Patents

Literature

100 results about "Full matrix" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tracking in Haptic Systems

ActiveUS20190196578A1Reduce noiseFast response timeInput/output for user-computer interactionImage enhancementTransducerFull matrix

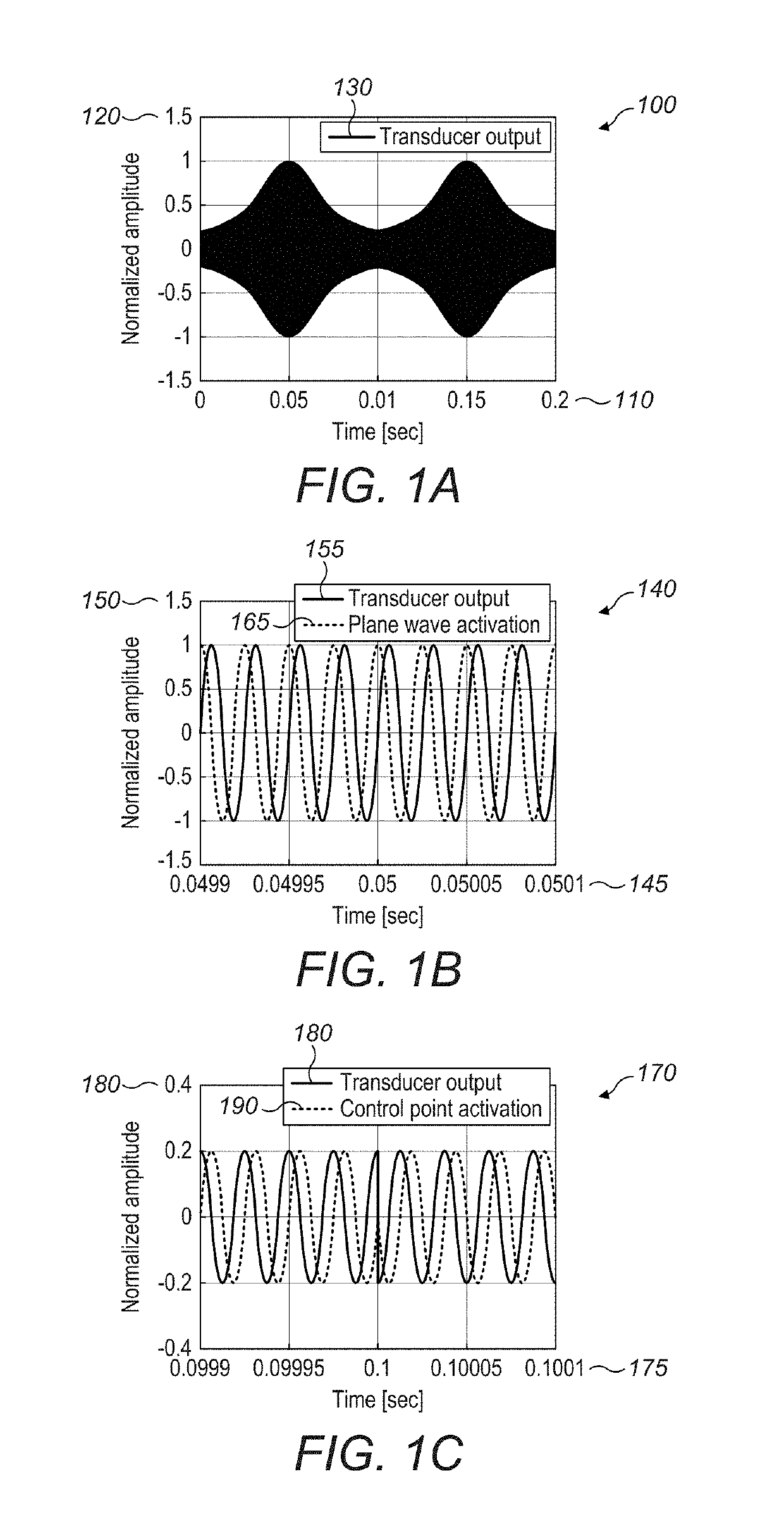

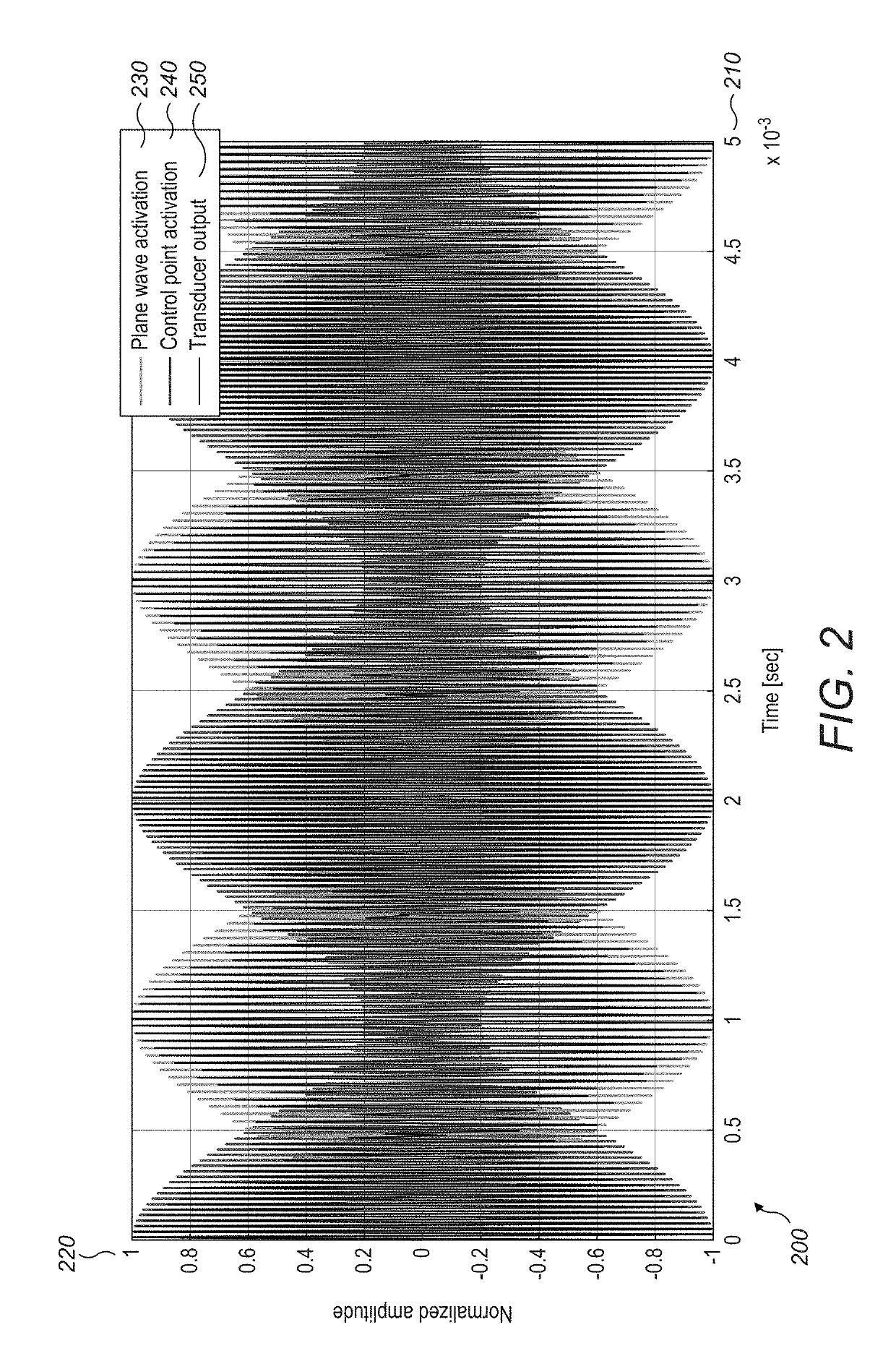

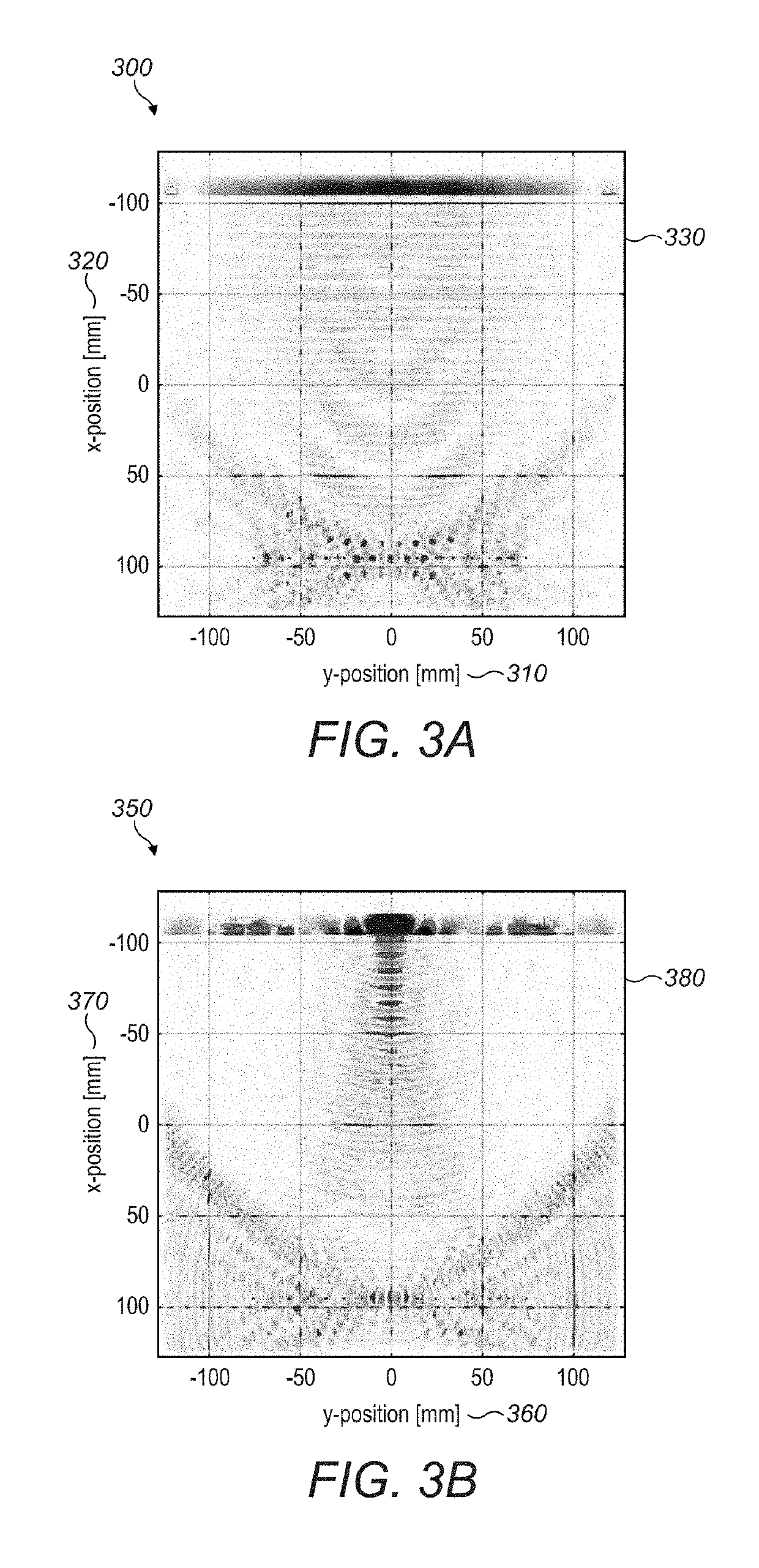

Described herein are techniques for tracking objects (including human body parts such as a hand), namely: 1) two-state transducer interpolation in acoustic phased-arrays; 2) modulation techniques in acoustic phased-arrays; 3) fast acoustic full matrix capture during haptic effects; 4) time-of-flight depth sensor fusion system; 5) phase modulated spherical wave-fronts in acoustic phased-arrays; 6) long wavelength phase modulation of acoustic field for location and tracking; and 7) camera calibration through ultrasonic range sensing.

Owner:ULTRAHAPTICS IP LTD

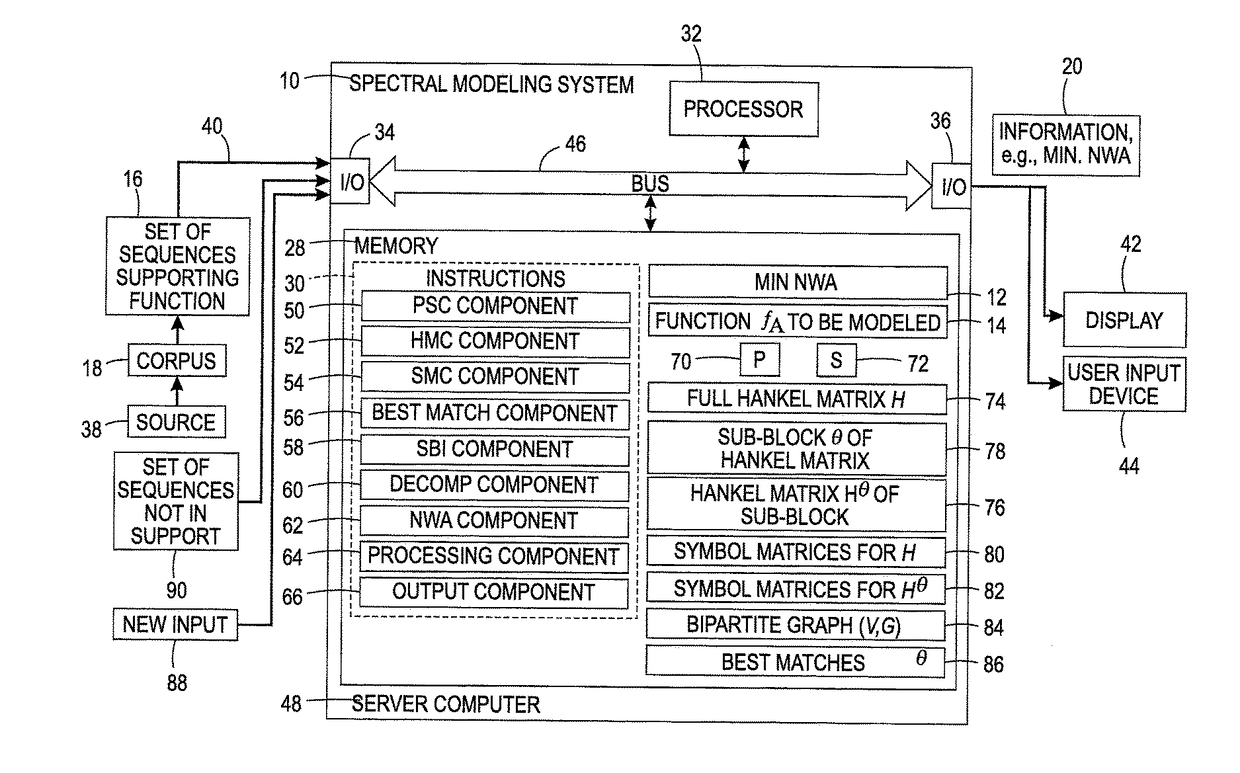

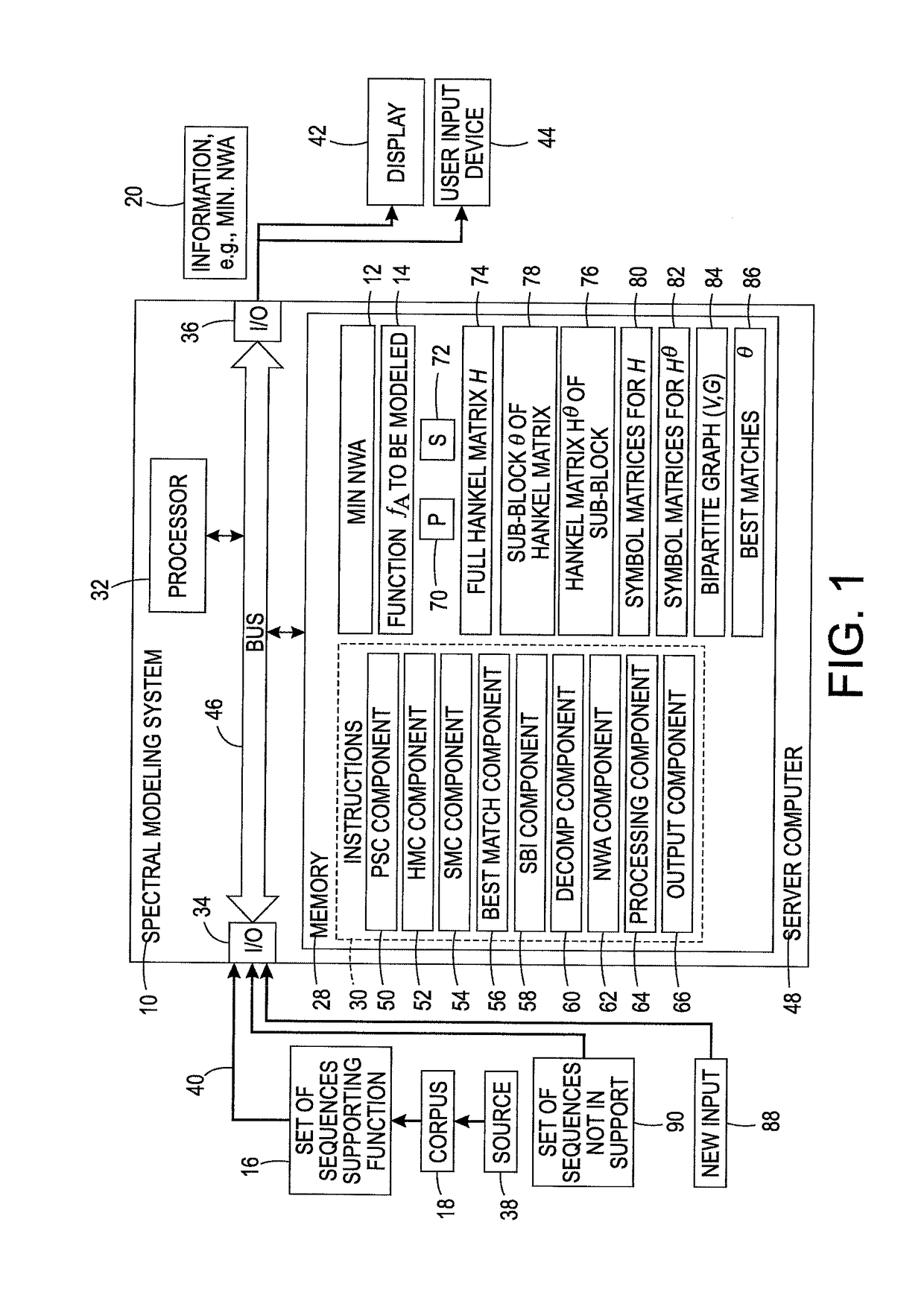

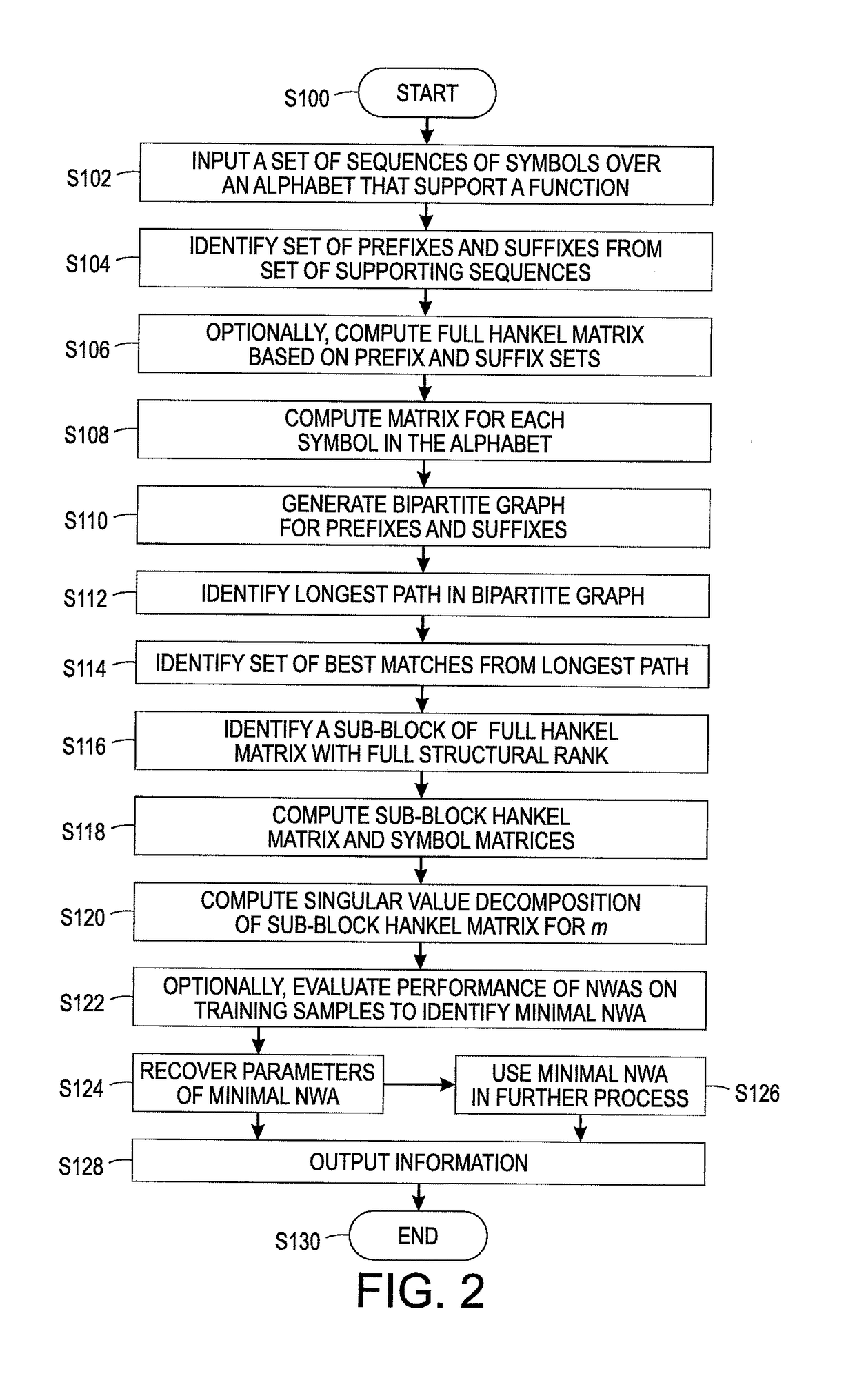

Scalable spectral modeling of sparse sequence functions via a best matching algorithm

InactiveUS20170351786A1Natural language data processingDesign optimisation/simulationAlgorithmFull matrix

A method for modeling a sparse function over sequences is described. The method includes inputting a set of sequences that support a function. A set of prefixes and a set of suffixes for the set of sequences are identified. A sub-block of a full matrix is identified which has the full structural rank as the full matrix. The full matrix includes an entry for each pair of a prefix and a suffix from the sets of prefixes and suffixes. A matrix for the sub-block is computed. A minimal non-deterministic weighted automaton which models the function is computed, based on the sub-block matrix. Information based on the identified minimal non-deterministic weighted automaton is output.

Owner:XEROX CORP

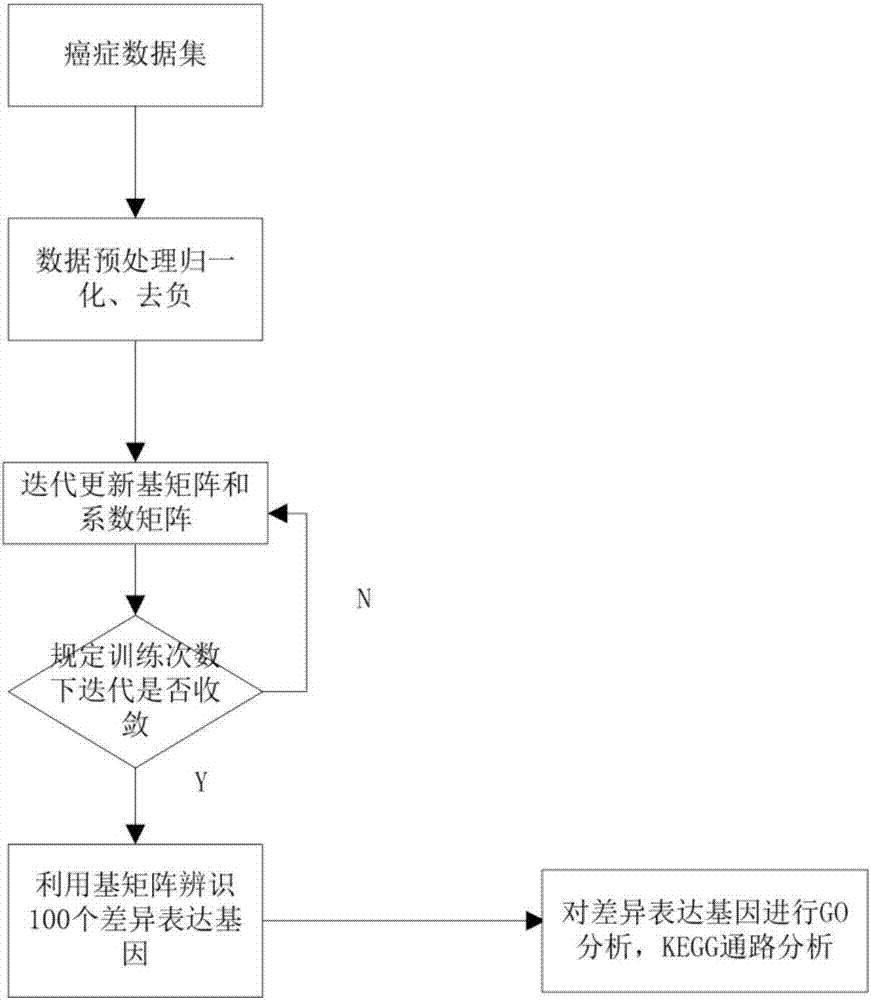

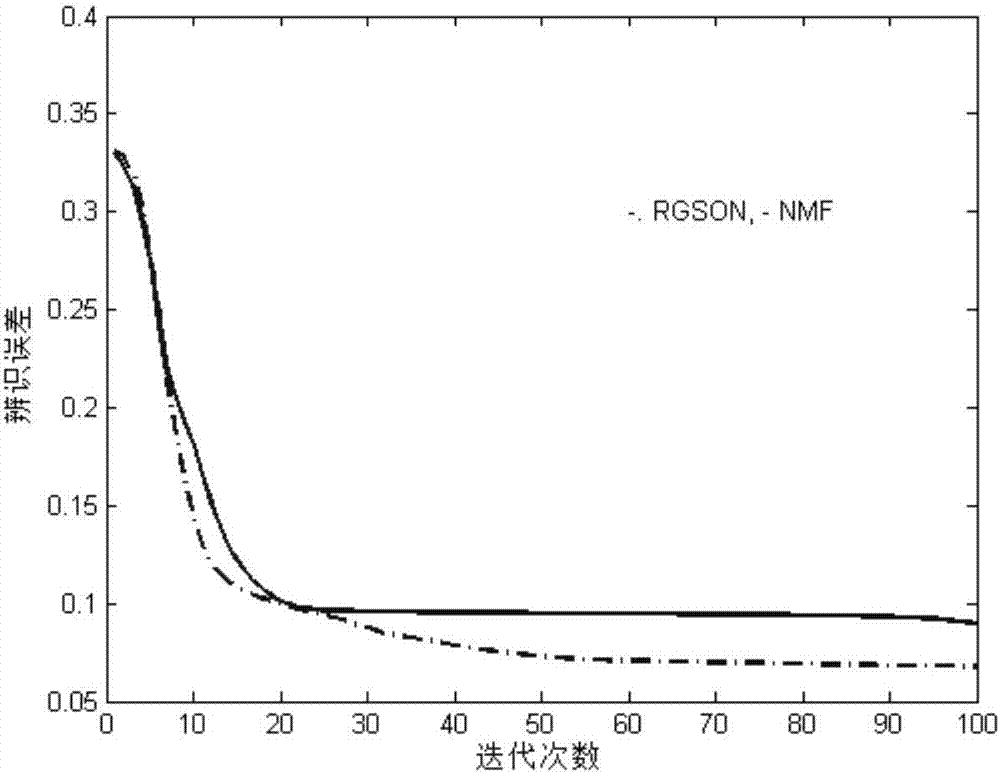

Differentially expressed gene identification method based on combined constraint non-negative matrix factorization

ActiveCN107016261AEffective decomposition resultsEfficient Sparse Decomposition ResultsSpecial data processing applicationsData setAlgorithm

The invention discloses a differentially expressed gene identification method based on combined constraint non-negative matrix factorization. The method comprises the following steps of 1, representing a cancer-gene expression data set with a non-negative matrix X, 2, constructing a diagonal matrix Q and an element-full matrix E, 3, introducing manifold learning in the classical non-negative matrix factorization method, conducting orthogonal-constraint sparseness and constraint on a coefficient matrix G, and obtaining a combined constraint non-negative matrix factorization target function, 4, calculating the target function, and obtaining iterative formulas of a basis matrix F and the coefficient matrix G, 5, conducting semi-supervision non-negative matrix factorization on the non-negative data set X, and obtaining the basis matrix F and the coefficient matrix G after iteration convergence, 6, obtaining an evaluation vector (the formula is shown in the description), sorting elements in the evaluation vector (the formula is shown in the description) from large to small according to the basis matrix F, and obtaining differentially expressed genes, 7, testing and analyzing the identified differentially expressed genes through a GO tool. The identification method can effectively extract the differentially expressed genes where cancer data is concentrated, and be applied in discovering differential features in a human disease gene database. The identification method has important clinical significance for early diagnosis and target treatment of diseases.

