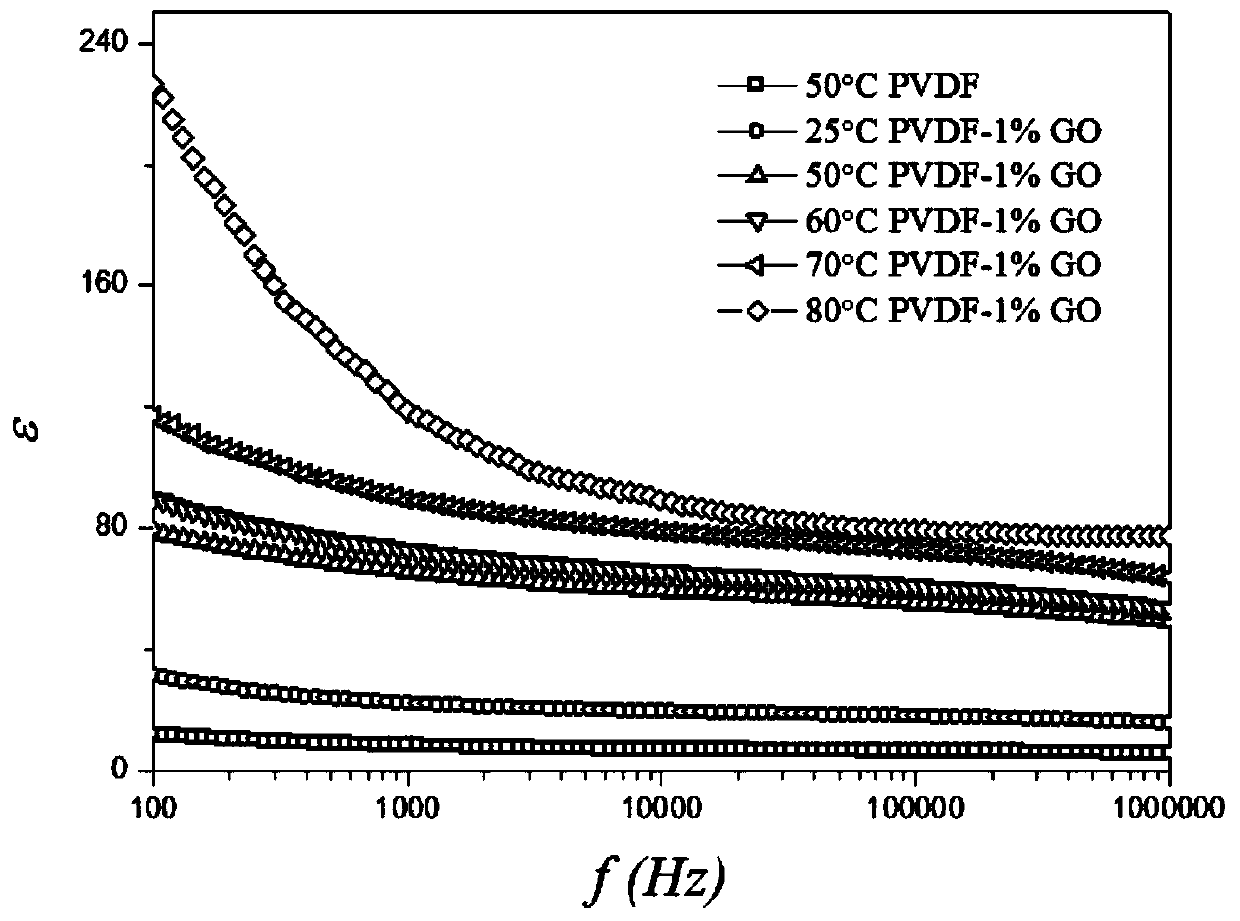

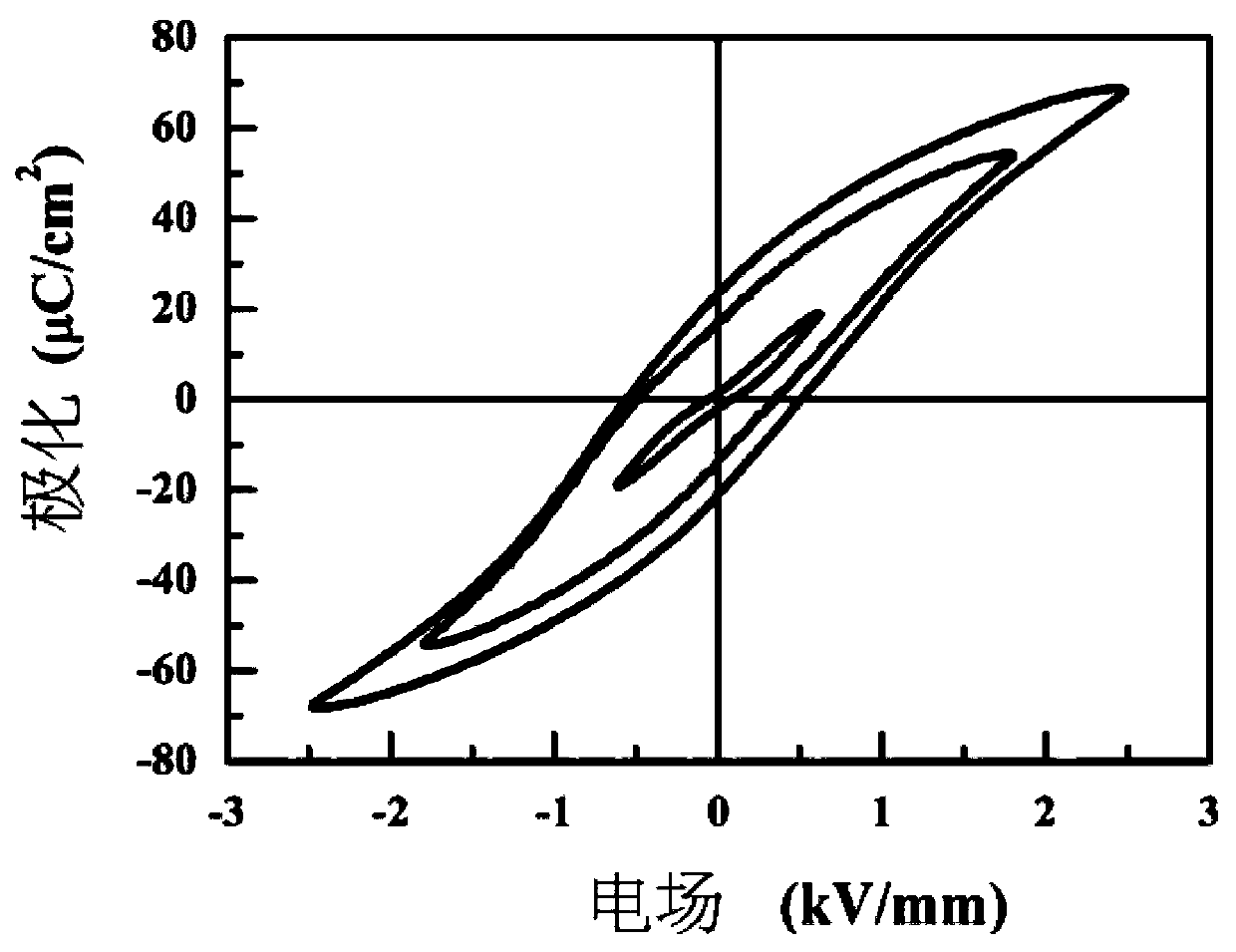

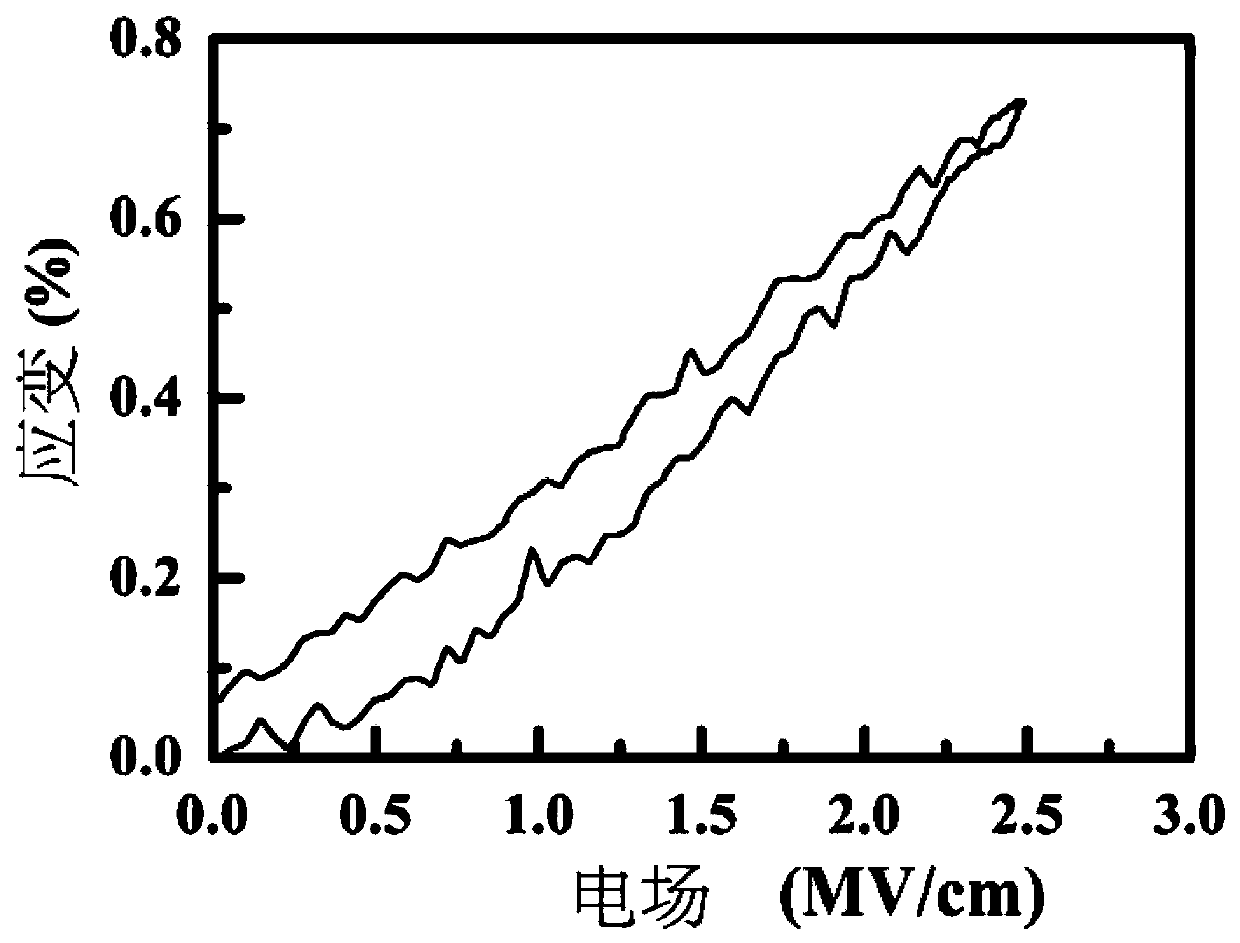

Temperature control-based high-energy storage flexible composite membrane and preparation method thereof

ActiveCN110070990AGood dispersionHigh dielectric constantFixed capacitor dielectricHigh energyFerroelectric hysteresis

The invention discloses a temperature control-based high-energy storage flexible composite membrane and a preparation method thereof. According to the flexible composite membrane, polyvinylidene fluoride is taken as a matrix; a certain amount of graphene oxides are uniformly dispersed in the polyvinylidene fluoride matrix; through controlling the composite temperature, the reduction degree of thegraphene oxides is controlled so that the content of conducting particles in the composite membrane is controlled; and through measuring ferroelectric hysteresis loops, energy storage density in one-to-one correspondence with the ferroelectric hysteresis loops is obtained. Only the temperature needs to be changed, and the amount of the graphene oxides does not need to be changed, so that when being compared with the traditional method for increasing the conducting particles, the method is capable of avoiding the gathering of reduced graphene oxides, effectively improving the dispersion effectof the reduced graphene oxides in the polyvinylidene fluoride matrix, reducing the dielectric loss and increasing the energy storage density. In addition, the flexible composite membrane and the preparation method are simple and easy in process, low in cost and soft and light in membrane, can easily realize a surface mounting function of micro capacitors and can be widely applied to the fields offlexible material energy storage and the like.

Owner:NANJING UNIV OF POSTS & TELECOMM

Bi0.5Na0.4Li0.1MxTi1-xO3 unleaded antiferroelectric high energy density ceramic and preparation method thereof

The invention relates to a Bi0.5Na0.4Li0.1MxTi1-xO3 unleaded antiferroelectric high energy density ceramic and a preparation method thereof. X satisfies the relation of 0.03<= x<=0.3; M is one of (Me1 / 3Nb2 / 3), (Mb1 / 2Nb1 / 2), (Me1 / 3Ta2 / 3) and (Mb1 / 2Ta1 / 2); Me in (Me1 / 3Nb2 / 3), (Mb1 / 2Nb1 / 2), (Me1 / 3Ta2 / 3) and (Mb1 / 2Ta1 / 2) represents one of Mg, Zn and Ni; and Mb in (Me1 / 3Nb2 / 3), (Mb1 / 2Nb1 / 2), (Me1 / 3Ta2 / 3) and (Mb1 / 2Ta1 / 2) represents one of Al, Co and Cr. The method employs a high temperature and pressure sintering furnace for preparing the Bi0.5Na0.4Li0.1MxTi1-xO3 unleaded antiferroelectric high energy density ceramic, which has energy density calculated based on the ferroelectric hysteresis loop up to 0.8-1.6 J / cm<3>.

