Barium strontium titanate/polyether-ether-ketone composite material with dielectric frequency stability and preparation method of barium strontium titanate/polyether-ether-ketone composite material

A technology of frequency stability and polyether ether ketone, which is applied in the field of ceramic/polymer dielectric functional composite materials, can solve the problems of poor bonding of inorganic-organic phase interfaces and difficult processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

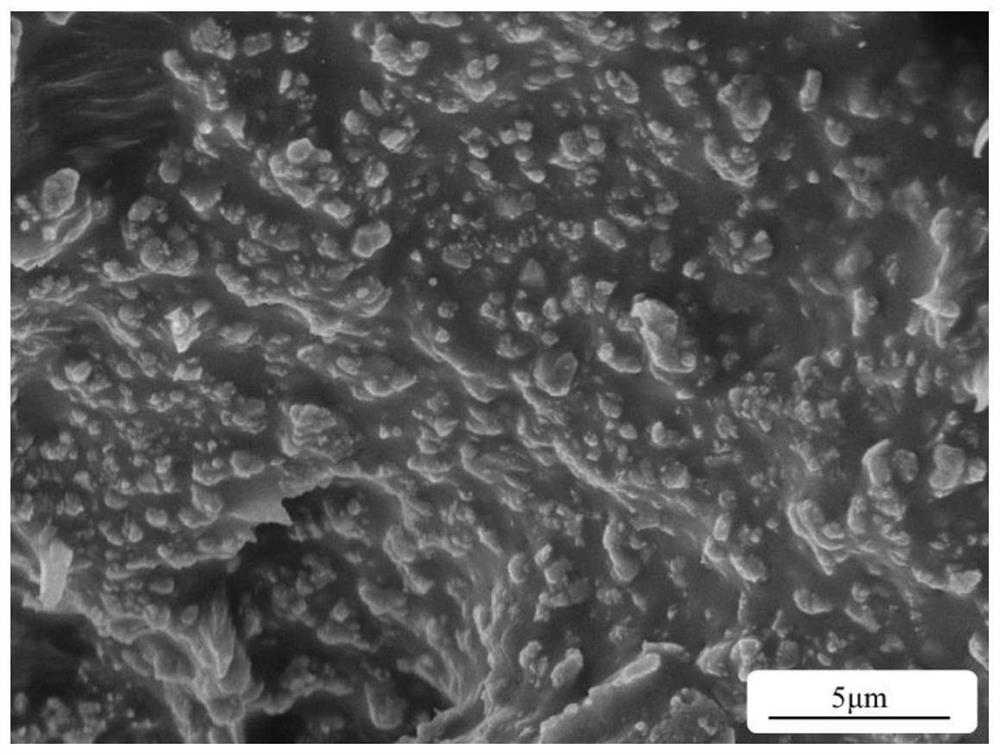

Image

Examples

preparation example Construction

[0053] The specific process of preparing the polyethersulfone-modified barium strontium titanate / polyetheretherketone composite material proposed in this example is as follows:

[0054] Step 1, Ingredients:

[0055] The barium strontium titanate powder, the polyethersulfone powder and the polyetheretherketone powder are respectively weighed according to the volume fraction of each material. stand-by.

[0056] Step 2, configure the homogeneous solution of polyethersulfone:

[0057] The weighed polyethersulfone powder is completely dissolved in the N'N dimethylformamide solution; the mass ratio of the polyethersulfone to the N'N dimethylformamide solution is 1:4-9. Magnetic stirring at 60-80°C for 30-40min to obtain a homogeneous solution of polyethersulfone.

[0058] The parameters of step 2 of each embodiment of table 4

[0059]

[0060] Step 3, prepare the strontium barium titanate suspension:

[0061] adding the weighed barium strontium titanate powder into the obtai...

