Patents

Literature

65results about How to "Improve defect detection performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mobile phone casing defect detecting method based on depth learning

ActiveCN106875381AImprove detection accuracyReliable test resultsImage analysisGeometric image transformationFeature extractionMobile phone

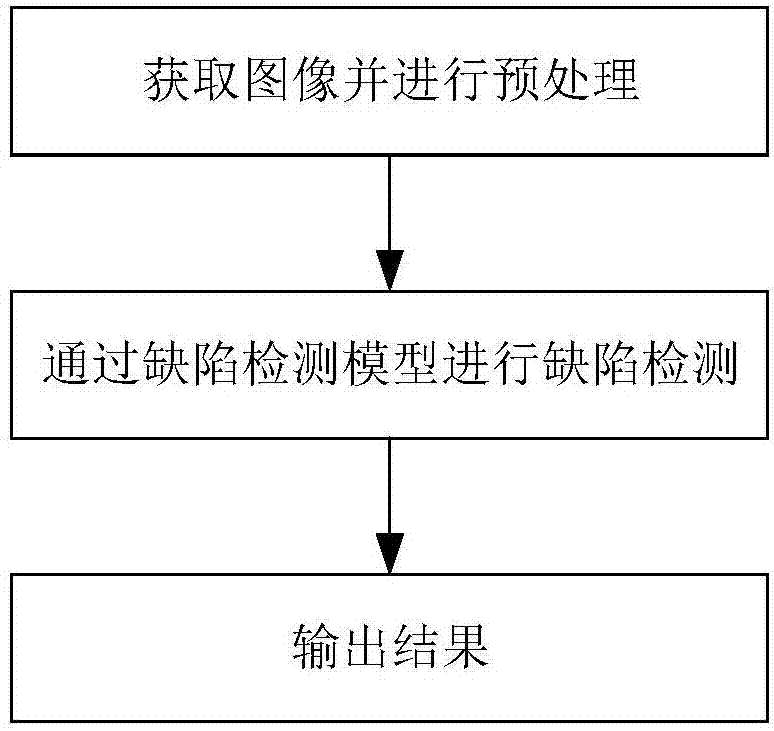

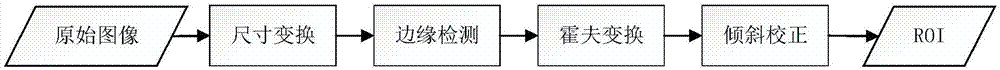

The invention relates to a mobile phone casing defect detecting method based on depth learning. The method comprises the steps that (1) the image of a mobile phone casing to be detected is acquired and pre-processed; and (2) the pre-processed image is input into a pre-trained defect detection model for defect detecting to acquire the position of a defect on the mobile phone casing, and the confidence of the position as the defect is provided. The defect detection model is a depth network based on depth learning, and comprises a feature extraction network and a classifier and regression device network, wherein the feature extraction network and the classifier and regression device network are in successive cascade. The feature extraction network carries out feature extraction on the pre-processed image to acquire a feature image. The classifier and regression device network classifies and regresses the feature image to acquire the defect position and the confidence of the mobile phone casing. Compared with the prior art, the method provided by the invention has the advantages of high detection precision and accurate and reliable detection result.