Owner:GUILIN UNIV OF ELECTRONIC TECH

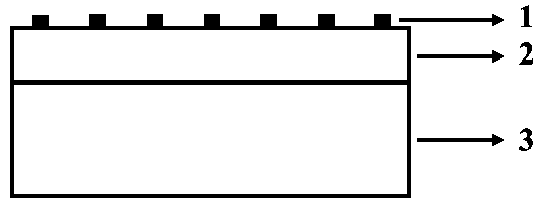

Bismuth ferrite based thin film having high polarization intensity and large strain characteristics and preparation method thereof

InactiveCN110937925AHigh polarizationLarge strain characteristicsIron compoundsCrystallographyFerroelectric thin films

The invention discloses a bismuth ferrite based thin film having high polarization intensity and large strain characteristics and a preparation method thereof. The bismuth ferrite based thin film includes a substrate, a bismuth ferrite based ferroelectric layer, and a top electrode, wherein the bismuth ferrite based ferroelectric layer has the composition of 0.7BixFeO3-BaTiO3+ywt%MnCO3, wherein x= 1.0-1.2, y = 0.1-0.2. The bismuth ferrite based ferroelectric thin film is highly oriented, and has a ferroelectric hysteresis loop of great rectangularity at room temperature, is high in polarization intensity, can reach up to 120 [mu]C / cm<2> in self intensity of polarization, can reach up to 1.26% in monopole strain, and has excellent strain performance.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Lead-free high-energy-storage-density ceramic material and preparation method of same

A lead-free high-energy-storage-density ceramic material and a preparation method of same. The preparation method includes the following steps: 1) preparing raw materials according to the chemical formula (1-x)Bi<0.48>La<0.02>Na<0.48>Li<0.02>Ti<0.98>Zr<0.02>O<3>-xNa<0.73>Bi<0.09>NbO3, wherein x refers to molar fraction, 0.06 <= x <= 0.12; 2) performing ball-milling and drying to obtain a powder; 3) adding a binder to the powder for granulation, and aging the granules for 24-48 h, pressing the granules into sheets, performing glue removal treatment, and sintering the mixture at 1100-1200 DEG C to obtain the lead-free high-energy-storage-density ceramic material. The preparation method is simple and stable and is suitable for industrial production. The ceramic material has high energy-storage performance, is more than 2 J / cm<3> in energy storage density calculated on the basis of ferroelectric hysteresis loop at room temperature and reaches 1.66 J / cm<3> in energy storage density at 90 DEG C under electric field of 140 kV / cm.

