Dielectric composite material based on filler with core-shell structure

A composite material and core-shell structure technology, applied in the field of dielectric composite materials, can solve problems such as crystal structure differences and core-shell interface cracks, reduce interface polarization and remanent polarization, increase energy storage density and efficiency, increase The effect of large resistance to breakdown electric field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

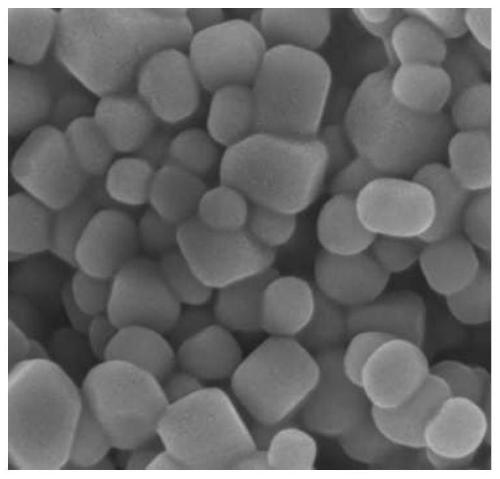

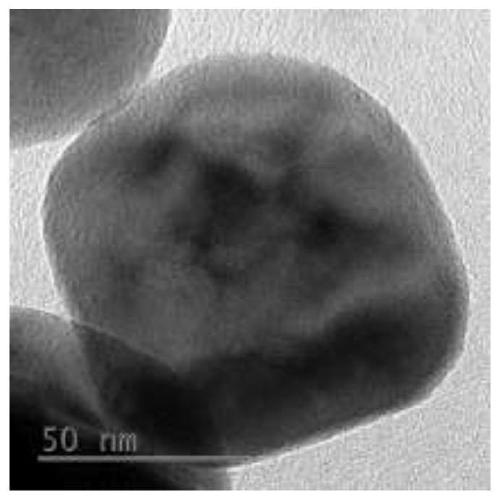

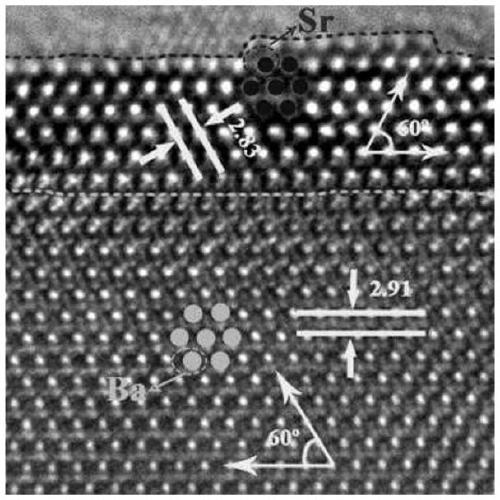

[0041] Example 1: Preparation of BaTiO 3 -SrTiO 3 core shell filler

[0042] The BaTiO 3 -SrTiO 3 The core-shell filler was prepared by a two-step hydrothermal method. 2.1809g of Ba(OH) 2 ·8H 2 O was added to 16mL of 1M acetic acid solution, stirred and dissolved thoroughly to obtain solution 1. Then 0.8 mL of TiCl 4 Added to 16mL absolute ethanol solution to obtain solution 2.

[0043] Mix the solution 1 and the solution 2 to obtain a precursor solution. Then 5.0g flake NaOH was added to the precursor solution, and mechanically stirred for 10min to obtain a mixture containing BaTiO 3 Intermediate suspension of nanoparticles and unreacted gel.

[0044] 0.0967g Sr(OH) 2 ·8H 2 O was dissolved in 24 mL of 1M acetic acid solution to obtain solution 3. The Ba(OH) 2 ·8H 2 O, TiCl 4 and Sr(OH) 2 ·8H 2 The amount of O needs to ensure that the molar ratio of Ba(Sr) to Ti is 1:1.

[0045] Add the solution 3 into the intermediate suspension, stir and mix evenly, transf...

Embodiment 2

[0047] Example 2: Preparation of Dielectric Composite Materials

[0048] 1. Using N,N-dimethylformamide (DMF) as a solvent and commercially available polyvinylidene fluoride-hexafluoropropylene copolymer (hereinafter referred to as P(VDF-HFP)) as a polymer, according to P(VDF -HFP) 1vol%, 2vol% and 3vol% of the volume, respectively weigh three groups of BaTiO prepared in Example 1 3 -SrTiO 3 Core-shell fillers, as experimental groups 1, 2, and 3; were added to DMF solvent, ultrasonically dispersed for 30 minutes, and stirred for 2 hours to fully disperse and evenly.

[0049] Then, in each group of solvents, add the required mass of solid P(VDF-HFP) respectively, stir at 50°C for 12h, and sonicate for 1h to obtain BaTiO with good dispersibility. 3 -SrTiO 3 Core-shell filler / P(VDF-HFP) solution.

[0050] It should be understood that, as described above to obtain BaTiO 3 -SrTiO 3 For the core-shell filler / P(VDF-HFP) solution, those skilled in the art can choose a further dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com