Diisopropyl propylamine tetrafluoroborate crystal material as well as preparation method and application thereof

A technology of diisopropylpropylamine tetrafluoroborate and diisopropylpropylamine cation, which is applied in the field of organic-inorganic hybrid materials, can solve the problems of difficult practical application of materials and location in low temperature areas, and achieve easy operation and excellent performance , the effect of facilitating industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Weigh 20.2g (0.2mol) of diisopropylamine, dissolve it in 40mL of acetonitrile, weigh 12.2g (0.1mol) of 1-bromopropane, dissolve it in 30mL of acetonitrile, mix the two solutions, reflux and stir at 73°C for 72 hours, gradually white solid generate. After cooling to room temperature, 50 mL of distilled water was added, and the reaction solution was divided into two layers. Use a separatory funnel to separate the upper layer liquid, wash twice with 30 mL of distilled water, and obtain 11.3 g of a colorless transparent liquid, which is the crude product of diisopropylpropylamine, with a yield of 79%. The yield of the agent is increased by nearly 9 times (compared with Comparative Example 1), and the ammonium salt generated is separated from the reaction system as a precipitate, which can be collected by simple filtration and is easy to recycle. This method is more suitable for production.

Embodiment 2

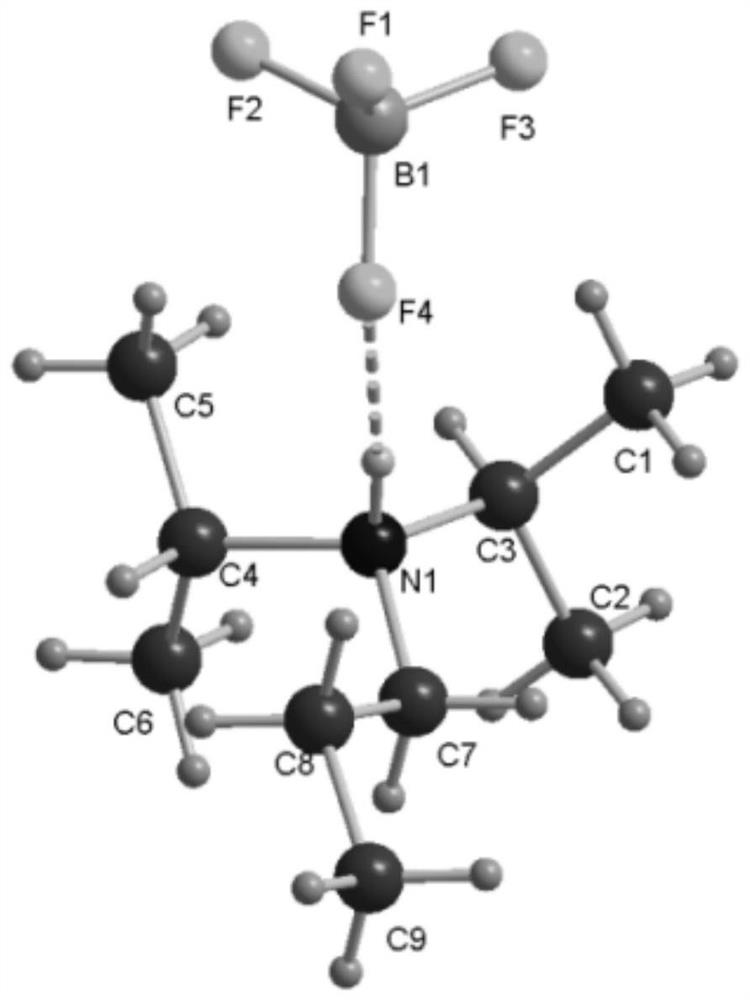

[0045] Weigh diisopropylpropylamine (1.43g, 10 mmol), dissolve in 20 mL of ethanol, add HBF dropwise under stirring 4 The solution was about 2 mL to weakly acidic (pH≈6), let it stand for a few minutes, filtered, the filtrate evaporated, and colorless needle-like crystals precipitated after about two days.