Embodiment 1

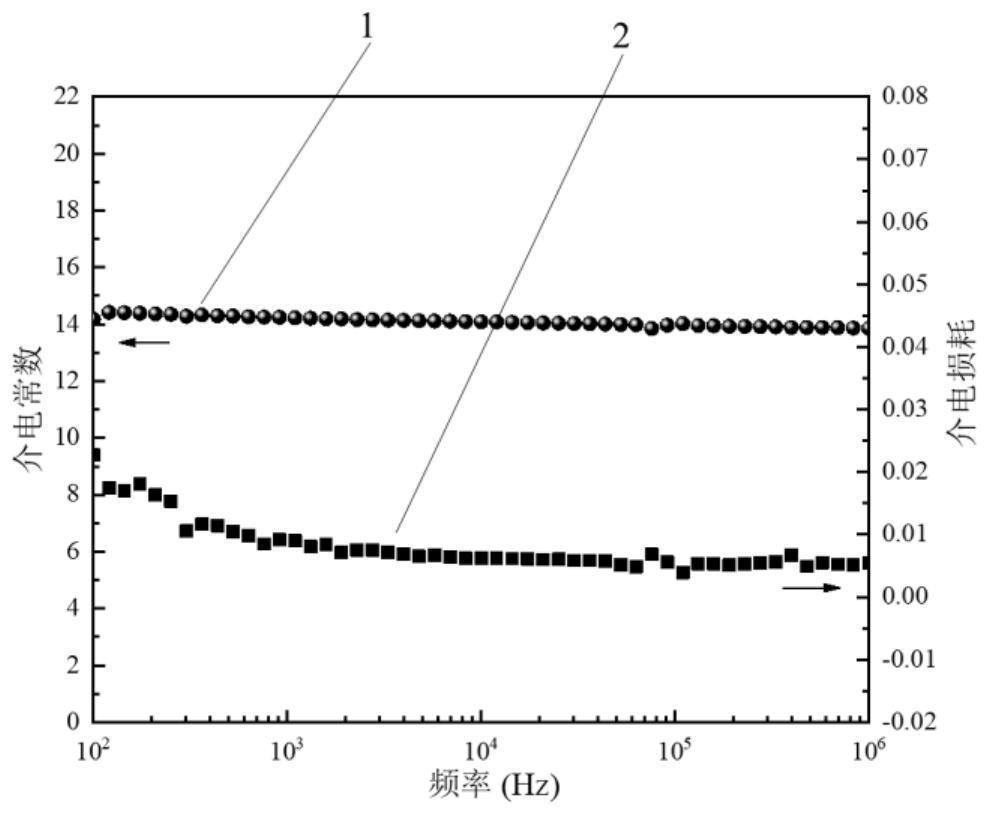

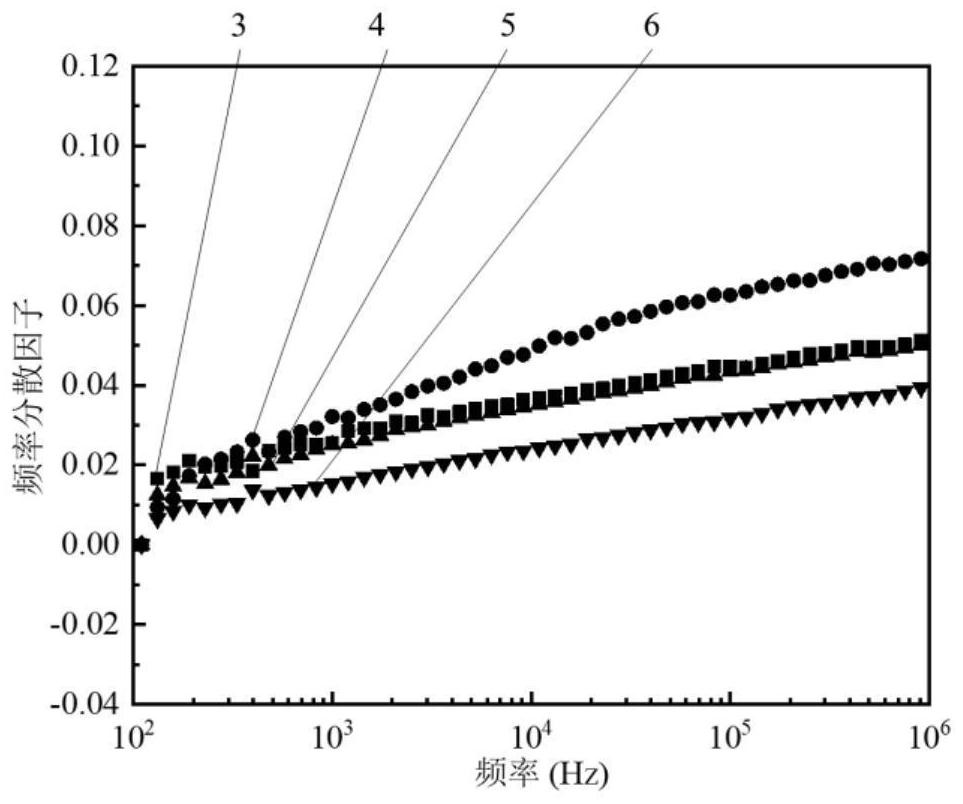

[0083] Test parameters under 1k Hz of each embodiment of table 10

[0084]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com