Owner:HANGZHOU HANGENE BIOTECH CO LTD

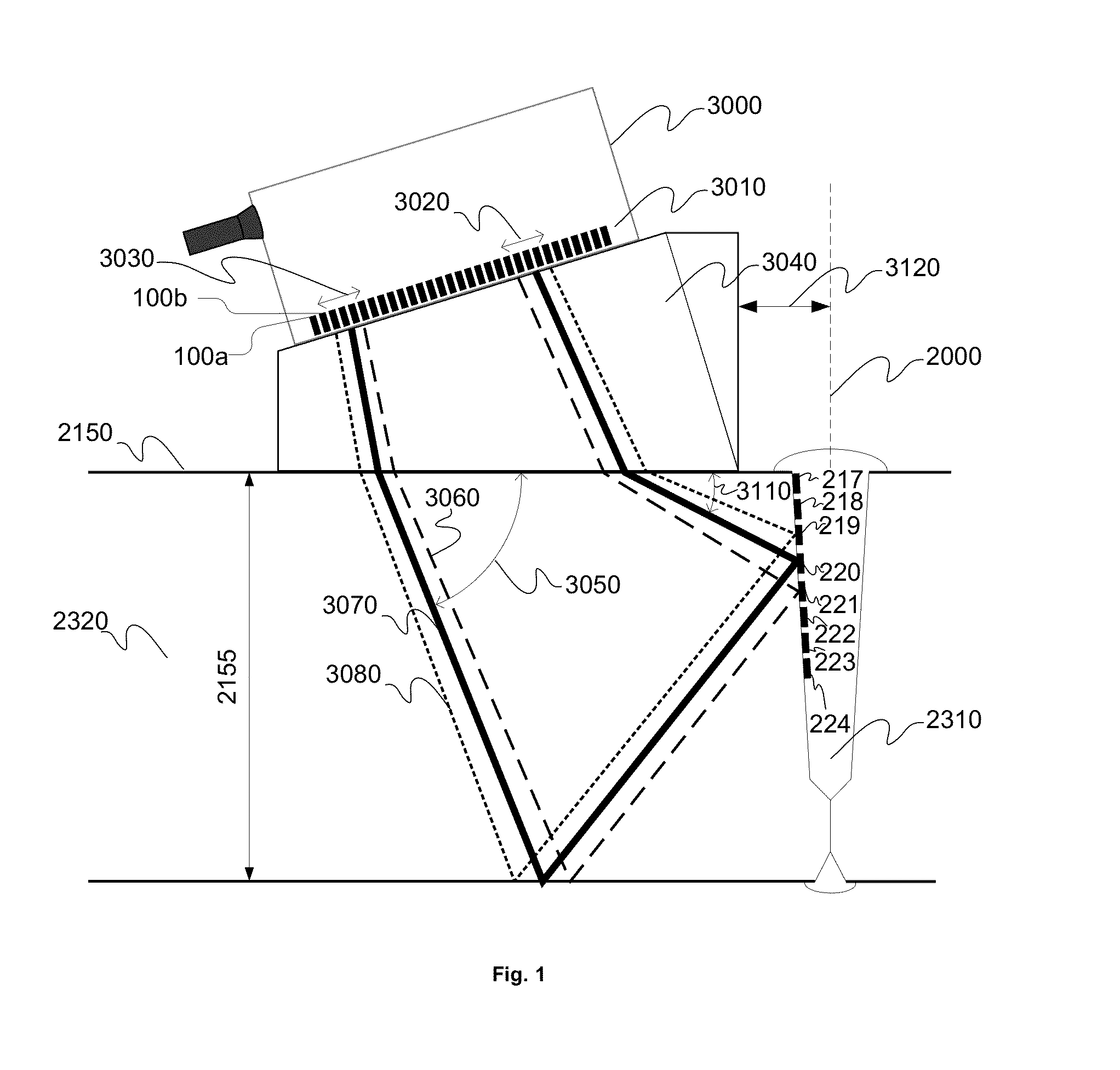

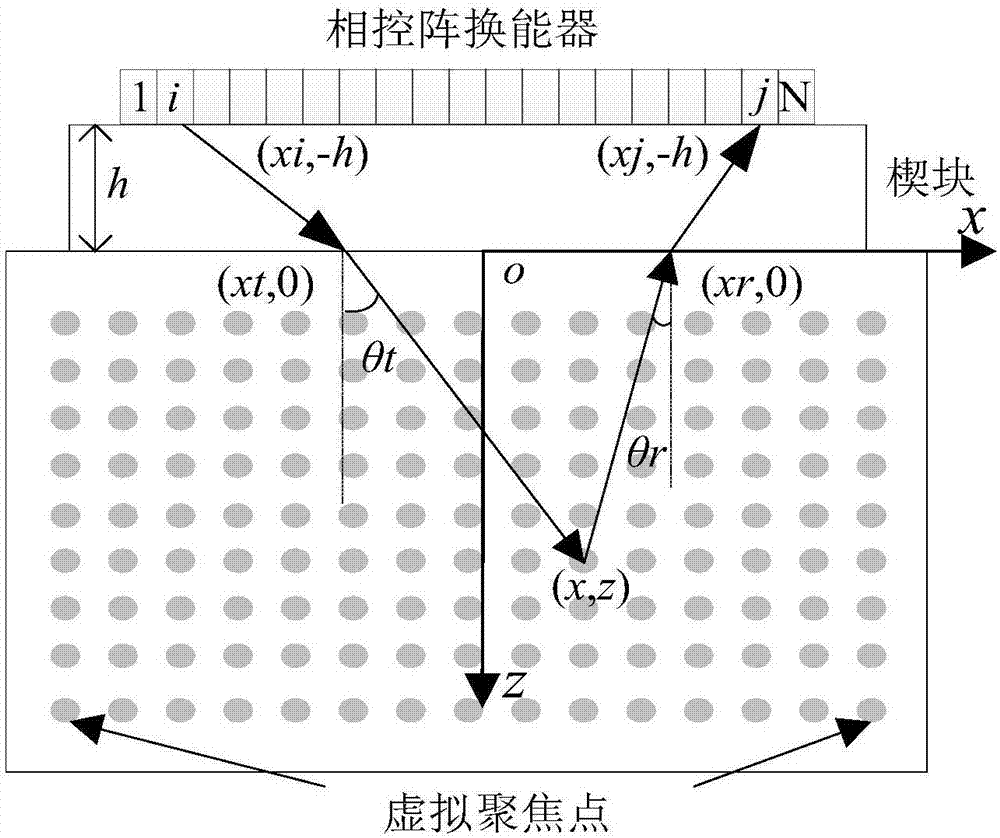

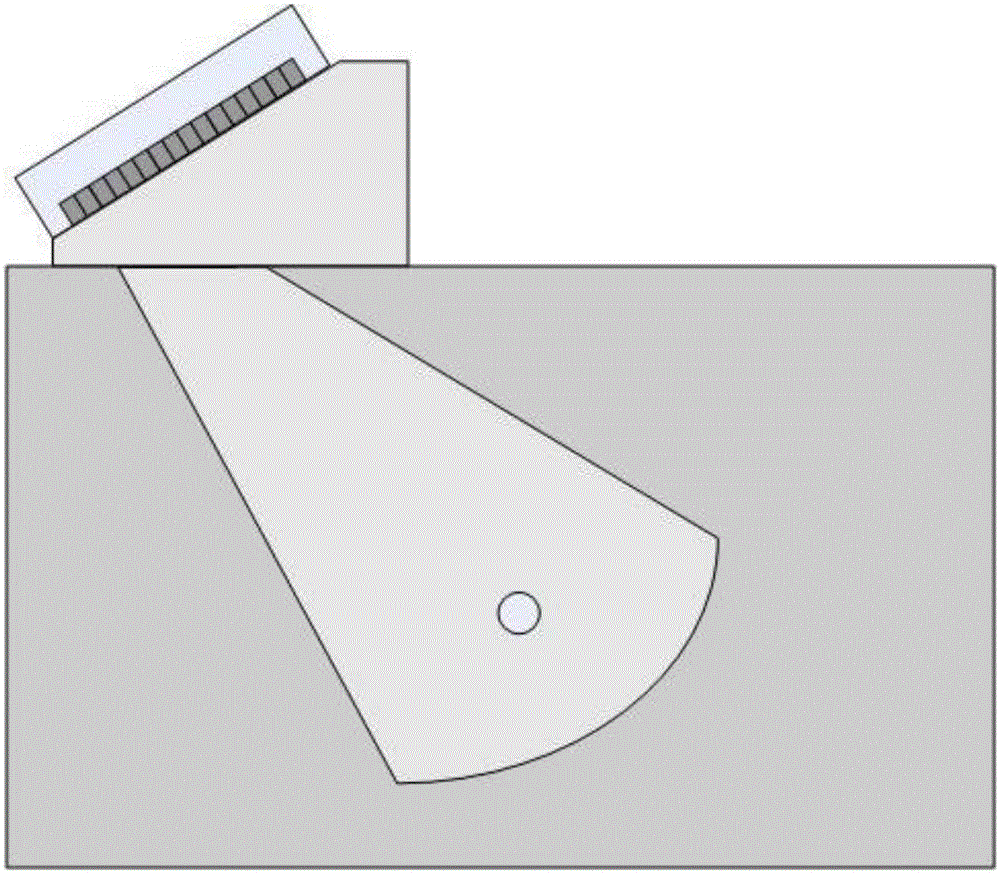

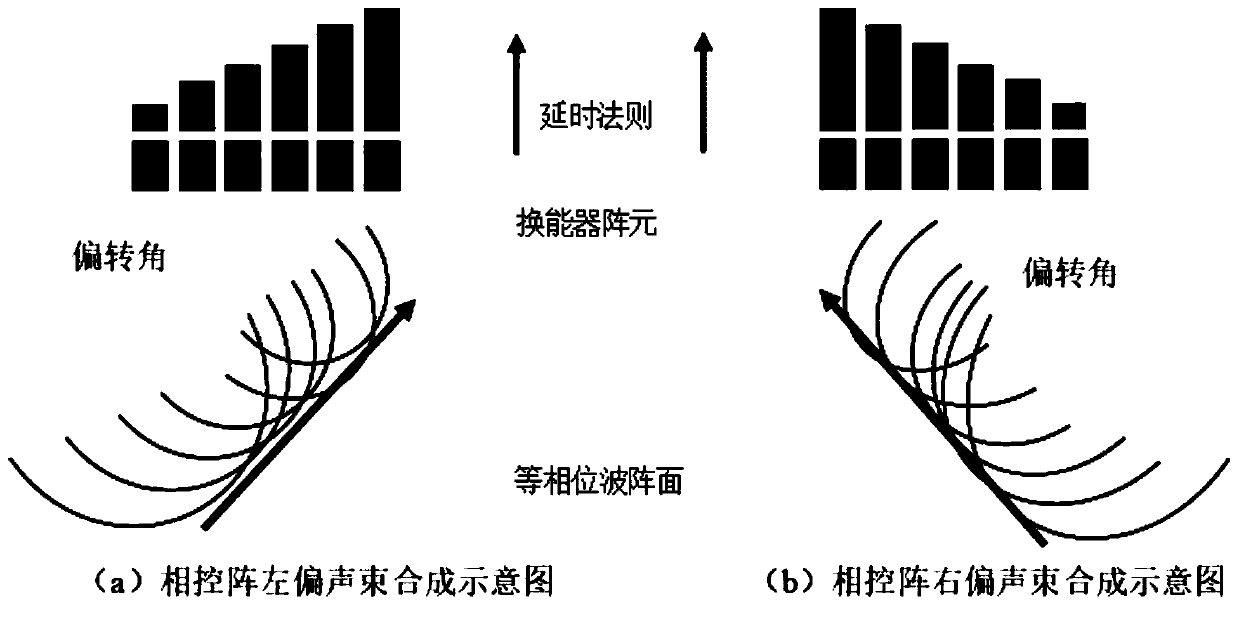

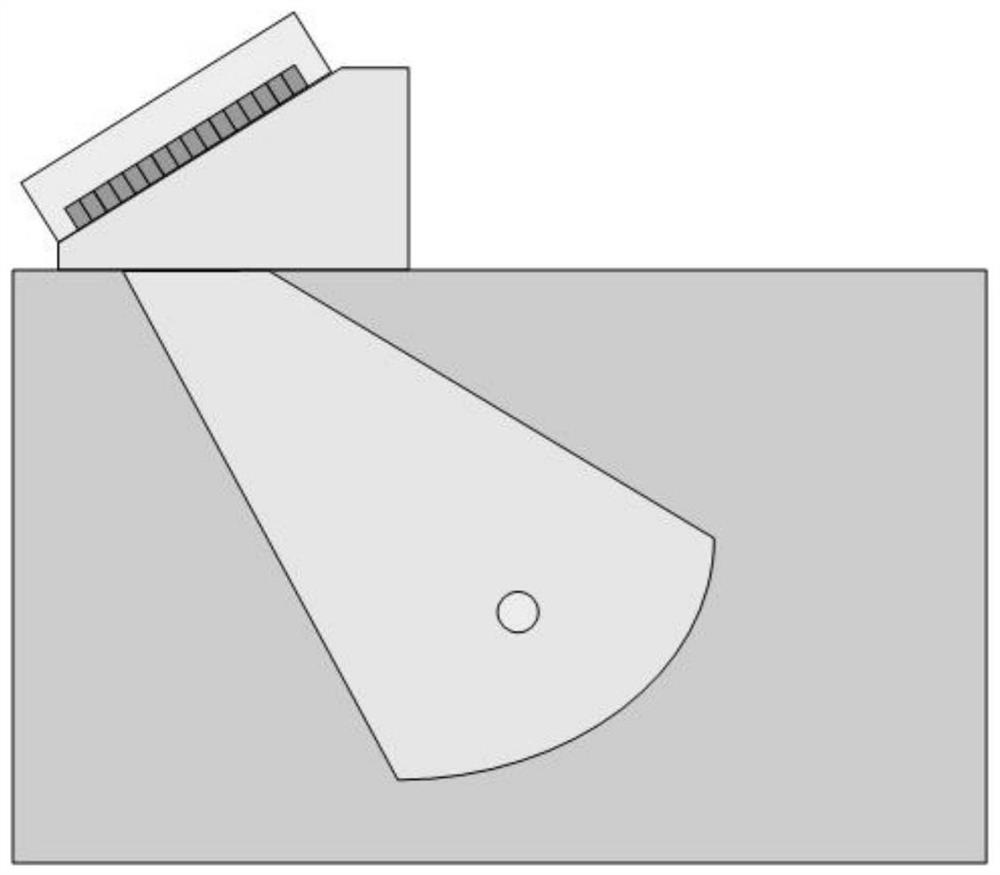

Method for welding line ultrasound array full focusing imaging based on oblique incidence longitudinal waves

InactiveCN106093206AImprove defect detection performanceEasy to detectAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalSonificationLongitudinal wave

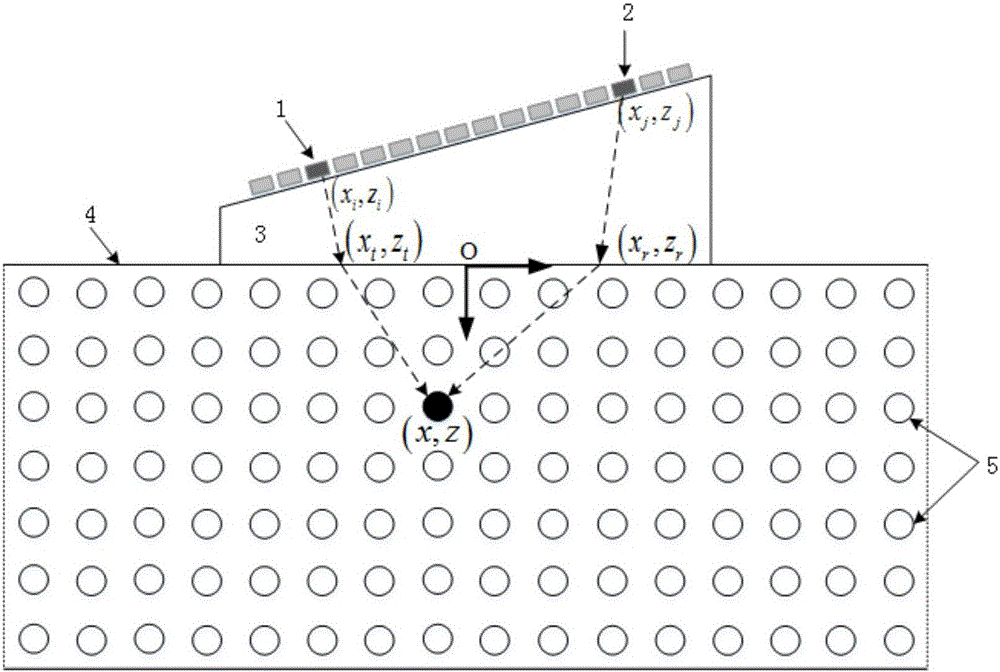

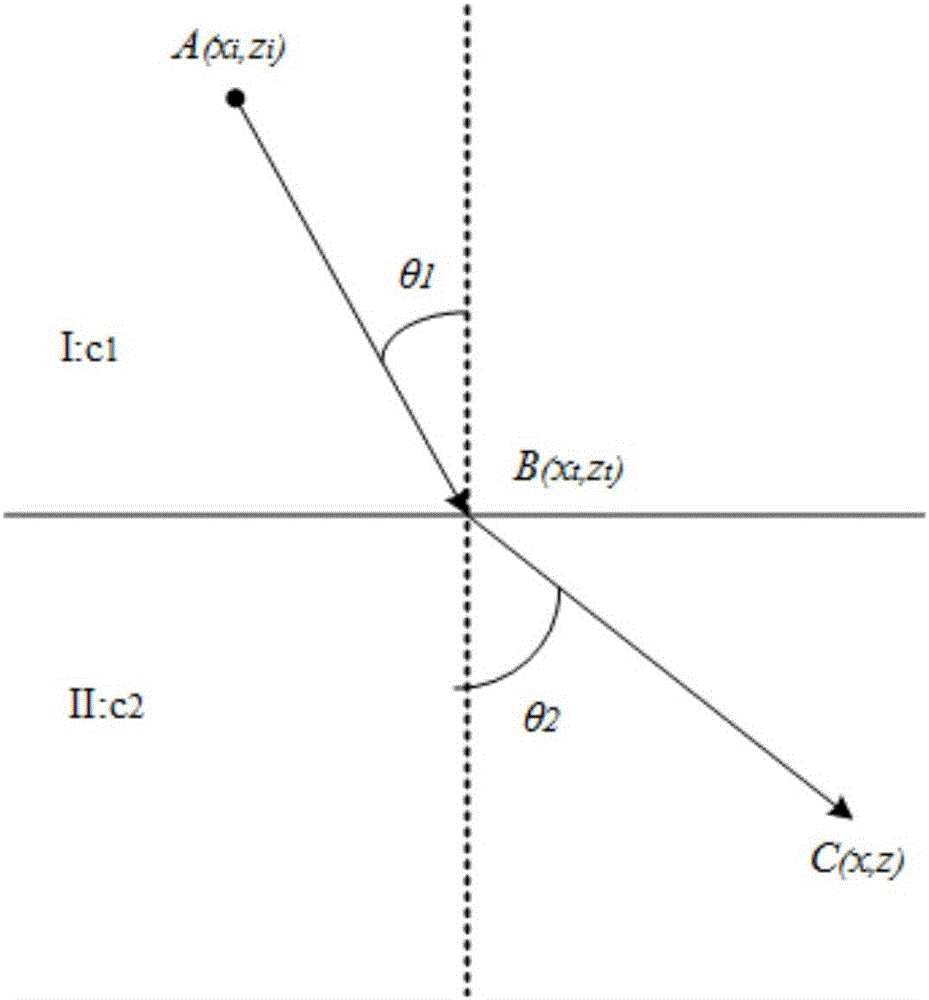

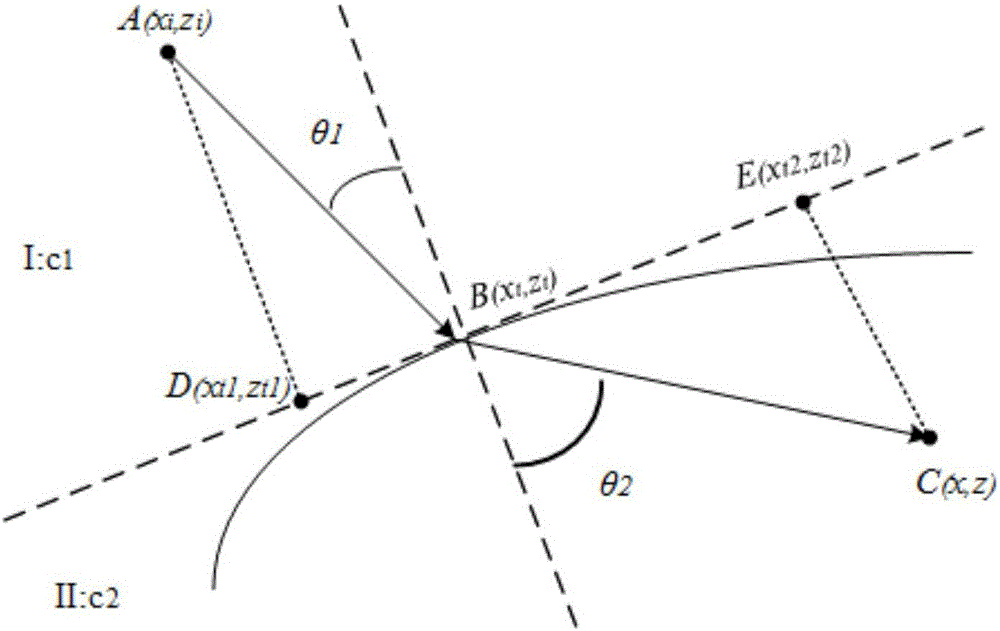

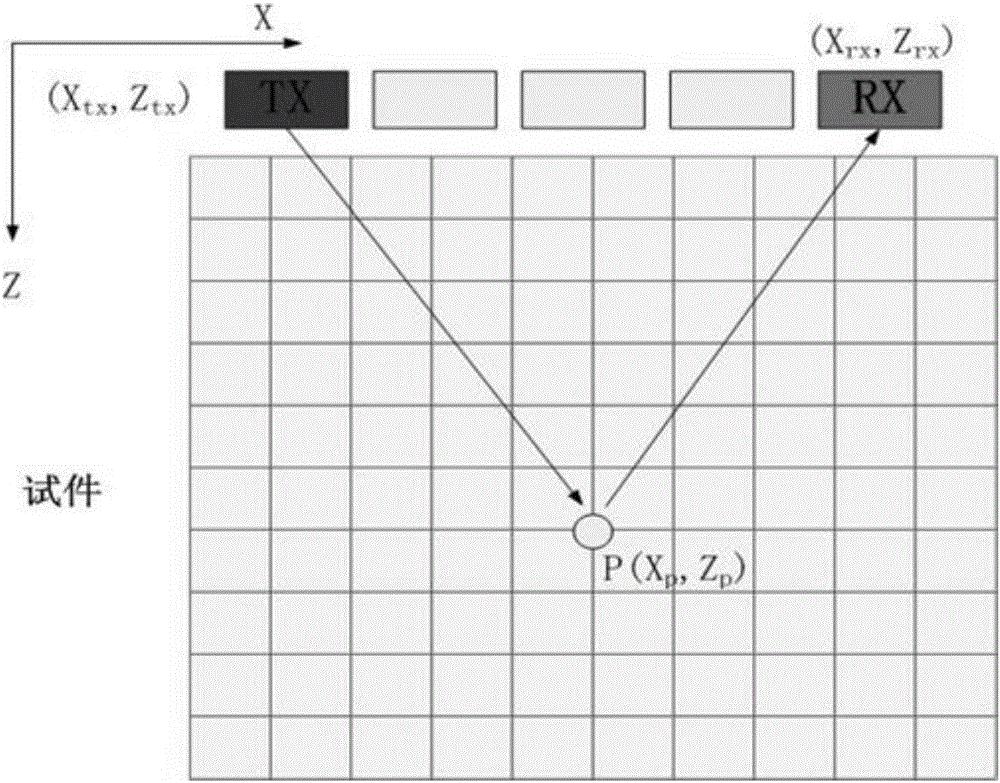

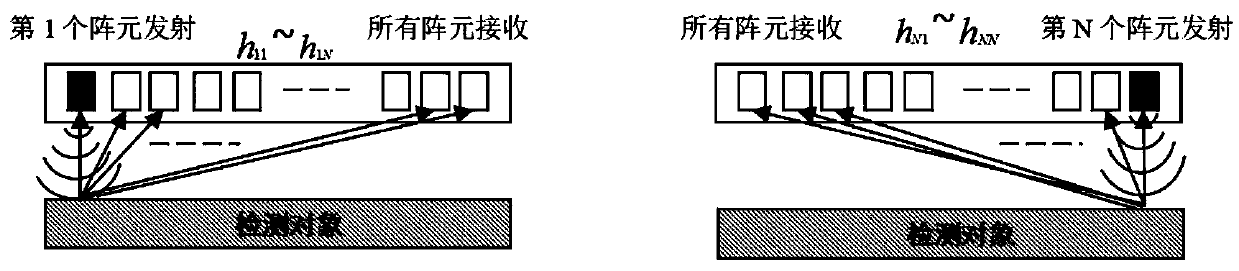

The invention discloses a method for welding line ultrasound array full focusing imaging based on oblique incidence longitudinal waves. A present array imaging postprocessing method is only applied to processing of full matrix data collected under the situation that a phased array probe acoustic beam vertically enters a to-be-tested piece. According to the method, a wedge block is added to a phased array probe, a main acoustic beam of longitudinal waves enters a welding line of the to-be-tested piece through the wedge block; by processing the full matrix data excited and received by a phased array sensor and calculating a refraction intersection point of the acoustic beam on an interface through the wedge block based on a Snell principle, the acoustic beam propagation time of each array element reaching all imaging points is calculated, amplitudes of focus points are obtained through calculation, and then the amplitude of each focus point is focused; and finally full focusing imaging of the oblique incidence longitudinal waves is achieved. The longitudinal wave main acoustic beam in a specific direction can be generated, the defect detection effect in a welding line area and the defect recognition rate are improved; and a probe protecting effect is achieved.