Owner:TONGJI UNIV

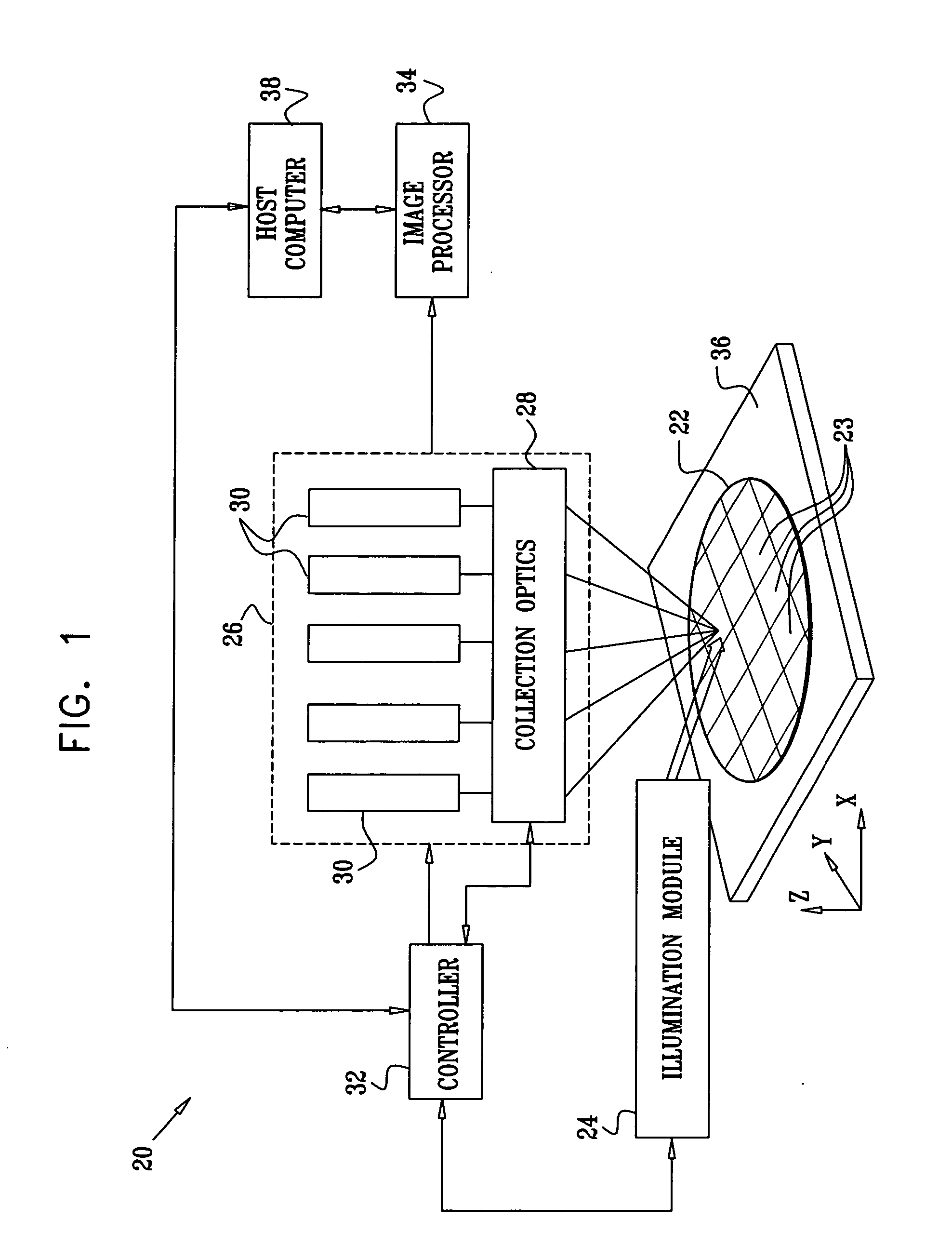

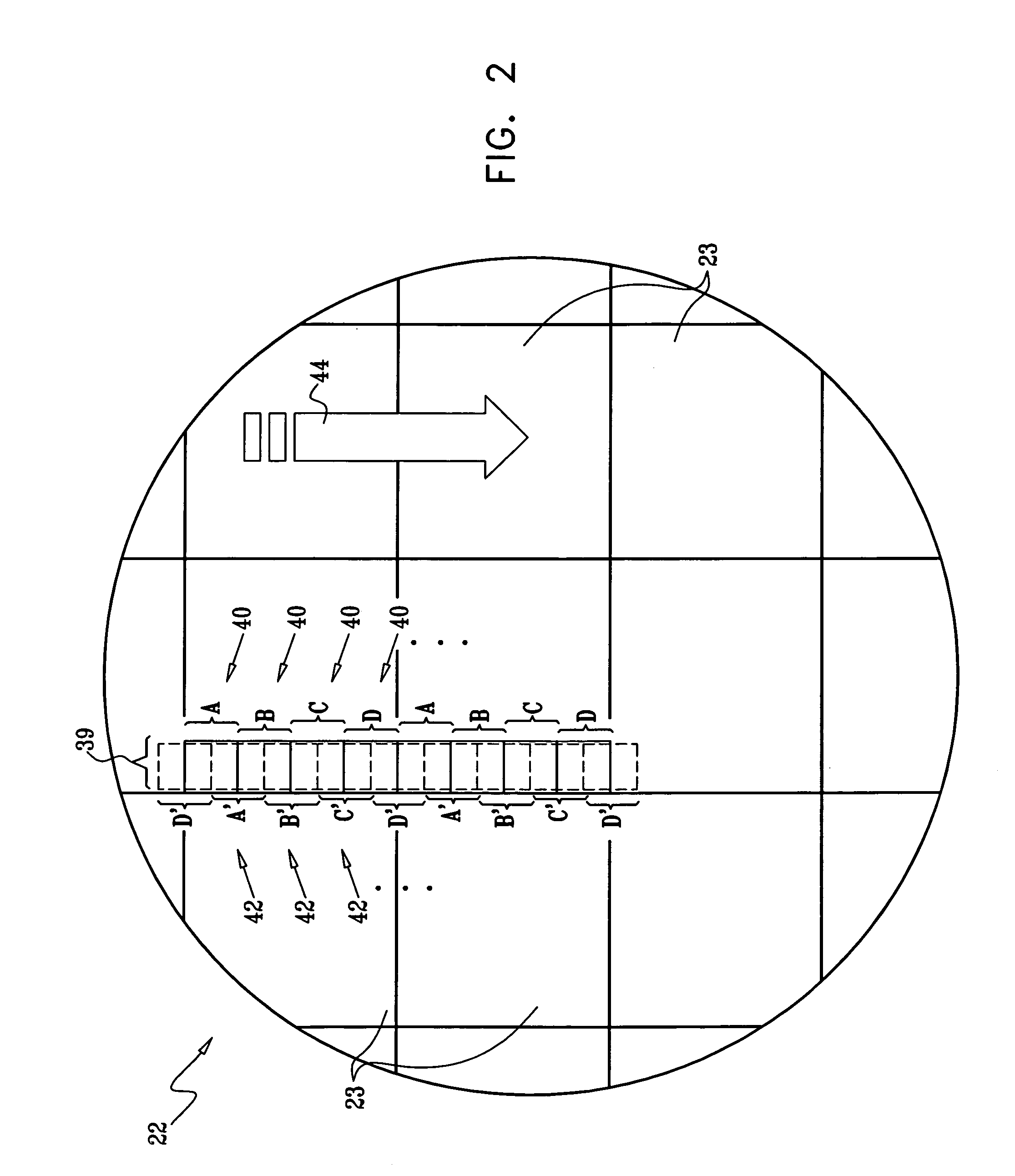

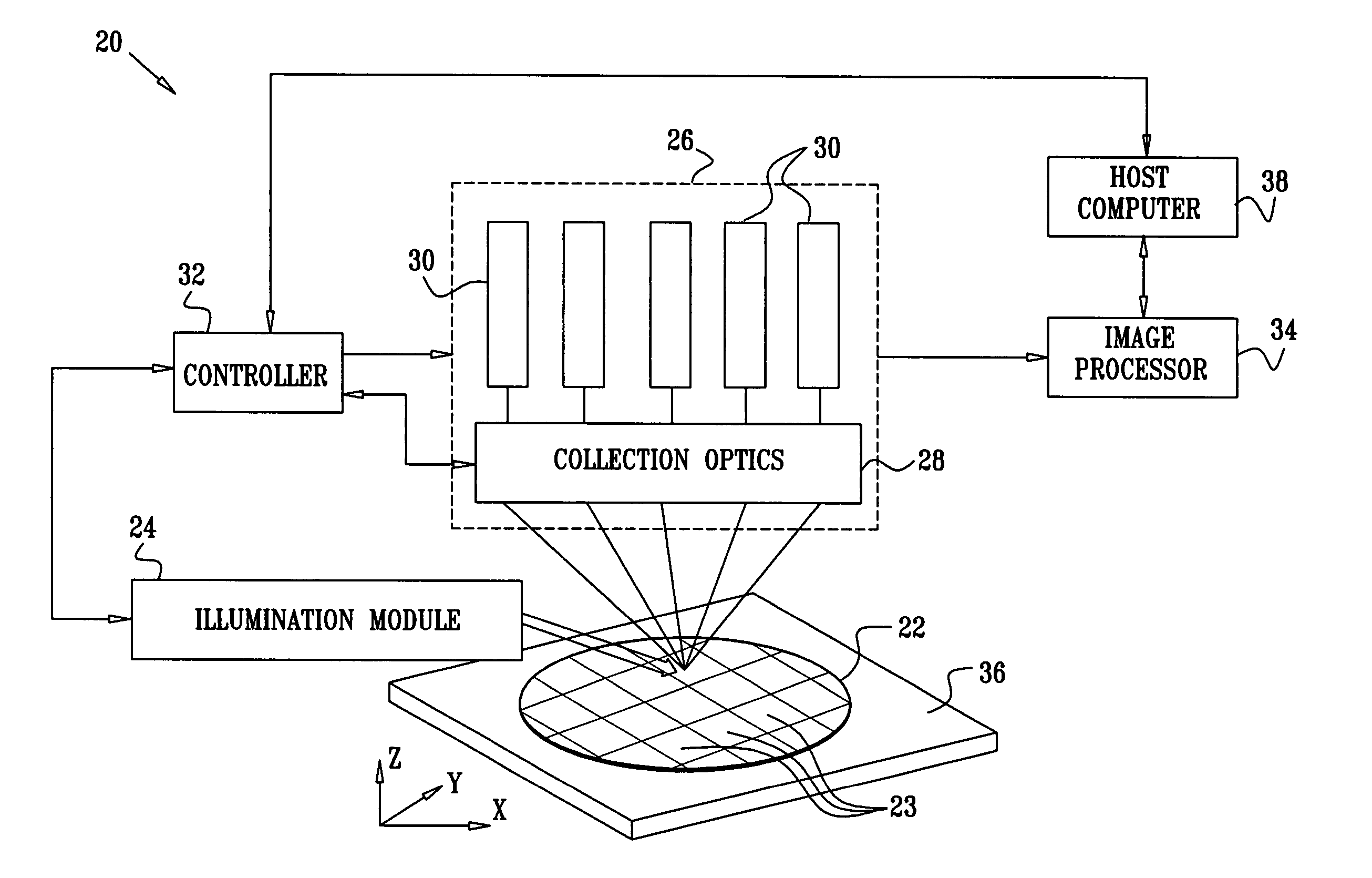

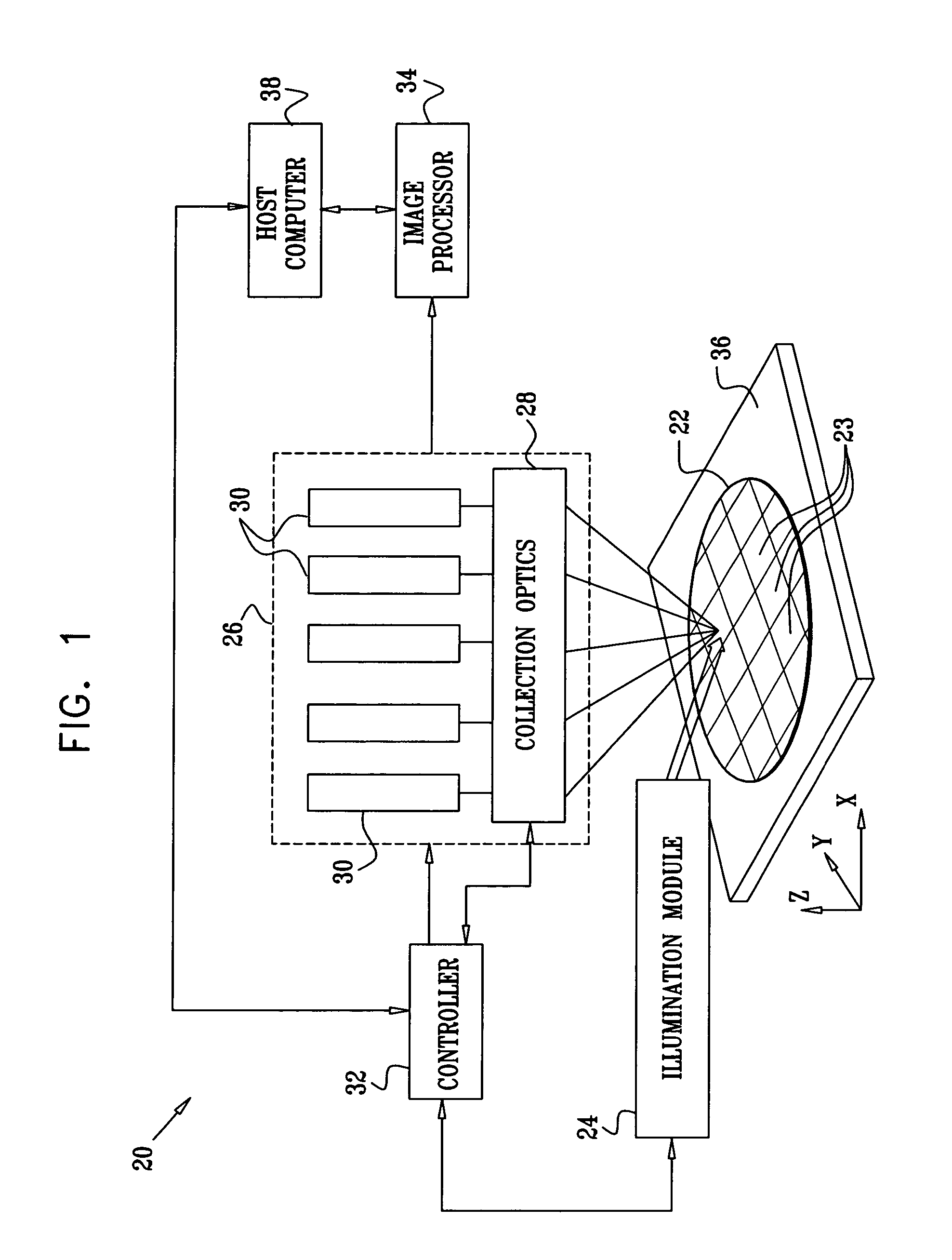