Owner:SHAANXI UNIV OF SCI & TECH

Lead-free anti-ferroelectric material and preparation method thereof

The invention relates to a preparation method of a lead-free anti-ferroelectric material, belonging to the technical field of ceramic preparation. The preparation method comprises the following steps of: selecting analysis-class Na2CO3, Bi2O3, BaCO3 and TiO2 as raw materials, blending the raw materials according to a chemical formula of NayBizTi(1-x)-xBaTiO3, then carrying out ball milling and precalcination, carrying out secondary ball milling, then bonding, pelleting and pressing to obtain a blank body, and finally sintering the blank body to obtain the lead-free anti-ferroelectric material. In the invention, the mol ratio of sodium to bismuth is less than 1, i.e. the bismuth is rich and the sodium is deficient, or the bismuth is rich independently or the sodium is deficient independently; the prepared material can display a double ferroelectric hysteresis loop at the room temperature and generate the change from the anti-ferroelectric phase to the ferroelectric phase under the electric field action; and the stability for inducing the ferroelectric phase can be adjusted by the sodium-bismuth ratio.

Owner:SHANGHAI JIAO TONG UNIV

Rex/3(Ba0.06Bi0.47Na0.47)1-xTi1-xRxO3 leadless antiferroelectric ceramic with high energy density and preparation method thereof

The invention relates to Rex / 3(Ba0.06Bi0.47Na0.47)1-xTi1-xRxO3 leadless antiferroelectric ceramic with high energy density and a preparation method thereof. x is greater than or equal to 0.02 and is less than or equal to 0.2, Re is one of La, Sm, Nd, Gd, Dy, Er and Y and R is one of Nb and Ta. Rex / 3(Ba0.06Bi0.47Na0.47)1-xTi1-xRxO3 powder is synthesized by a traditional powder synthesis technology and Rex / 3(Ba0.06Bi0.47Na0.47)1-xTi1-xRxO3 leadless antiferroelectric ceramic is prepared by a spark plasma sintering (SPS) technology. Energy density of the Rex / 3(Ba0.06Bi0.47Na0.47)1-xTi1-xRxO3 leadless antiferroelectric ceramic with high energy density is calculated based on ferroelectric hysteresis loop and is in a range of 0.5-1.5J / cm<3>.

Owner:GUILIN UNIV OF ELECTRONIC TECH

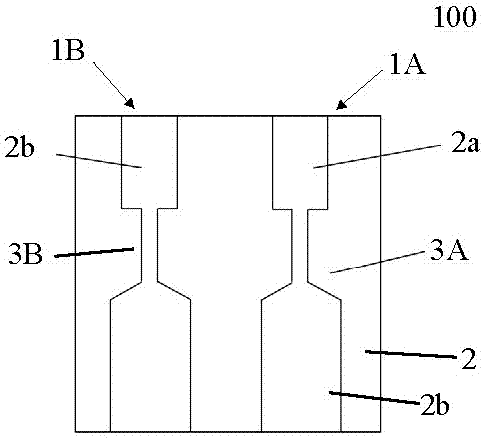

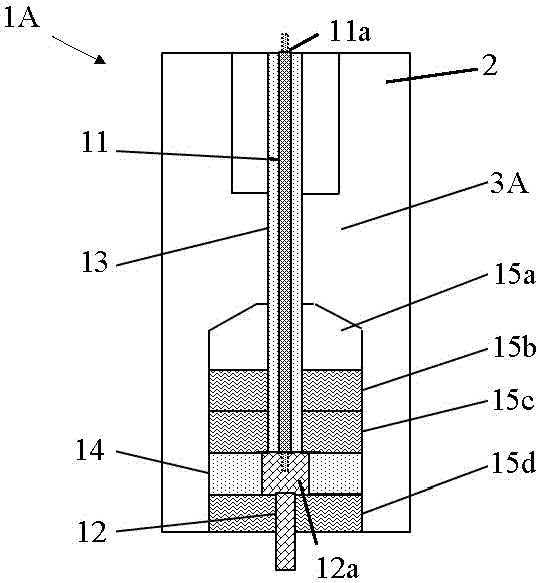

Clamp for measuring ferroelectric hysteresis loop made of ferroelectric materials under isostatic pressing

ActiveCN107402316AAccurate measurementRealize measurementMeasurement instrument housingElectricityElectrical performance

The invention provides a clamp for measuring a ferroelectric hysteresis loop made of ferroelectric materials under isostatic pressing. The clamp comprises a support equipped with a pair of hollow parts, a pair of clamp main bodies (1A, 1B) which are respectively installed in the hollow parts, and a top cover (4) which covers the clamp main body (1A, 1B) and is fixed on the upper part of the support. Each clamp main bodies (1A, 1B) comprises a conductive bar (11) and a steel column (2) which are connected with each other in upper and lower directions and electrically conducted with each other. Free ends of the conductive bars (11) stretch out of the top cover (4), so first ports (11a) connected with a ferroelectric hysteresis loop measurement meter are formed. Second ports connected with to-be-measured ferroelectric materials are formed in free ends of the steel columns (12). The conductive bars and the steel columns are insulated with the support. According to the invention, research on principles of phase transition of the materials and deepening of understanding of the principles of phase transition are facilitated; actual electrical performance of the materials in the outer field can be acquired; and in addition, the clamp is simple in structure, low in cost and suitable for popularization.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