Owner:ELECTRIC POWER RES INST OF STATE GRID ZHEJIANG ELECTRIC POWER COMAPNY +2

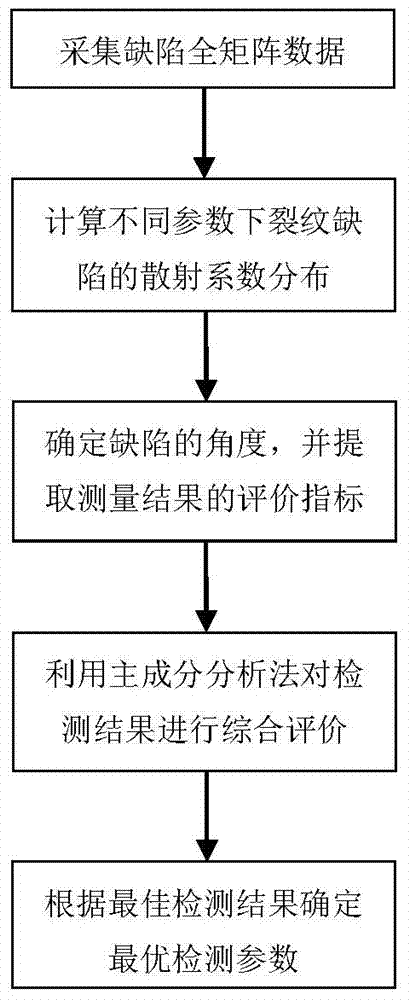

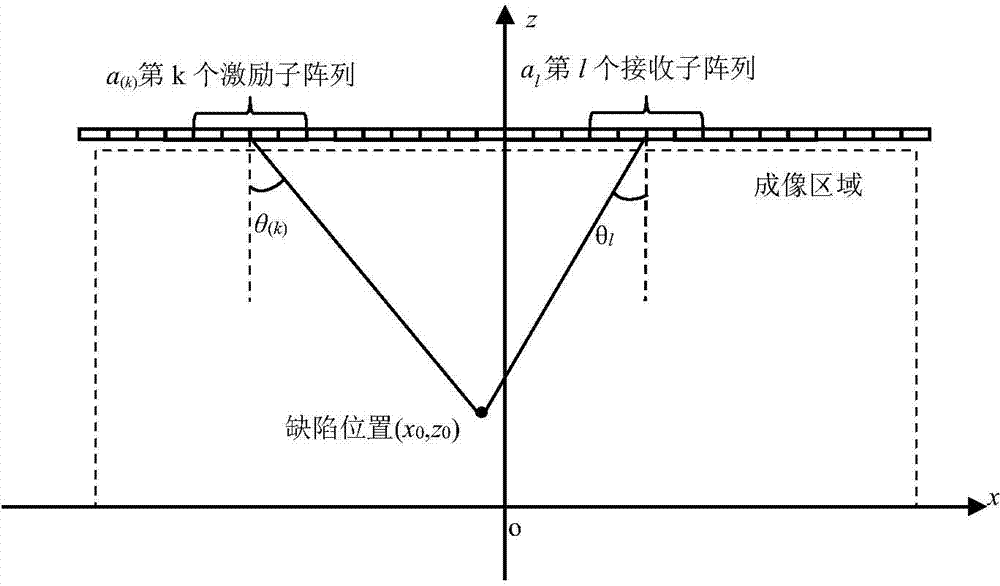

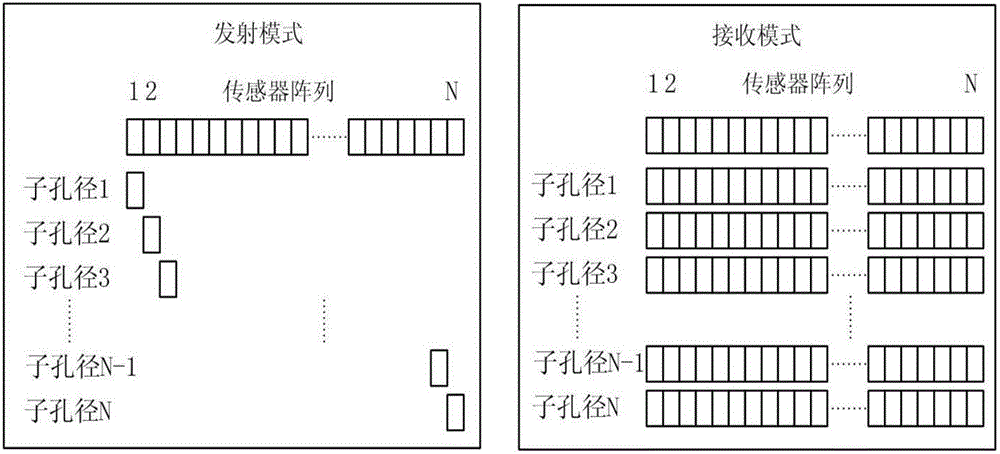

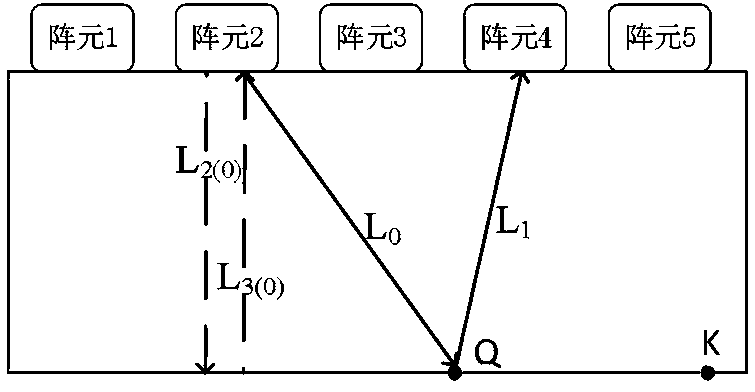

Ultrasonic scattering coefficient optimal computation method for crack direction recognition

ActiveCN104280455AAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalFull matrixMeasurement precision

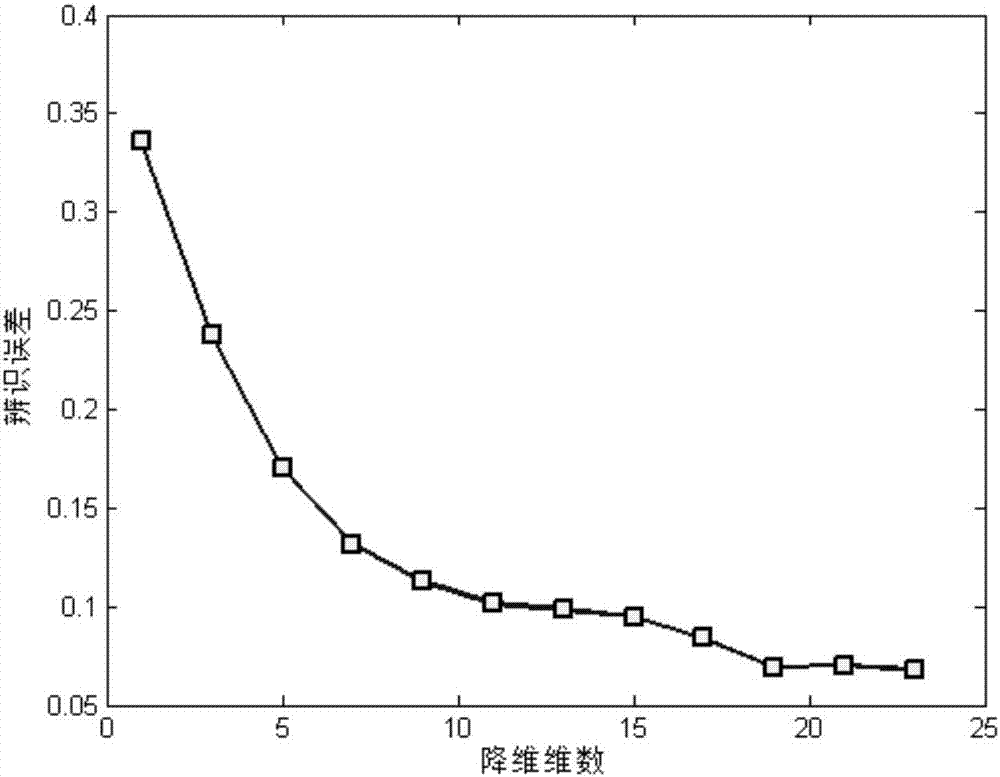

The invention relates to an ultrasonic scattering coefficient optimal computation method for crack direction recognition, belonging to the field of nondestructive examination. According to the method, an ultrasonic phased array detection system is used for acquiring full-matrix data of a crack defect; firstly, the acquired data are used for performing full-focusing imaging on the defect to determine the position of the defect and then a scattering coefficient space distribution of the crack defect is computed to determine an angle of the crack; the quantity of wafers included in a sub array and the quantity of wafers between adjacent sub arrays greatly affect the measurement precision of the crack angle. A plurality of evaluation indexes are used for evaluating the quantity of a crack angle measurement result according to the quantities of the wafers included in different sub arrays and the wafers between the adjacent sub arrays, and the measurement result is comprehensively evaluated by a main component analysis method to obtain an optimal measurement result; corresponding parameters, namely the quantities of the wafers included in the sub arrays and the quantity of the wafers between the adjacent sub arrays, are optimal detection parameters.

Owner:BEIJING UNIV OF TECH

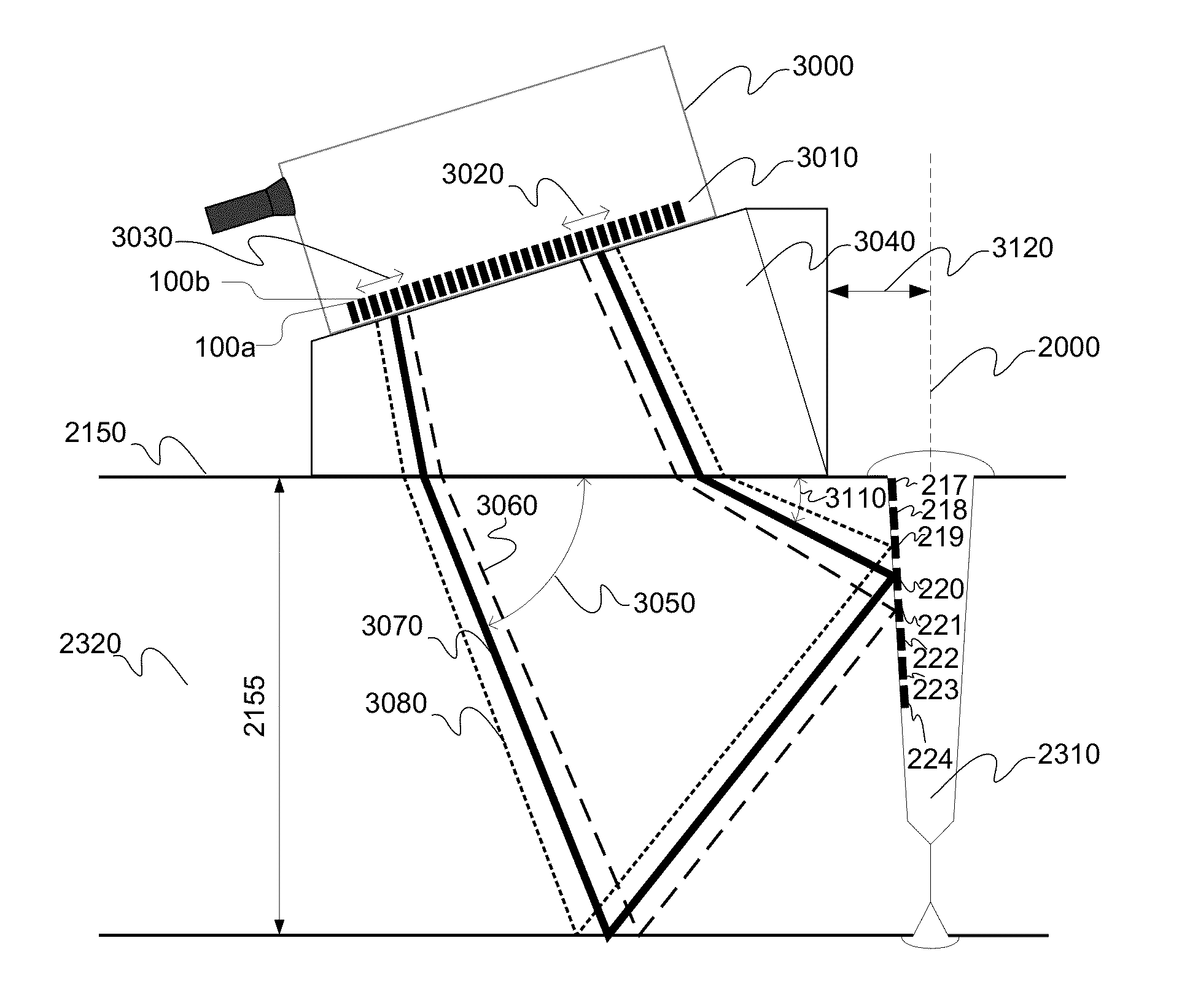

Automatic calibration for phased array inspection of girth weld

ActiveUS20150168355A1Material analysis using sonic/ultrasonic/infrasonic wavesStatic/dynamic balance measurementFull matrixBeam steering

A calibration method for calibrating a phased array probe that is used for testing girth welds for defects. The method utilizes a calibration device on which is defined a series of reflectors that correspond to a series of target zones. The phased array probe is placed via a wedge relative to the calibration device and the phased array probe is configured with an initial set of acoustic parameters which define at least a transmitting aperture, a receiving aperture and a beam steering angle. Using a Full Matrix Capture (FMC) acquisition process and a ray-tracing module, the values of the initial set of acoustic parameters are optimized to evolve a final set of acoustic parameters which the phased array probe utilizes for testing actual devices for weld defects.

Owner:OLYMPUS AMERICA

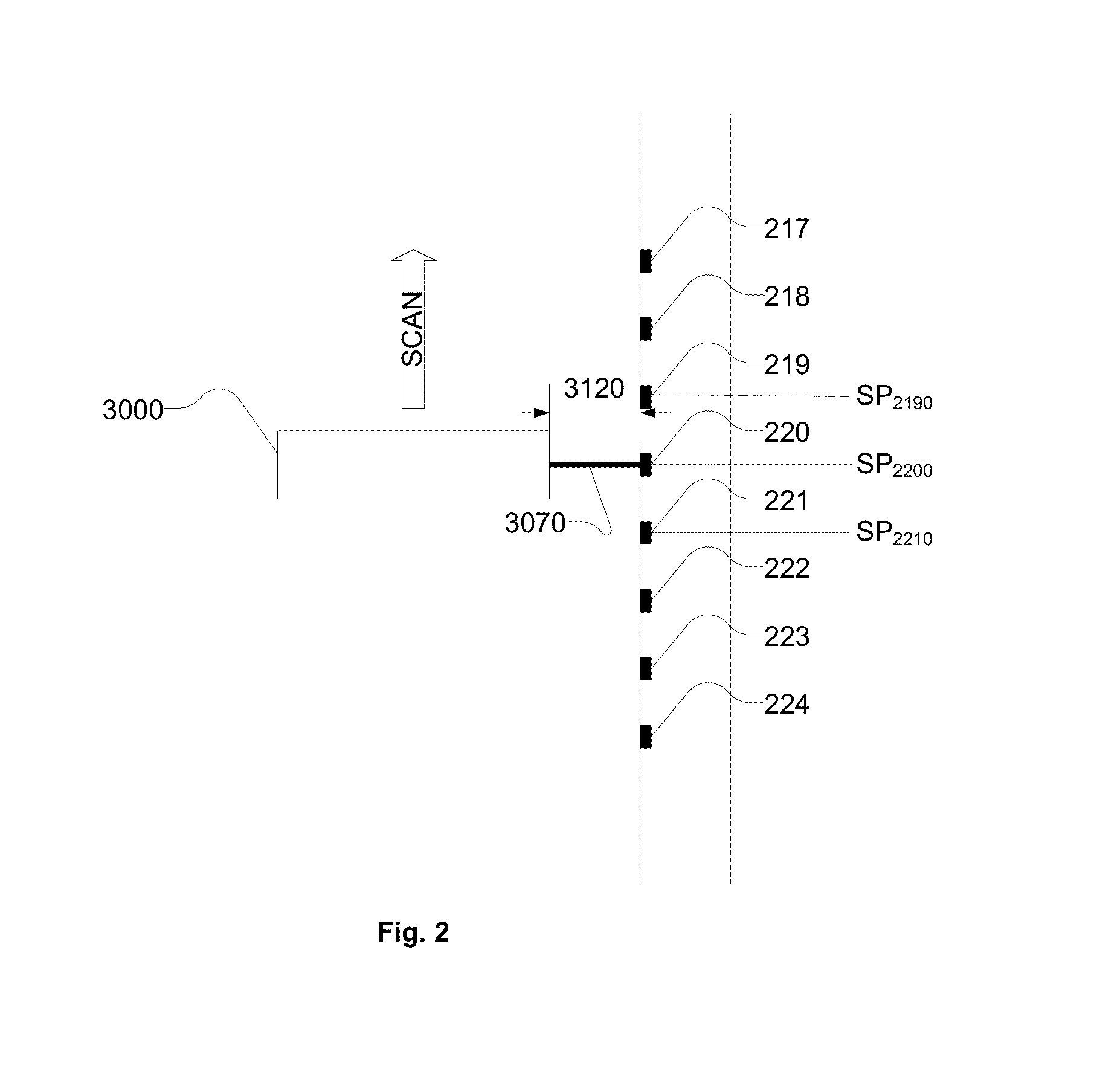

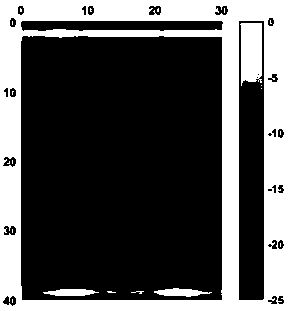

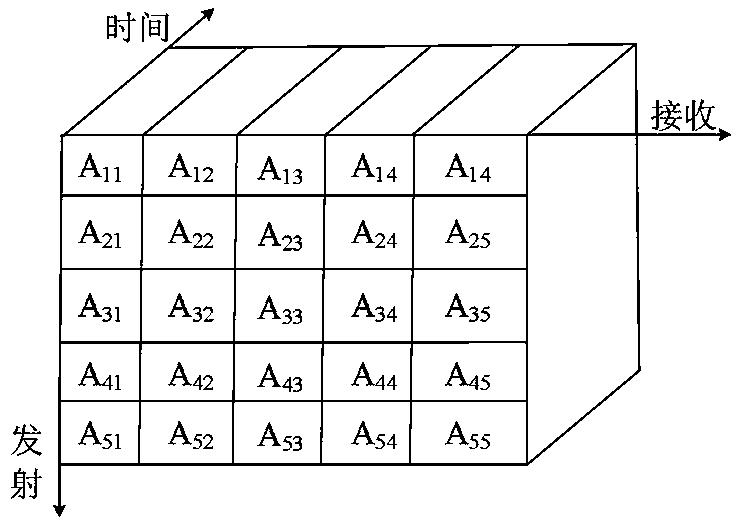

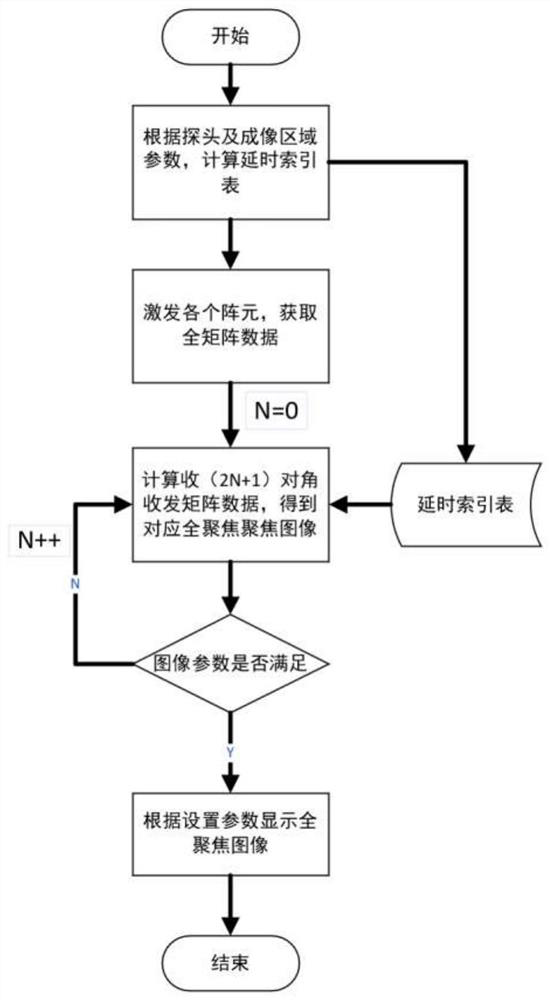

Quick phased array ultrasonic whole-focusing imaging technology

InactiveCN108693253ASolve the problem of difficult real-time full-focus imagingAchieve high-precision quantificationAnalysing solids using sonic/ultrasonic/infrasonic wavesFull matrixComputer vision

The invention discloses a quick phased array ultrasonic whole-focusing imaging technology, which includes steps of: separating a collected full-matrix data A*NRX*NTX into N two-dimensional sub-matrixdata An*NRX; performing virtual focusing to all sub-matrix data by means of algorithm based on two-dimensional forward / inverse Fourier transform; performing circulation calculation to acquire the two-dimensional focusing images of the first to Nth sub-matrixes; finally fusing the two-dimensional focusing images of all sub-matrixes to form the whole-focusing image. The method is expected to solve aproblem that a phased array ultrasonic fault detector cannot achieve real-time whole-focusing imaging, can quickly and effectively achieve high-precise quantization, positioning and qualification tointernal defects of materials, and has great promotion and application prospect.

Owner:NANCHANG HANGKONG UNIVERSITY

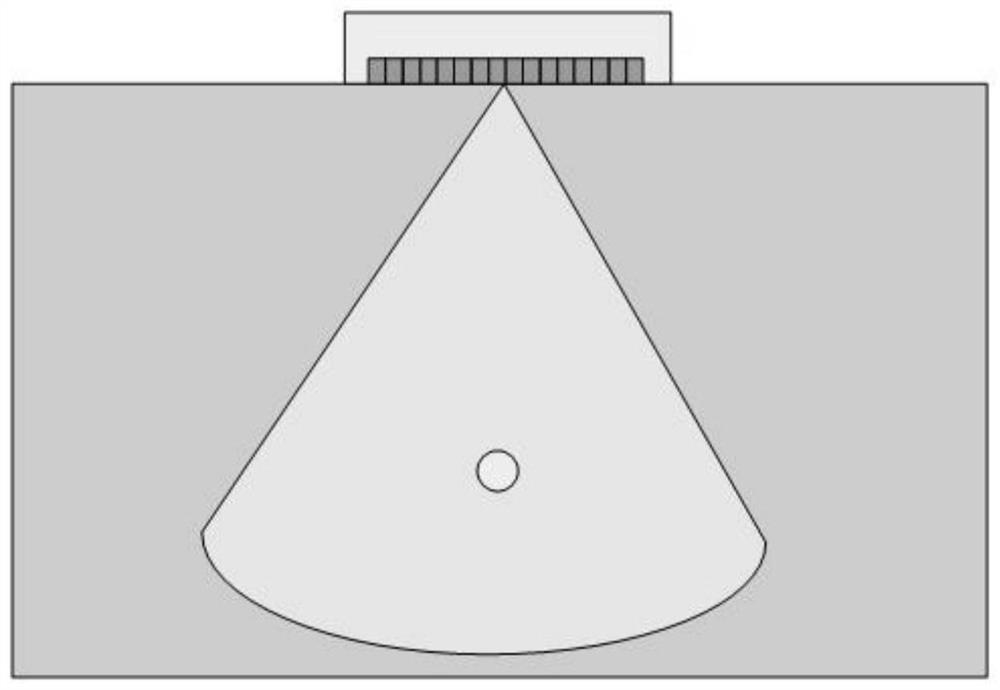

Full-focusing imaging detection method based on ring array transducer

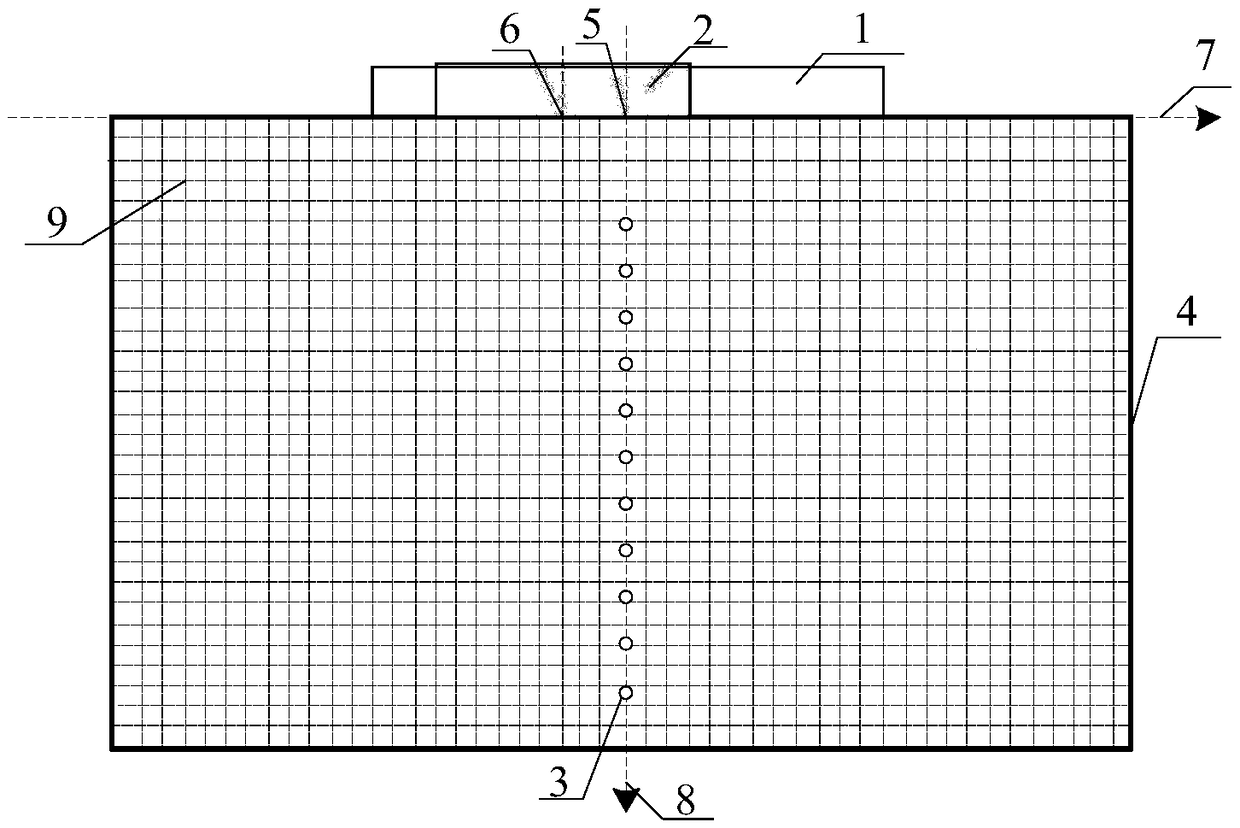

ActiveCN107219305AReduce control complexityStrong focused sound fieldAnalysing solids using sonic/ultrasonic/infrasonic wavesNon destructiveSonification

The invention provides a full-focusing imaging detection method based on a ring array transducer and belongs to ultrasonic non-destructive testing. The method comprises the following steps: setting a detection imaging region as a linear region along the axial direction of the ring array transducer; clamping the ring transducer with a mechanical clamp to scan the detection regions, successively motivating single array elements when the detection regions are scanned, wherein all array elements receive ultrasonic echo time domain signals for every motivation to form full matrix data of the detection regions; discretizing each detection region to a plurality of detection points, determining the sound wave spreading paths at the detection points according to the Fermat principle to obtain the spreading times, fully focusing the full matrix data collected to monitoring points by means of a time delay method to obtain the amplitude of the detection points. The method can generate a relatively strong sound field under the circumstance of using few array elements, so that the circuit control complicated degree is greatly reduced, the detection thickness and detection precision are improved, and intelligence and efficiency of detection can be realized.