Embodiment 3

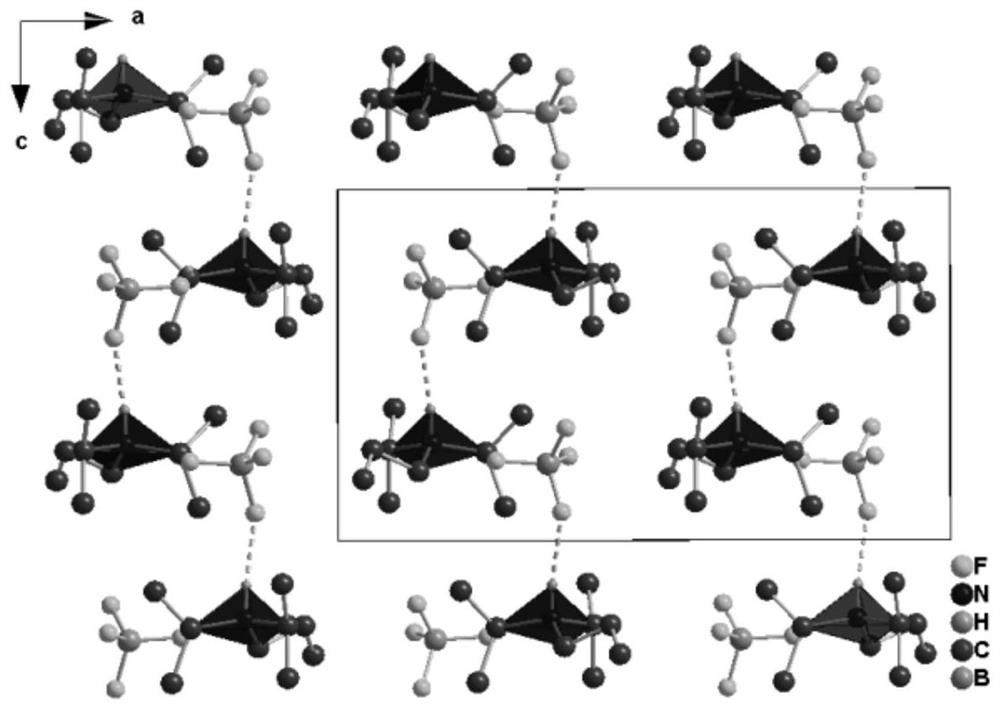

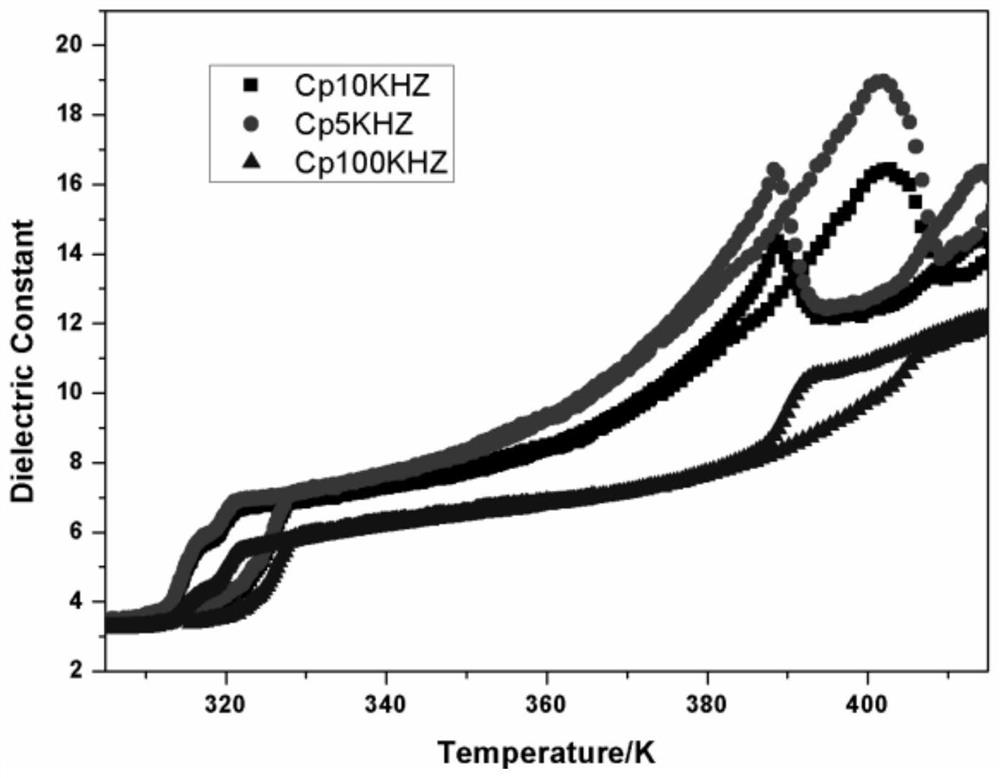

[0047]Take the powder sample of the compound diisopropylpropylamine tetrafluoroborate crystal and press it into a sheet with a thickness of about 0.6mm, and make an electrode with an electrode holder, copper wire, and carbon conductive adhesive, and measure the area covered by the carbon conductive adhesive on the electrode and The thickness of the electrode is then placed on a dielectric measuring instrument to measure the data of the dielectric constant corresponding to the temperature change; the nonlinear optical effect test uses a Nd with a wavelength of 1064 nm: YAG pulsed laser beam; the differential scanning volume is performed on the Rigaku DSC8230 instrument Thermal measurements were performed under a nitrogen atmosphere at a heating or cooling rate of 10 K / min in an aluminum crucible; the crystal structure was resolved by the direct method, and the olex2. 2 The full matrix method refinement.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com