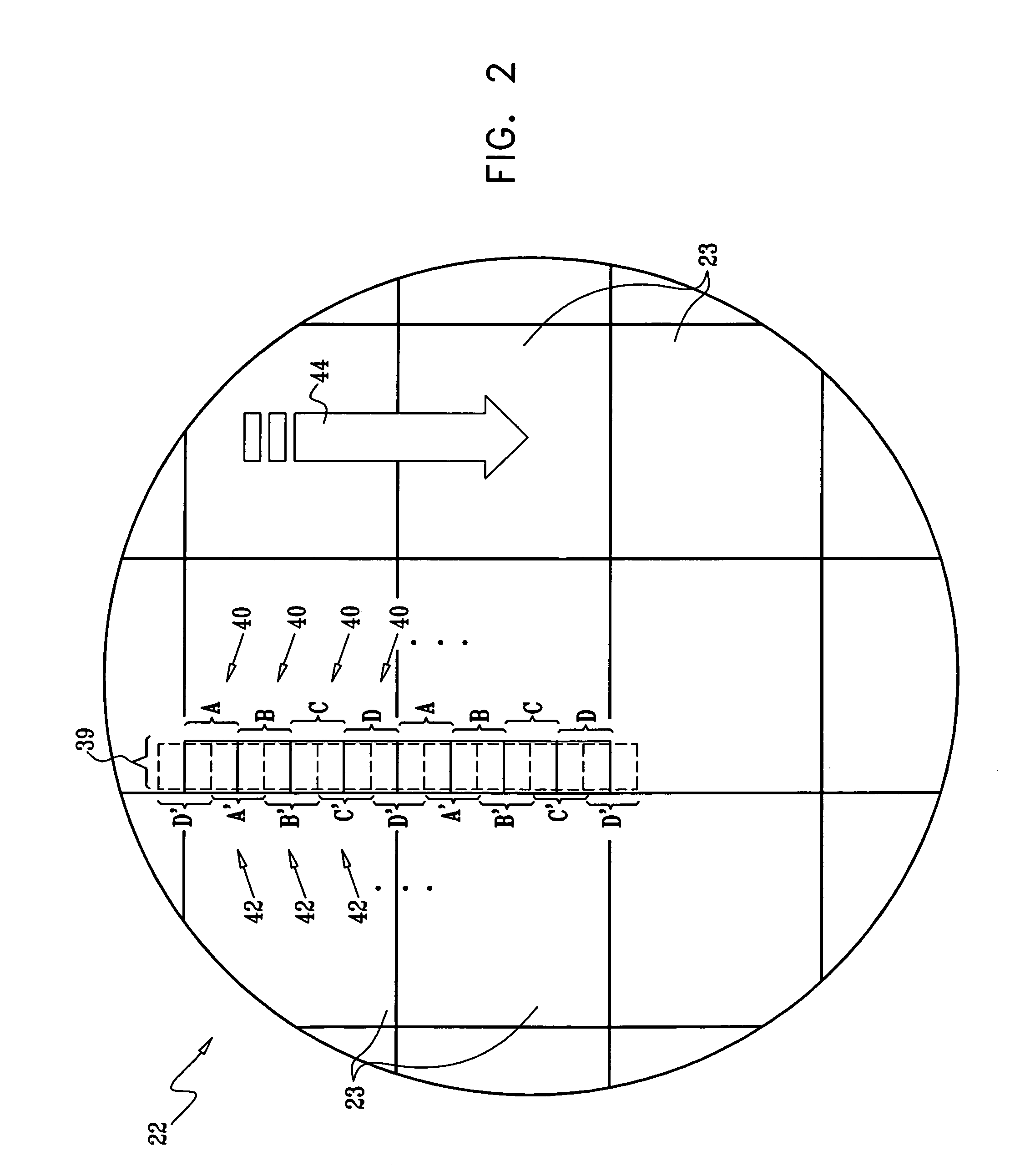

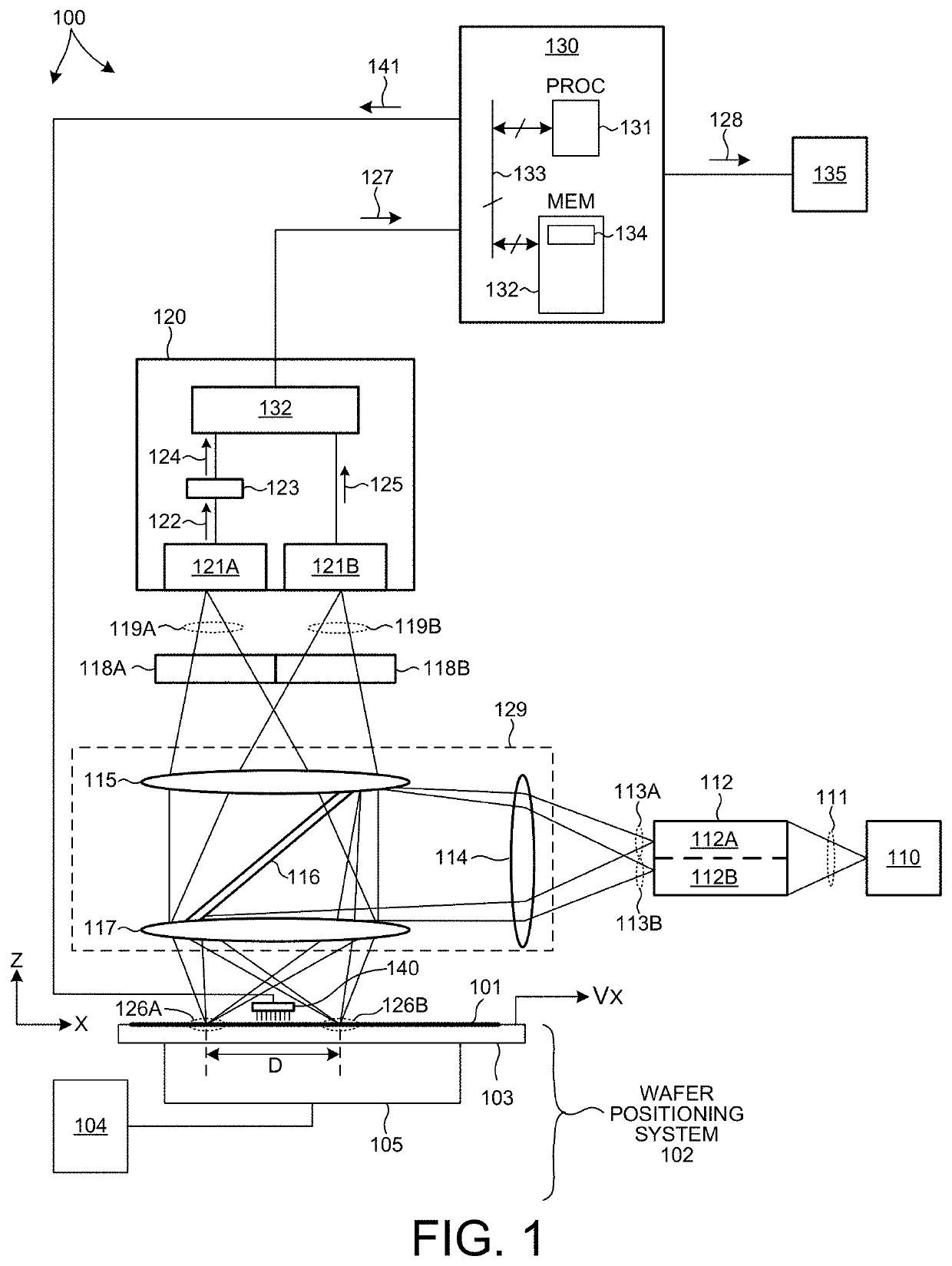

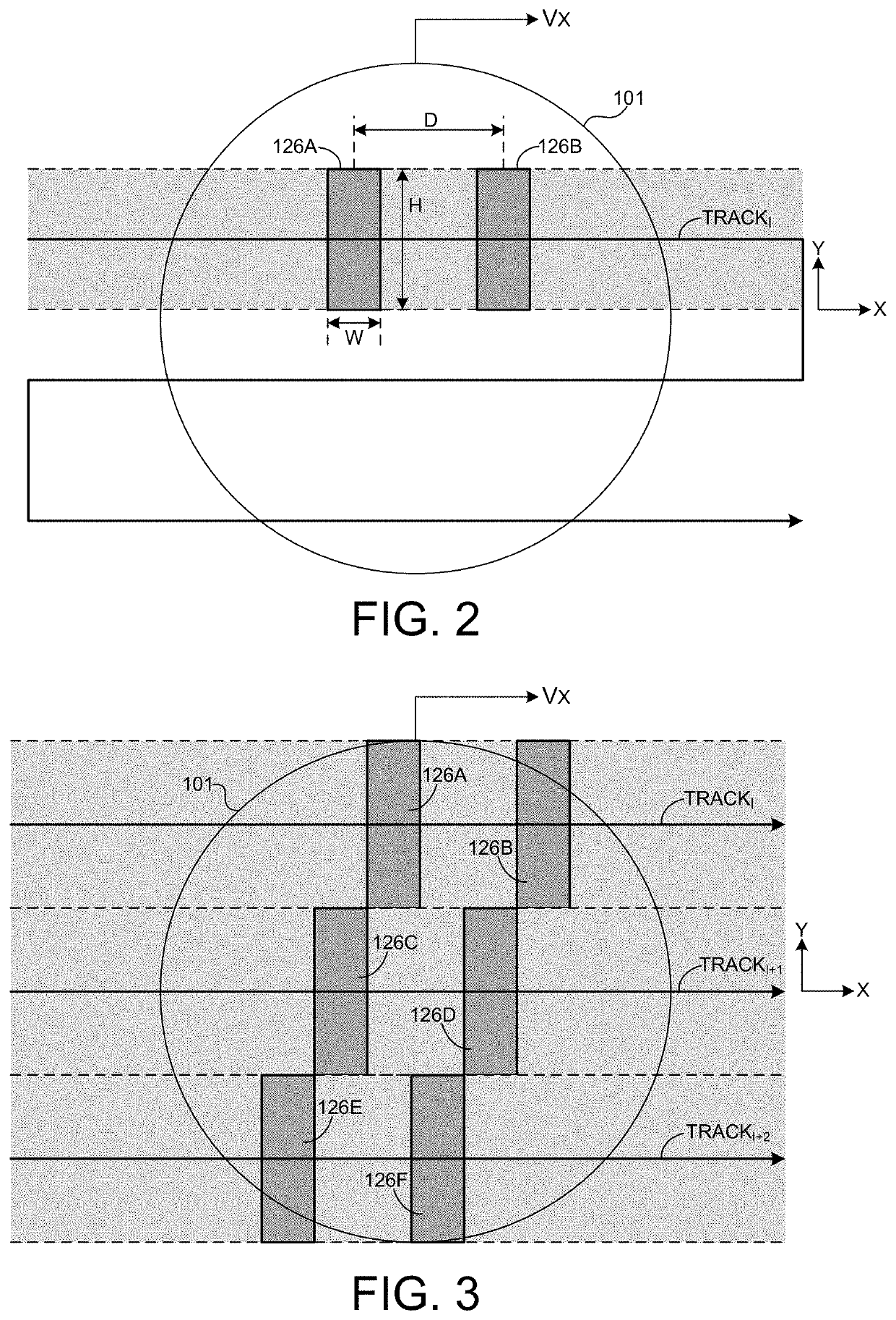

Optical inspection with alternating configurations

ActiveUS20060066843A1Enhance defect detection capabilityImprove defect detection performanceOptically investigating flaws/contaminationPulsed radiationOptical radiation