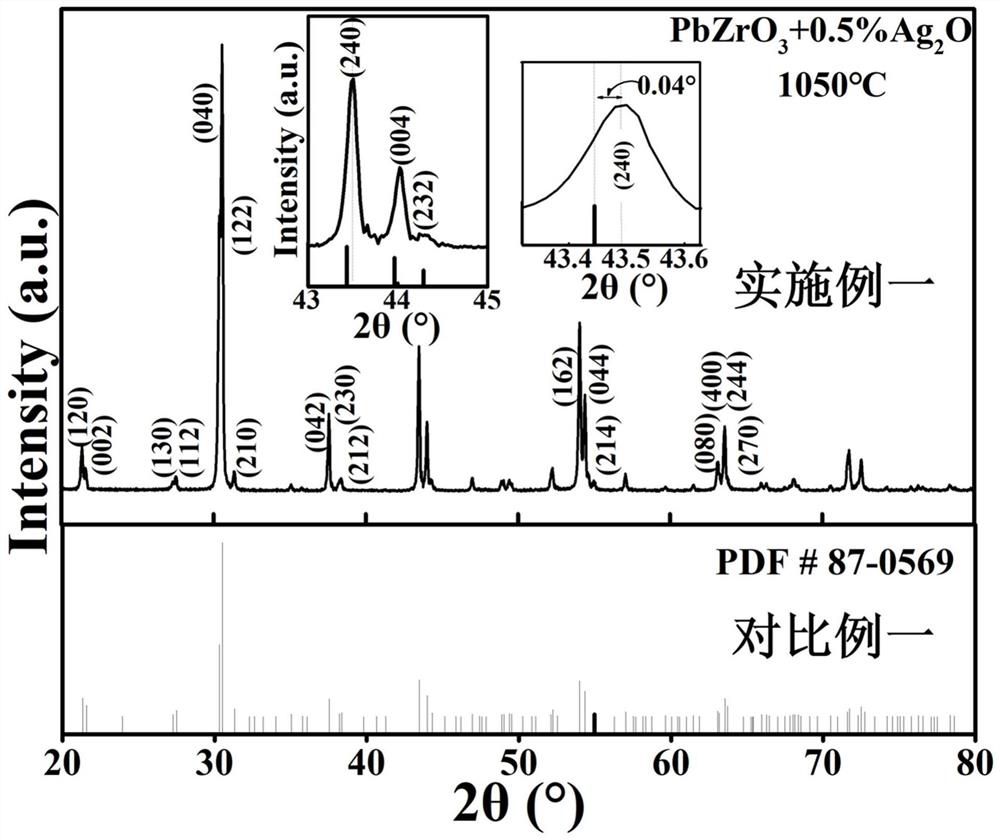

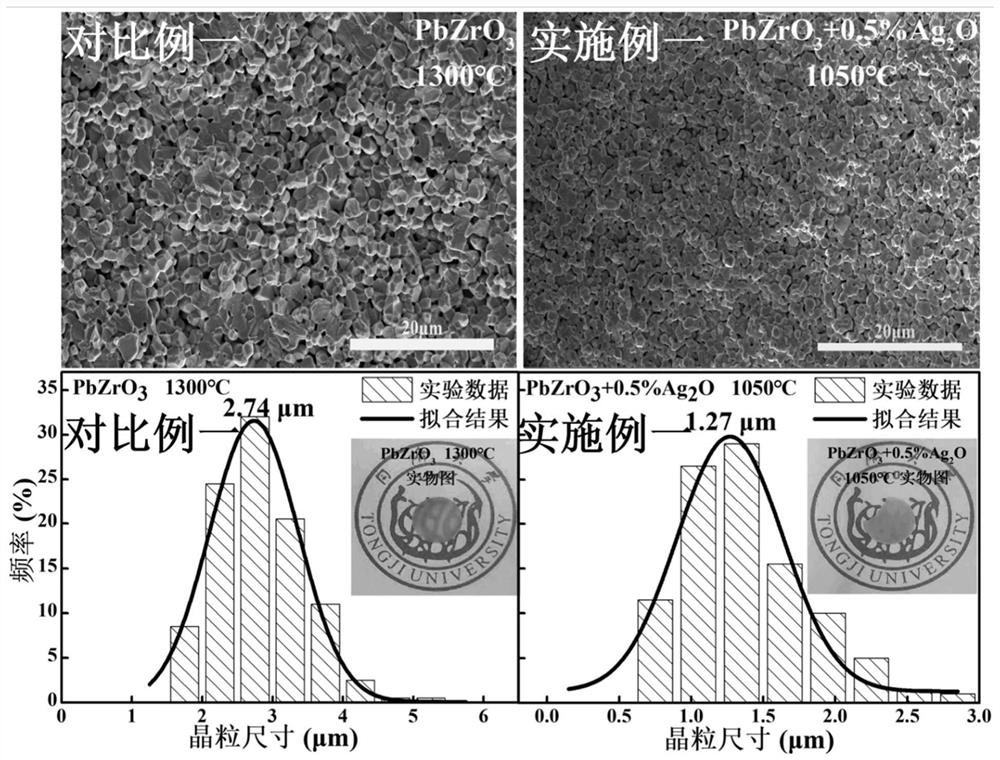

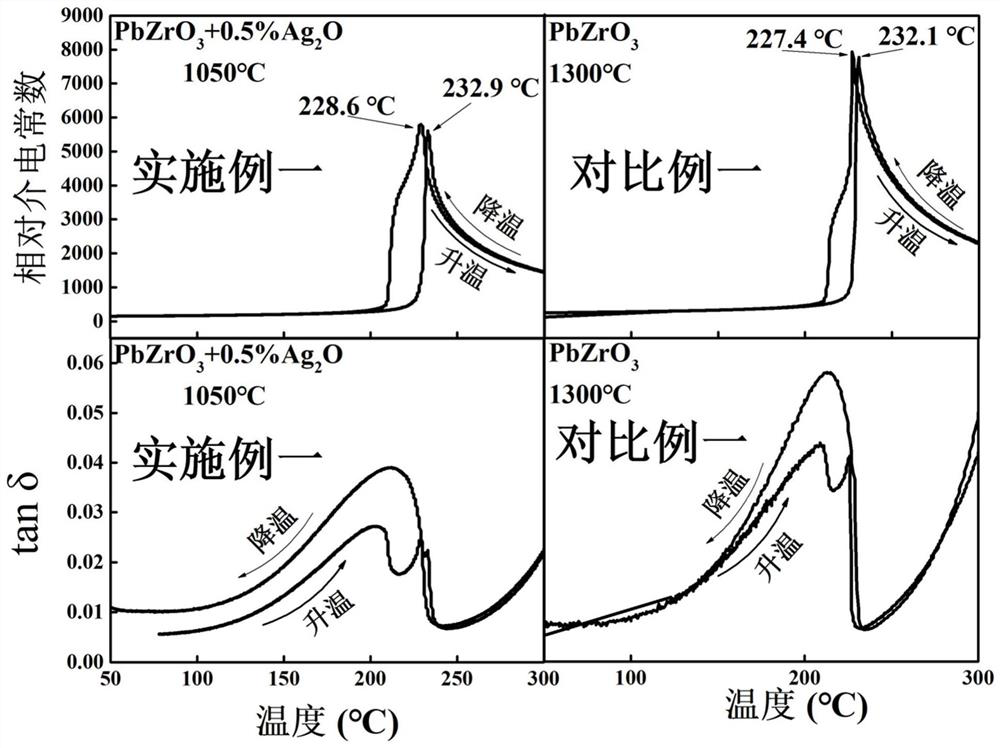

Anti-ferroelectric ceramic material and low-temperature sintering method thereof

ActiveCN112062559ASignificant impactNo reduction in saturation polarizationHigh energyEnergy storage efficiency

The invention relates to an anti-ferroelectric ceramic material and a low-temperature sintering method thereof. The chemical general formula of the anti-ferroelectric ceramic material is PbZrO3. Ag2Opowder is added into anti-ferroelectric ceramic material powder in the secondary ball milling process, and a compact ceramic body is prepared by regulating and controlling the content of Ag2O, compensating lead atmosphere in the sintering process and the like. The sintering temperature of the system is as low as 1050 DEG C, the prepared ceramic body is relatively good in ceramic forming property,and the double ferroelectric hysteresis loop of the PbZrO3 antiferroelectric ceramic at room temperature is obtained. Compared with the prior art, the dielectric material prepared by the invention hasthe advantages of high energy storage density (8.82 J / cm<3>), higher energy storage efficiency (71.71%) and the like, and has very important significance for developing pulse power capacitors with high energy storage density and low-temperature firing capability.

Owner:TONGJI UNIV

Lead-free multi-layer ceramic material with high energy storage density and preparation method thereof

ActiveCN108640675AHigh energy storage densitySimple preparation processStrontium titanium oxideOrganic solvent

The invention relates to a lead-free multi-layer ceramic material with high energy storage density and a preparation method thereof. The preparation method comprises the following steps of uniformly mixing an organic solvent and an emulsifier; adding powder, an adhesive, a dispersant and a plasticizer, and uniformly mixing, so as to obtain a first tape casting slurry, wherein the powder is a mixture of SrTiO3 (strontium titanate) powder and Li2CO3 (lithium carbonate); uniformly mixing the organic solvent and the emulsifier, adding powder, an adhesive, a dispersant and a plasticizer, and uniformly mixing, so as to obtain a second tape casting slurry; respectively performing tape casting and forming the first tape casting slurry and the second tape casting slurry in a tape casting and forming way, so as to obtain a first tape casting layer or a second tape casting layer; then, overlapping, pressurizing, discharging glue, sintering and forming ceramic, so as to obtain the lead-free multi-layer ceramic material with high energy storage density. The lead-free multi-layer ceramic material has the advantages that the preparation technology is simple, the technique is matured, and the lead-free multi-layer ceramic material is suitable for industrialized production; the energy storage density which is calculated on the basis of a ferroelectric hysteresis loop can reach 2.72J / cm<3>, andthe intensity of an electric field can reach 200kV / cm or above.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method of high-performance potassium-sodium niobate-based lead-free energy storage ceramic

InactiveCN112266247AImprove energy storage performanceMaintain maximum polarizationFixed capacitor dielectricHigh energyPotassium niobate

The invention belongs to the field of dielectric capacitor materials, and particularly relates to a preparation method of high-performance potassium-sodium niobate-based lead-free energy storage capacitor ceramic. The potassium-sodium niobate-based ceramic powder is obtained from industrial raw materials through a solid-phase method, a ceramic sample is obtained through unique two-stage sintering,and the energy storage density of the sample is obtained through ferroelectric hysteresis loop testing and calculation. Firstly, the ball milling time of ceramic powder and the two-stage sintering schedule of a green body are adjusted, and then the effective energy storage density and efficiency of the ceramic powder are obtained through ferroelectric analysis. The preparation method of the potassium-sodium niobate-based energy storage ceramic material is simple, convenient and capable of effectively obtaining high energy storage density and efficiency, and has reference significance for preparation of energy storage ceramic materials of other systems.