Owner:BEIHANG UNIV

Method and device for jointly processing data by two parties

ActiveCN111162896ALow trafficSmall amount of calculationKey distribution for secure communicationCommunication with homomorphic encryptionSecret shareAlgorithm

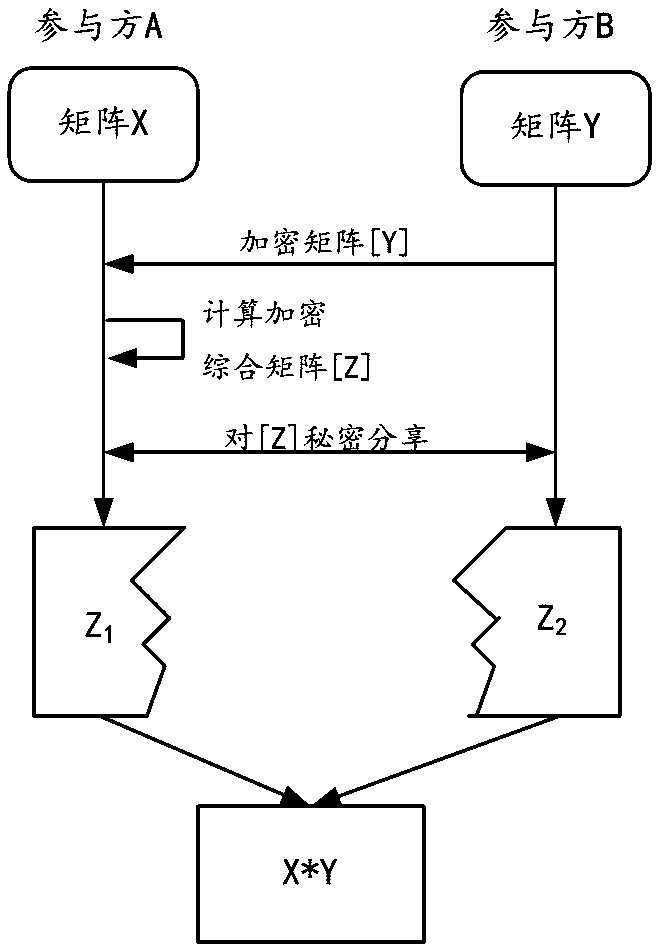

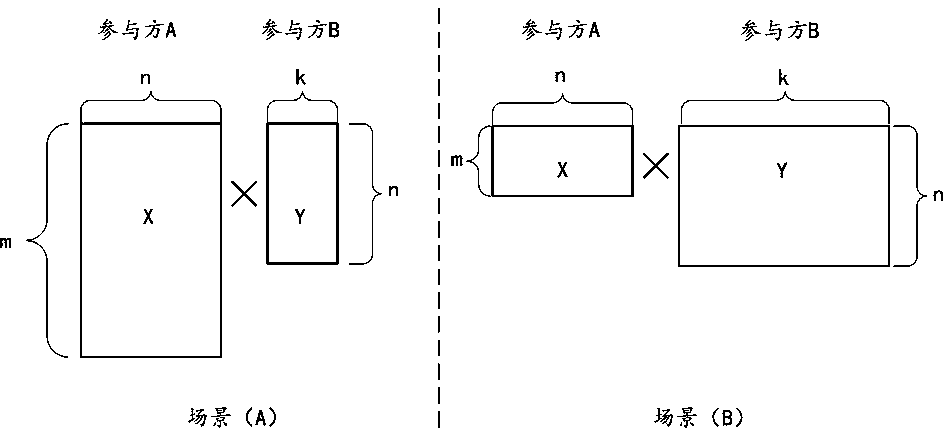

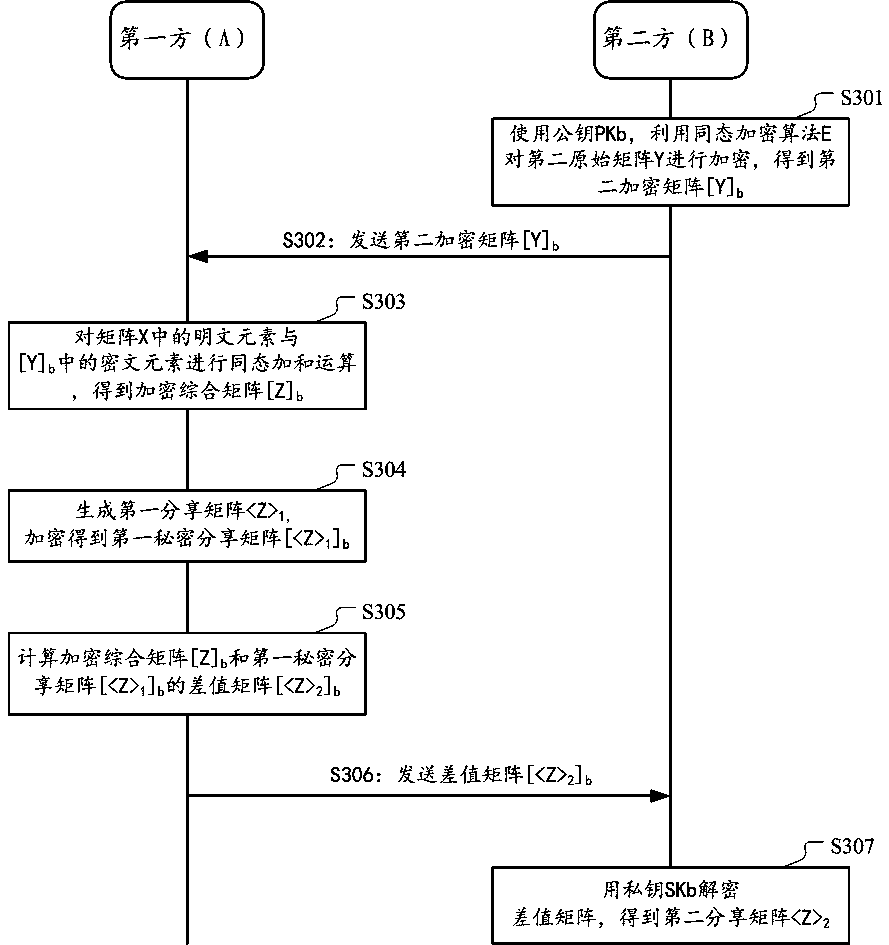

The embodiment of the invention provides a method and device for jointly processing data by two parties for protecting data privacy. The two parties respectively maintain an original matrix formed byprivate data. According to the method, homomorphic encryption is carried out on the matrix of one party with the smaller matrix dimension in the two parties, and the encrypted matrix is sent to the other party. And on the other hand, homomorphic addition operation is carried out on the encryption matrix by using the original matrix of the encryption matrix to obtain an encrypted comprehensive matrix. The encrypted comprehensive matrix is equivalent to a matrix obtained after a multiplication matrix is encrypted. And then, the two parties perform secret sharing under homomorphic encryption forthe encryption comprehensive matrix, and finally, a matrix fragment is obtained respectively, so that the sum of the fragments is the multiplication matrix, and the security matrix operation of the two parties is realized.

Owner:ALIPAY (HANGZHOU) INFORMATION TECH CO LTD

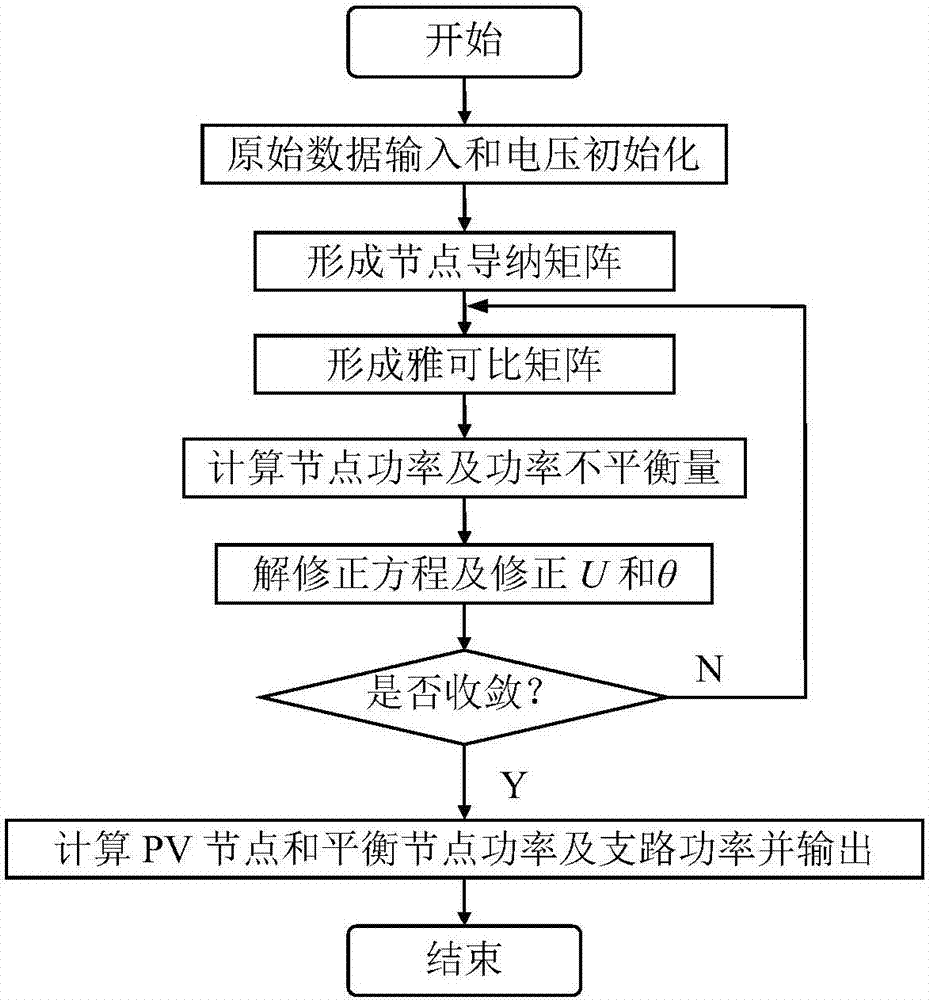

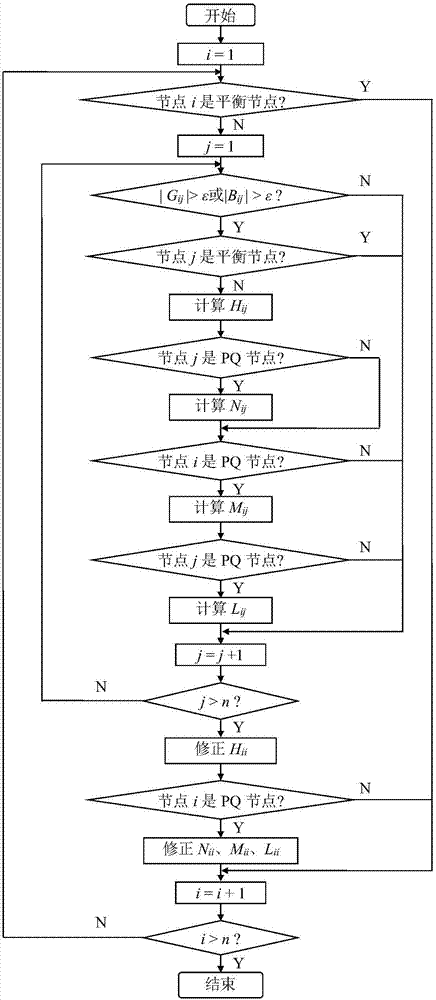

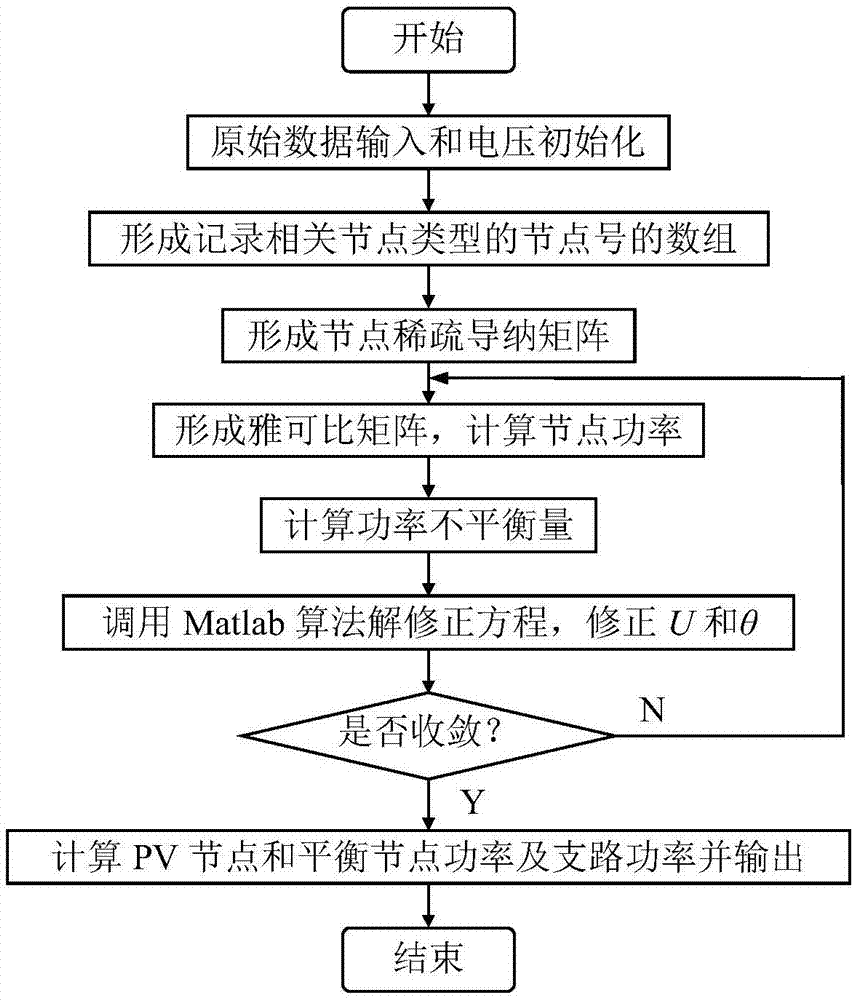

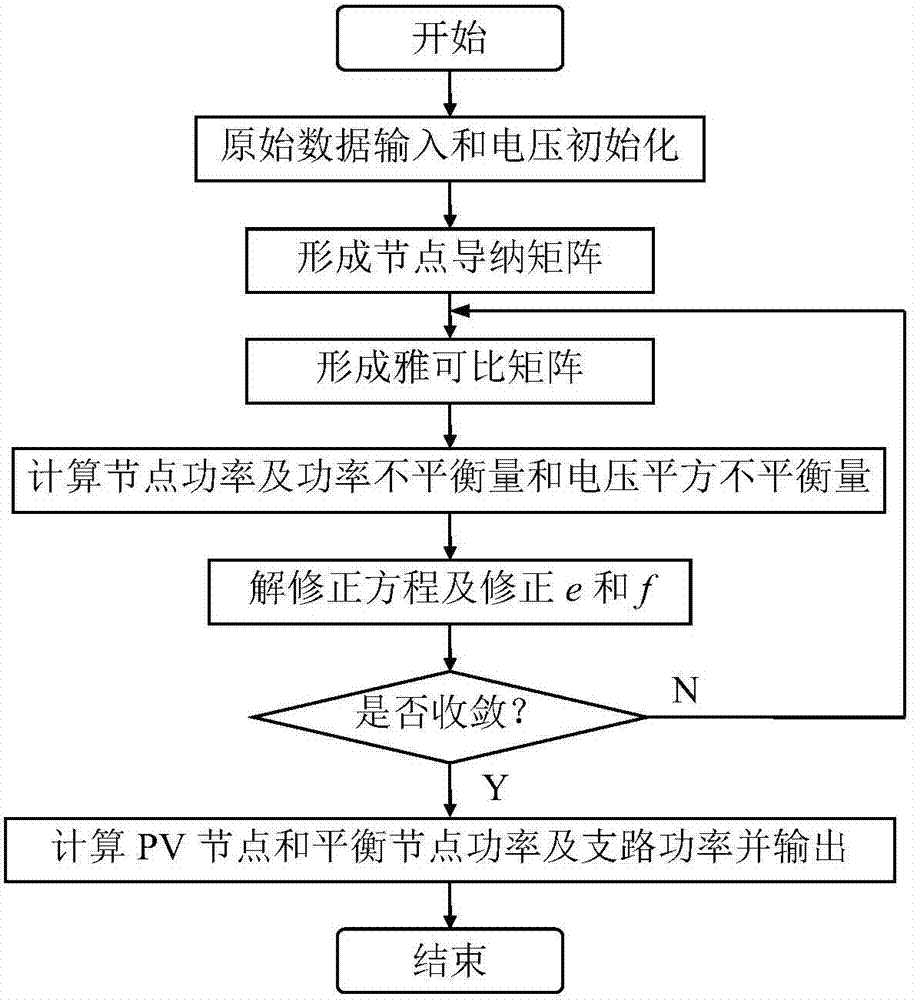

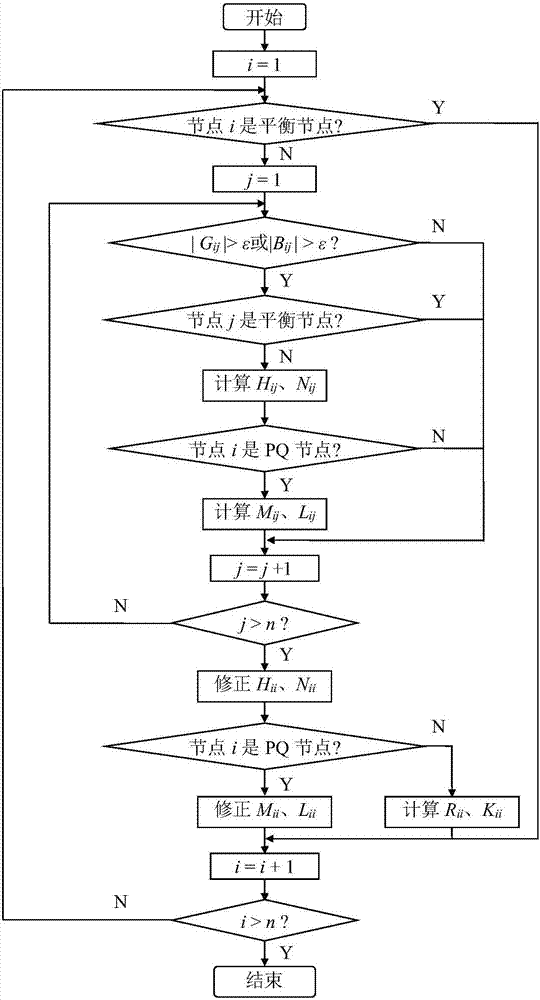

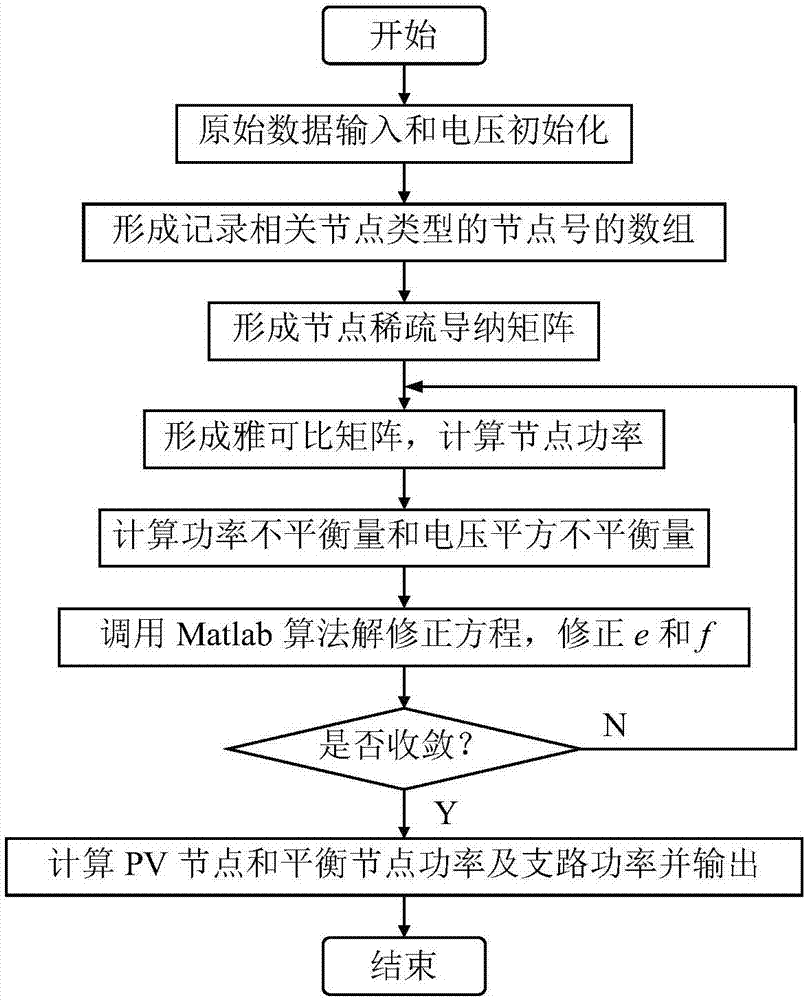

Polar coordinate Newton method load flow calculation method based on Matlab sparse matrix

InactiveCN107194131AEasy to testEasy to analyzeDesign optimisation/simulationSpecial data processing applicationsAlgorithmAnalysis tools

The invention discloses a polar coordinate Newton method load flow calculation method based on a Matlab sparse matrix, adopting matrix operation and complex operation and using a sparse matrix technology provided by Matlab. The method is implemented on a Matlab platform, so that researchers are facilitated to use various tools and functions provided by Matlab to test and analyze a calculation method. The main part of the method adopts both the matrix operation and the complex operation, reduces program codes and simplifies a programming process, so that the program is clearer, and the researchers are facilitated to modify the program, debug the program, and improve and add new functions for the program. The method provided by the invention adopts the sparse matrix technology of Matlab, so that calculation speed is greatly improved, meanwhile the sparse matrix of Matlab is very convenient to use, elements of the sparse matrix can be directly used by using a column number like a full matrix, design of a sparse storage structure is not needed, and an excellent analysis tool is provided for scientific research of the researchers.

Owner:DALIAN MARITIME UNIVERSITY

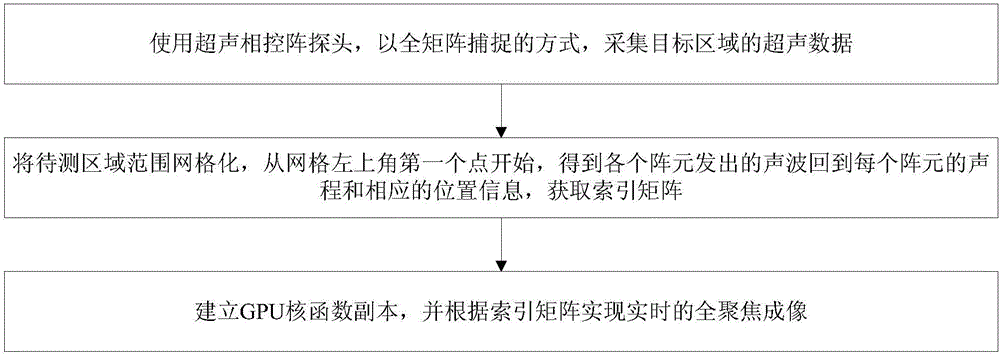

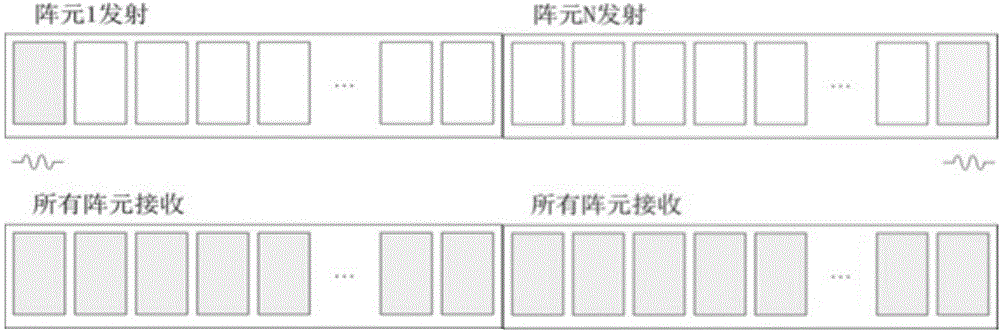

Real-time ultrasonic phased array total focusing imaging method

InactiveCN106596736AImproving Imaging AccuracyHigh resolutionProcessing detected response signalSonificationImage resolution

The invention discloses a real-time ultrasonic phased array total focusing imaging method. The imaging method comprises the following steps: acquiring ultrasonic data of a target area in a full matrix capture manner by using an ultrasonic phased array probe; gridding an area range to be detected, acquiring a sonic path distance of sound waves emitted by every array element, returning to every array element, from the first point in the top left corner of grids and corresponding position information, and acquiring an index matrix; and establishing a GPU kernel function copy, and realizing real-time total focusing imaging according to the index matrix. The method realizes real-time highly precise ultrasonic imaging and improves the resolution of images.

