Lithium ion battery electrolyte, preparation method thereof and lithium ion battery

A lithium-ion battery and electrolyte technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, secondary batteries, etc., can solve the problems of narrowing the battery operating temperature range, reducing the battery cycle retention rate, and affecting the battery performance. The effect of improving safety and stability performance and cycle life, reducing migration distance and increasing migration speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

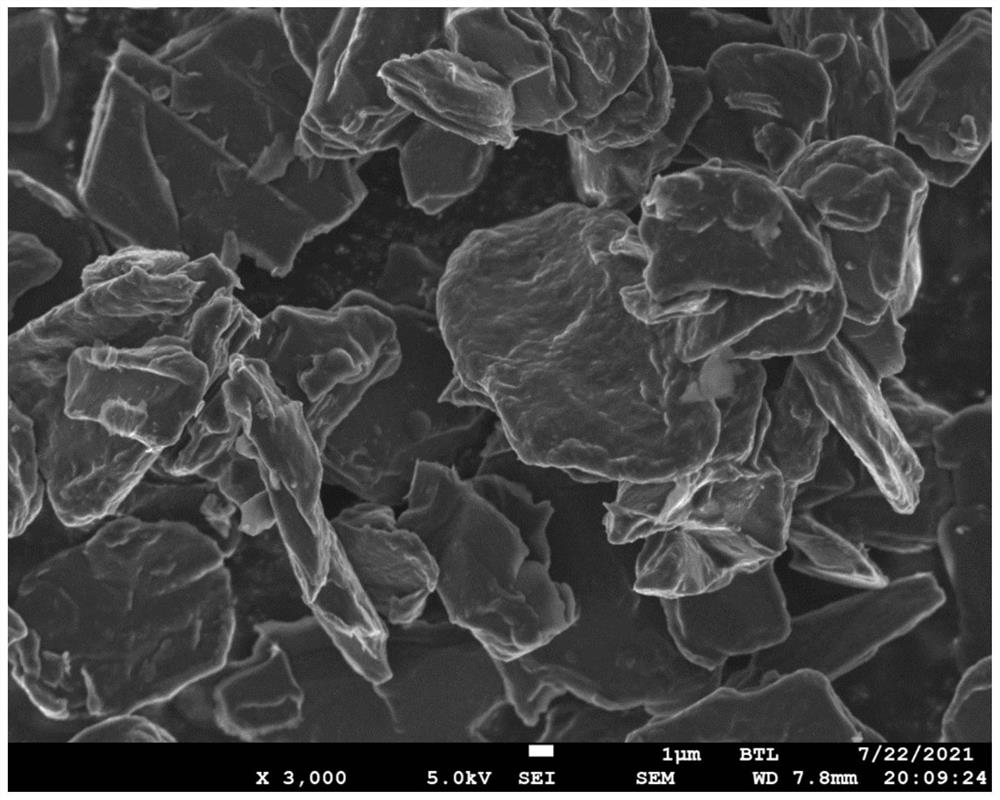

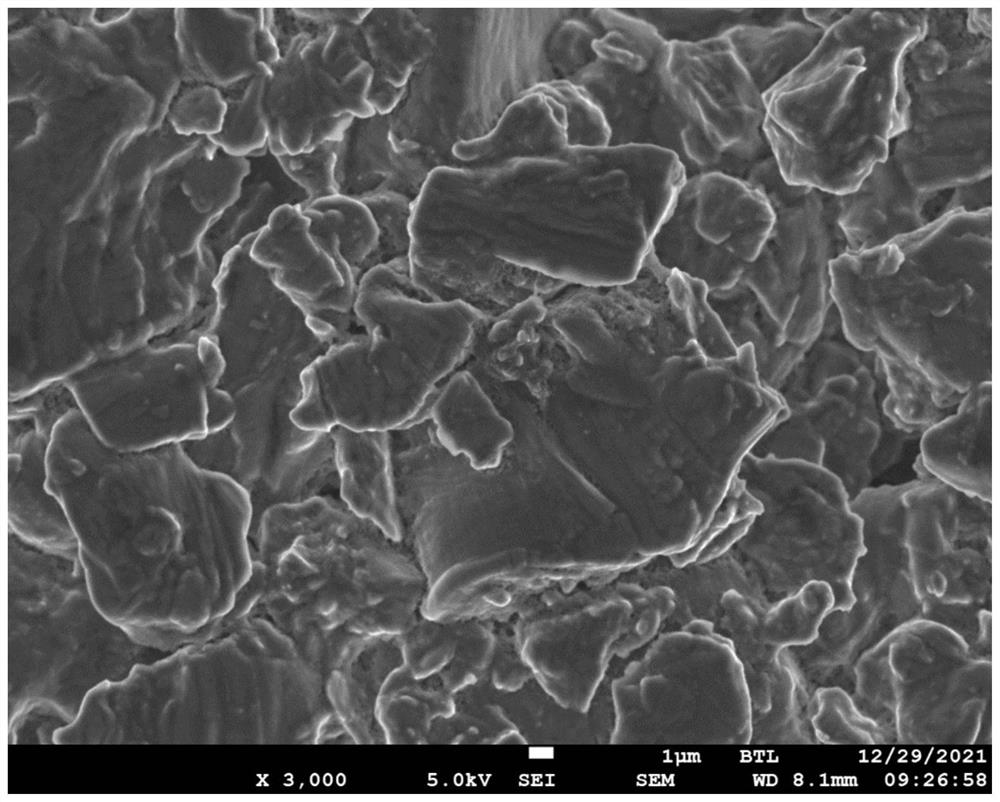

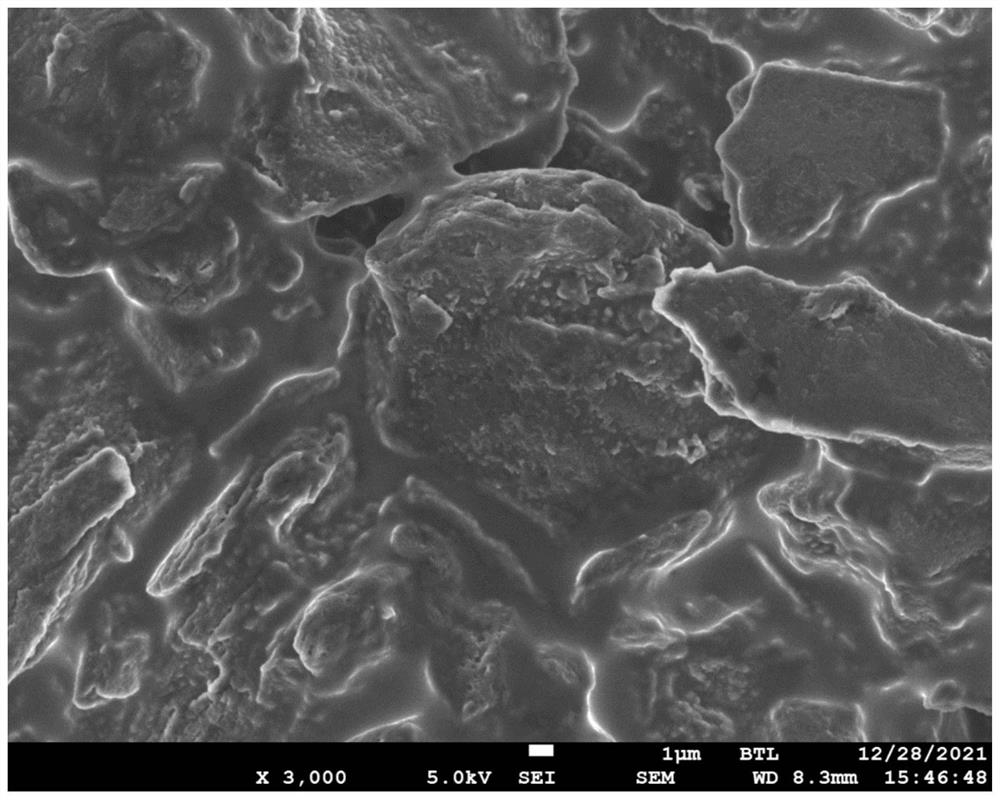

Image

Examples

preparation example Construction

[0026] A first object of the present invention is to provide a method for preparing a lithium ion battery electrolyte, comprising the following steps:

[0027] (1) LiPF is dissolved in the mixed solution to obtain a mixed solution;

[0028] (2) adding erythritol bis(carbonate) to the mixed solution obtained in step (1), and post-processing to obtain a lithium ion battery electrolyte.

[0029] In one embodiment of the present invention, in step (1), the mixed solution is a solution obtained by mixing any two or three of ethylene carbonate, dimethyl carbonate or ethyl methyl carbonate.

[0030] In an embodiment of the present invention, in the mixed solution, the weight ratio of ethylene carbonate, dimethyl carbonate and ethyl methyl carbonate is 0-5:0-5:0-5.

[0031] In one embodiment of the present invention, in step (1), LiPF 6 And the weight ratio of mixed solution is 1-10:90-99.

[0032] In one embodiment of the present invention, in step (2), the weight ratio of erythri...

Embodiment 1

[0041] This embodiment provides a lithium-ion battery.