Owner:UNIV OF JINAN

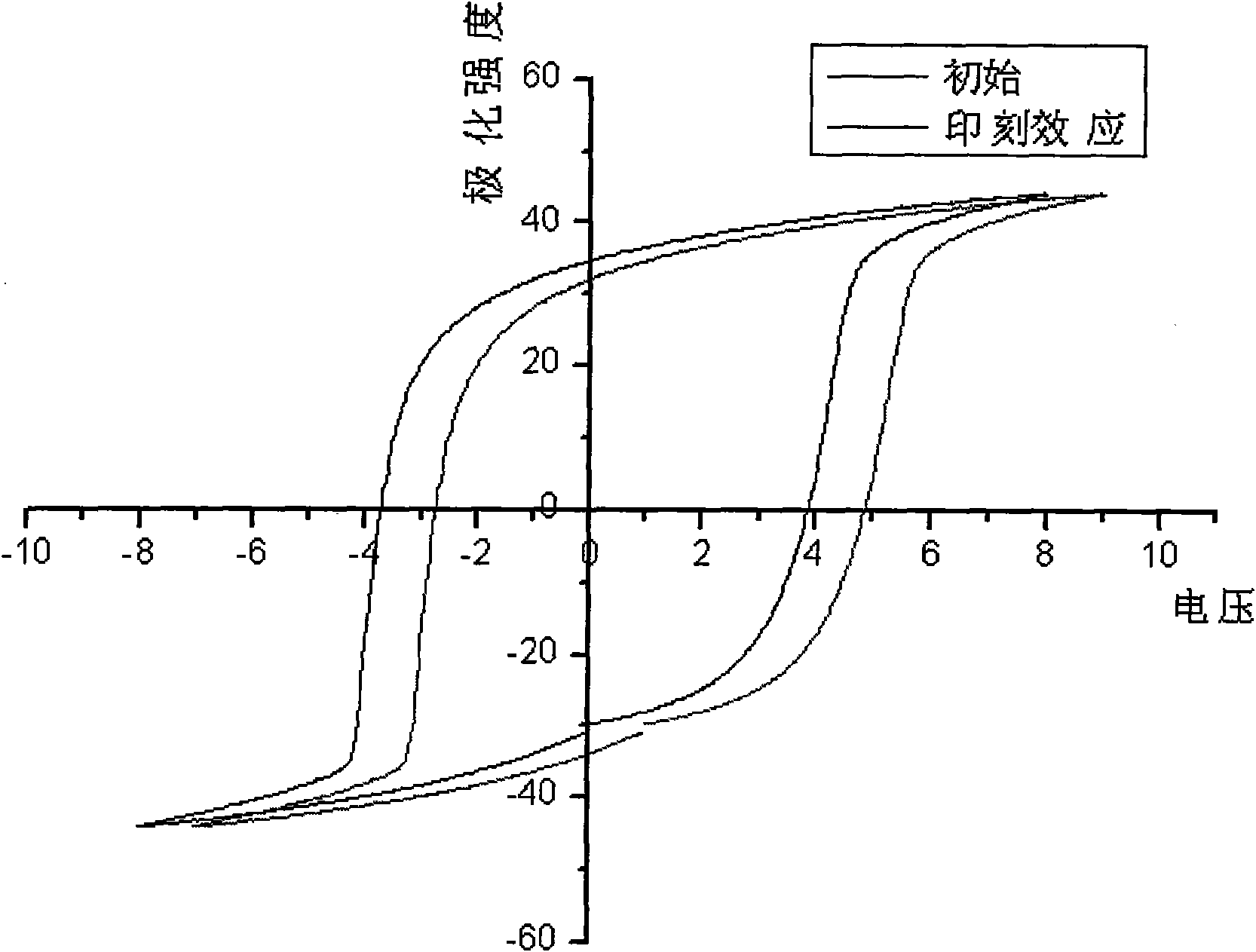

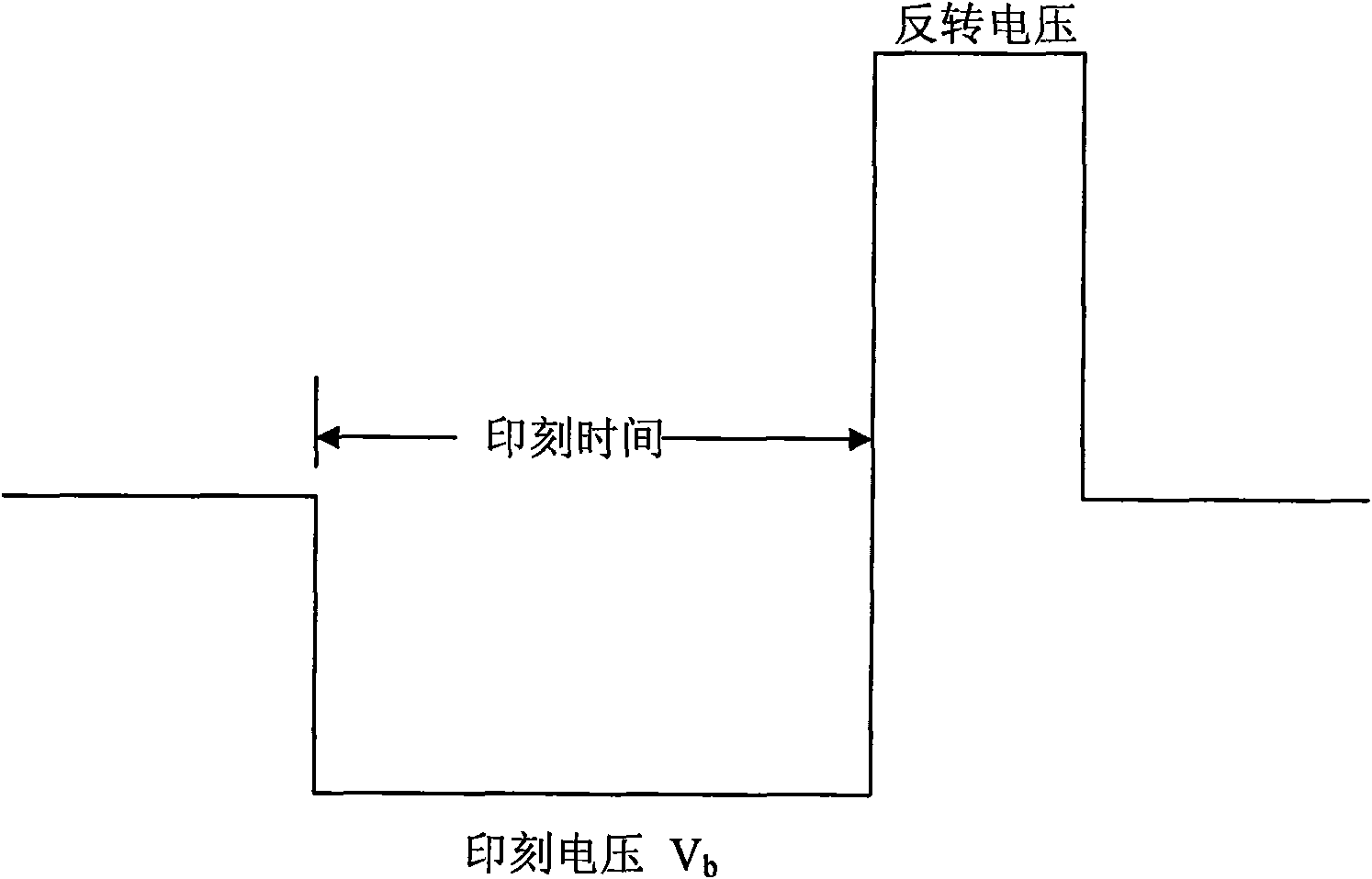

Method for fast measuring imprinting effect of ferroelectric film

The invention belongs to the technical field of microelectronics, and relates to a method for testing the imprinting effect of a ferroelectric film. In the method, the imprinting effect of the ferroelectric film is fast measured by measuring the polarization reversal current of the ferroelectric film; and the method comprises the following steps of: (1) applying a pulse voltage with polarity opposite to that of an imprinting voltage immediately when the pulse voltage which produces the imprinting effect is applied, and measuring the reversal current of the ferroelectric film; and (2) applying the pulse voltage with a preset polarization direction, applying the pulse voltage which has both positive polarity and negative polarity and functions in imprinting after a period of relaxation time, producing the imprinting effect after a period of time, and finally applying a voltage which has both the positive polarity and negative polarity and is exactly the same as the pulse voltage with both the positive polarity and negative polarity to measure the reversal current. The method can replace the conventional methods for obtaining Vc by measuring a ferroelectric hysteresis loop, and has the advantages of capacity of greatly shortening time required by test on the imprinting effect and vast application prospect.