An imaging system for inspection of a sample includes an illumination module, which irradiates a surface of the sample with pulsed optical radiation. A mechanical scanner translates at least one of the sample and part of the imaging system so as to scan an area irradiated by the pulsed optical radiation over the surface in order to irradiate successive, partially overlapping frames on the surface by respective successive pulses of the pulsed radiation. A collection module collects the optical radiation scattered from the surface so as to capture a sequence of images of the irradiated frames. A system controller varies a configuration of the imaging system in alternation between at least first and second different optical configurations in synchronization with the pulsed optical radiation.

Owner:APPL MATERIALS ISRAEL LTD

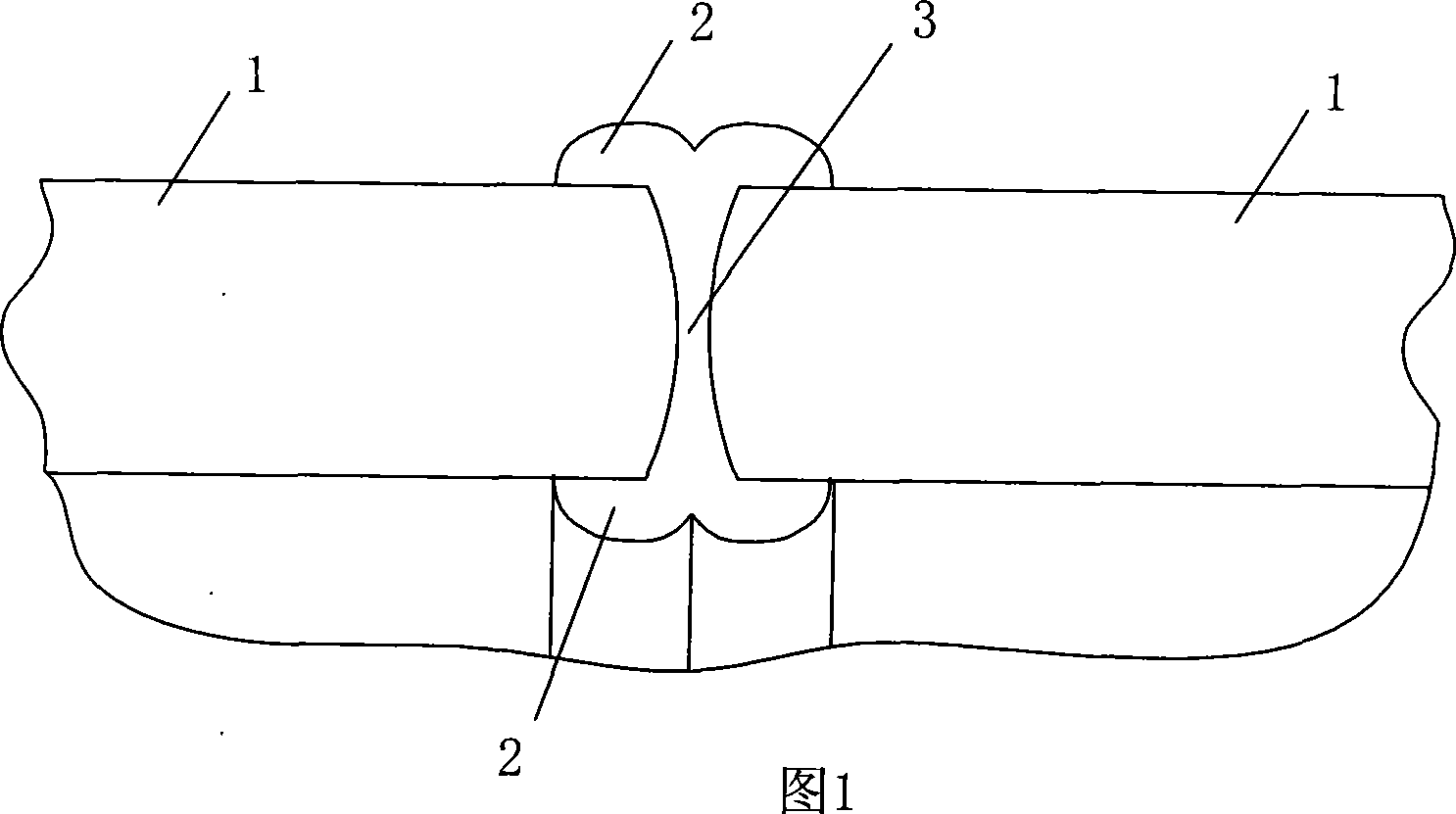

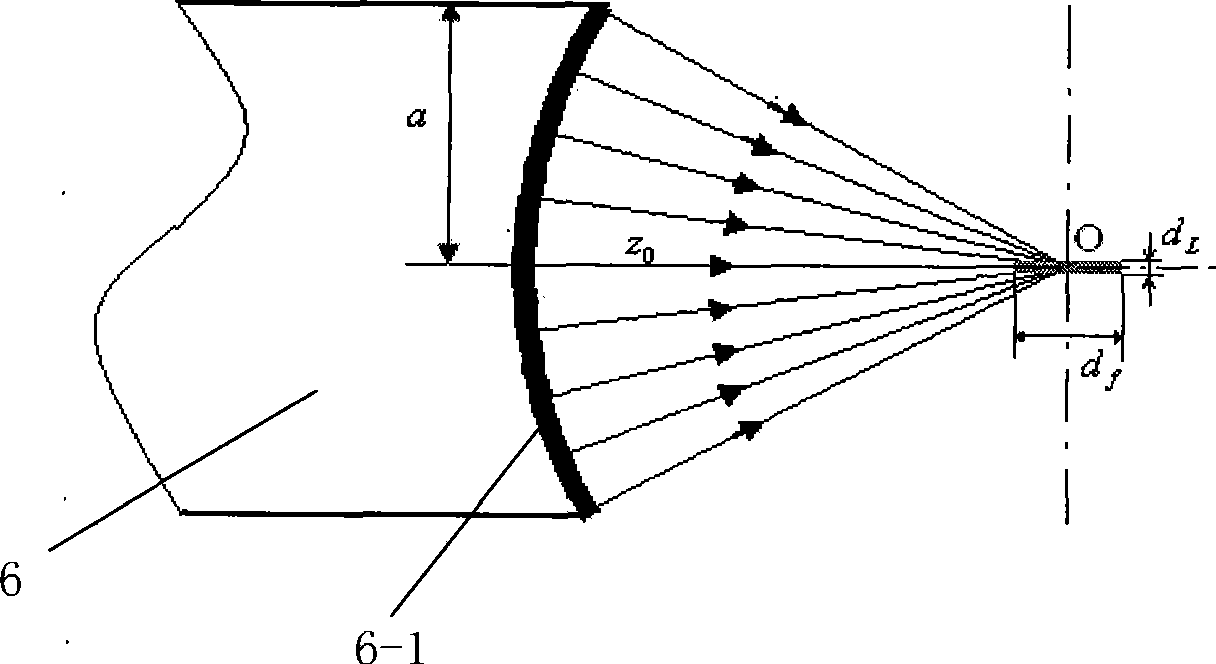

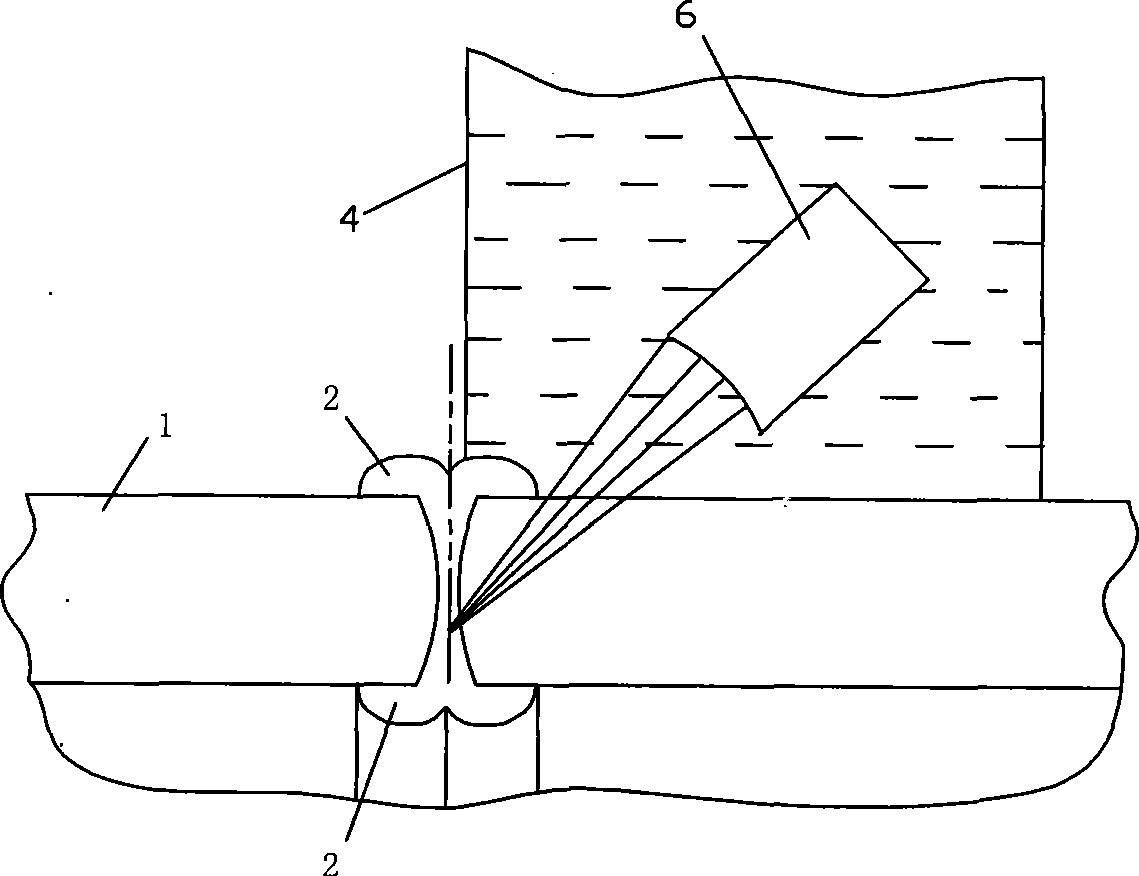

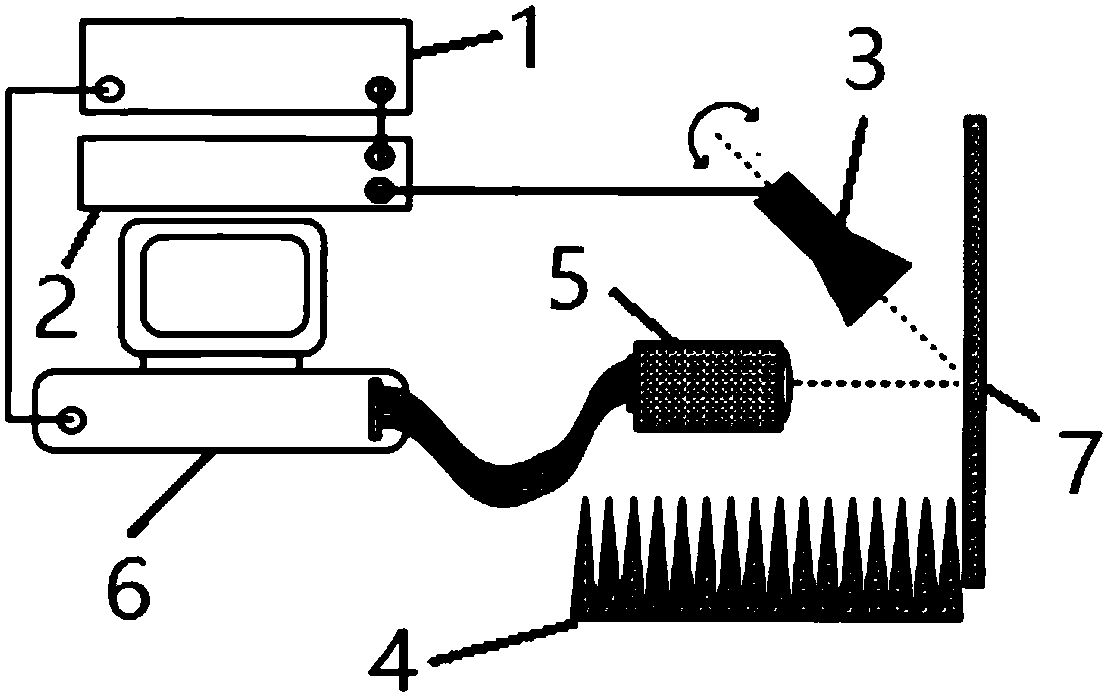

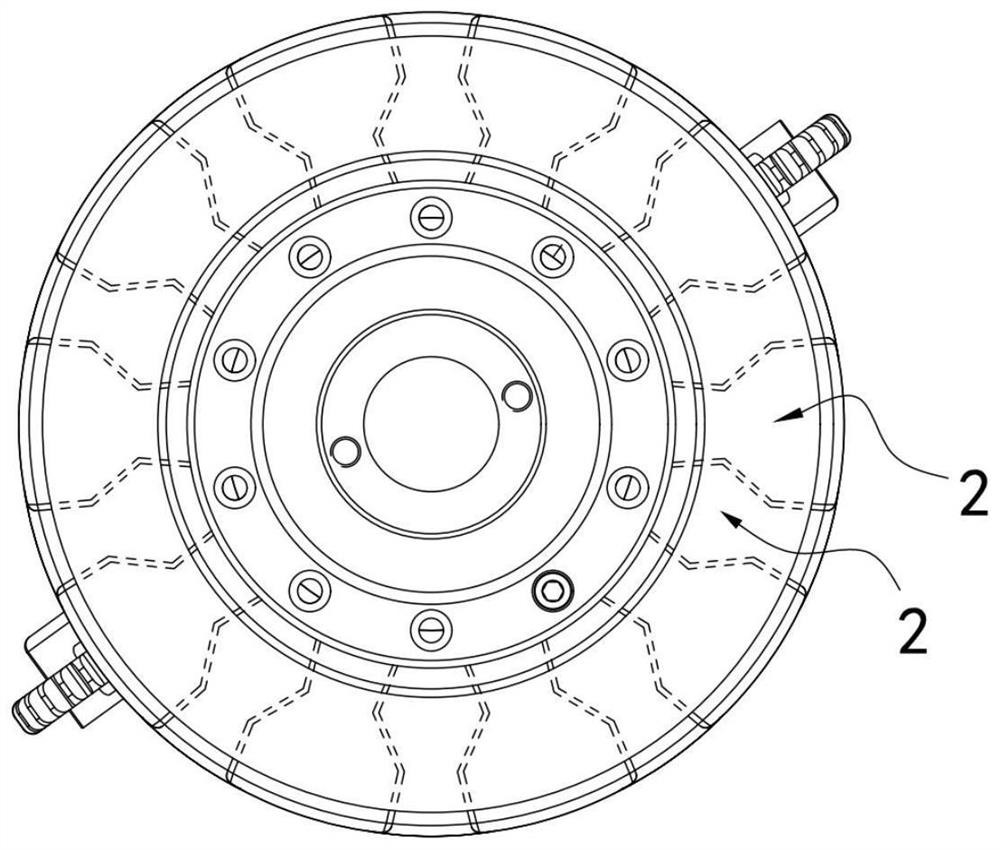

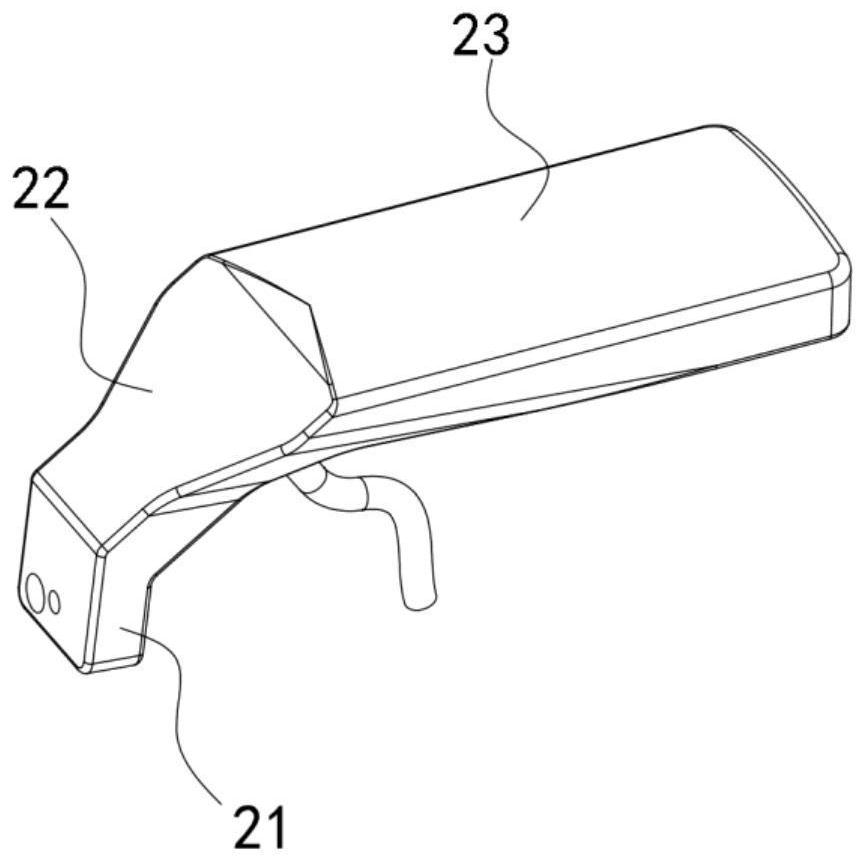

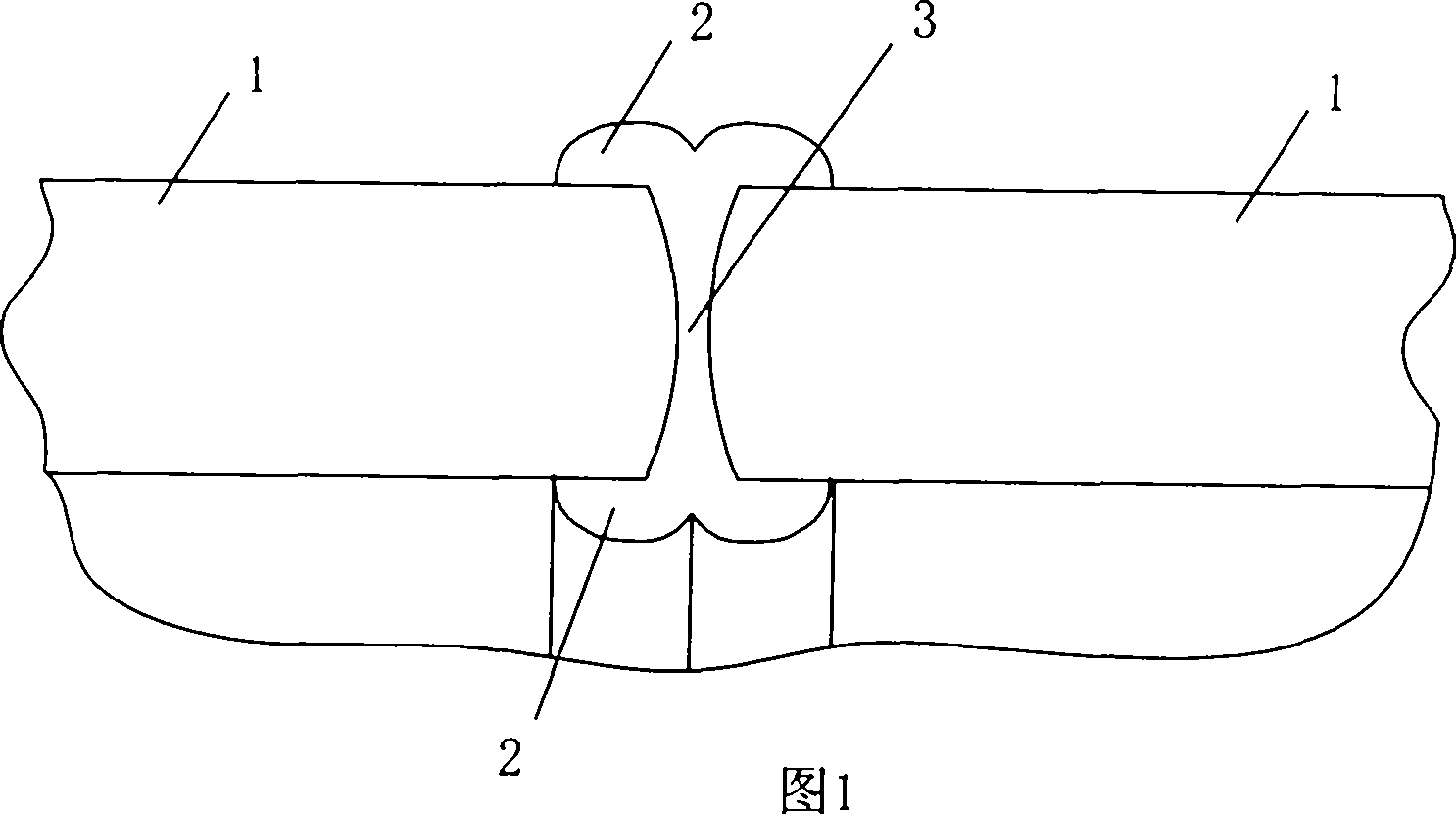

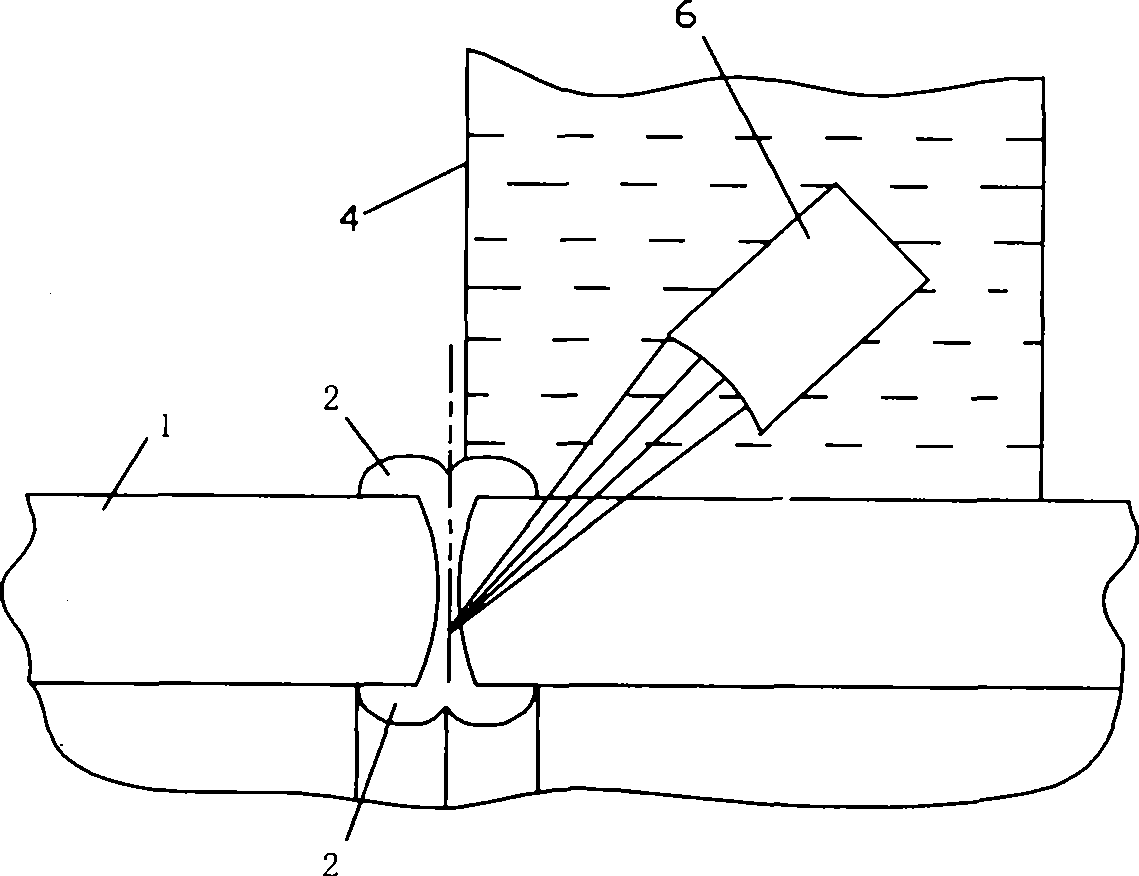

Coupling and focusing ultrasonic detection method and detection device for polyethylene pipe hot melt butt joint

ActiveCN101393170AHigh detection sensitivityImprove detection sensitivityAnalysing solids using sonic/ultrasonic/infrasonic wavesMiddle lineSonication

The invention relates to a method for detecting the welding quality of a hot-melt even joint of a polyethylene pipeline and a detection device thereof. The aim of the invention is that the provided detection method and the detection device have the characteristics of high sensitivity, high detection precision, high reliability, high detection efficiency and low misoperation rate. The technical proposal is a method for the coupling focusing ultrasonic detection of the hot-melt even joint of the polyethylene pipeline, which comprises the following steps: (1) a coupling agent liquid is positioned on the outer surface of a pipeline joint fusion region; (2) an ultrasonic probe adopting a spherical curved wafer is immersed into the coupling agent liquid in order that the focus is positioned in the centerline of the pipeline joint fusion region; and (3) the ultrasonic probe does linear scanning motion along the diameter direction of the pipeline and does uniform scanning motion along the circumferential direction of the pipeline; and obtained signal data is processed by a computer to form a C scanning picture. The ultrasonic detection device comprises a coupling receiving device, the ultrasonic probe adopting the spherical curved wafer, a mechanical scanning device, a signal processing and controlling system, and the computer.