[0042] (1) Production of positive electrode active material slurry: dry-mix 16.044 kg of lithium iron phosphate, 0.42 kg of superconducting carbon black conductive agent, and 0.336 kg of binder polyvinylidene fluoride for 30 minutes, and then add solvent N-methyl fluoride. 13.2 kg of pyrrolidone was stirred for 6 h to obtain a positive electrode slurry with a viscosity of about 8000 mPa·s.

[0043] (2) Production of positive electrode sheet: The positive electrode slurry is uniformly coated on the front and back sides of an aluminum foil with a thickness of 8 mm. Coating process control areal density at 24mg / cm 2 At the same time, 20mm of pole ear area is reserved on both sides; the coated pole piece is passed through a 20m-long 110℃ oven at a speed of 3m / s to remove the solvent NMP to obtain a positive pole piece; use a roller press to roll the pole piece , so that its compacted density reaches 2.85g / cm 3 , and then ...

Embodiment 2

[0051] This embodiment provides a lithium-ion battery.

[0052] (1) Production of positive electrode active material slurry: dry-mix 16.044 kg of lithium iron phosphate, 0.42 kg of superconducting carbon black conductive agent, and 0.336 kg of binder polyvinylidene fluoride for 30 minutes, and then add solvent N-methyl fluoride. 13.2 kg of pyrrolidone was stirred for 6 h to obtain a positive electrode slurry with a viscosity of about 8000 mPa·s.

[0053] (2) Production of positive electrode sheet: The positive electrode slurry is uniformly coated on the front and back sides of an aluminum foil with a thickness of 8 mm. Coating process control areal density at 24mg / cm 2 At the same time, 20mm of pole ear area is reserved on both sides; the coated pole piece is passed through a 20m-long 110℃ oven at a speed of 3m / s to remove the solvent NMP to obtain a positive pole piece; use a roller press to roll the pole piece , so that its compacted density reaches 2.85g / cm 3 , and then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com