Owner:FUDAN UNIV

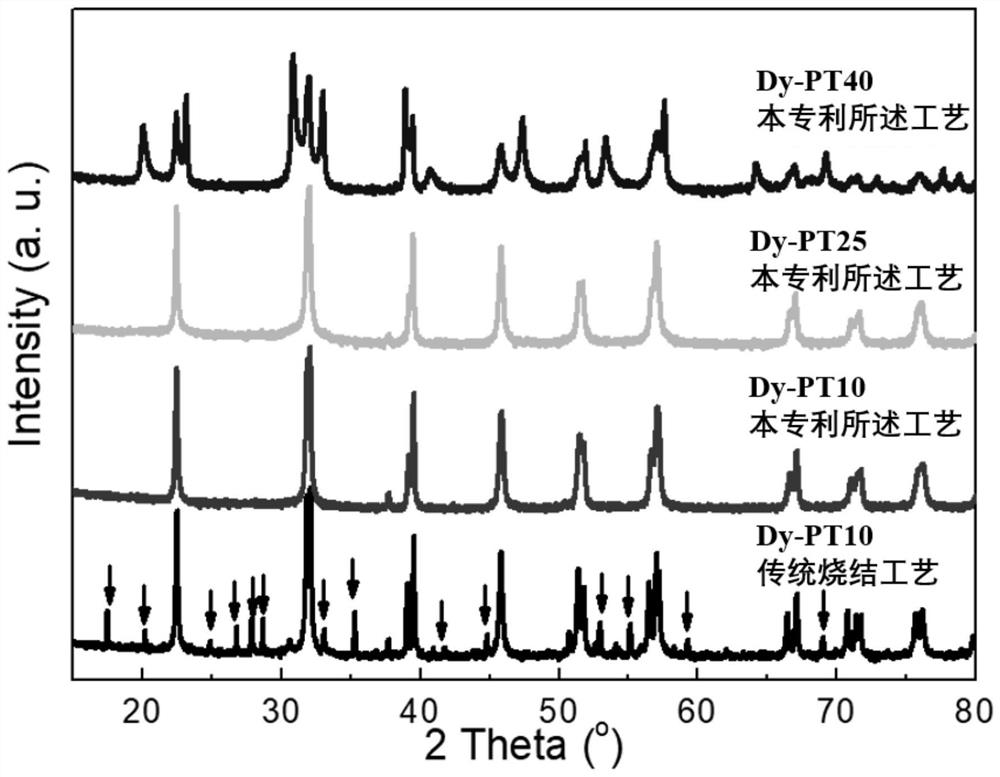

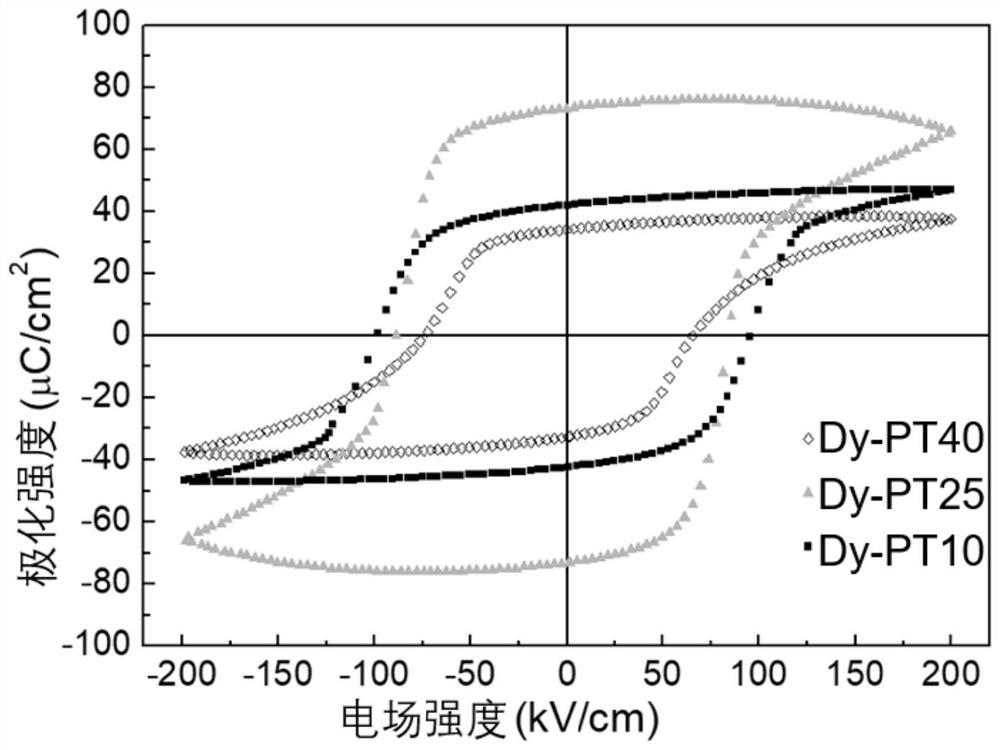

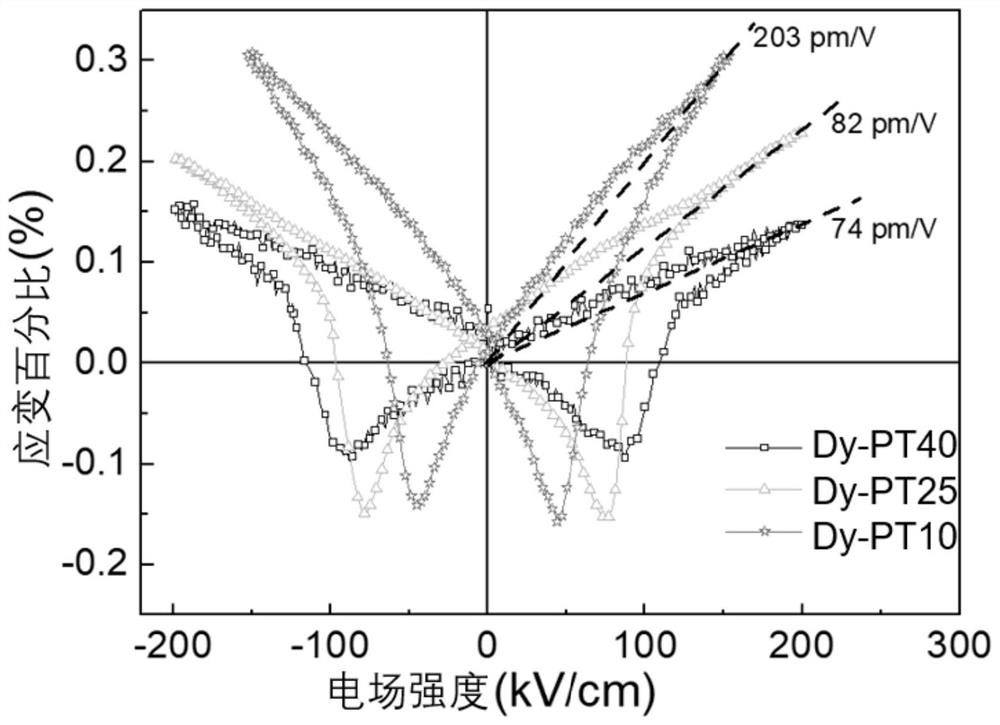

Bismuth ferrite/lead titanate based functional ceramic material and preparation method thereof

ActiveCN112851329AImprove electrical performanceReduce volatilityPerovskite (structure)Piezoelectric coefficient

The invention discloses a bismuth ferrite / lead titanate based functional ceramic material and a preparation method thereof. The preparation method comprises the following steps: weighing required raw materials according to a stoichiometric ratio, fully and uniformly mixing the raw materials, grinding the raw materials to a relatively small particle size to obtain an original material, prepressing the original material into a sheet, and pre-sintering the sheet in a high-temperature reaction furnace; grinding the sample obtained through presintering in a mortar into powder with the appropriate particle size for the second time, adding a binder for granulation, and conducting the tabletting and shaping on the sample again in a high-temperature reaction furnace, heating the sample to 500 DEG C and conducting heat preservation for 30 min for viscosity removal, and heating the sample to the target sintering temperature of 1000-1300 DEG C at the high temperature rising rate, meanwhile, feeding oxygen into the furnace, and performing heat preservation for 100-300 min; finally, conducting in-furnace cooling to the room temperature to obtain a target ceramic sample. The ceramic crystal phase structure is a pure perovskite phase, has excellent multifunctionality, shows a saturated ferroelectric hysteresis loop, has the maximum ferroelectric polarization exceeding 70 [mu] C / cm < 2 >, has significant piezoelectric response, has the positive piezoelectric coefficient exceeding 100 pC / N, the inverse piezoelectric coefficient reaching 200 pm / V and the like.