Owner:TIANJIN UNIV

Full focus imaging beam calibration method

ActiveCN109490419AImprove uniformityReduce mistakesAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalUltrasound attenuationAcoustic energy

The invention discloses a full focus imaging beam calibration method. According to the method, a beam calibration matrix is established by amplitude information of a horizontal through hole in an actual measured standard test block so as to compensate acoustic energy attenuation. The calibration method comprises the following steps: making a standard test block; acquiring and storing full matrix data; extracting full matrix sub-data; performing full focus imaging on each full matrix sub-data; extracting the amplitude information of the horizontal through hole and generating original calibration data; performing linear interpolation calculation on the original calibration data to generate the beam calibration matrix; and performing beam calibration on full focus imaging. According to the method disclosed by the invention, the quantitative defect detection errors and the missing detection rate can be effectively reduced, and the full focus imaging energy uniformity is improved.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

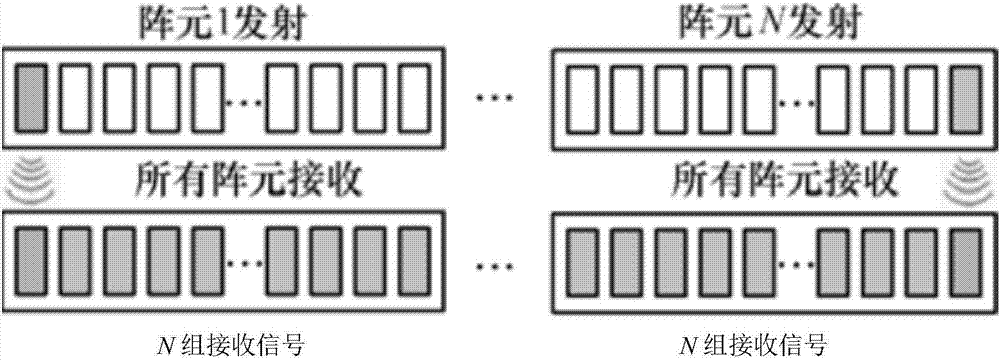

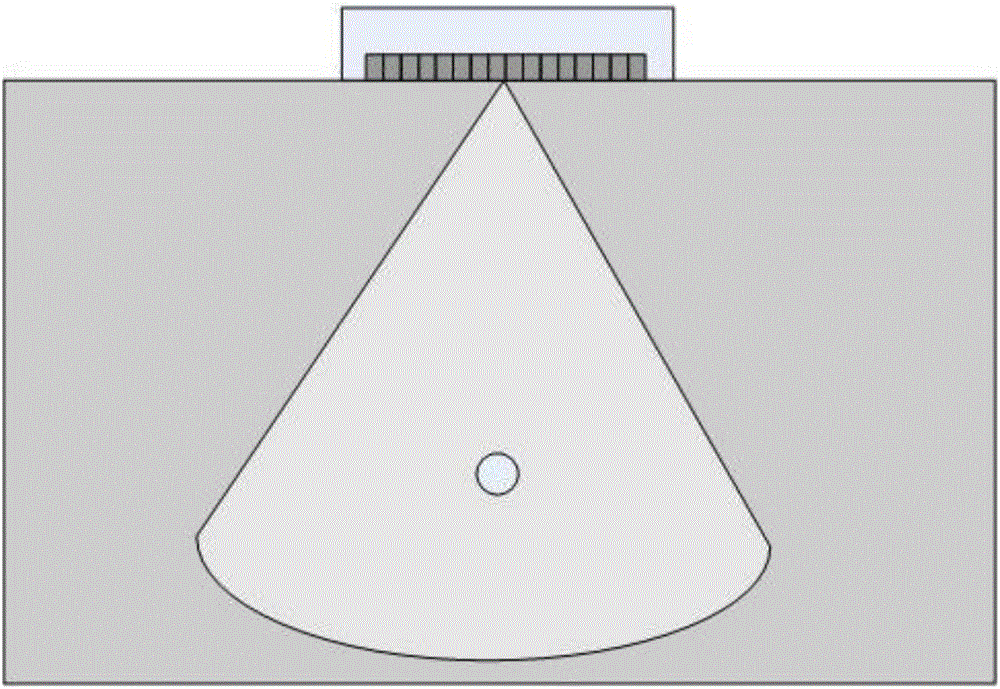

Acoustic array imaging system and method thereof

ActiveCN106680825ASave storage spaceFast operationAcoustic wave reradiationHigh frame rateHigh resolution imaging

The method relates to an acoustic array imaging system and a method thereof. The system comprises a data acquisition module 101, a first imaging module 102, a second imaging module 103 and an image composite module 104. The method comprises the following steps of successively emitting array elements in an acoustic array and collecting echo signals so as to acquire an analysis signal; according to a sound propagation relation between the emitted array elements and receiving array elements in an array, acquiring a time-delay value, and according to the analysis signal and the time-delay value, calculating images of the receiving array elements; using a cascaded parallel composite processing unit to recombine the image of all the receiving array elements; and superposing all the composite images and carrying out envelope processing so as to acquire a full-matrix data acquisition imaging result. The system and the method have advantages that when each array element data is collected, processing is performed so that an occupied storage space is small; a parallel mode is used to increase an operation speed; during an actual application, calculating time consuming is less, and high frame rate imaging can be realized; and the method and the system are suitable for real-time data processing and high resolution imaging. In addition, the system and the method are suitable for acoustic array imaging under different frequency and application scenes.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

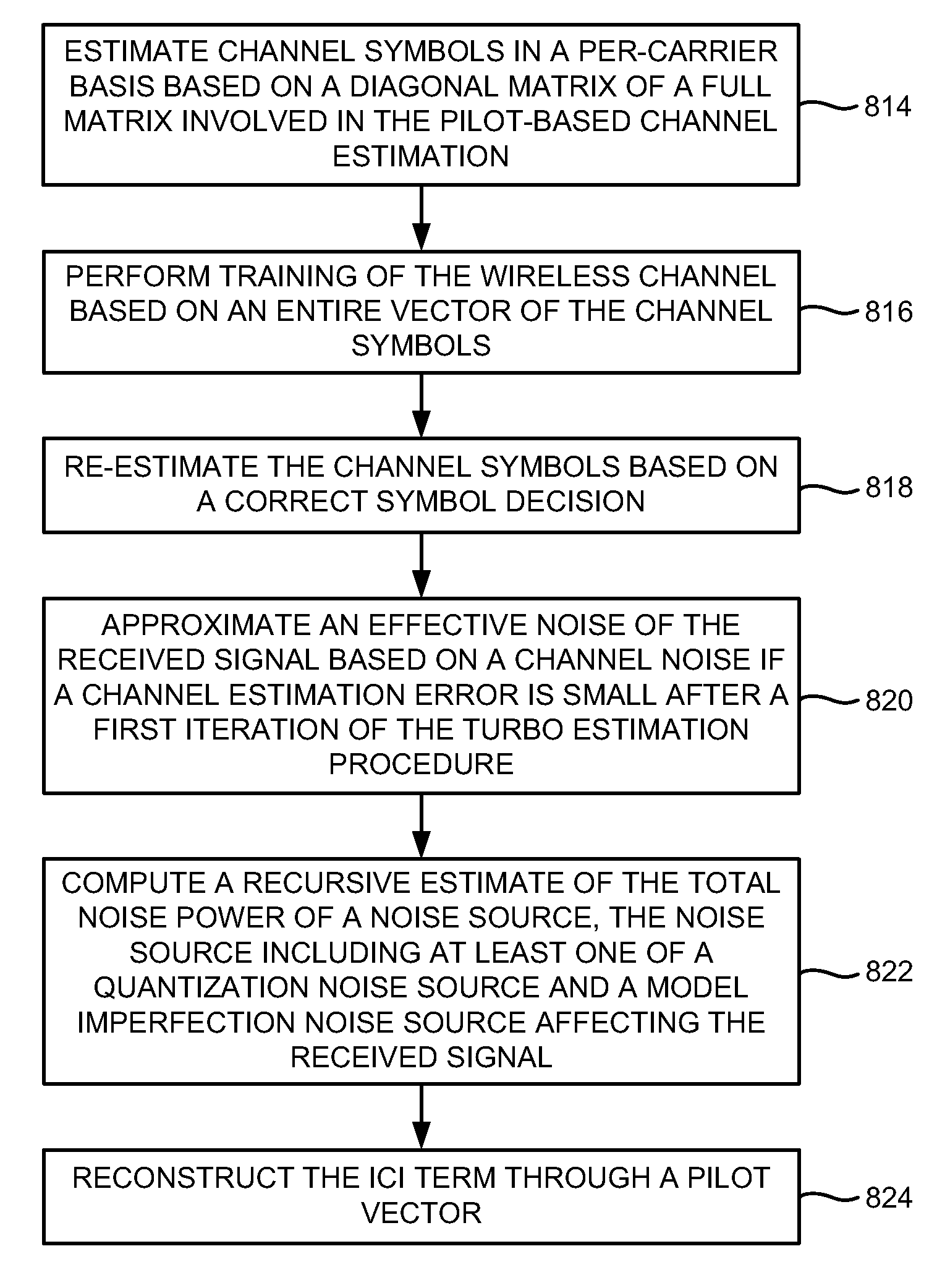

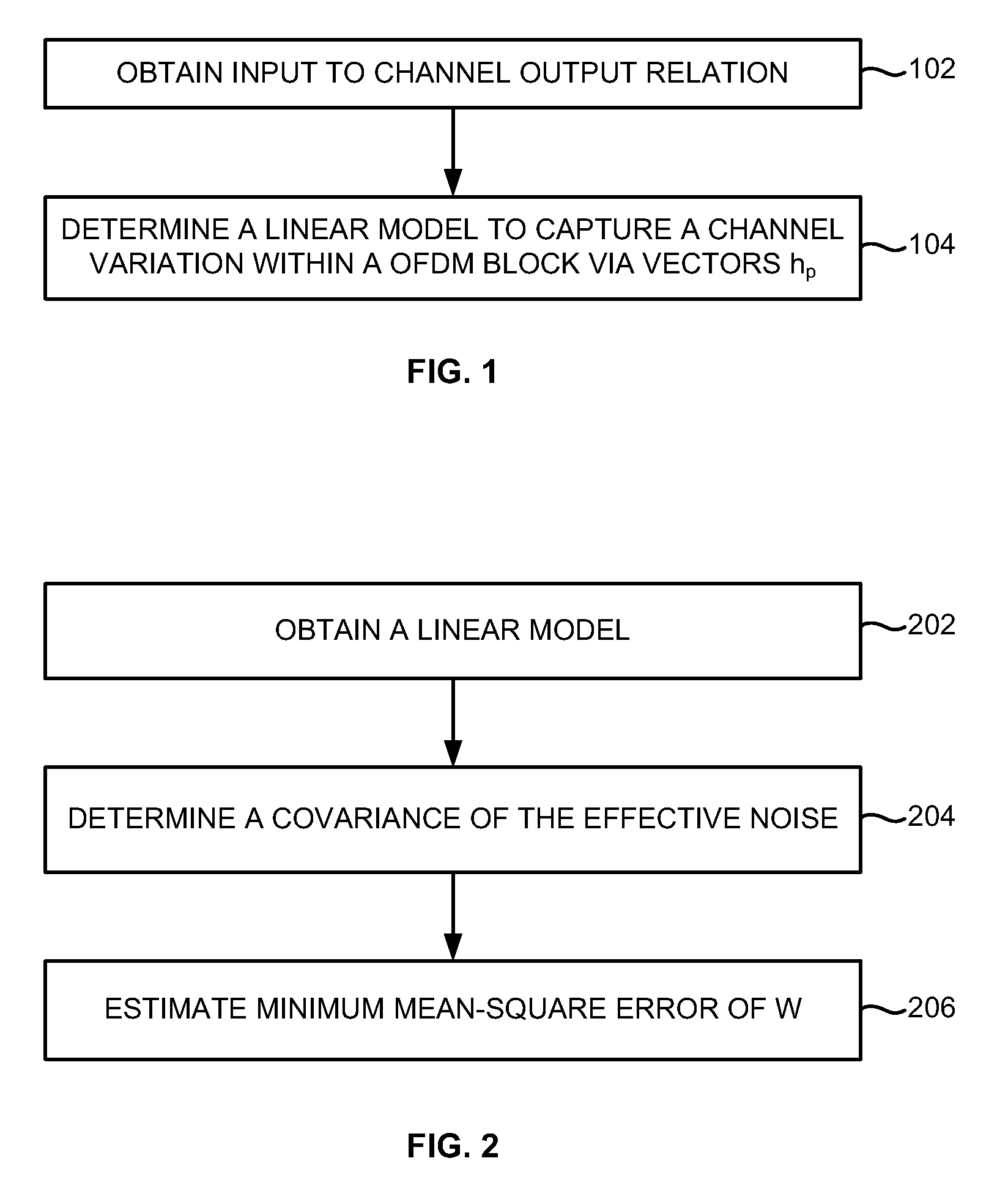

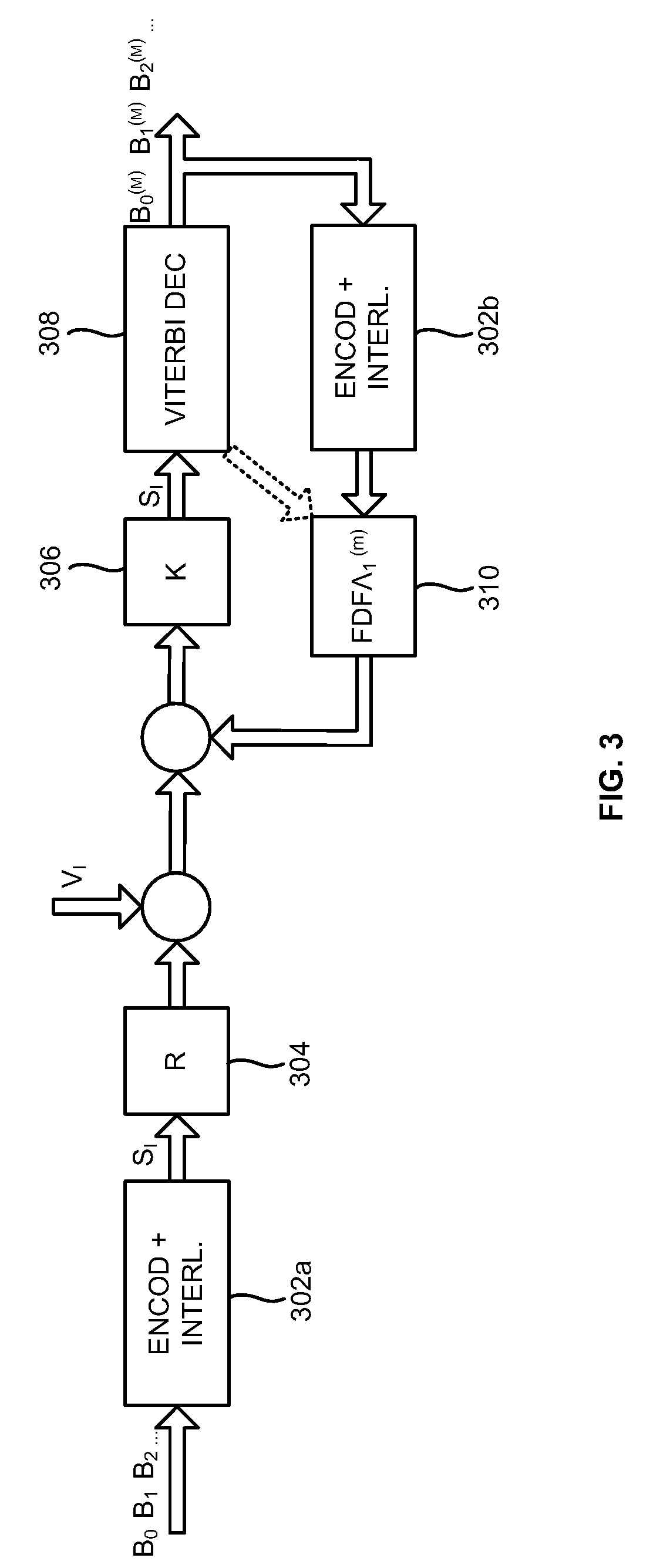

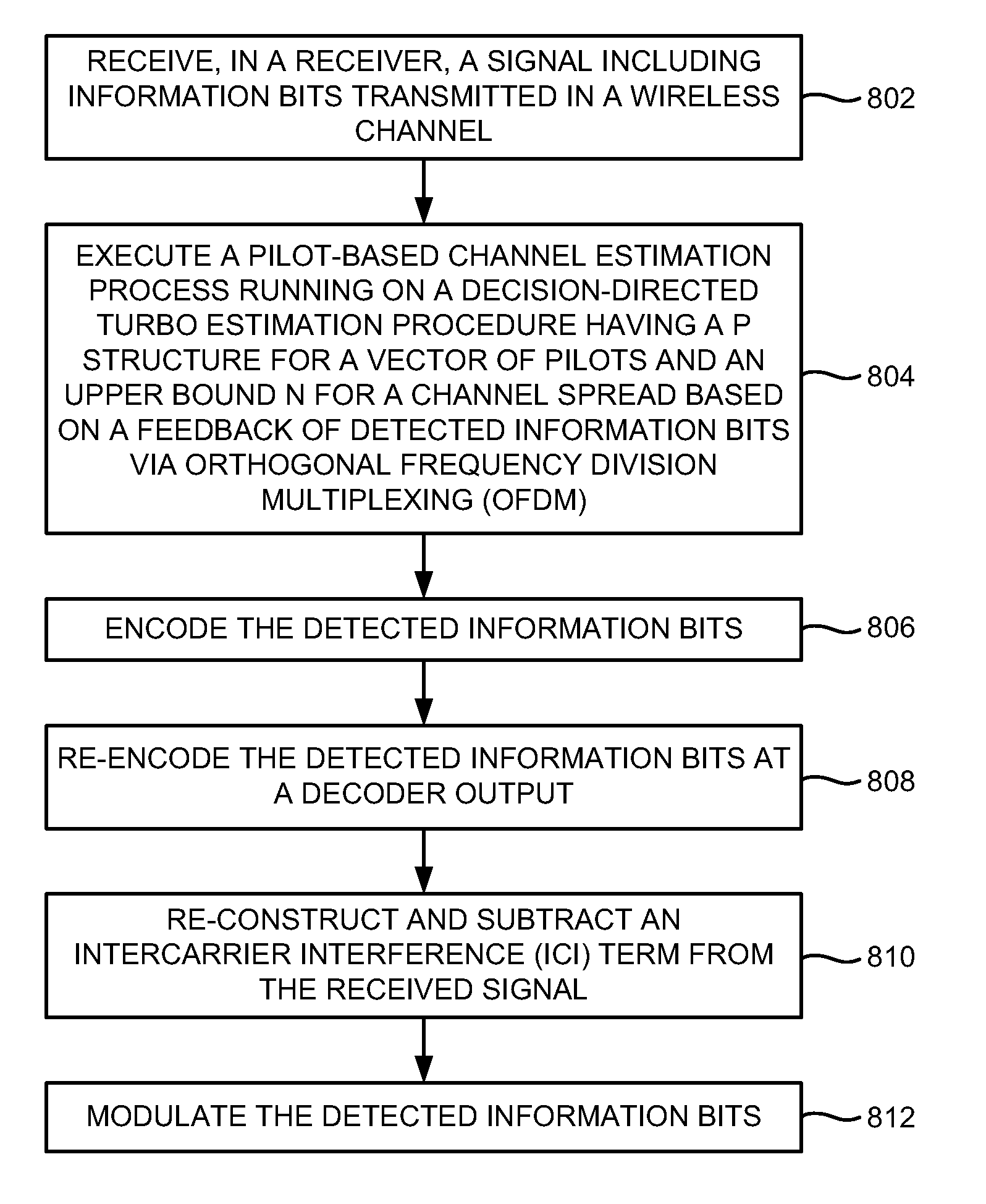

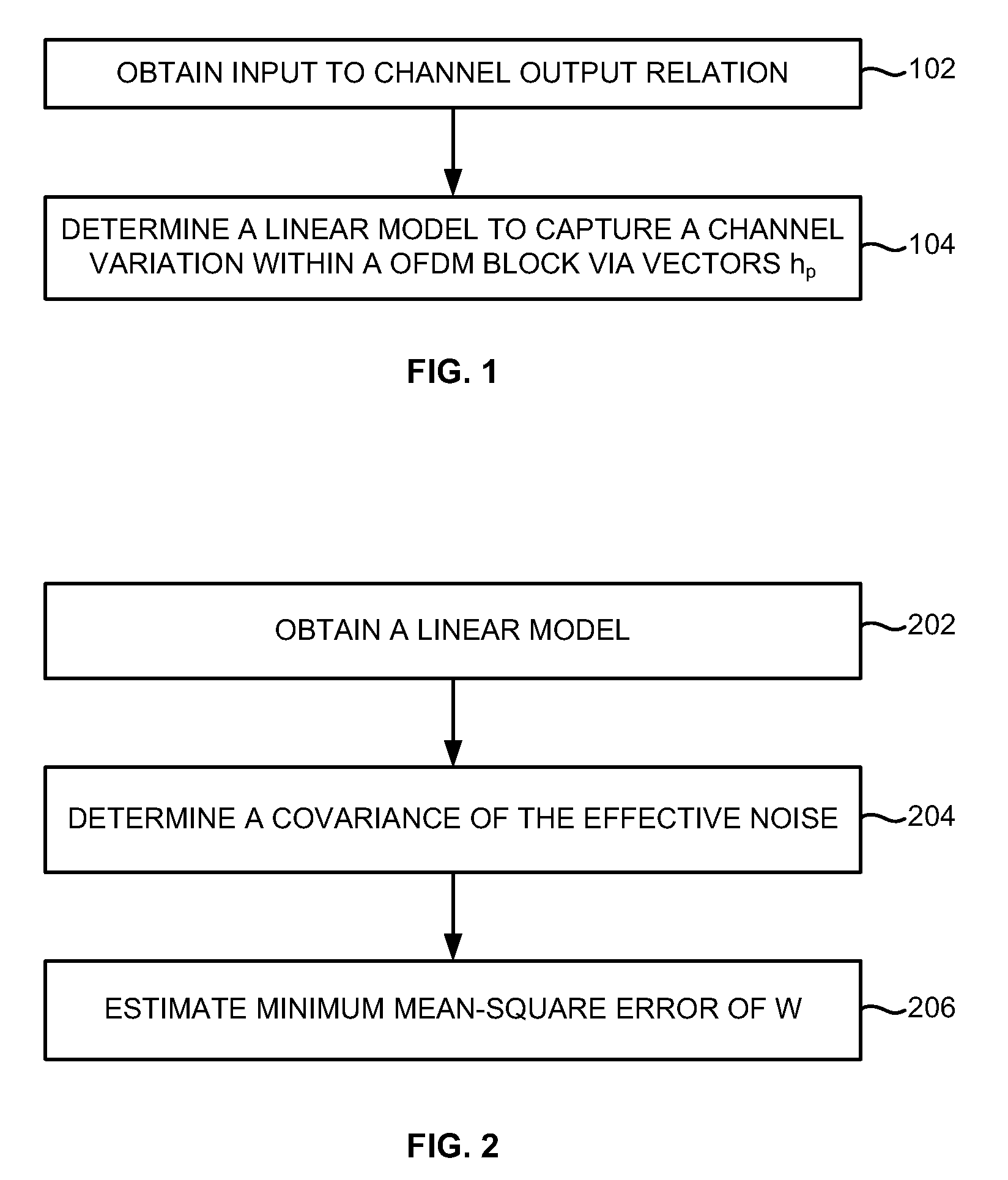

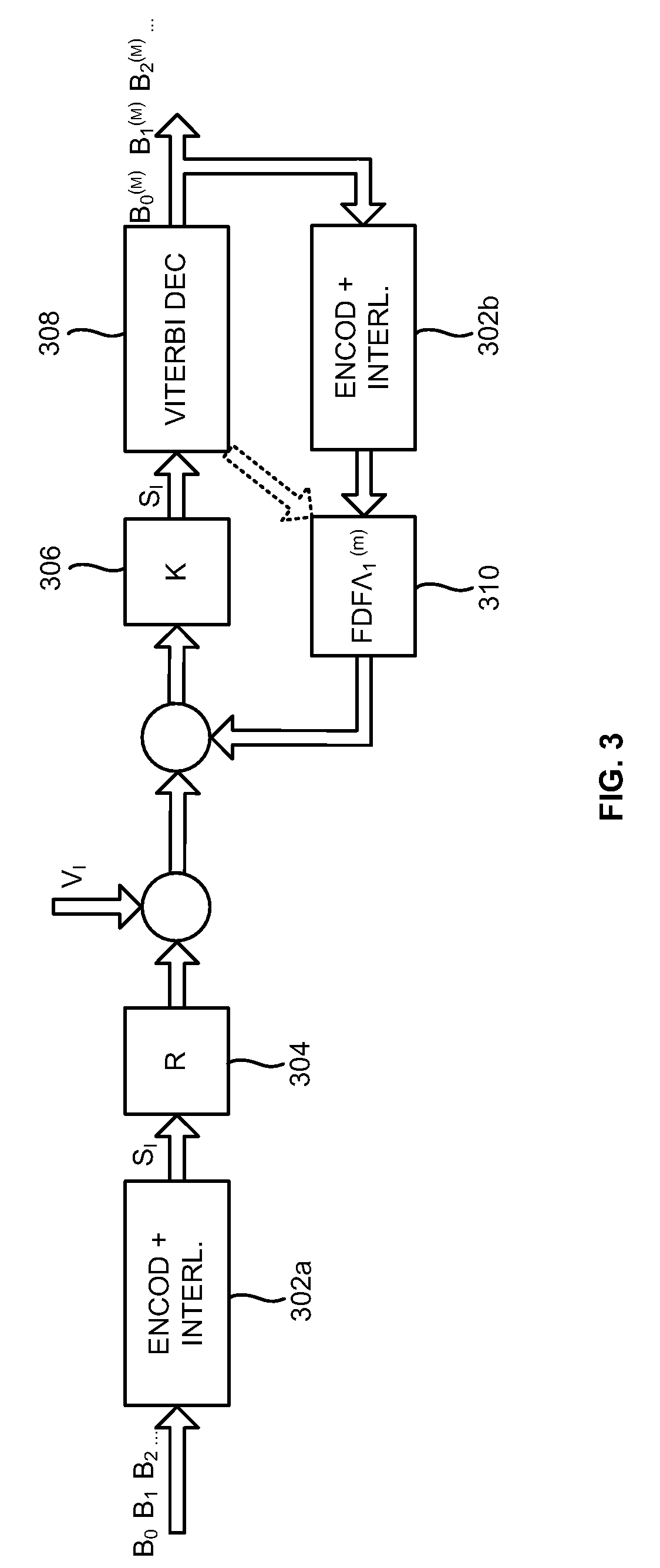

Channel Estimation for High Doppler Mobile Environments

An apparatus and method of applying a fast algorithm to a pilot-based channel estimation process includes receiving, in a receiver, a signal comprising information bits transmitted in a wireless channel, executing a pilot-based channel estimation process running on a decision-directed turbo estimation procedure having a p structure for a vector of pilots and an upper bound N for a channel spread based on a feedback of detected information bits via OFDM, encoding the detected information bits, re-encoding the detected information bits at a decoder output, re-constructing and subtracting an ICI term from the received signal, modulating the detected information bits, estimating channel symbols in a per-carrier basis based on a diagonal matrix of a full matrix involved in the pilot-based channel estimation, and performing training of the wireless channel based on an entire vector of the channel symbols.

Owner:ATMEL CORP

Matlab sparse matrix-based Cartesian coordinate Newton power flow calculation method

InactiveCN107181260AEasy to testEasy to analyzeAc networks with different sources same frequencyPower flowAlgorithm

The present invention discloses a Matlab sparse matrix-based Cartesian coordinate Newton power flow calculation method. Matrix operation and complex operation are adopted, and a sparse matrix technique provided by the Matlab is used. The method of the invention is realized on the Matlab platform, so that scientific researchers can be facilitated to use various tools and functions provided by the Matlab to test and analyze calculation results; and the main part of the method of the invention adopts the matrix operation and complex operation, and therefore, program codes can be reduced, programming is simplified, a program is more clear, the scientific researchers can be facilitated to modify, debug and improve the program and add new features. The sparse matrix technique of the Matlab and the matrix operation are adopted, and therefore, calculation speed can be greatly improved; and the sparse matrix of the Matlab is very easy to use, and line and column numbers can be adopted to directly use the elements of the sparse matrix just as a full matrix, and an excellent analytical tool is provided for the scientific research work of the scientific researchers.

