Self-doped strontium titanate ferroelectric film and preparation method thereof

A ferroelectric thin film, strontium titanate technology, applied in self-doped strontium titanate ferroelectric thin film and its preparation, ferroelectric thin film field, can solve the problems of high cost, complex synthesis, low phase transition temperature, etc., and the method is simple Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

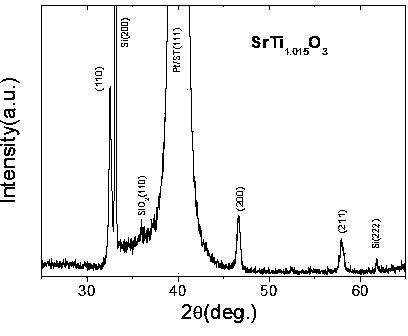

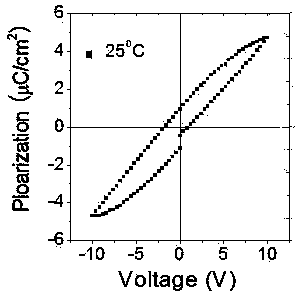

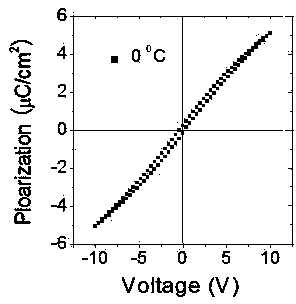

[0023] A method for preparing a self-doped strontium titanate ferroelectric thin film, comprising the following steps: step 1, respectively weighing strontium acetate, butyl titanate and acetylacetone according to a molar ratio of 1:1.015:0.7, and set aside;

[0024] Step 2, the strontium acetate taken by step 1 is all dissolved in 99.5% acetic acid with a purity of 99.5%, and an appropriate amount of ethylene glycol methyl ether is added after forming a transparent colorless solution, so that the molar concentration of strontium acetate in the solution reaches 0.4mol / L, Stir for 1 hour to form solution A, add the weighed butyl titanate into solution A, stir for 30 minutes to form solution B, and set aside;

[0025] Step 3: Add the acetylacetone weighed in step 1 into solution B, then add an appropriate amount of ethylene glycol methyl ether to dilute solution B until the molar concentration of strontium acetate reaches 0.3mol / L, then stir for 6-8 hours, and filter Remove the ...

Embodiment 2

[0030] A method for preparing a self-doped strontium titanate ferroelectric thin film, comprising the following steps: step 1, respectively weighing strontium acetate, butyl titanate and acetylacetone according to a molar ratio of 1:1.02:0.7, and set aside;

[0031] Step 2, the strontium acetate taken by step 1 is all dissolved in 99.5% acetic acid with a purity of 99.5%, and an appropriate amount of ethylene glycol methyl ether is added after forming a transparent colorless solution, so that the molar concentration of strontium acetate in the solution reaches 0.4mol / L, Stir for 1 hour to form solution A, add the weighed butyl titanate into solution A, stir for 30 minutes to form solution B, and set aside;

[0032] Step 3: Add the acetylacetone weighed in step 1 into solution B, then add an appropriate amount of ethylene glycol methyl ether to dilute solution B until the molar concentration of strontium acetate reaches 0.3mol / L, then stir for 6-8 hours, and filter Remove the i...

Embodiment 3

[0035] A method for preparing a self-doped strontium titanate ferroelectric thin film, comprising the following steps: step 1, respectively weighing strontium acetate, butyl titanate and acetylacetone according to a molar ratio of 1:1.017:0.7, and set aside;

[0036] Step 2, the strontium acetate taken by step 1 is all dissolved in 99.5% acetic acid with a purity of 99.5%, and an appropriate amount of ethylene glycol methyl ether is added after forming a transparent colorless solution, so that the molar concentration of strontium acetate in the solution reaches 0.4mol / L, Stir for 1 hour to form solution A, add the weighed butyl titanate into solution A, stir for 30 minutes to form solution B, and set aside;

[0037] Step 3: Add the acetylacetone weighed in step 1 into solution B, then add an appropriate amount of ethylene glycol methyl ether to dilute solution B until the molar concentration of strontium acetate reaches 0.3mol / L, then stir for 6-8 hours, and filter Remove the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com