Owner:XI AN JIAOTONG UNIV

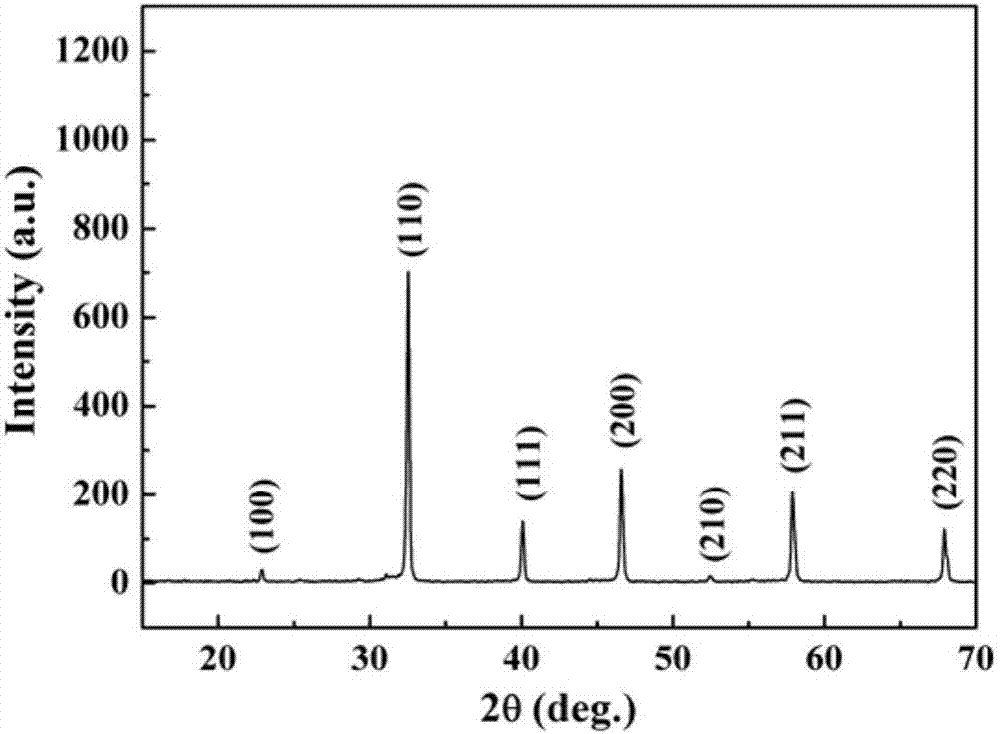

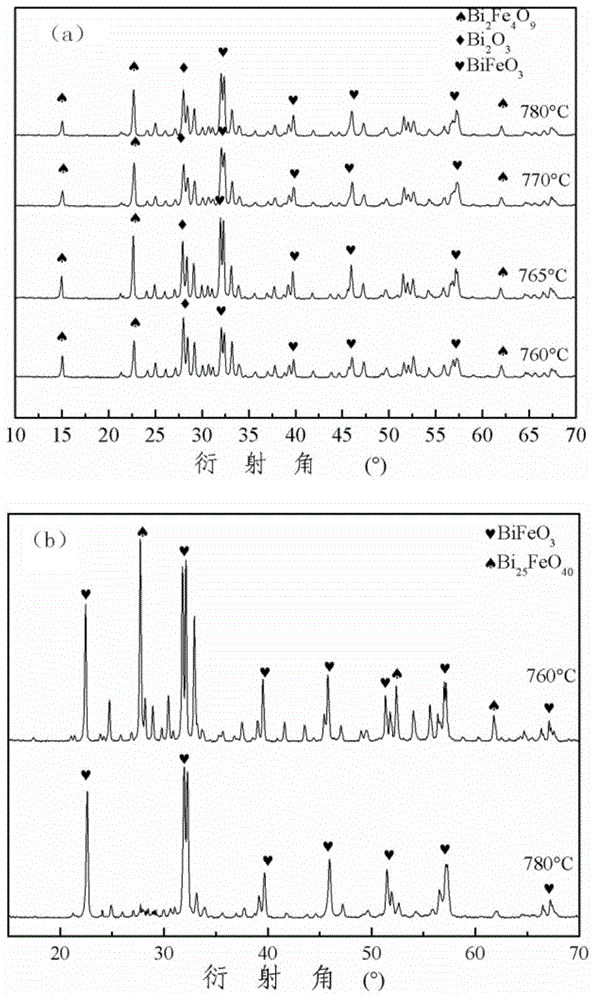

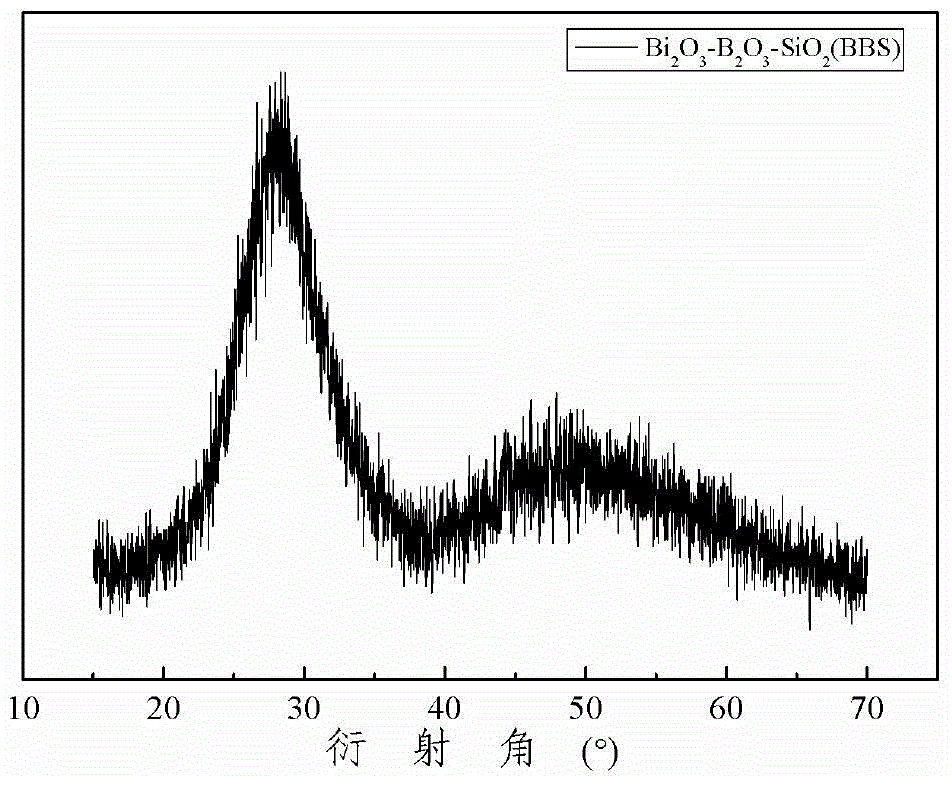

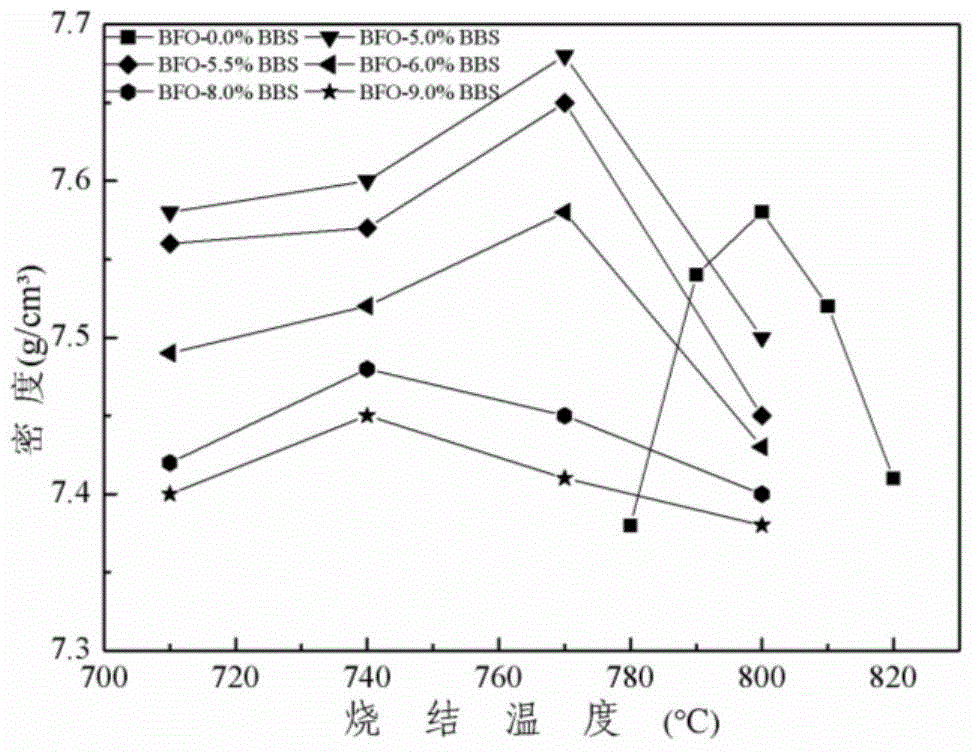

Preparation method of BiFeO3 porcelain added with Bi2O3-B2O3-SiO2 glass

The invention discloses a preparation method of BiFeO3 porcelain added with Bi2O3-B2O3-SiO2 glass. The method is characterized by comprising the following steps: step one, preparing BiFeO3; step two, preparing Bi2O3-B2O3-SiO2 glass; step three, adding the Bi2O3-B2O3-SiO2 glass obtained in the step two in mass percent of 5-9wt% in the BiFe3O obtained in the step to form a mixture, mixing the mixture with zirconia ball stone and deionized water, ball-milling and drying to obtain dried material, orderly pelleting and screening the dried material to form pelletized material; step four, manufacturing the pelletized material obtained in the step three into a sample, sintering to obtain a sintered sample; step five, grinding and cleaning the sintered sample obtained in the step four, uniformly coating the front and back sides of the ground and cleaned sintered sample with silver electrode slurry, sintering to obtain the BiFeO3 porcelain added with Bi2O3-B2O3-SiO2 glass. The low-loss porcelain dielectric material obtained by using the method disclosed by the invention is simple in preparation process and low in material cost, and has saturated ferroelectric hysteresis loop and low dielectric loss.

Owner:SHAANXI UNIV OF SCI & TECH

Novel Fe-doped SrBi2Nb2O9 multiferroic ceramic material with Aurivillius structure and preparation method of ceramic material

The invention discloses a novel Fe-doped SrBi2Nb2O9 multiferroic ceramic material with an Aurivillius structure, and further discloses a preparation method of the ceramic material. The method comprises the following steps of preparing by respectively adopting SrCO3, Bi2O3, Nb2O5 and Fe2O3 as raw materials; carrying out ball-milling, pre-sintering, sieving and molding on powder, and