Owner:ZHEJIANG PROVINCIAL SPECIAL EQUIP INSPECTION & RES INST +1

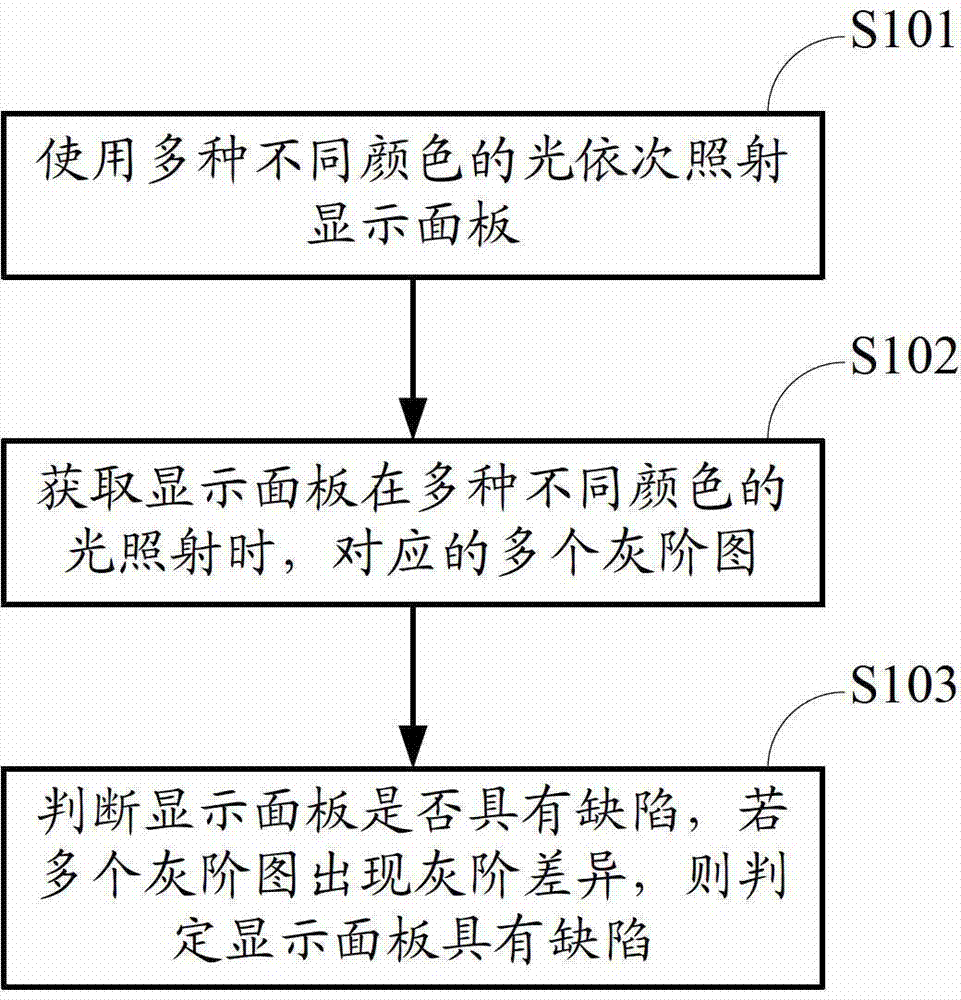

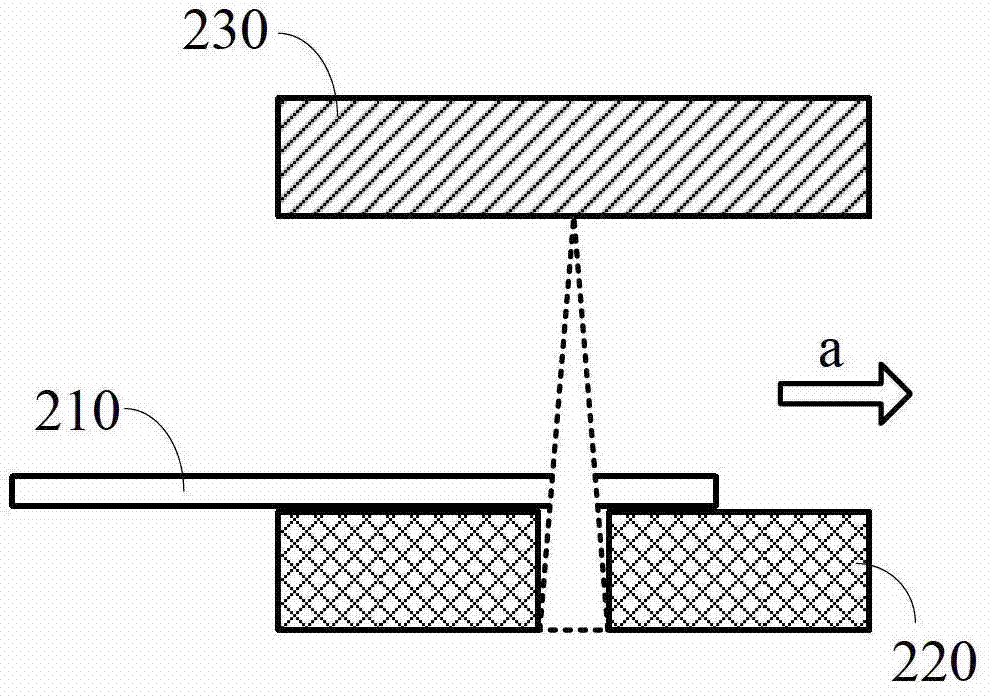

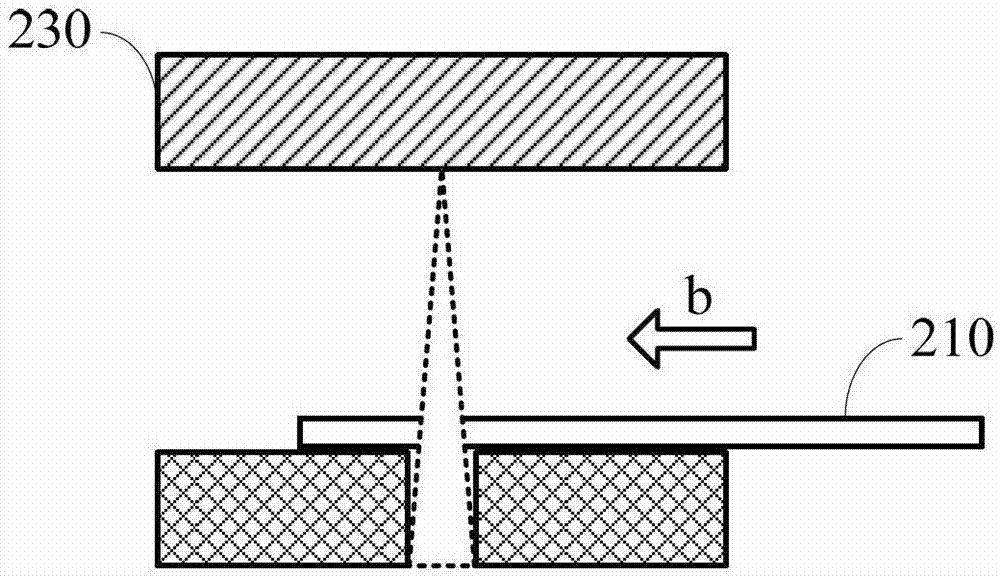

Defect detection method and device for display panel

InactiveCN103076344AImprove defect detection performanceAvoid missing detectionOptically investigating flaws/contaminationComputer science

The invention provides a defect detection method and device for a display panel. The detection method comprises the following steps: using various light of different colors to sequentially irradiate the display panel; acquiring a plurality of corresponding gray-scale pictures when the display panel is irradiated by the various light of different colors; and judging whether the display panel has defects or not, and the result is yes when the plurality of gray-scale pictures have gray-scale differences. Through the method, the defect detection capability of an optical defect detector to the display panel is improved and undetected errors are avoided.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

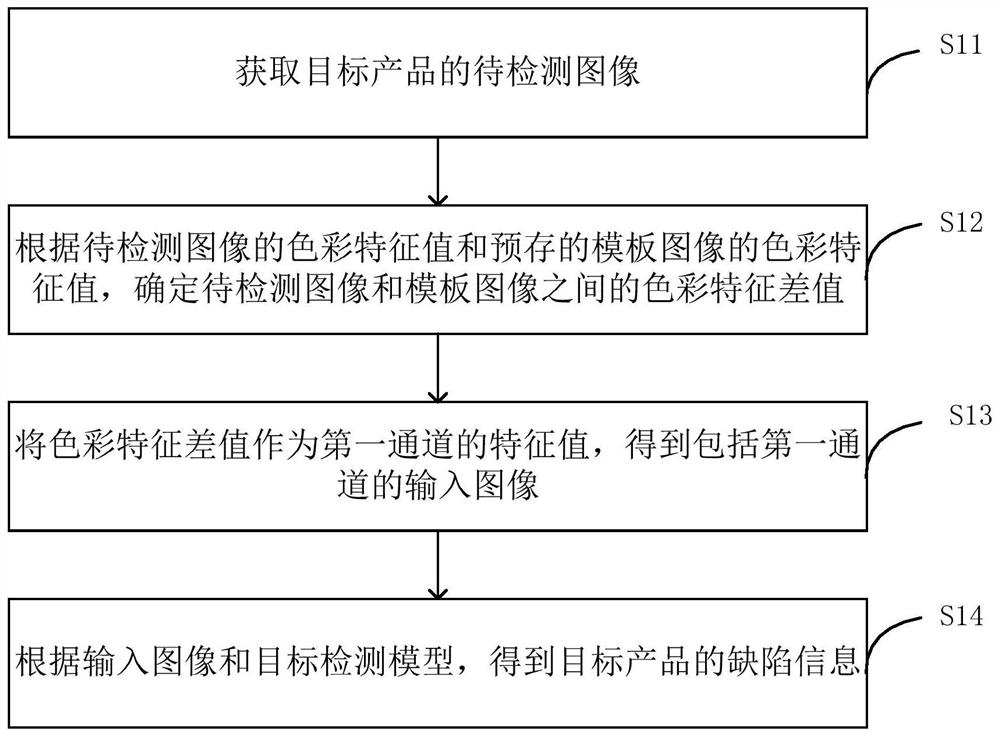

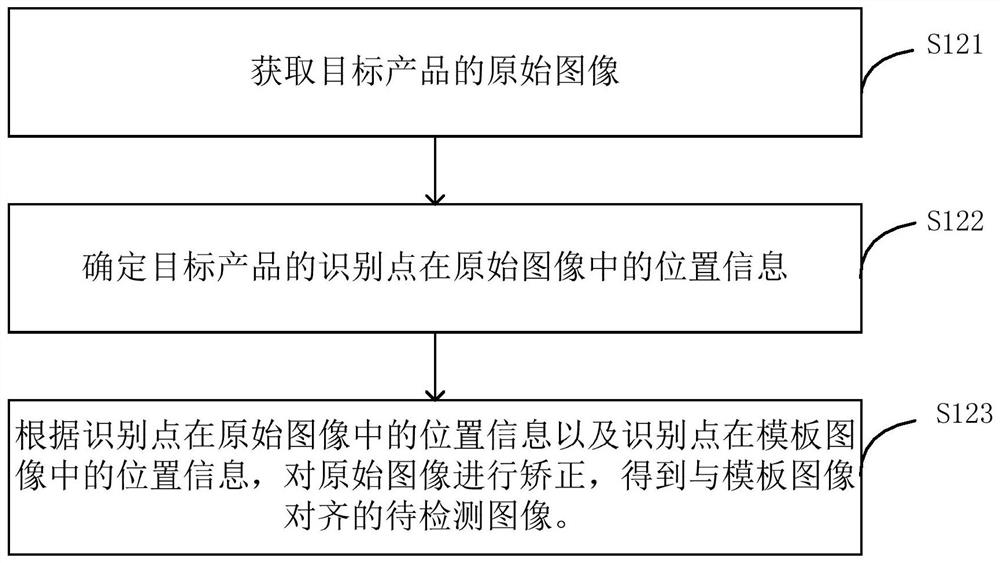

Product defect detection method and device, electronic equipment and storage medium