Owner:DALIAN MARITIME UNIVERSITY

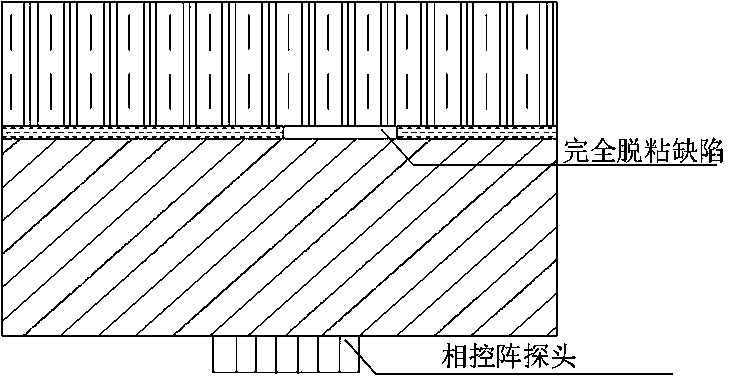

Interface detect detection method based on improved multi-reflection full focusing imaging algorithm

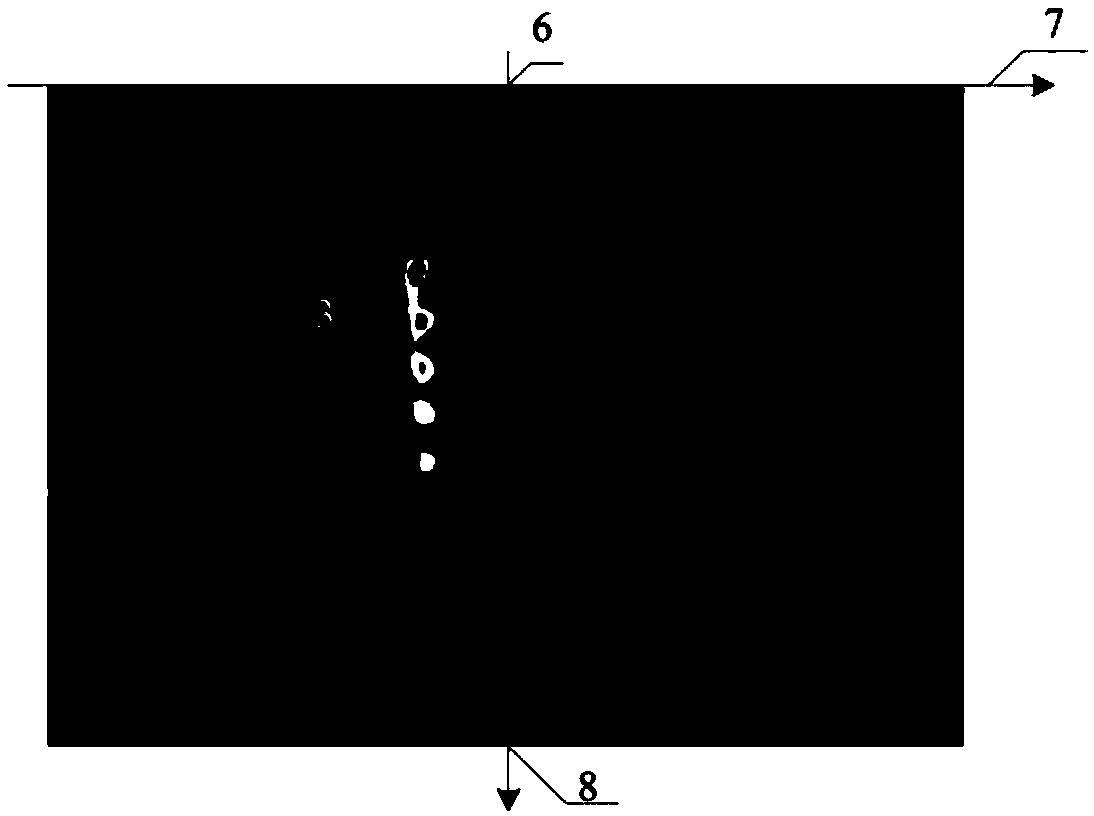

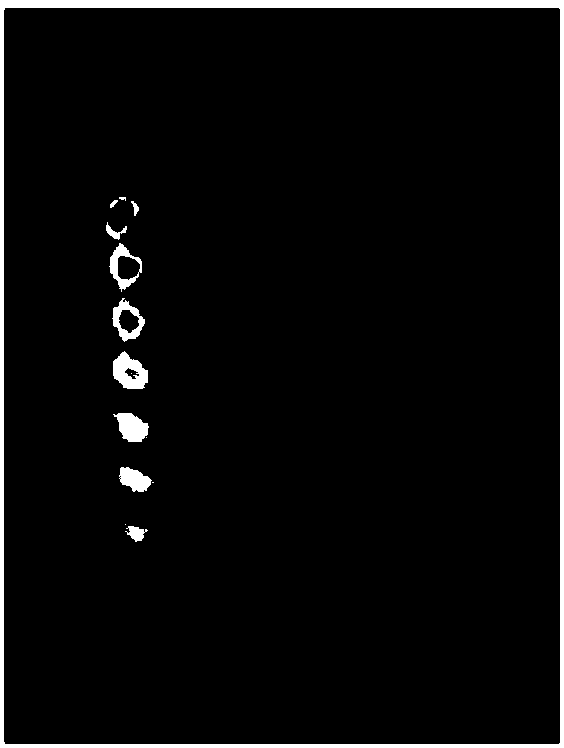

ActiveCN109212032AEnhanced defect featuresHigh precisionAnalysing solids using sonic/ultrasonic/infrasonic wavesImaging algorithmFull matrix

The invention relates to an interface detect detection method based on an improved multi-reflection full focusing imaging algorithm. The method comprises the following steps: step S1, according to interface depth S and duration needed for receiving echo for P times, setting instrument parameters; step S2, performing echo capturing for a to-be-tested workpiece through a full matrix capturing technology; step S3, performing virtual focusing for each discrete target imaging point in a to-be-tested region through the improved multi-reflection full focusing imaging algorithm, and thereby obtainingan interface detect detection result of the to-be-tested region. The method provided by the invention is based on the improved multi-reflection full focusing imaging algorithm, acquires echo of many times and performs depth accumulation for target imaging point information contained in the echo of each time, thus, features of interface defects are highlighted, and detection rate of defects of unsticking is improved greatly.

Owner:FUZHOU UNIV

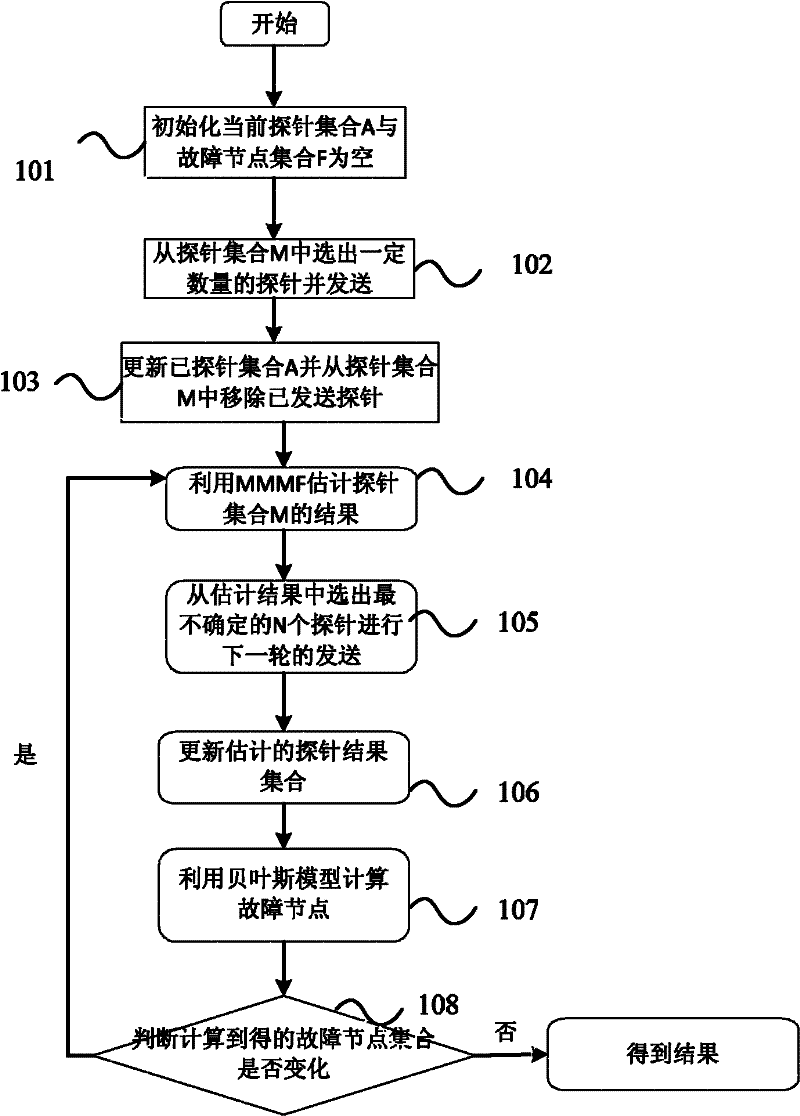

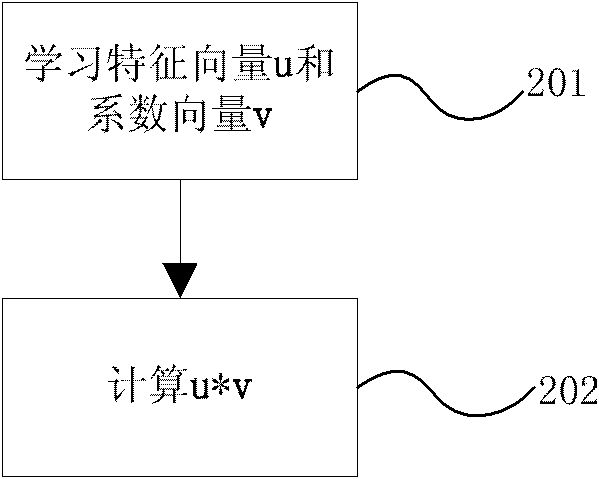

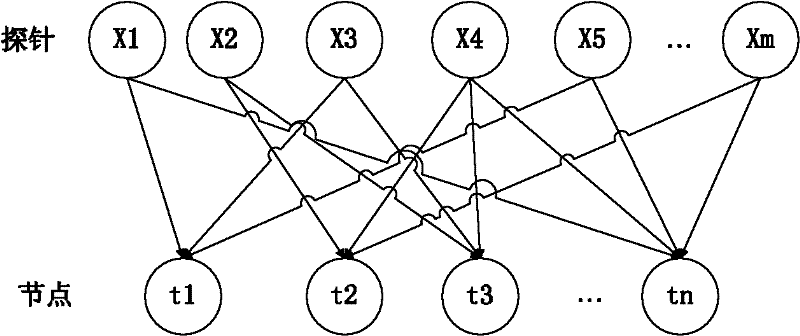

Network fault positioning method based on probe prediction

The invention discloses a network fault positioning method based on probe prediction. The network fault positioning method comprises step 101, initializing a current detected set A and a current fault node set F to be empty, wherein the detected set A represents sent probes selected from a probe set M, and the fault node set F represents positioned fault node set; step 102, selecting K probes from the probe set M and sending the K probes; step 103, obtaining a sparse matrix through the detected set A and removing the sent probes from the probe set M; step 104, predicating the obtained sparse matrix to obtain a complete matrix; step 105, selecting N probes which are the most uncertain from the complete matrix and sending the N probes; step 106, updating the complete matrix by utilizing results of the sent probes in the step 105; and step 107, positioning fault nodes and performing calculation to obtain a fault node set. By means of the network fault positioning method based on the probe prediction, quantity of the sent probes required by the active detection technology is reduced.

Owner:BEIJING UNIV OF POSTS & TELECOMM

Transverse wave full-focus ultrasonic imaging detection method for crack defect of steel plate weld

InactiveCN106383171AAccurate quantitative analysisAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalUltrasonic imagingTransverse plane

Owner:GUANGDONG GOWORLD

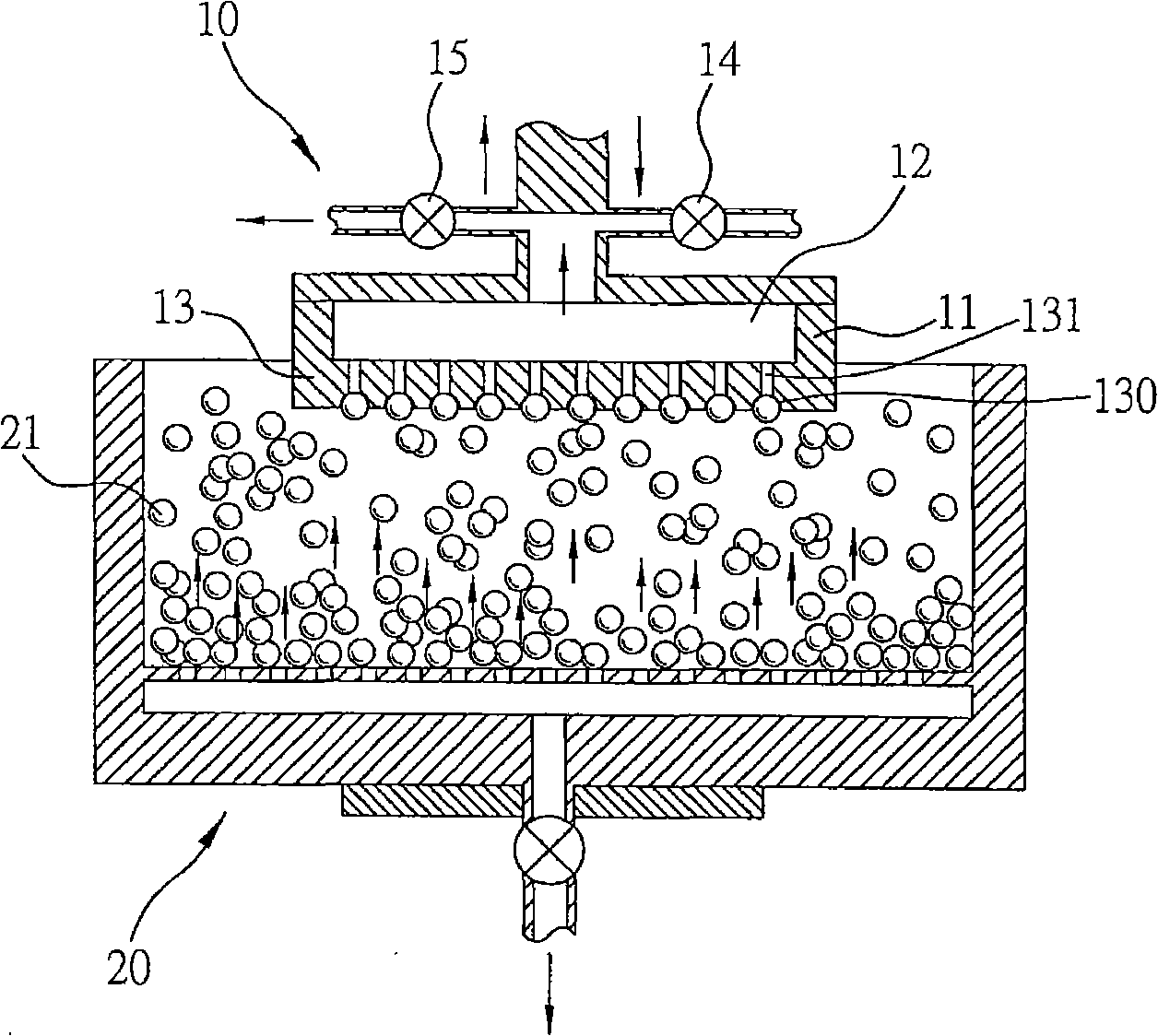

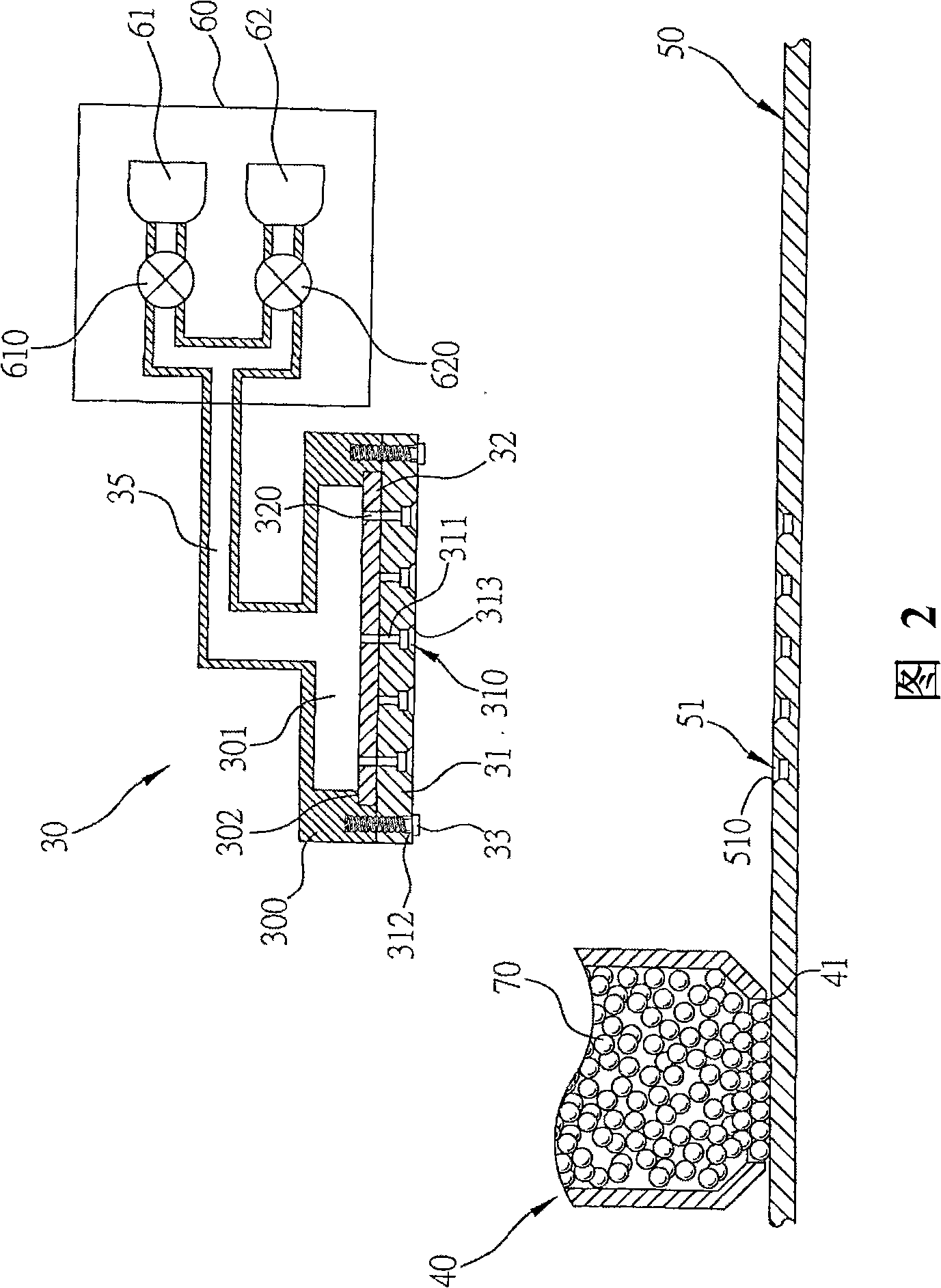

Equipment for soldering and planting ball as well as acquisition apparatus

ActiveCN101276759ALow costPrinted circuit assemblingSemiconductor/solid-state device manufacturingProcess equipmentAcquisition apparatus

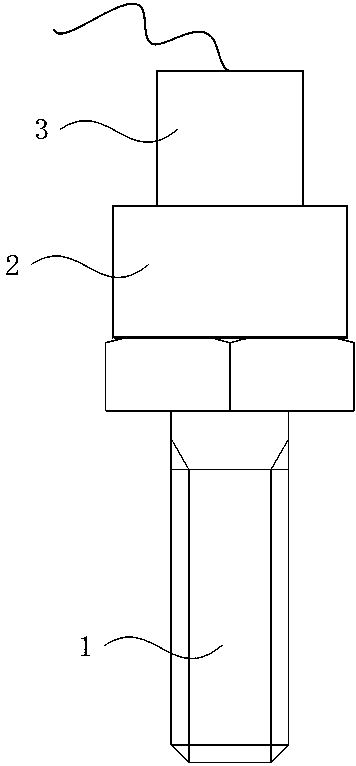

A solder ball mounting ball apparatus and collecting device thereof are disclosed, the solder ball mounting ball apparatus comprises a solder ball containing instrument whose surface is provided with a plurality of containing holes; a solder ball storing instrument which is used for storing a plurality of solder balls, provided above the solder ball containing instrument in a movable manner of being parallel to the surface direction of the solder ball containing instrument and installed with a supply hole corresponding to the surface of the solder ball containing instrument; and a solder ball collecting device which is provided above the solder ball containing instrument in a movable manner; the solder ball collecting device includes a main body and a first, and a first and second templates provided at one end of the main body in the detachable manner, the main body includes a containing chamber, the first template includes a plurality of a first guide-through holes arrayed in a manner of full matrix and perforated the first template, the second template includes a plurality of a second guide-through holes; and part of the first guide-through holes in the first template is communicated with the second guide-through holes at the corresponding position in the second template, wherein on account of the fact that diverse solder ball distributions are able to vary the disposal locations and quantity of the second guide-through holes in the second template, the cost of process apparatus is saved.

Owner:SILICONWARE PRECISION IND CO LTD

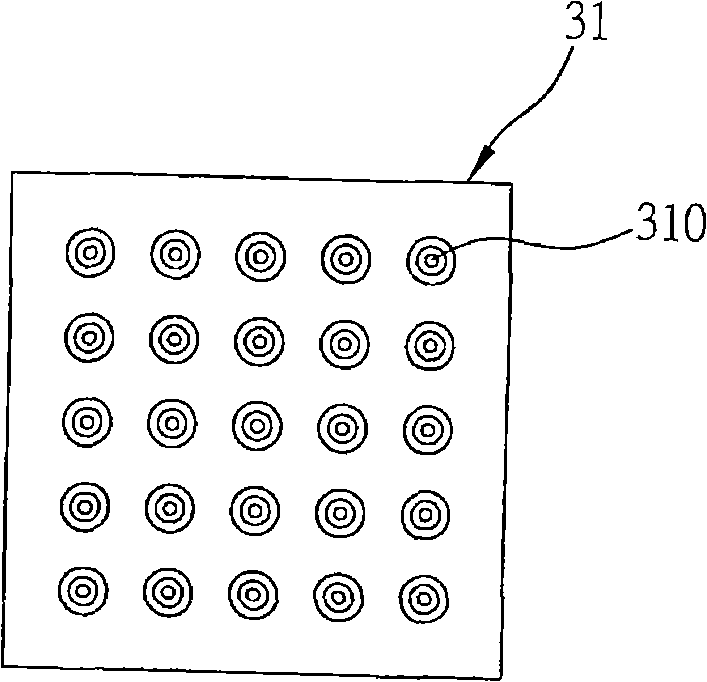

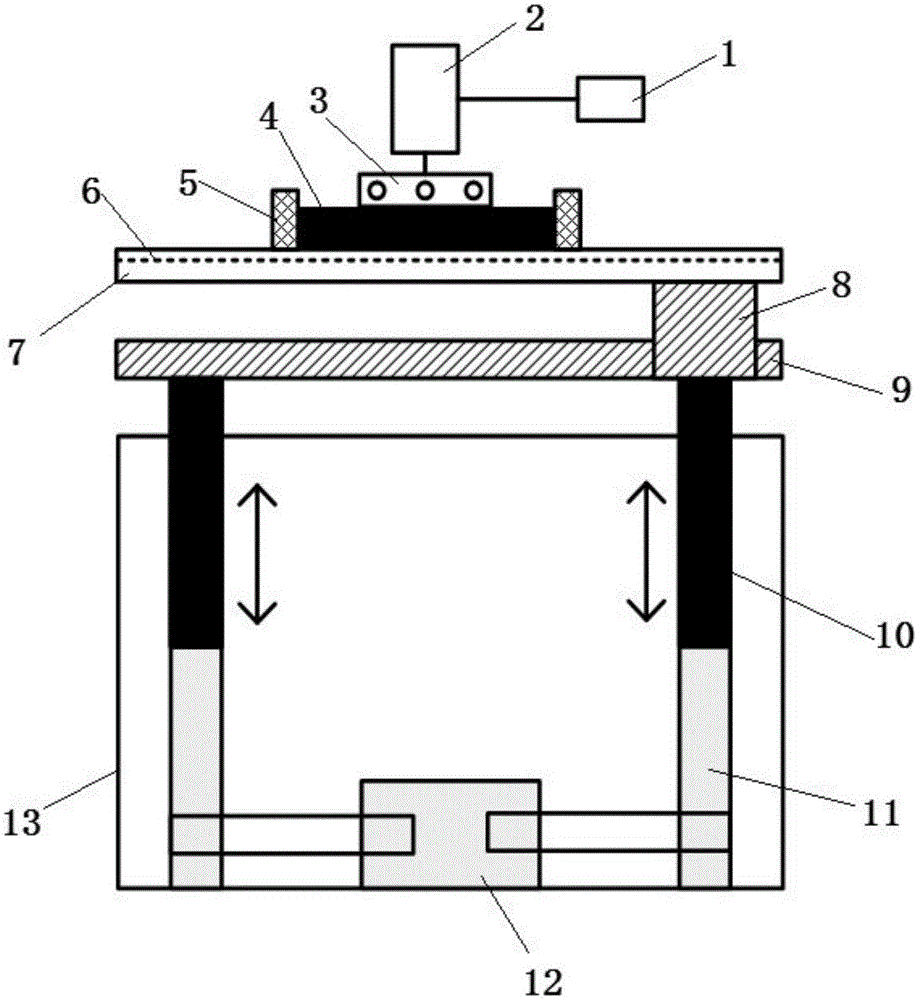

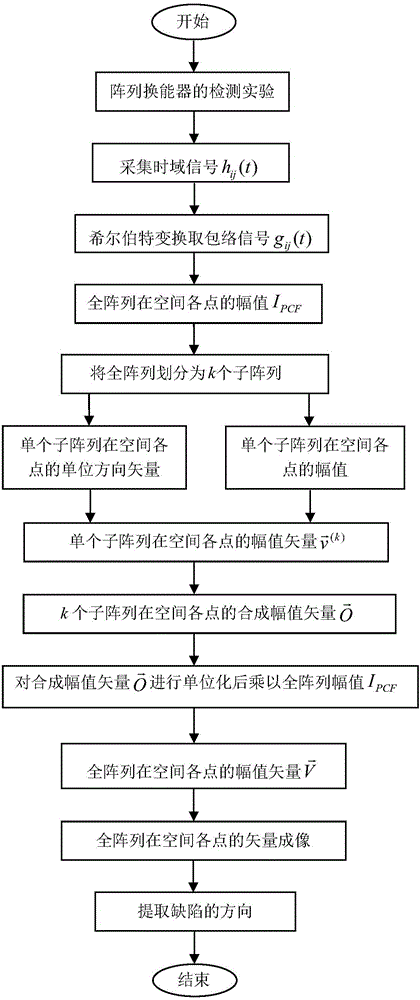

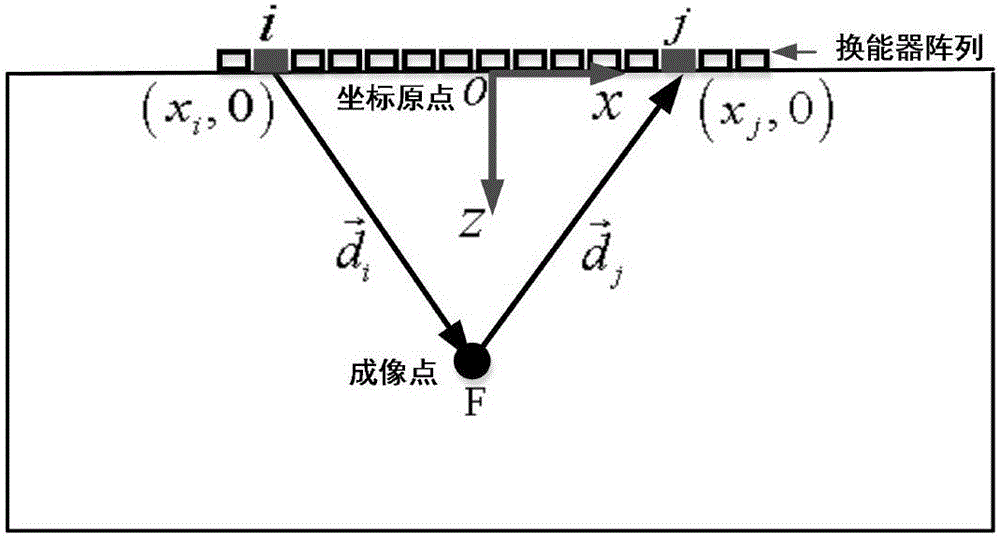

Phase weighting vector fully focusing imaging device and method for identifying forge piece cracks quantitatively

InactiveCN106093204AAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalFeature vectorForge

The invention relates to a phase weighting vector fully focusing imaging device and method for identifying forge piece cracks quantitatively. The method comprises the steps: firstly, analyzing phase information of whole matrix data, and extracting to obtain a phase characteristic parameter-a phase consistent factor; then, dividing a whole array into a plurality of sub arrays, and weighting an imaging amplitude value of each sub array by using the provided phase characteristic parameter, to obtain a phase weighted imaging amplitude value matrix; multiplying the two results to further obtain a weighted characteristic vector of each sub array; finally, compositing the weighted characteristic vectors of all the sub arrays, conducting global treatment on the amplitude value of the composite characteristic vector, in other words, making the amplitude value of the composite characteristic vector be equal to the amplitude value, at any imaging point, of obtained phase-weighted imaging of the whole array, and thus obtaining the amplitude vector, at any imaging point, of the whole array; and ultimately, extracting a local vector diagram of a target defect according to a defect position, and determining the direction of the target defect by means of the direction of the vector in the local vector diagram.