finally sintering at the temperature of 920-1,215 DEG C to obtain a single-phase multiferroic ceramic material with the Aurivillius structure. The SrBi2Nb2-xFexO9-2x single phase multiferroic Aurivillius compound ceramic material prepared by the method is simple in process and low in raw material cost and manufacturing cost, at room temperature, a ferroelectric hysteresis loop and a hysteresis loop can be obtained, and the material has a certain antiferromagnetic property on the basis of retaining material ferroelectricity.

Owner:SHAANXI UNIV OF SCI & TECH

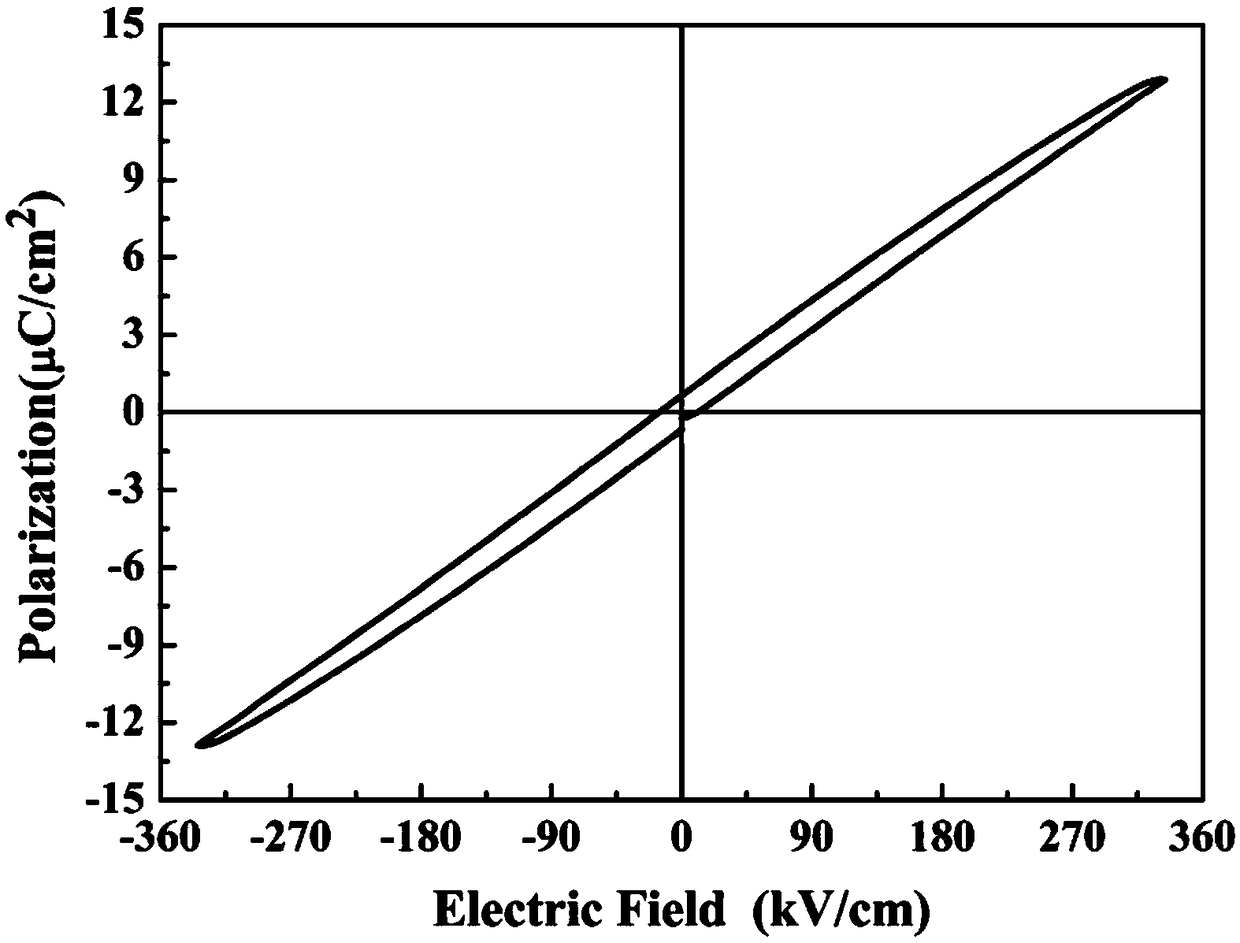

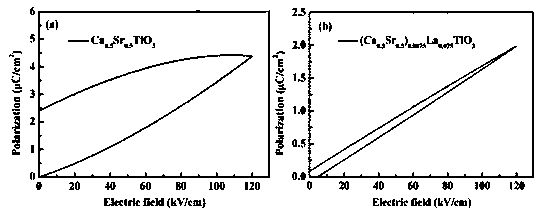

Efficient La-doped energy-storage linear dielectric ceramic material for high temperature and preparation method thereof

ActiveCN109928748AImprove the breakdown fieldHigh breakdown field strengthElectricityRoom temperature

The invention discloses an efficient La-doped energy-storage linear dielectric ceramic material for a high temperature. A preparation method of the material comprises the following steps: firstly, taking SrCO3, CaCO3, TiO2 and La2O3 as raw materials, and proportioning and selecting the raw materials according to a chemical formula (Ca0.5Sr0.5)1-1.5xLaxTiO3; mixing the powder by wet ball-milling; pre-sintering the dried powder at a temperature of 1200 DEG C for 2 hours; performing secondary ball-milling, screening and molding; finally sintering at a temperature of 1400 DEG C for 2 hours to obtain the required linear dielectric ceramic material. The prepared ceramic material disclosed by the invention has the advantages of simple preparation process, low raw material price, and low production cost; a linear ferroelectric hysteresis loop can be obtained at room temperature, the energy storage density can be up to 2.07 J / cm<3>, which is 3 times that of non-doped SrTiO3, and the energy storage efficiency can be 94 percent or above at a high temperature of 200 DEG C.

Owner:SHAANXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com