Low-dielectric-constant polyimide film and preparation method thereof

A technology of polyimide film and low dielectric constant, which is applied in the field of low dielectric constant polyimide film and its preparation, can solve the problems of lowering mechanical properties, increasing dielectric constant of polyimide composite materials, and adhesion Poor problems, to achieve the effect of reducing the dielectric constant, reducing interface polarization, and increasing thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

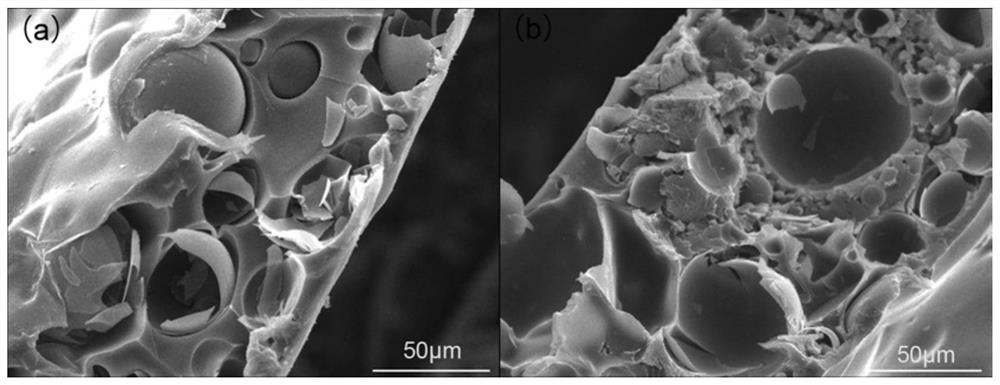

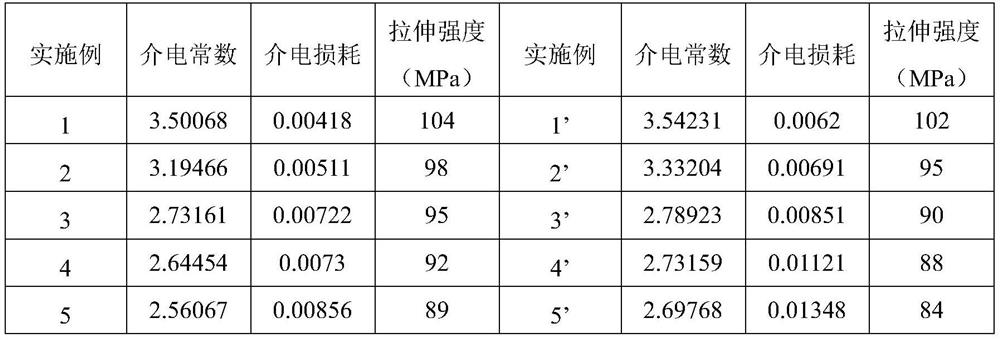

[0028] Under nitrogen, add 4.7073g 4,4-diaminodiphenyl ether into 100mL of N,N-dimethylformamide solution, wait until 4,4-diaminodiphenyl ether is completely dissolved, then add 7.2927g 3 , After 3'4,4'-biphenyltetracarboxylic dianhydride was reacted for 2 hours, 12g of glass microspheres were added and stirred for 3 hours, then 7.4386g of pyridine and 9.6005g of acetic anhydride were added at 80°C for 6 hours. Wash and dry with 150 mL of ethanol to obtain glass microspheres with a core-shell structure. Add 1.5g of the above-mentioned modified glass microspheres into 100mL of N,N-dimethylformamide solution and sonicate for 2h, then add 5.9792g of 4,4-diaminodiphenyl ether under nitrogen, and wait until it is completely dissolved Add 9.2632g of 3,3'4,4'-biphenyltetracarboxylic dianhydride and react for 2 hours to obtain a hybrid solution of modified glass microspheres and polyimide precursor. The above-mentioned hybrid solution of modified glass beads and polyimide precursor w...

Embodiment 2

[0030] Under nitrogen, add 4.7073g 4,4-diaminodiphenyl ether into 100mL of N,N-dimethylformamide solution, wait until 4,4-diaminodiphenyl ether is completely dissolved, then add 7.2927g 3 , After 3'4,4'-biphenyltetracarboxylic dianhydride was reacted for 2 hours, 12g of glass microspheres were added and stirred for 3 hours, then 7.4386g of pyridine and 9.6005g of acetic anhydride were added at 80°C for 6 hours. Wash and dry with 150 mL of ethanol to obtain glass microspheres with a core-shell structure. Add 3 g of the above-mentioned modified glass microspheres into 100 mL of N,N-dimethylformamide solution and sonicate for 2 hours, then add 5.9792 g of 4,4-diaminodiphenyl ether under nitrogen, wait until it is completely dissolved, then add 9. 2632 g of 3,3'4,4'-biphenyltetracarboxylic dianhydride was reacted for 2 hours to obtain a hybrid solution of modified glass microspheres and polyimide precursors. The above-mentioned hybrid solution of modified glass beads and polyimid...

Embodiment 3

[0032] Under nitrogen, add 4.7073g 4,4-diaminodiphenyl ether into 100mL of N,N-dimethylformamide solution, wait until 4,4-diaminodiphenyl ether is completely dissolved, then add 7.2927g 3 , After 3'4,4'-biphenyltetracarboxylic dianhydride was reacted for 2 hours, 12g of glass microspheres were added and stirred for 3 hours, then 7.4386g of pyridine and 9.6005g of acetic anhydride were added at 80°C for 6 hours. Wash and dry with 150 mL of ethanol to obtain glass microspheres with a core-shell structure. Add 4.5g of the above-mentioned modified glass microspheres into 100mL of N,N-dimethylformamide solution and sonicate for 2h, then add 5.9792g of 4,4-diaminodiphenyl ether under nitrogen, and wait until it is completely dissolved Add 9.2632g of 3,3'4,4'-biphenyltetracarboxylic dianhydride and react for 2 hours to obtain a hybrid solution of modified glass microspheres and polyimide precursor. The above-mentioned hybrid solution of modified glass beads and polyimide precursor w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com