Lead-free high-energy-storage-density and high-energy-storage-efficiency ceramic material and preparation method of same

A technology with high energy storage density and energy storage efficiency, applied in the field of energy storage ceramics, can solve the problems of immature batch production technology, difficulty in meeting the needs of development, human body and environmental pollution, etc. The effect of small size and high breakdown field strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The preparation method of the lead-free high energy storage density and energy storage efficiency ceramic material of the present invention comprises the following steps:

[0047] (1) According to the chemical formula 0.65BaTiO 3 -0.35Bi 0.5 Na 0.5 TiO 3 will analyze pure BaCO 3 、Na 2 CO 3 、 Bi 2 o 3 、TiO 2 After batching, use absolute ethanol as the medium, mix evenly through ball milling for 20-24 hours, then dry at 100°C, pass through a 120-mesh sieve, briquette, and pre-calcine at 900-950°C for 3-5 hours to obtain blocks shape solid, then crush the massive solid and pass through a 120-mesh sieve to obtain 0.65BaTiO 3 -0.35Bi 0.5 Na 0.5 TiO 3 Powder;

[0048] (2) According to the chemical formula Na 0.73 Bi 0.09 NbO 3 will analyze pure Na 2 CO 3 、 Bi 2 o 3 , Nb 2 o 5 After batching, use absolute ethanol as the medium, mix evenly through ball milling for 20-24 hours, then dry at 100°C, pass through a 120-mesh sieve, briquette, and pre-calcine at ...

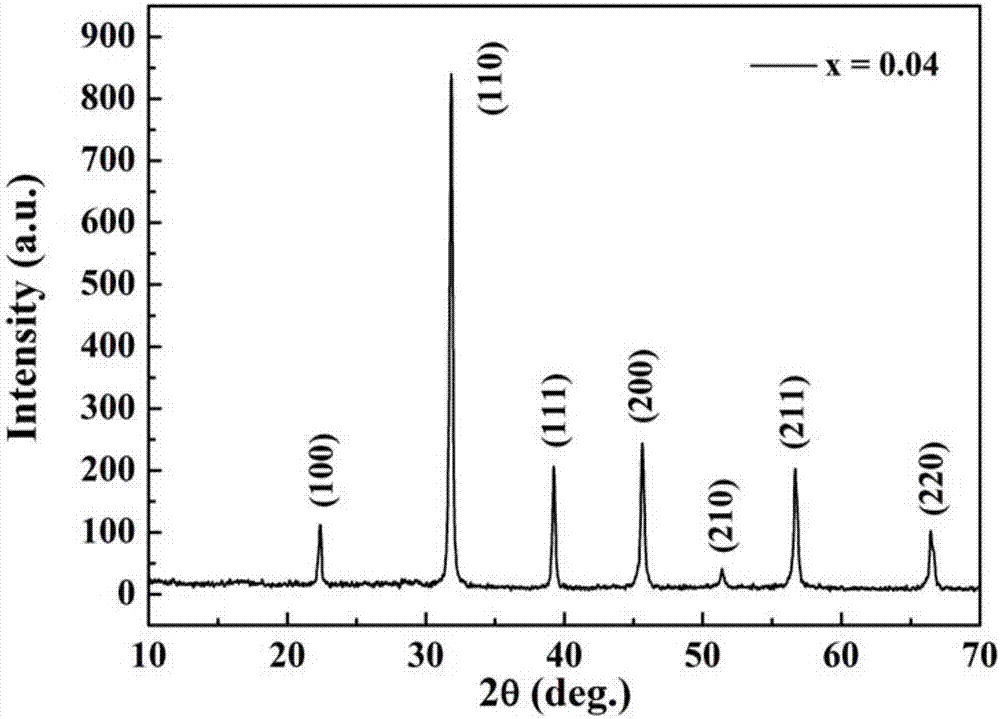

Embodiment 1

[0060] The chemical formula of the ceramic material in this case is: (1-x)(0.65BaTiO 3 -0.35Bi 0.5 Na 0.5 TiO 3 )-xNa 0.73 Bi 0.09 NbO 3 , wherein x represents the mole fraction, and x=0.04.

