A core-shell structure nanofiber/polyvinylidene fluoride based high energy storage film and its preparation method

A technology of polyvinylidene fluoride and core-shell structure, which is applied in fiber processing, filament/wire forming, fixed capacitor parts, etc., and can solve the problems of unreachable application level, low energy storage density, limited promotion and application, etc. problem, to achieve the effect of simple process and required equipment, improved breakdown field strength, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

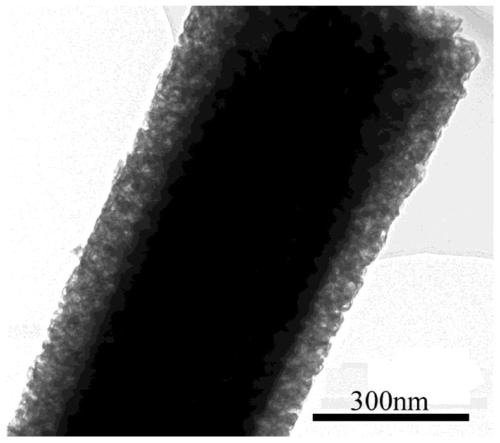

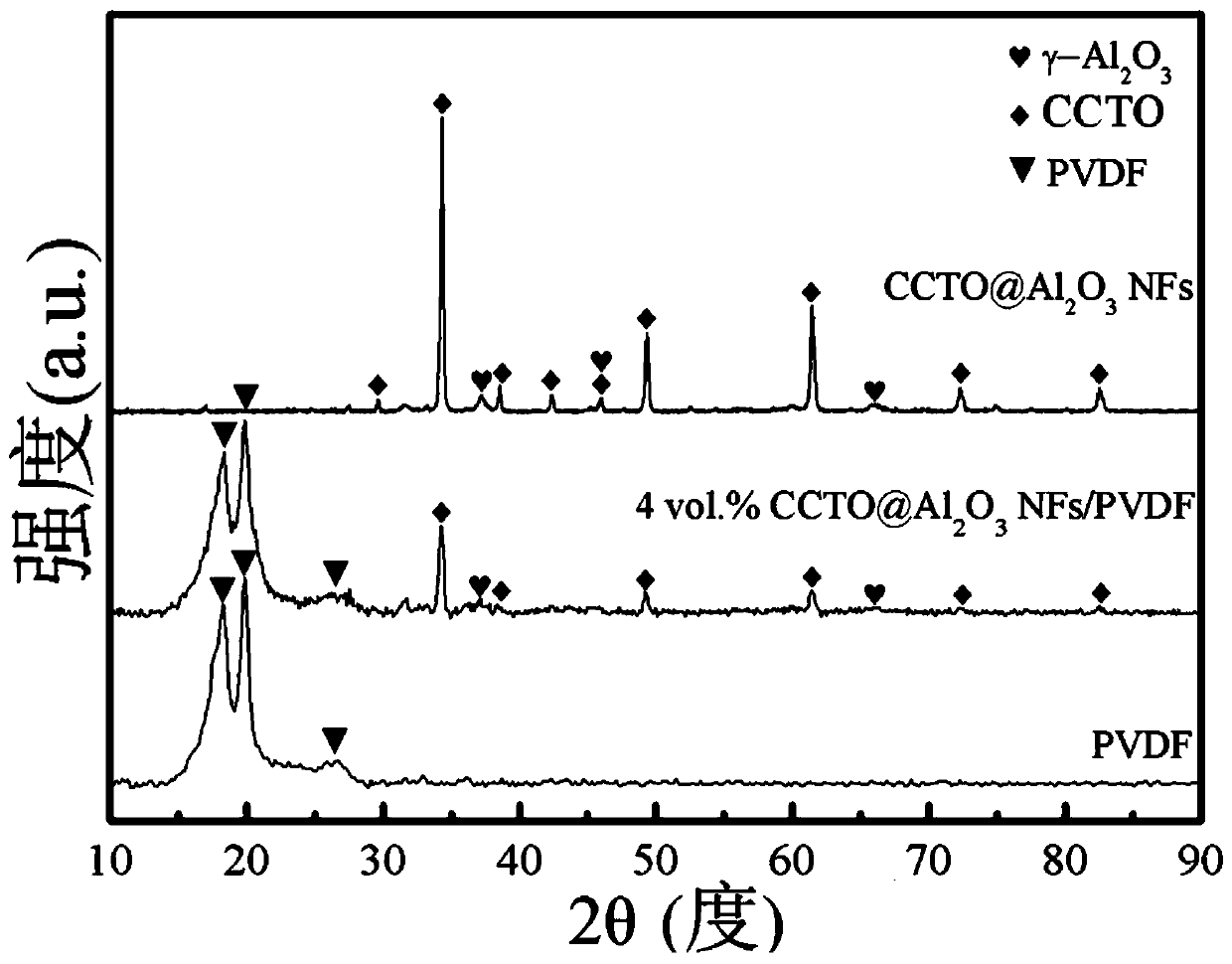

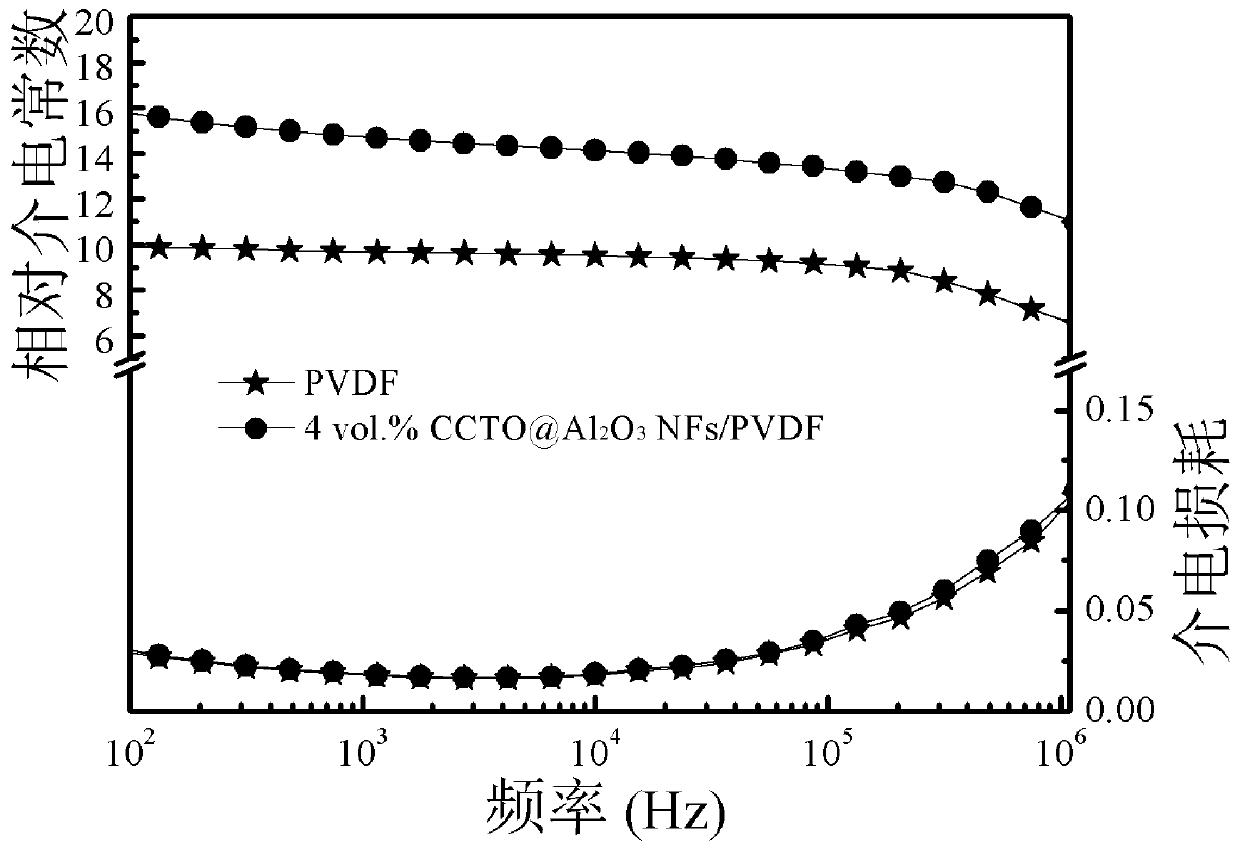

[0036] A core-shell structure nanofiber / polyvinylidene fluoride-based high-energy storage film, the core-shell structure nanofiber / polyvinylidene fluoride-based high-energy storage film contains a certain volume of crystallized copper calcium titanate@alumina nano Fiber, the copper calcium titanate@alumina nanofiber has a core-shell structure, the core layer is copper calcium titanate, and the shell layer is alumina.

[0037] A method for preparing a core-shell structure nanofiber / polyvinylidene fluoride-based high energy storage film is as follows:

[0038] step one:

[0039]Calcium nitrate tetrahydrate, copper acetate monohydrate, n-tetrabutyl titanate and acetic acid are prepared in a certain molar ratio, polyvinylpyrrolidone and dehydrated alcohol are prepared according to a certain mass volume ratio; the prepared dehydrated alcohol and acetic acid are mixed and mixed After stirring evenly, add copper acetate monohydrate and make it completely dissolved, then add calcium ...

Embodiment 2