Owner:南京兰博瑞达检测技术有限公司 +1

Ultrasonic guided wave defect positioning imaging method and system

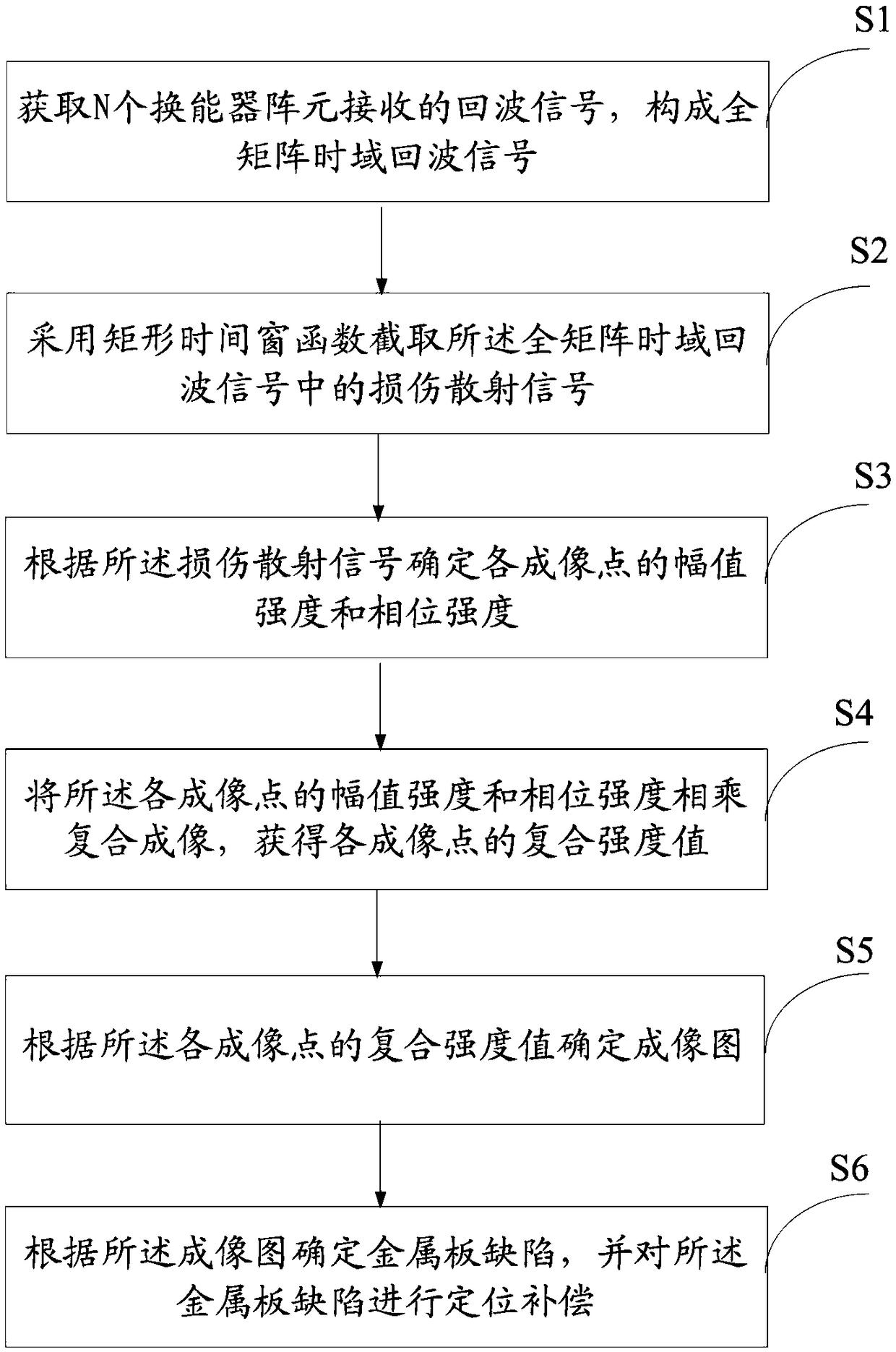

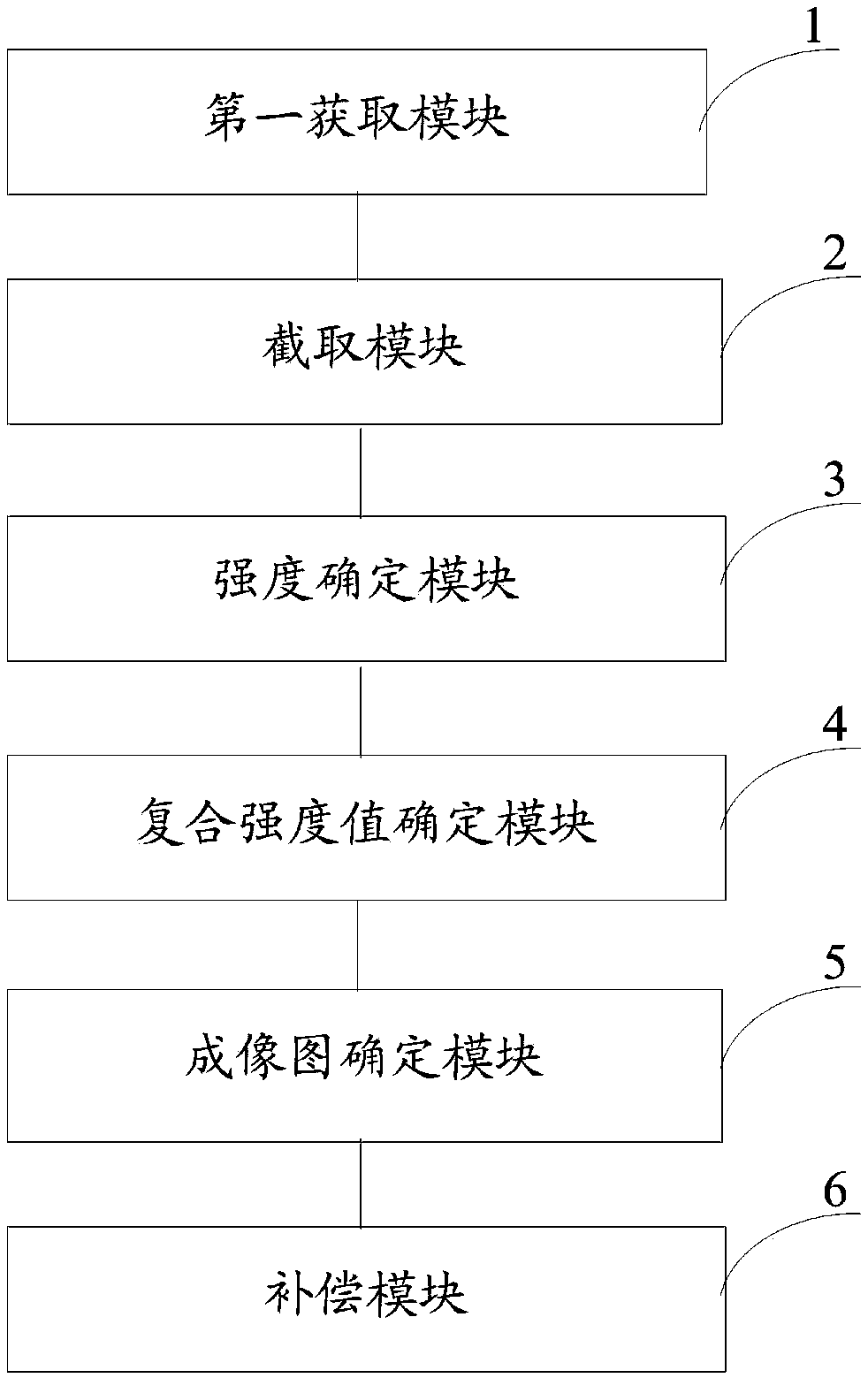

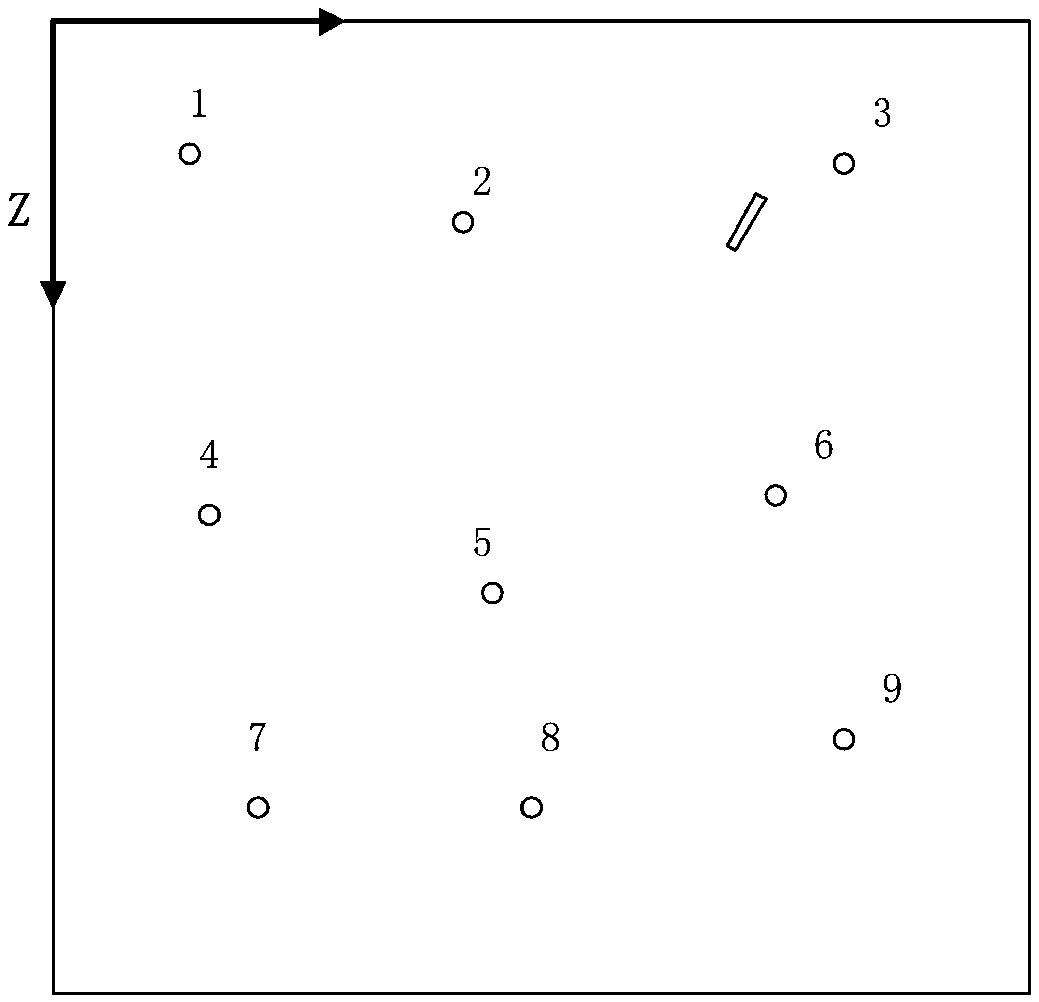

ActiveCN109239191AHigh positioning accuracyGood practical engineering application valueAnalysing solids using sonic/ultrasonic/infrasonic wavesTime domainTransducer

The invention discloses an ultrasonic guided wave defect positioning imaging method and system. The ultrasonic guided wave defect positioning imaging method comprises the following steps: obtaining echo signals received by N transducer array elements to form a full matrix time domain echo signal, wherein the N transducer array elements are randomly arranged on a metal plate; using a rectangular time window function to intercept damaged scatter signals in the full matrix time domain echo signal; determining amplitude intensity and phase intensity of each imaging point according to the damaged scatter signal; multiplying the amplitude intensity and the phase intensity of each imaging point to perform composite imaging to obtain a composite intensity value of each imaging point; determining an imaging graph according to the composite intensity value of each imaging point; and determining a metal plate defect according to the imaging graph, and performing positioning compensation on the metal plate defect. The invention effectively improves the positioning accuracy of the defects in the defect imaging graph, therefore, the invention has good engineering application value.

Owner:CHINA SPECIAL EQUIP INSPECTION & RES INST

Efficient calculation of node proximity on graphs with side information

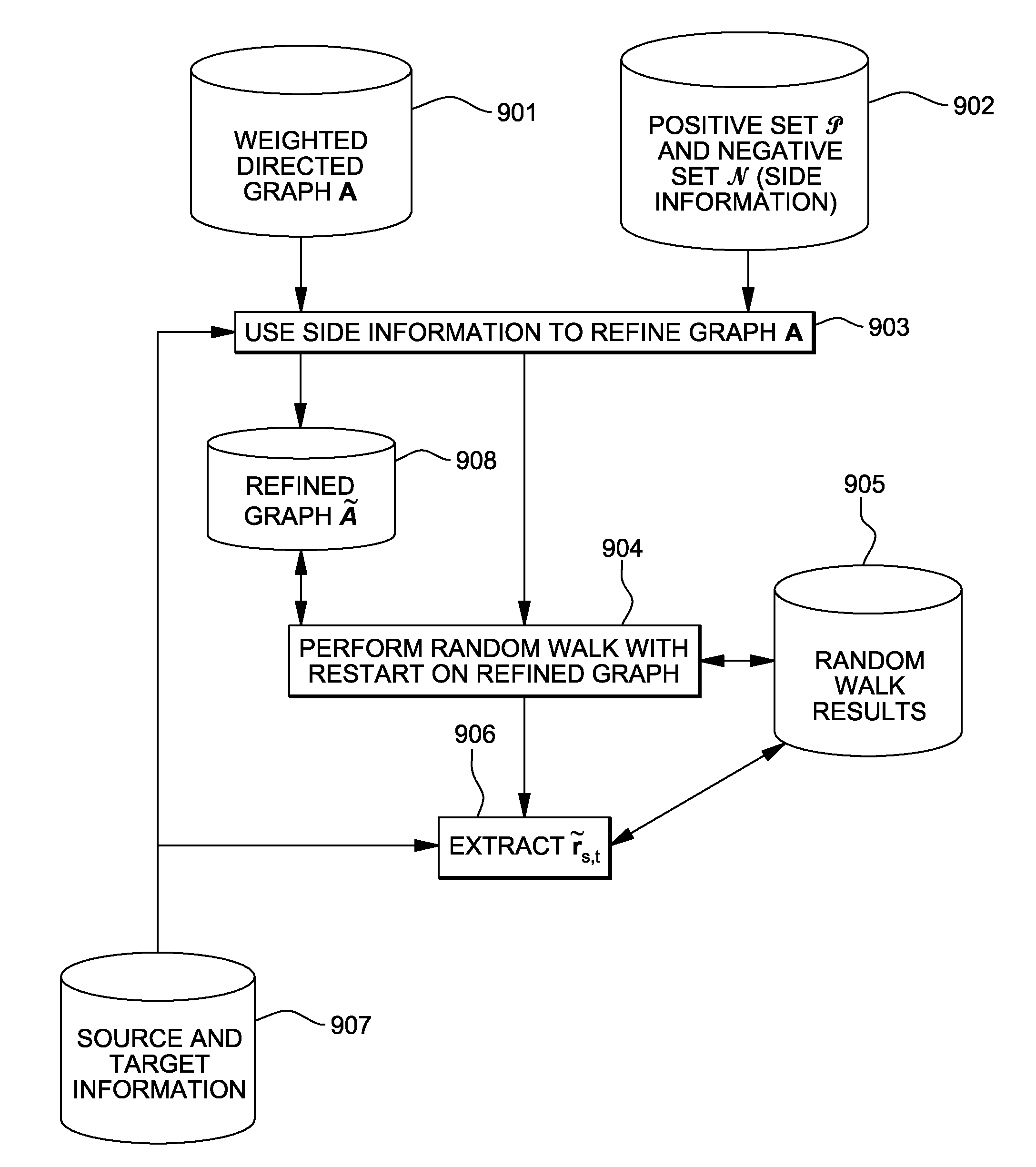

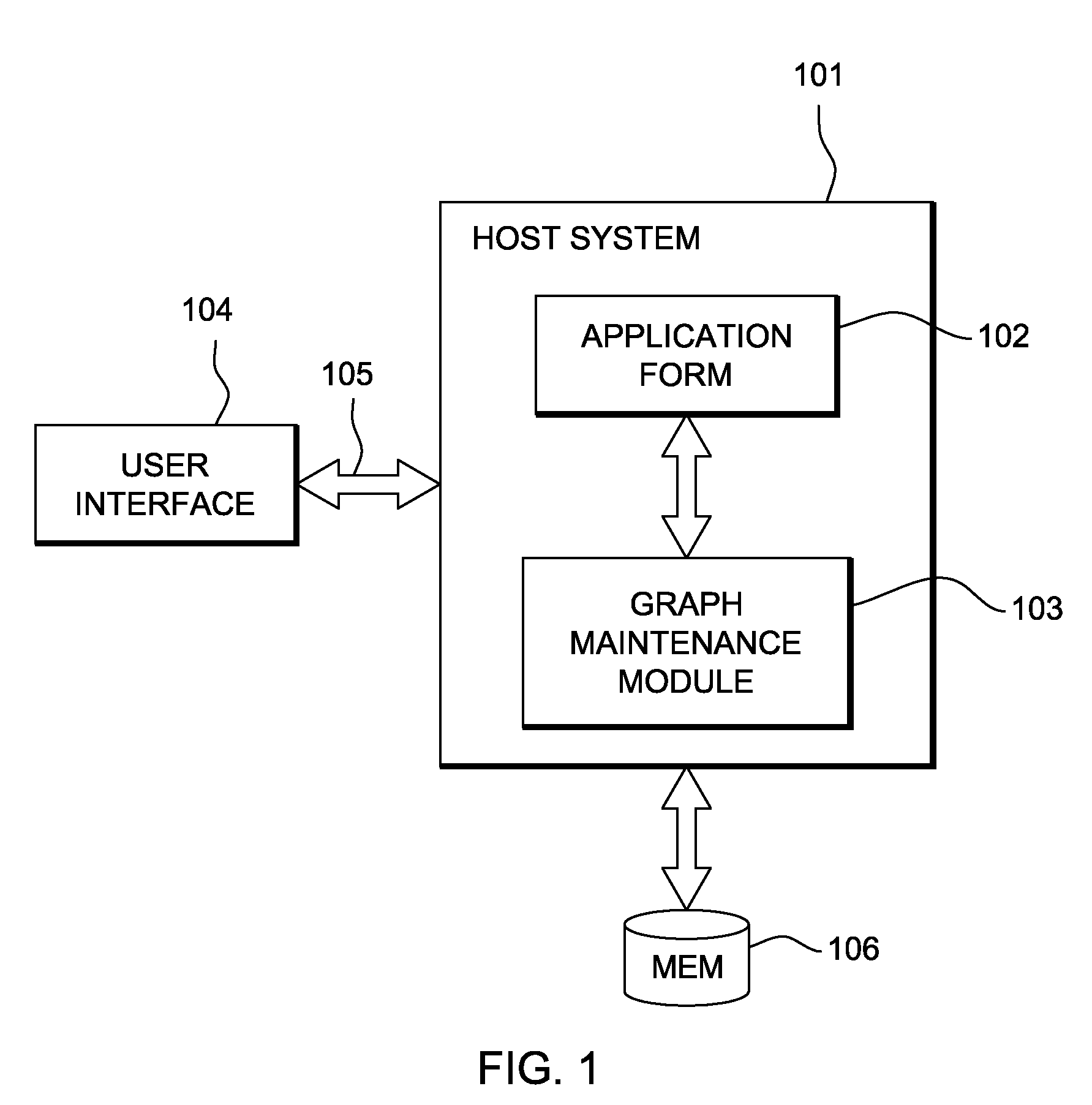

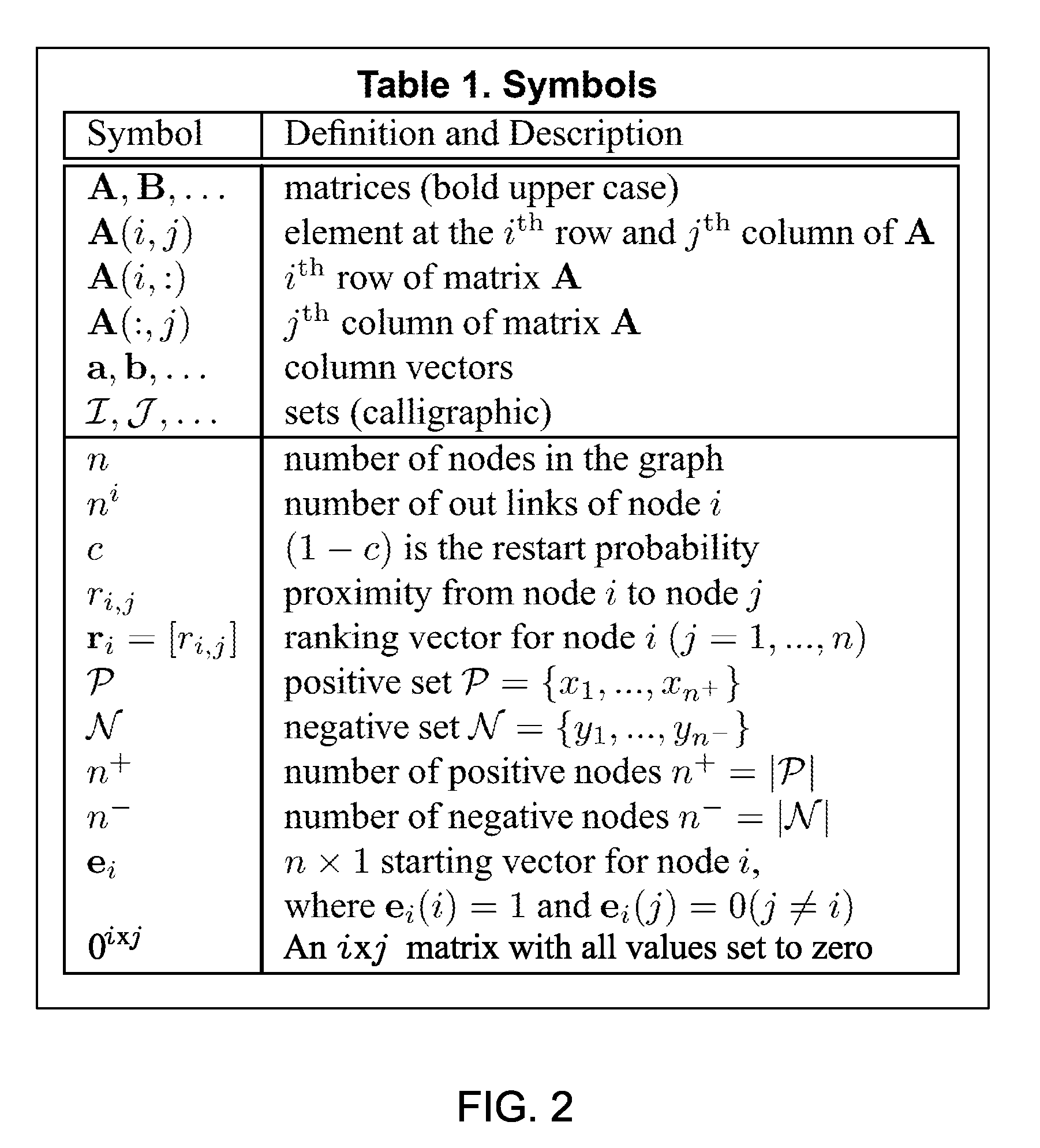

InactiveUS8346766B2Digital data information retrievalDigital data processing detailsDirected graphUser input

In a computerized data mining context, user input relating to positive and negative information is incorporated into node proximity measurements on a weighted, directed graph. Random walk results are updated without a full matrix inversion by using selective update to a low rank approximation and to inversion results.

Owner:IBM CORP

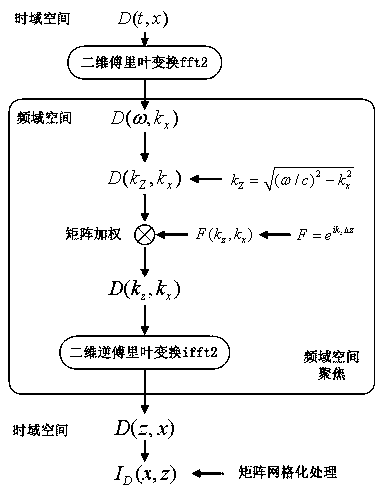

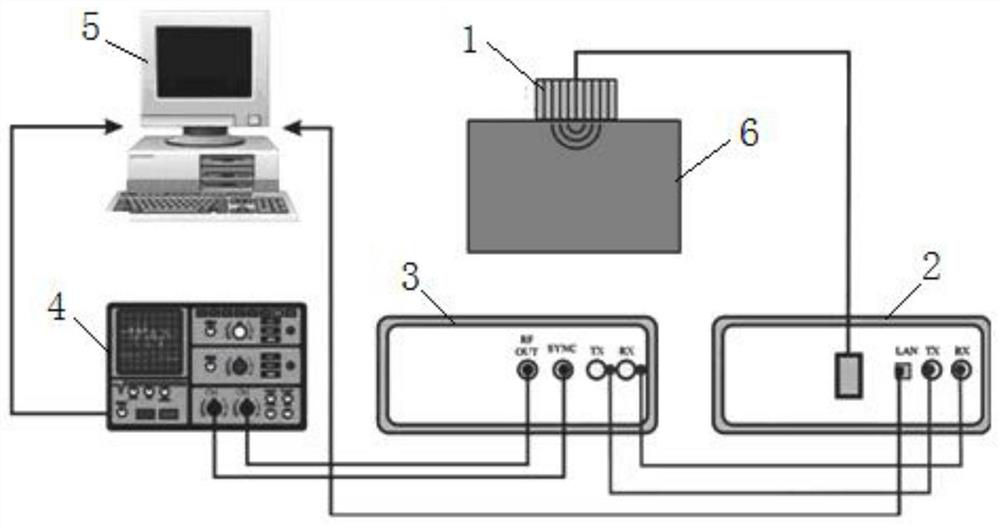

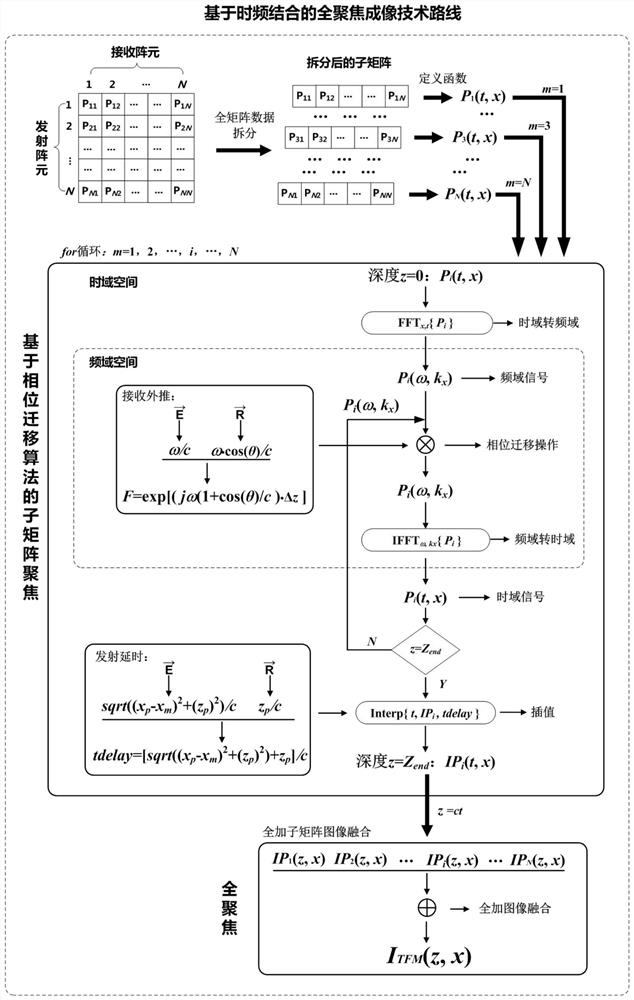

Time-frequency combined rapid full-focusing ultrasonic imaging method

ActiveCN112067698AReduce complexitySolve the problem of difficult real-time full-focus imagingAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalFocus ultrasoundWave field

The invention discloses a time-frequency combined rapid full-focusing ultrasonic imaging method, which comprises the following steps of firstly, splitting acquired three-dimensional full-matrix data into N two-dimensional matrix slices, secondly, by means of two-dimensional forward / inverse Fourier transform, achieving received wave field extrapolation on each depth layer on a certain slice step bystep, then, by calculating a delay matrix from each pixel point to a transmitting array element, interpolating the extrapolated time domain signal to realize focusing on the slice, and finally, repeating the phase shift and interpolation operation on the N two-dimensional slices and accumulating to obtain a time-frequency combined full-focus image. The method has the advantages that compared withtraditional time domain full focusing, the method is low in complexity and high in imaging speed, the problem that full focusing is difficult to achieve real-time imaging is expected to be solved, high-precision quantification, positioning and qualitative determination of internal defects of materials can be effectively achieved, and the method has good application and popularization prospects.

