Sodium-bismuth-titanate-based transparent ceramic material and preparing method and application thereof

A technology of sodium bismuth titanate-based, transparent ceramics, applied in the field of lead-free piezoelectric ceramics, can solve the problems of difficulty in achieving anti-breakdown electric field, low anti-breakdown electric field, limiting energy storage density, etc., to promote the sintering mass transfer process, crystallization Good performance and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

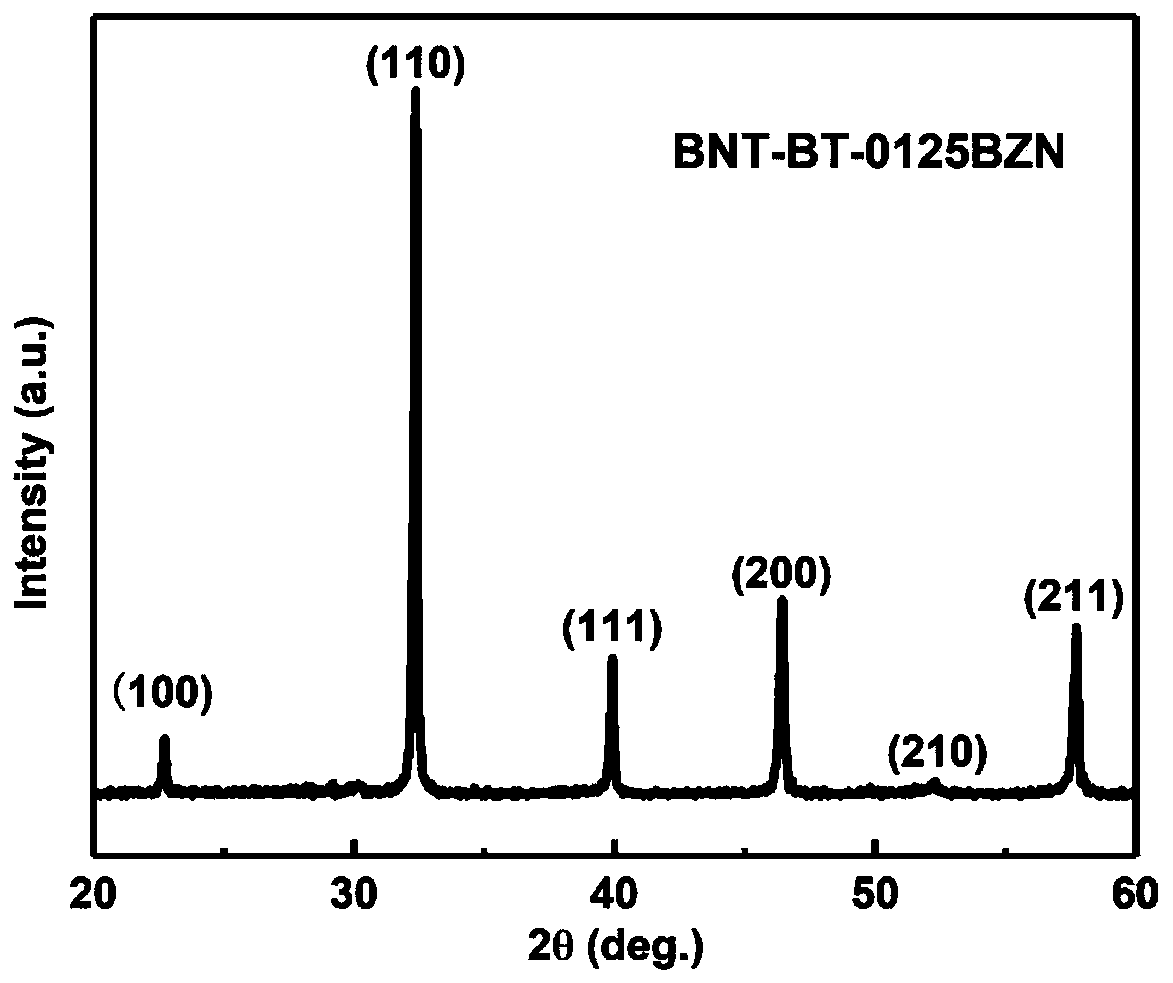

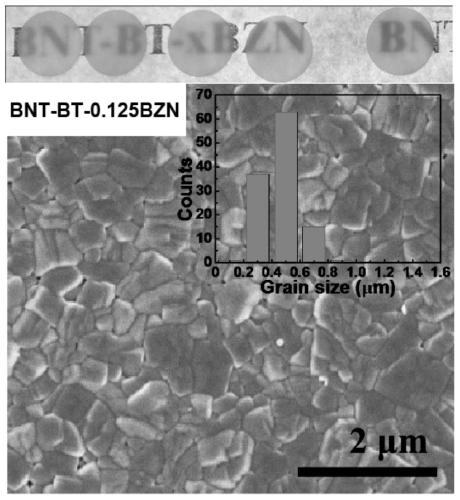

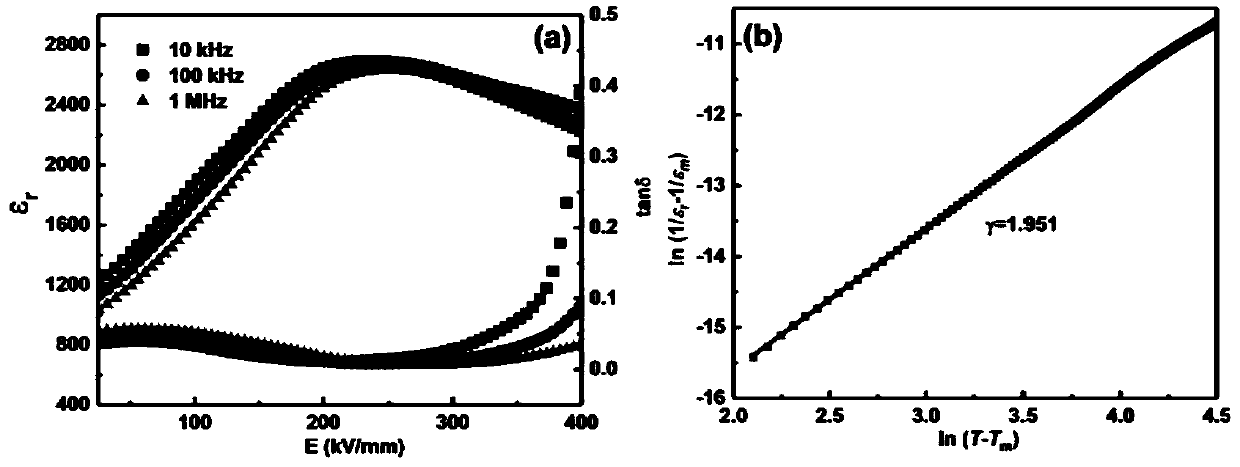

[0047] Preparation of BNT-BT-0.125BZN Fine Grain Transparent Ceramic Material

[0048] According to 0.825Bi 0.5 Na 0.5 TiO 3 -0.05BaTiO 3 -0.125Bi(Zn 2 / 3 Nb 1 / 3 )O 3 The molar stoichiometric ratio of the raw material Bi was weighed 2 o 3 , Na 2 CO 3 , BaCO 3 , ZnO, Nb 2 o 5 and TiO 2 Mix evenly, put the prepared material into a nylon tank with absolute ethanol as the medium and zirconia balls as the balls for ball milling, and ball mill for 8 hours at a speed of 250r / min. Then the ball-milled slurry was dried at 80°C. The dried powder was passed through a 200-mesh sieve, placed in an alumina crucible, and pre-fired at 800°C for 5 hours to obtain a pre-fired powder. Add 1wt.% B in calcined powder 2 o 3 -SiO 2 -ZnO glass sintering powder (average particle size 0.7 μm), then put it into a nylon jar with absolute ethanol as the medium and zirconia balls as the balls for ball milling, ball milling for 24 hours at a speed of 250r / min, and then Dry at 80°C. After ...

Embodiment 2

[0060] Other conditions are the same as in Example 1, except that the sintering temperature is 920°C. The density of the ceramic prepared at this sintering temperature is 92%, there are micropores in the ceramic, and its anti-breakdown electric field is 12kV / mm.

Embodiment 3

[0062] Other conditions are the same as in Example 1, except that the sintering temperature is 980°C. At this sintering temperature, the density of the ceramic is 90%, there are micropores in the ceramic, and its anti-breakdown electric field is 10kV / mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Energy storage density | aaaaa | aaaaa |

| Sintering temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com