Equipment for soldering and planting ball as well as acquisition apparatus

A solder ball and ball planting technology, which is applied in the direction of welding equipment, tin feeding equipment, metal processing equipment, etc., can solve the problems of process cost increase and process cost increase, and achieve the effect of low cost and saving process equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The implementation of the present invention is described below through specific examples. Those skilled in the art can easily understand other advantages and effects of the present invention from the content disclosed in this specification.

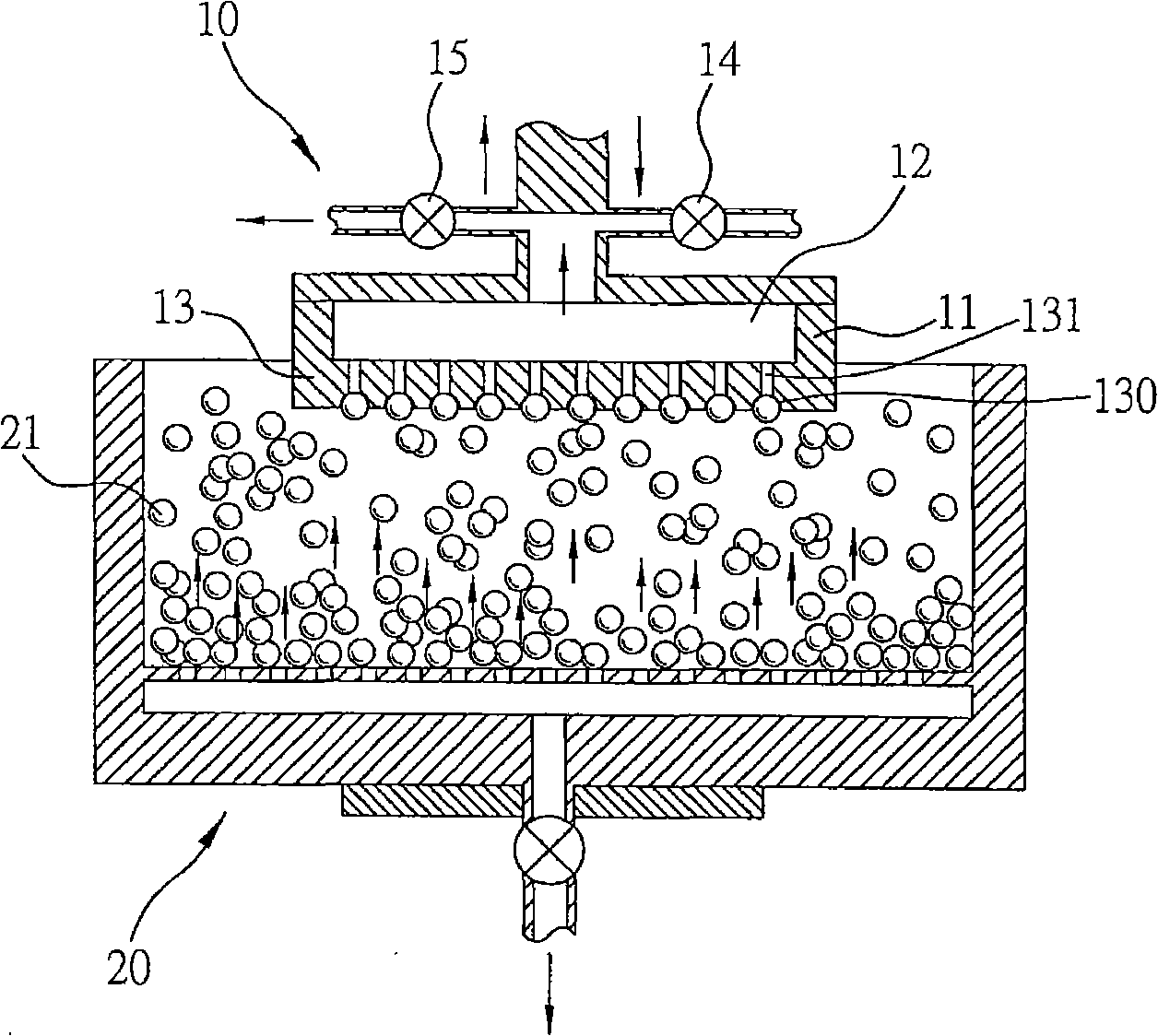

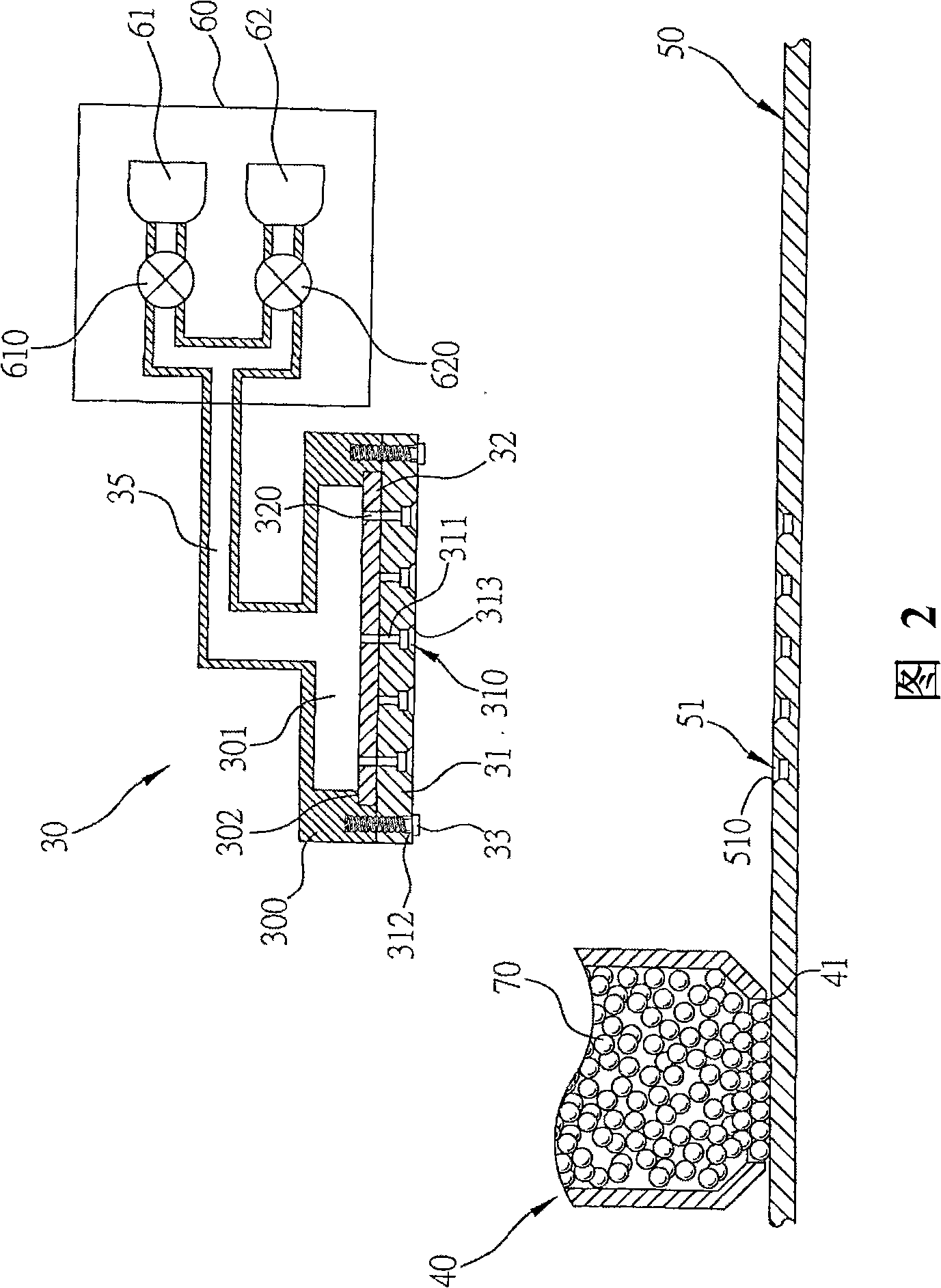