Owner:NANCHANG HANGKONG UNIVERSITY

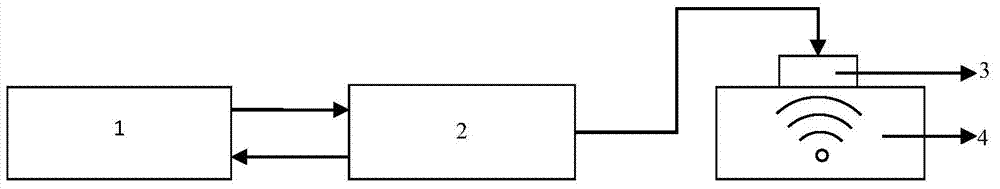

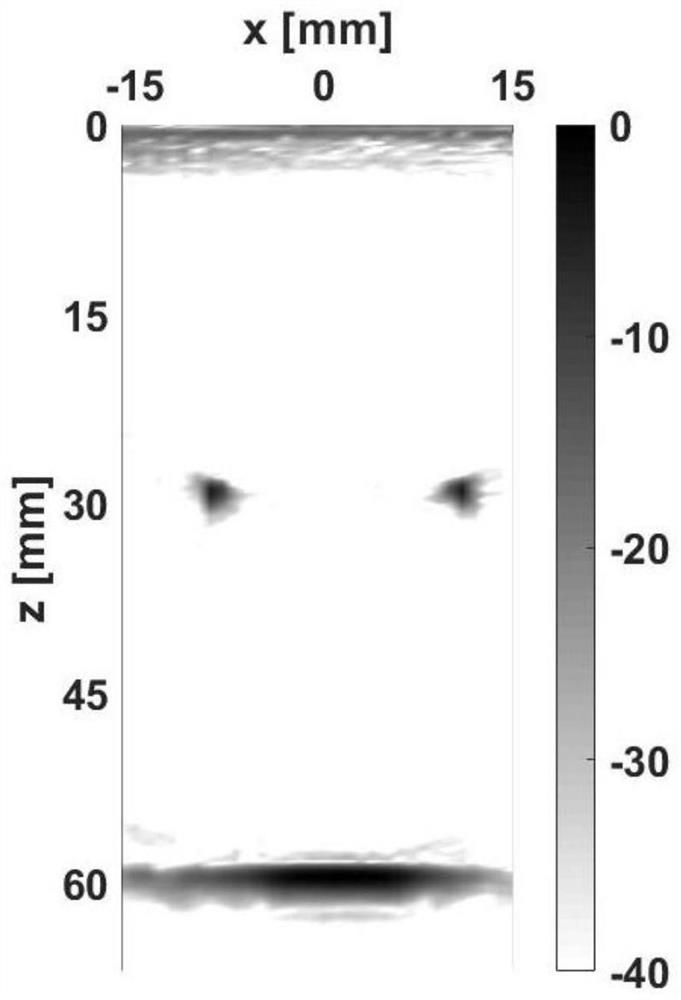

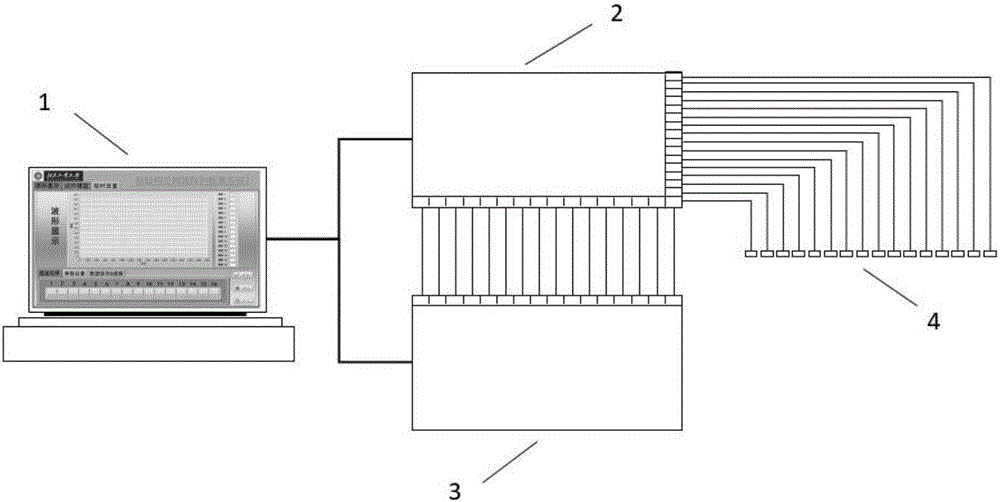

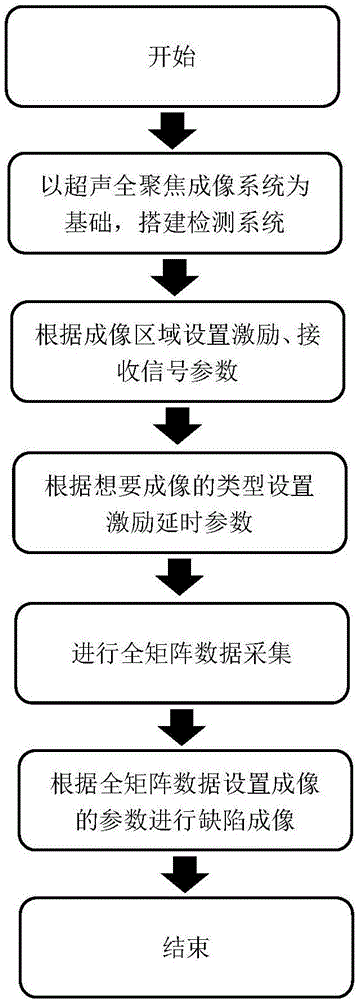

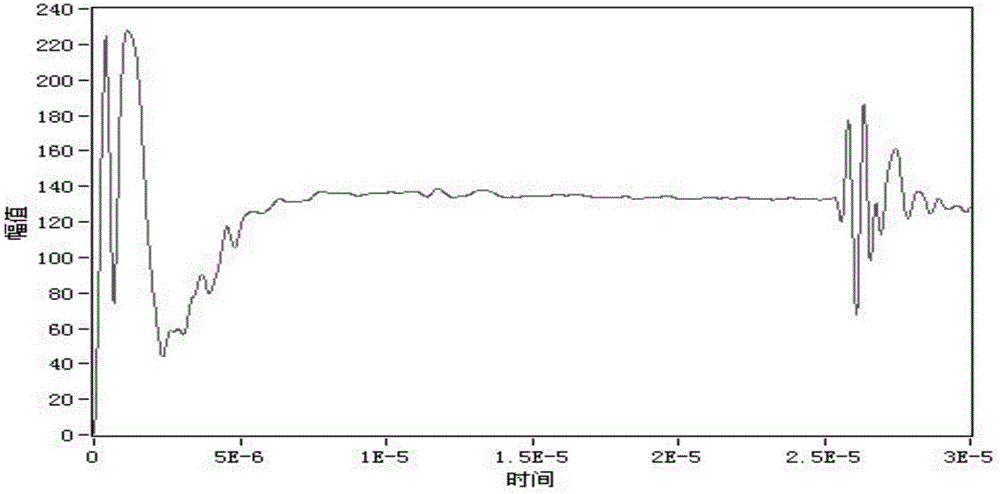

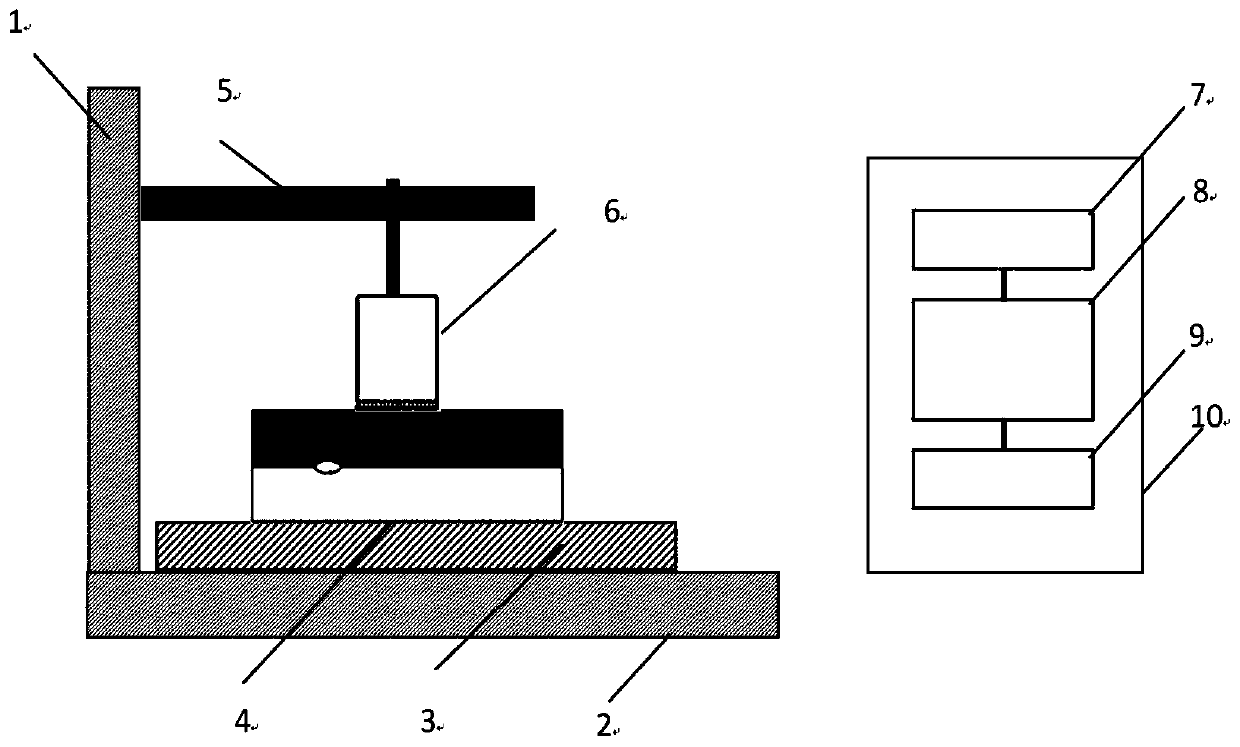

Full-matrix data based ultrasonic all focusing and imaging system

PendingCN106802323AQuick collectionAchieving any point of focusAnalysing solids using sonic/ultrasonic/infrasonic wavesResponse signal detectionSensor arraySonification

The invention discloses a full-matrix data based ultrasonic all focusing and imaging system. According to the system, a detection system is established by taking an ultrasonic all focusing and imaging system as a base; corresponding parameters of an excitation signal and a receiving signal are set respectively, and excitation and receiving signal parameters are set according to an imaging region; an excitation delay parameter is set according to a wanted imaged type; and a sensor array is carried to collect full-matrix data, imaging parameters are set according to the full-matrix data to carry out all focusing and imaging on a detection region, and a detection result is intuitively expressed.

Owner:BEIJING UNIV OF TECH

Nutrient solution specially used for strawberry plantation

InactiveCN105237096AChange the tasteIncrease cell wall strengthFertilizer mixturesFragariaMicroorganism

The invention discloses a nutrient solution specially used for strawberry plantation, relates to strawberry soilless plantation, and especially relates to a nutrient solution specially used for strawberry plantation to aim at full-matrix cultivation of strawberries. The nutrient solution specially used for strawberry plantation is characterized in that the nutrient solution contains a substance A, a substance B and a substance C, and the nutrient solution is prepared from the substance A, the substance B and the substance C through the following steps: (1) manufacturing a mother liquor; (2) mixing; and (3) diluting. The nutrient solution specially used for strawberry plantation allows element adjustment to be carried out according to different substance concentrates needed in different growth stages of the strawberries to adapt to strawberry growth; and a ratio of nitrate nitrogen to ammonia nitrogen is specially designed to approach 80% in consideration of partial inhibition of beneficial microbe florae in a matrix due to full-matrix cultivation, so use and absorption of the N element by roots of plants in full-matrix cultivation environment are benefited.

Owner:YUNNAN LUFENG QINPAN MODERN AGRI DEV CO LTD

Channel estimation for high doppler mobile environments

An apparatus and method of applying a fast algorithm to a pilot-based channel estimation process includes receiving, in a receiver, a signal comprising information bits transmitted in a wireless channel, executing a pilot-based channel estimation process running on a decision-directed turbo estimation procedure having a p structure for a vector of pilots and an upper bound N for a channel spread based on a feedback of detected information bits via OFDM, encoding the detected information bits, re-encoding the detected information bits at a decoder output, re-constructing and subtracting an ICI term from the received signal, modulating the detected information bits, estimating channel symbols in a per-carrier basis based on a diagonal matrix of a full matrix involved in the pilot-based channel estimation, and performing training of the wireless channel based on an entire vector of the channel symbols.

Owner:ATMEL CORP

Real-time 3D full-focus phased array ultrasonic imaging method and device and storage medium

InactiveCN108490077ARealize real-time 3D full-focus imaging detectionIntuitive detection and imaging resultsAnalysing solids using sonic/ultrasonic/infrasonic wavesSonificationRectangular coordinates

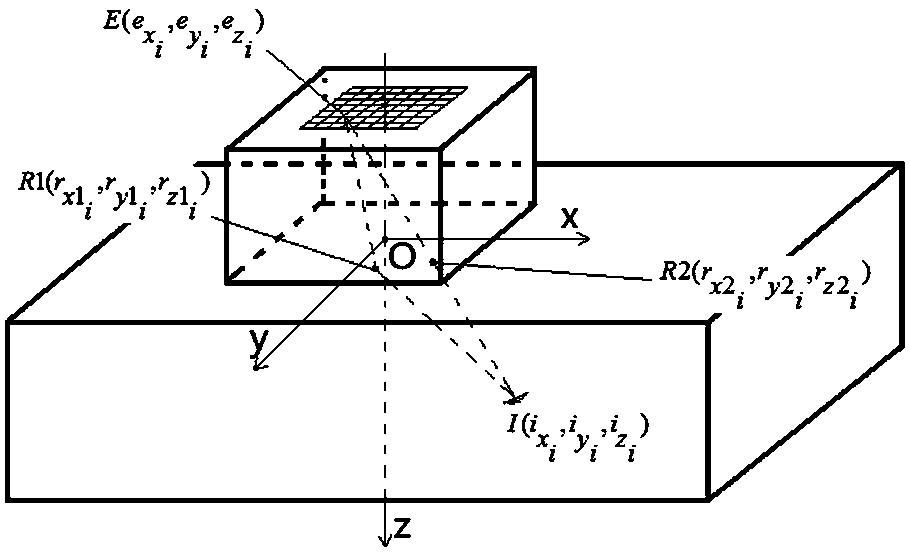

The embodiment of the invention discloses a real-time 3D full-focus phased array ultrasonic imaging method. The method comprises building a three-dimensional space rectangular coordinate system with the top surface of a workpiece to be tested, calculating launch time of ultrasonic wave, orderly transmitted by each array element of a two-dimensional area array transducer, transmitted from a coupledzone to a target defect point in a workpiece to be tested and reflection time of ultrasonic wave, reflected by the target defect point, transmitted from the workpiece to be tested to the coupled zoneand received by the two-dimensional area array transducer, building full-matrix data through the launch time and the reflection time and carrying out 3D full-focus reconstitution on the target defectpoint. The embodiment of the invention also discloses a device for real-time 3D full focus phased array ultrasonic imaging and a readable storage medium. The device collects the full-matrix waveformsignal of the three-dimensional space in the workpiece to be tested in real time, can carry out real-time 3D full-focus imaging detection, can produce visualized detection imaging results, has a fastdetection rate, produces a reliable detection result and realizes easy observation of damages.

Owner:GUANGDONG GOWORLD

Composite component interface rapid imaging quantitative detection method based on full-matrix data

ActiveCN111175381AComprehensive bonding statusSmall amount of calculationAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalRapid imagingData acquisition

The invention belongs to the technical field of defect detection, and particularly relates to a composite component interface rapid imaging quantitative detection method based on full-matrix data. Themethod comprises the following steps: 1) full-matrix data acquisition; 2) adopting a sector-scanning rapid imaging algorithm or a full-focusing rapid imaging algorithm based on the full-matrix data to realize rapid sector-scanning or full-focusing imaging of a component; 3) carrying out threshold processing on the imaging result by adopting a quantitative method aiming at the debonding detectioncharacteristics of the composite component, and determining an effective debonding area; and 4) performing binarization processing on the imaging result after threshold processing to obtain position and size information of the debonding defect, thereby realizing quick imaging quantitative detection of the interface bonding quality of the composite component based on the full-matrix data. Accordingto the method, the full-matrix data acquisition mode is adopted, when each sampling point is acquired, all array elements are acquired and echo information with a more comprehensive composite component interface bonding state can be obtained.

Owner:ZHONGBEI UNIV

Focused acoustic array imaging method and system

ActiveCN113109443AImproving Imaging ResultsEasy to detectUltrasonic/sonic/infrasonic diagnosticsAnalysing solids using sonic/ultrasonic/infrasonic wavesMain diagonalAcoustic array

The invention discloses a focused acoustic array imaging method and system, and the method comprises the steps: obtaining echo data of an imaging region through employing a single-array-element transmission and all-array collection mode, transmitting and traversing all array elements, and obtaining all echo data as full-matrix data; calculating a delay index table of the whole imaging area; taking a main diagonal line of the full matrix data as a reference, and calculating to obtain a reference image according to the delay index table; calculating a focused image by using secondary diagonal data of the full-matrix data according to the delay index table and echo data corresponding to the secondary diagonal, and superposing the focused image with the reference image; and continuing to gradually move towards the two sides until the superposed focused image meets the image quality requirement. According to the focused acoustic array imaging method and system, the focusing imaging real-time processing speed is increased, the target image with the better signal-to-noise ratio can be obtained according to needs, the acoustic array imaging result is greatly improved, and the acoustic array detection performance is improved.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

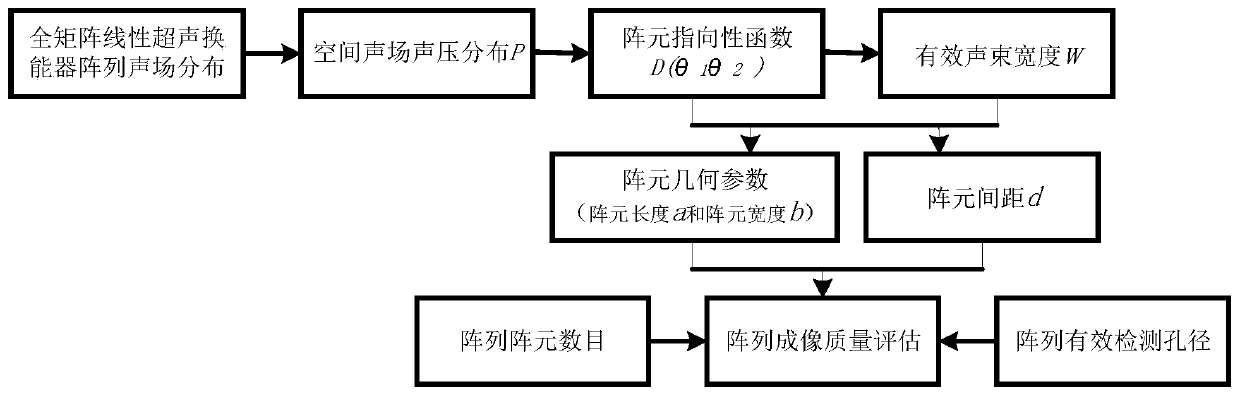

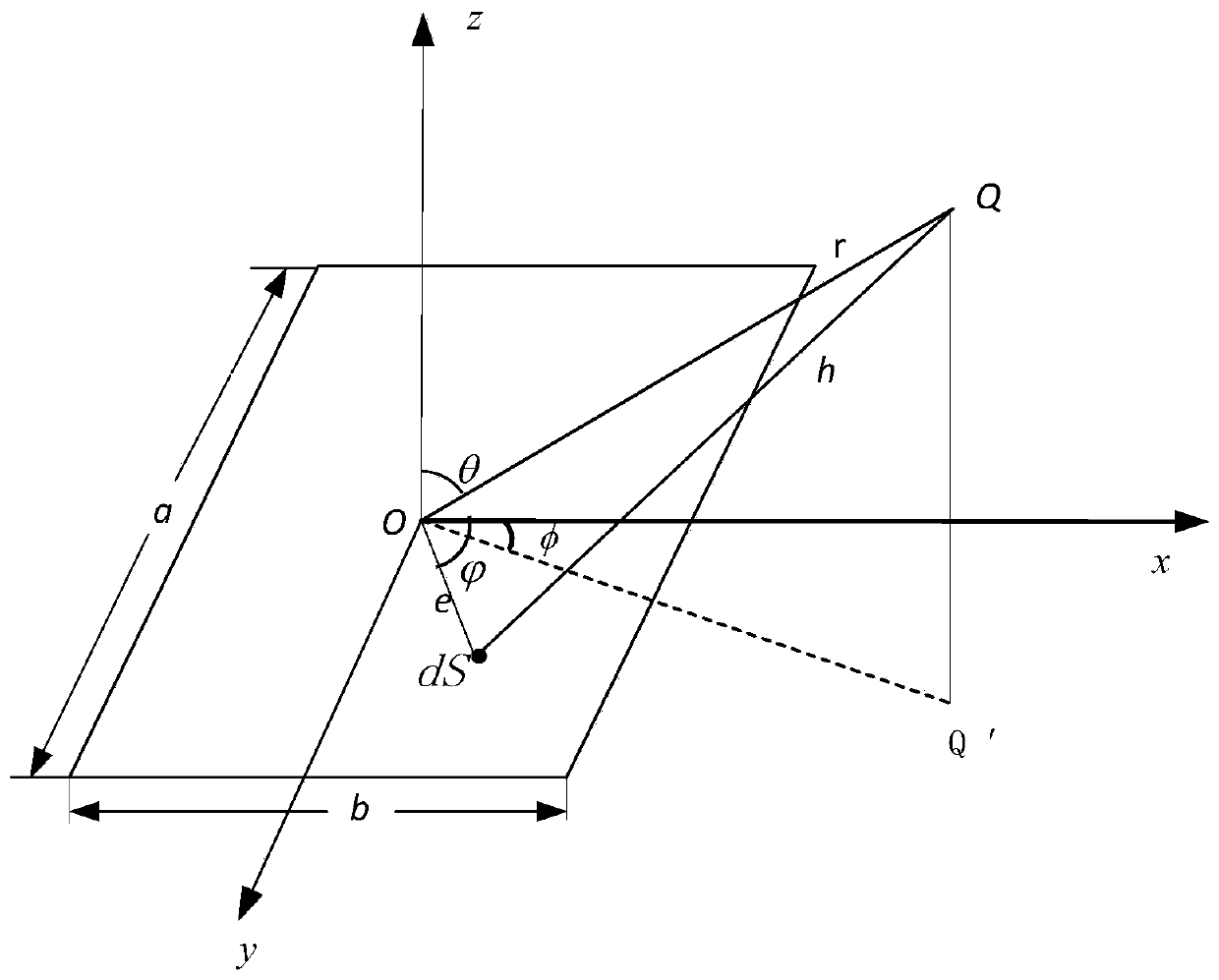

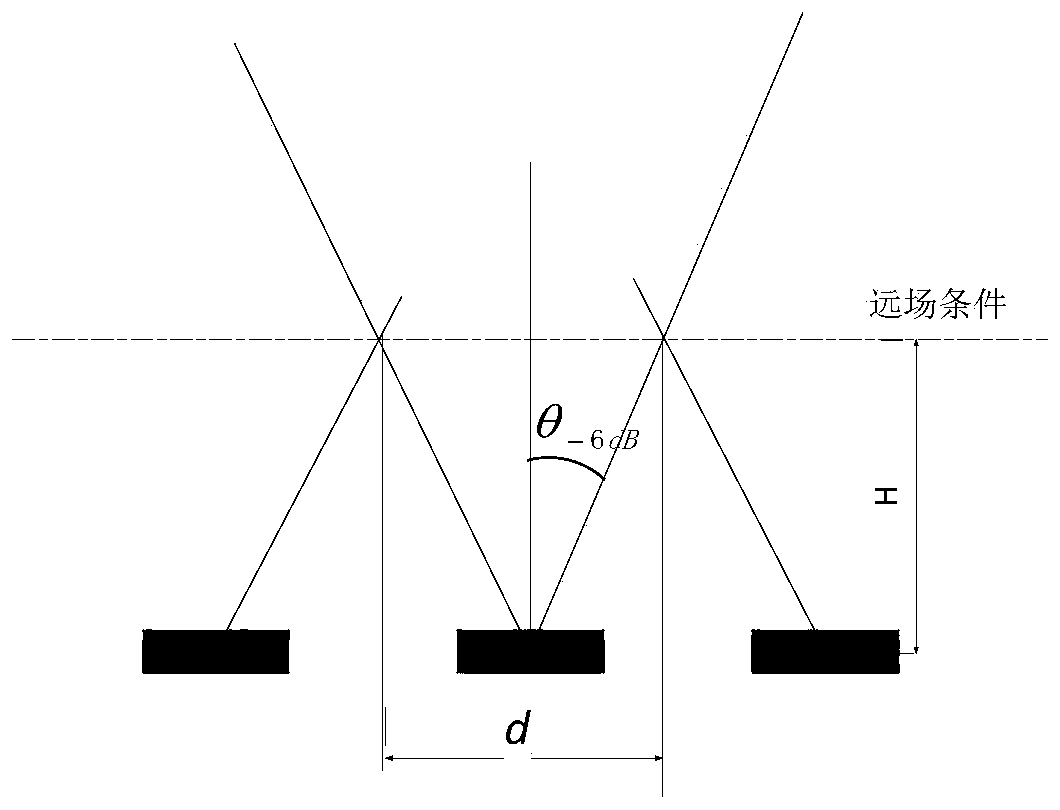

Design method of full-matrix linear ultrasonic transducer array

ActiveCN110059371AAverage image qualityDeep detection depthSustainable transportationDesign optimisation/simulationSensor arrayImaging quality

The invention provides a design method of a full-matrix linear ultrasonic transducer array. The design method comprises the following steps: establishing single-array element space sound field distribution P of the full-matrix linear ultrasonic transducer array; establishing an array element directivity function D (theta 1, theta 2); solving an effective sound beam width w; determining a rectangular array element length a and a rectangular array element width b; determining an array element interval d; and evaluating the imaging quality of the array according to the number of given array elements and the effective detection aperture. The problem that no special sensor array design method exists in the existing full-matrix ultrasonic imaging technology is solved. The defect detection effectand the imaging quality superior to those of a conventional phased array are achieved. The number of array elements is reduced and the detection time efficiency is improved.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com