Molten steel smelting technology for preventing nozzle clogging during sulfur-containing aluminium-containing steel pouring process

A technology for molten steel smelting and reclaimed water, which is applied in the field of special steel metallurgy to eliminate the problem of nodule at the nozzle, ensure smooth production, and improve the cleanliness of molten steel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

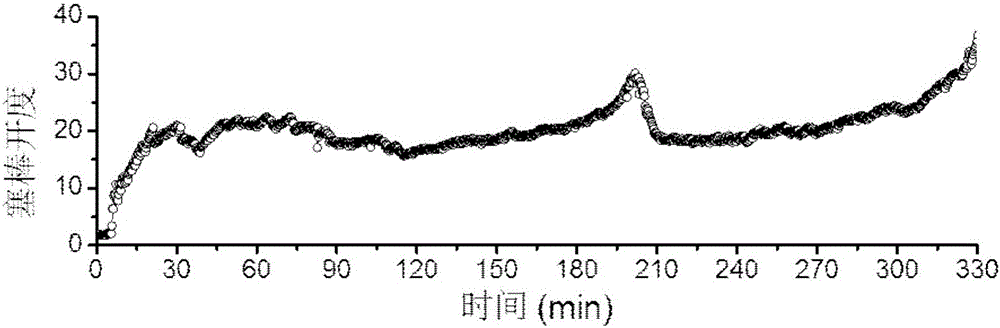

Image

Examples

Embodiment 1

[0028] In this embodiment, LD converter smelting-LF refining-VD vacuum refining-continuous casting billet forming process route is used to produce 42CrMoS sulfur-containing steel, and the mass percentages of various components of 42CrMoS sulfur-containing steel are: C: 0.40%-0.43%, Si: 0.24 %-0.30%, Mn: 0.77%-0.83%, P<0.015%, S: 0.020%-0.32%, Cr: 1.0%-1.1%, Mo: 0.21%-25%, Al: 0.020%-0.32%.

[0029] The molten iron is directly put into the converter for smelting without desulfurization, and the final sample of the converter is analyzed by spectrum, and the sulfur content is 0.026%-0.035%. The steel output of the converter is 85.8t. During the tapping process, 100kg-120kg of aluminum cake and 360kg of ferrosilicon are added for deoxidation alloying, 395kg-412kg of lime and 97kg-103kg of pre-melted refining slag are added for slagging, and the CaO content of pre-melting refining slag 37.6%, Al 2 o 3 The content is 49.2%.

[0030] The total weight of LF refining slag to the sta...

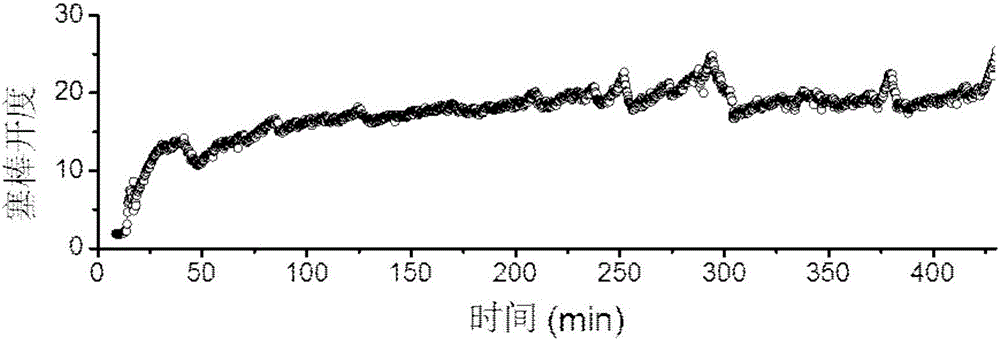

Embodiment 2

[0039] In this embodiment, the LD converter smelting-LF refining-RH vacuum refining-continuous casting billet forming process route is used to produce F45MnVS sulfur-containing steel, and the mass percentages of various components of F45MnVS sulfur-containing steel are: C: 0.43%-0.46%, Si: 0.35 %-0.45%, Mn: 1.30%-1.48%, P<0.025%, S: 0.035%-0.055%, Cr: 0.15%-0.025%, V: 0.09%-0.012%, Al: 0.010%-0.025%, N: 0.009%-0.013%.

[0040] The molten iron is directly smelted in the converter without desulfurization, and the final sample of the converter is analyzed by spectrum, and the sulfur content is 0.025%-0.033%. The steel output of the converter is 86.9t. During the steel tapping process, 80kg-110kg of aluminum cake and 540kg of ferrosilicon are added for deoxidation and alloying, and 346kg-453kg of lime and 98kg-103kg of pre-melted refining slag are added for slagging. CaO in the pre-melting refining slag The content is 41.6%, Al 2 o 3 The content is 53.1%.

[0041] The total we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com