[0061] The preparation method of the above-mentioned lead-free high energy storage density ceramic material comprises the following steps:

[0062] (1) According to the chemical formula 0.65BaTiO 3 -0.35Bi 0.5 Na 0.5 TiO 3 will analyze pure BaCO 3 、Na 2 CO 3 、 Bi 2 o 3 、TiO 2 After batching, use absolute ethanol as the medium, mix evenly through ball milling for 24 hours, then dry at 100°C, pass through a 120-mesh sieve, briquette, and pre-calcine at 950°C for 3 hours to obtain a block solid, and then the block The solid was crushed and passed through a 120-mesh sieve to obtain 0.65 BaTiO 3 -0.35Bi 0.5 Na 0.5 TiO 3 Powder;

[0063] (2) According to the chemical formula Na 0.73 Bi 0.09 NbO 3 will analyze pure Na 2 CO 3 、 Bi 2 o 3 , Nb 2 o 5 After batching, us...

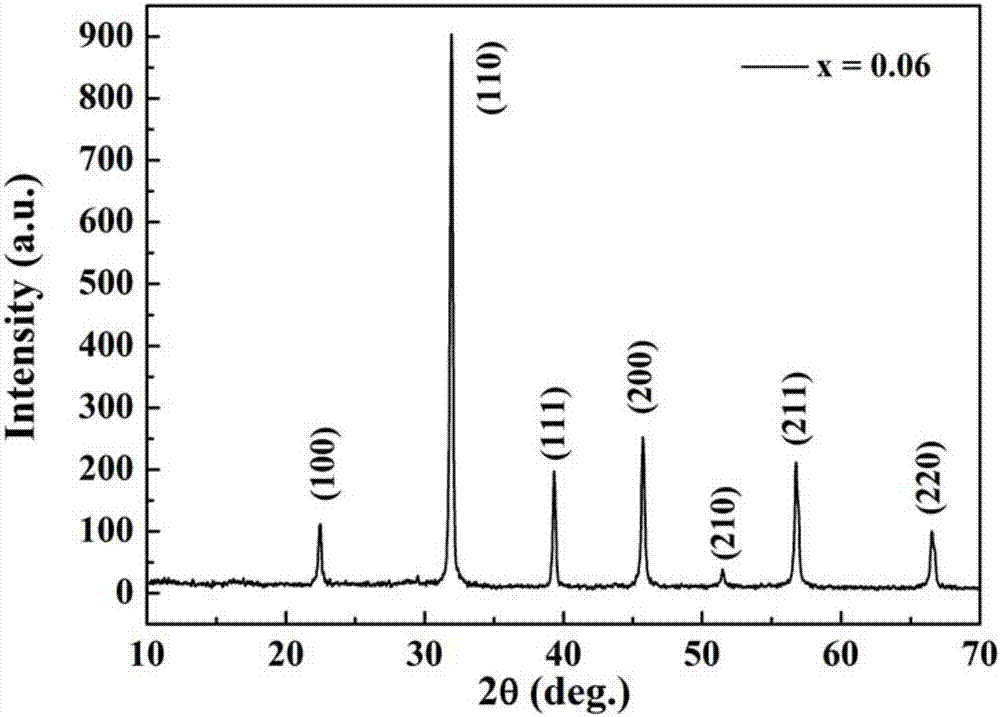

Embodiment 2

[0070] The chemical formula of the ceramic material in this case is: (1-x)(0.65BaTiO 3 -0.35Bi 0.5 Na 0.5 TiO 3 )-xNa 0.73 Bi 0.09 NbO 3, where x represents the mole fraction, and x=0.06.

[0071] The preparation method of the above-mentioned lead-free high energy storage density ceramic material comprises the following steps:

[0072] (1) According to the chemical formula 0.65BaTiO 3 -0.35Bi 0.5 Na 0.5 TiO 3 will analyze pure BaCO 3 、Na 2 CO 3 、 Bi 2 o 3 、TiO 2 After batching, use absolute ethanol as the medium, mix evenly through ball milling for 22 hours, then dry at 100°C, pass through a 120-mesh sieve, briquette, and pre-calcine at 930°C for 3 hours to obtain a block solid, and then the block The solid was crushed and passed through a 120-mesh sieve to obtain 0.65 BaTiO 3 -0.35Bi 0.5 Na 0.5 TiO 3 Powder;

[0073] (2) According to the chemical formula Na 0.73 Bi 0.09 NbO 3 will analyze pure Na 2 CO 3 、 Bi 2 o 3 , Nb 2 o 5 After batching, use a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Breakdown strength | aaaaa | aaaaa |

| Energy storage density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com