Method for welding line ultrasound array full focusing imaging based on oblique incidence longitudinal waves

An ultrasonic array and imaging method technology, which is applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, and processing response signals of detection, etc. Good coupling effect, improve defect detection effect, protect phased array probe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Basic principle of the present invention is as follows:

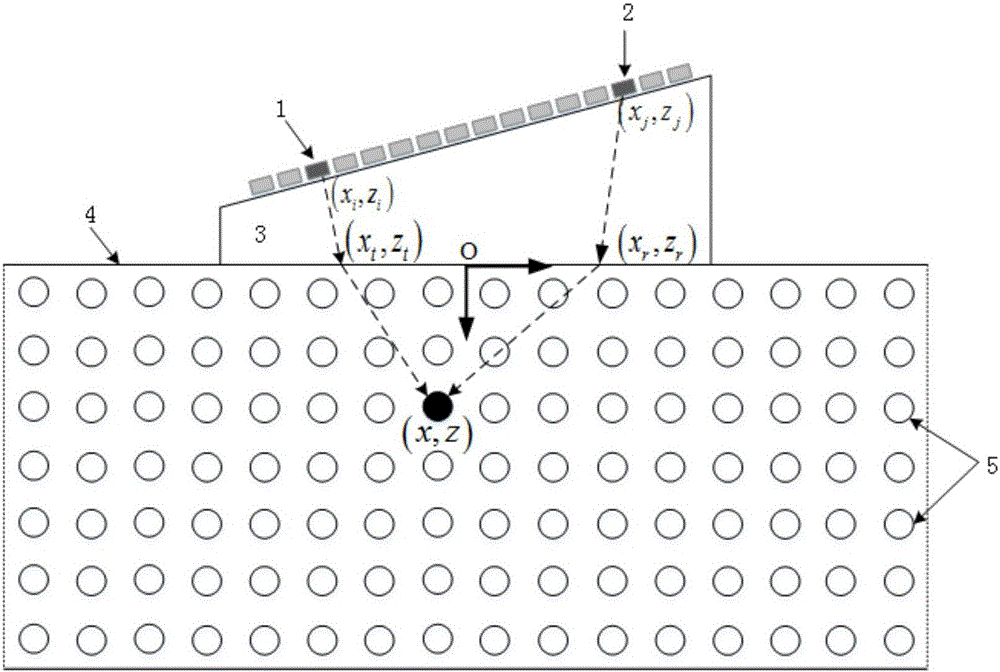

[0032] like figure 1 As shown, it is assumed that the number of array elements of the linear array transducer is N, i is the excitation array element, and j is the receiving array element. The acoustic beam excited by array element i reaches the focal point (x, z) of the imaging area through the wedge, and then is received by array element j through the wedge. One array element is excited separately, and all array elements are received, and each array element is excited separately in turn, and the above-mentioned "one excitation and all collection" process is repeated, and finally N×N groups of full matrix data are obtained. Denote the ultrasonic echo signal (that is, the full-matrix time-domain signal) collected by the excitation array element i and the receiving array element j as g ij (t), put g ij (t) denoted as h after Hilbert transform ij (t),

[0033] Then the amplitude I(x,z) of the focal point (x,z)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com