[0049] A core-shell structure nanofiber / polyvinylidene fluoride-based high energy storage film, the core-shell structure nanofiber / polyvinylidene fluoride-based high energy storage film contains Crystallized copper calcium titanate@alumina nanofibers with a volume of 2-6% of the energy storage film, the copper calcium titanate@alumina nanofibers have a core-shell structure, the core layer is copper calcium titanate, and the shell layer is oxide aluminum.

[0050] A method for preparing a core-shell structure nanofiber / polyvinylidene fluoride-based high energy storage film, characterized in that the steps of the preparation method are as follows:

[0051] step one:

[0052] Prepare calcium nitrate tetrahydrate, copper acetate monohydrate, n-tetrabutyl titanate and acetic acid at a molar ratio of 1:3:4:7.94, prepare polyvinylpyrrolidone and absolute ethanol at a mass-volume ratio of 1g:20mL; prepare After mixing absolute ethanol with acetic acid and stirring evenly, add copper...

Embodiment 3

[0062] A core-shell structure nanofiber / polyvinylidene fluoride-based high energy storage film, the core-shell structure nanofiber / polyvinylidene fluoride-based high energy storage film contains Crystallized copper calcium titanate@alumina nanofibers with 2% volume of the energy storage film, the copper calcium titanate@alumina nanofibers have a core-shell structure, the core layer is copper calcium titanate, and the shell layer is alumina.

[0063] A method for preparing a core-shell structure nanofiber / polyvinylidene fluoride-based high energy storage film, characterized in that the steps of the preparation method are as follows:

[0064] step one:

[0065] Weigh 0.208g calcium nitrate tetrahydrate and 0.527g copper acetate monohydrate at a molar ratio of 1:3:4:7.94, measure 1.2ml n-tetrabutyl titanate and 0.4ml acetic acid, and measure 1g according to the mass-volume ratio of 1g:20mL Polyvinylpyrrolidone and 20ml of absolute ethanol; after mixing absolute ethanol and aceti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com