[0059] Please refer to FIG. 2 , which shows the solder ball planting equipment of the present invention, which includes a solder ball setting device 50 , a solder ball storage device 40 , and a solder ball picking device 30 .

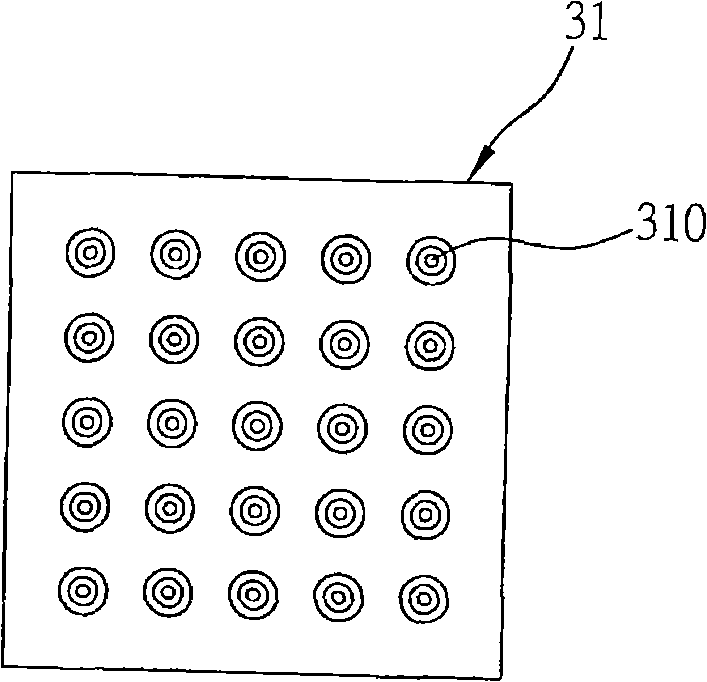

[0060]The solder ball holder 50 has a plurality of accommodating holes 51 for accommodating the solder balls 70 disposed on a surface, and each accommodating hole 51 has an oblique section 510 of the accommodating hole surrounding the periphery of the accommodating hole 51, When the solder ball 70 is placed in the accommodating hole 51 , it will not be too tight to take out the solder ball 70 smoothly.

[0061] The solder ball storage device 40 is set close to the surface of the solder ball holder 50 with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com