PendingCN111986178AImprove defect detection performanceEasy to understandImage enhancementImage analysisEngineeringProduct defect

The invention discloses a product defect detection method and device, electronic equipment and a storage medium, and relates to the fields of computer vision, image processing, deep learning and the like. According to the specific implementation scheme, the method includes obtaining a to-be-detected image of a target product; determining a color feature difference value between the to-be-detectedimage and a template image according to the color feature value of the to-be-detected image and a pre-stored color feature value of the template image; taking the color feature difference value as a feature value of the first channel to obtain an input image comprising the first channel; and obtaining defect information of the target product according to the input image and the target detection model. According to the embodiment of the invention, the defect detection effect on products with small sizes and weak texture features in an industrial scene can be improved.

Owner:BEIJING BAIDU NETCOM SCI & TECH CO LTD

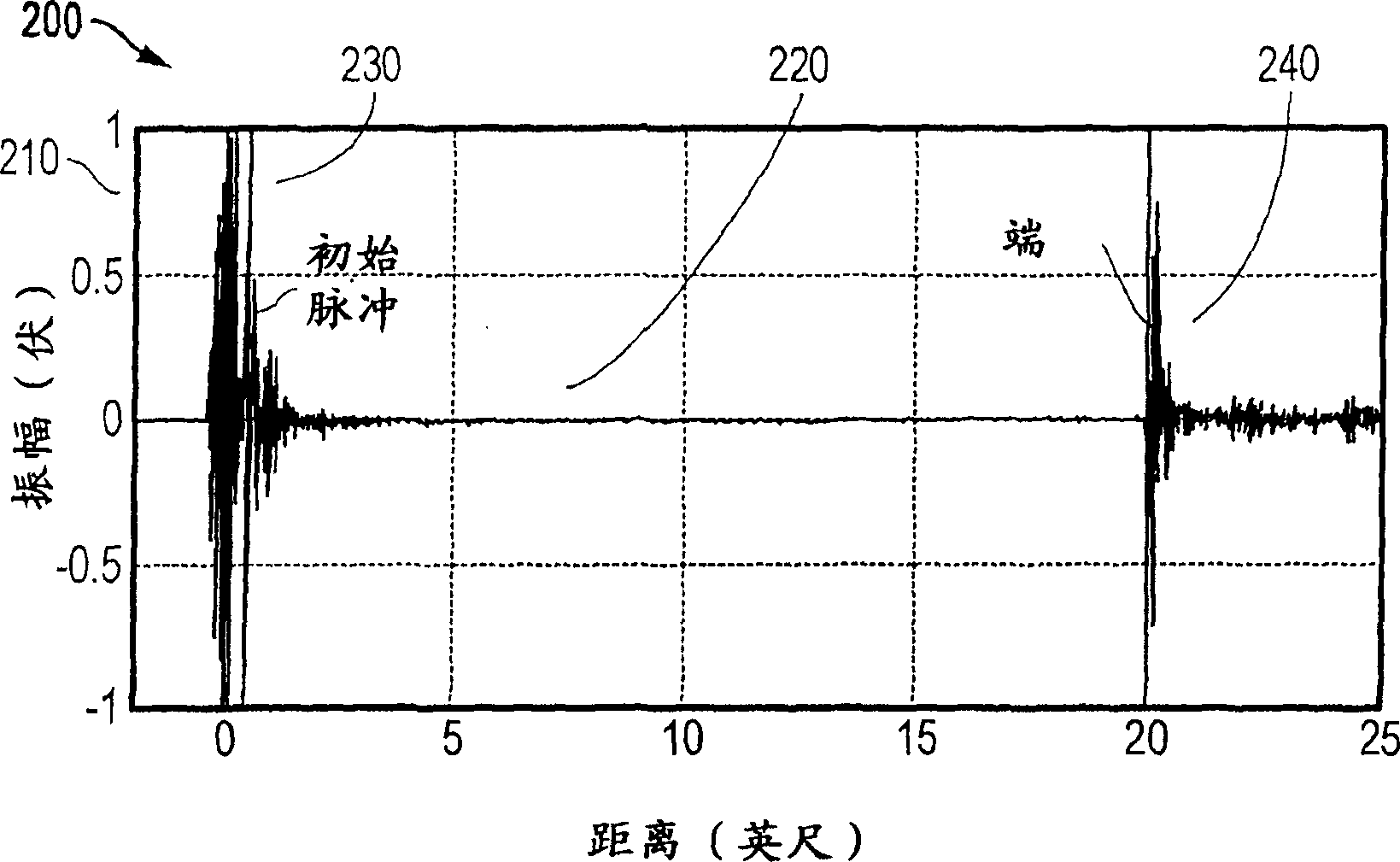

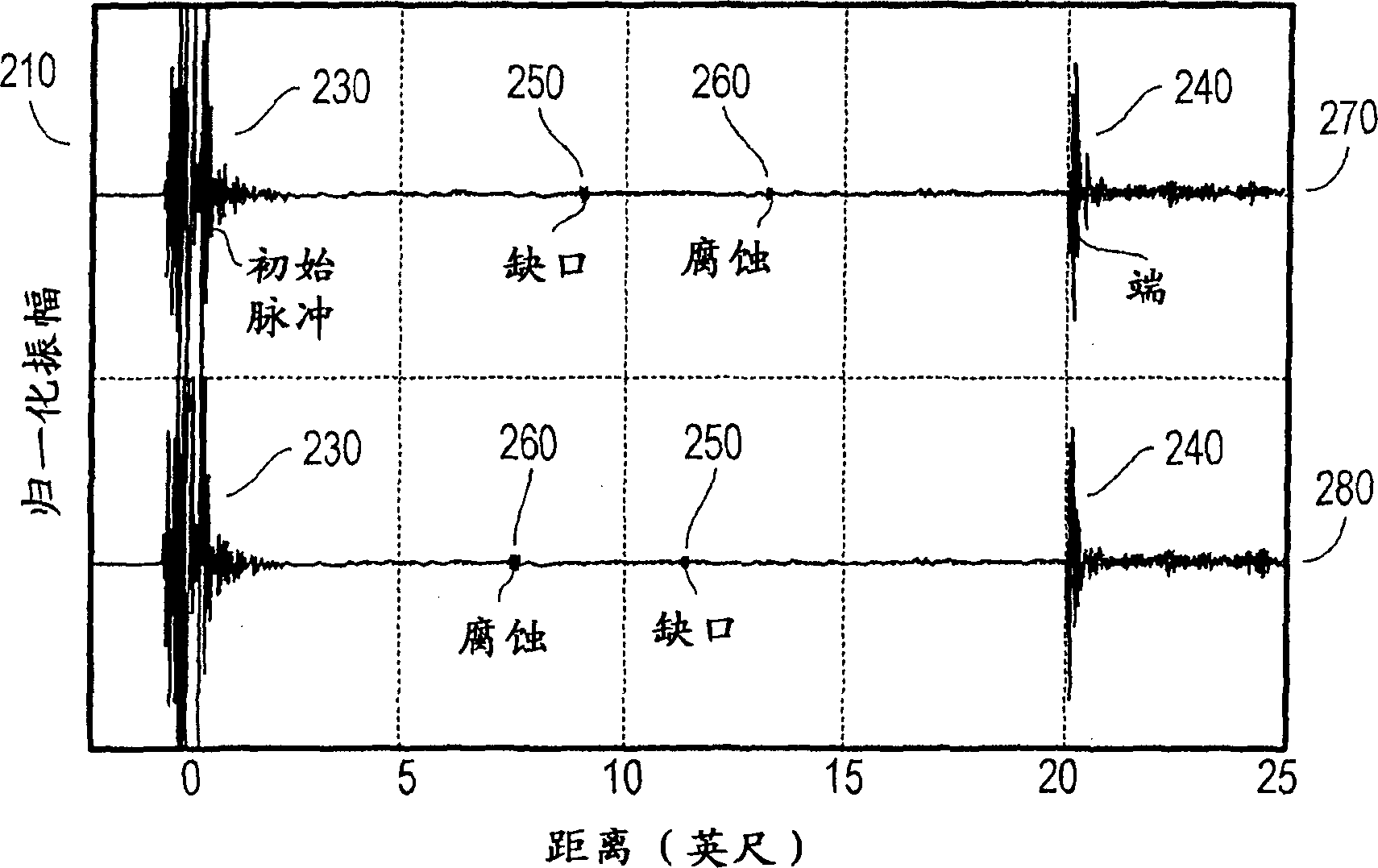

Method and system for torsional wave inspection of heat exchanger tubes

InactiveCN1898558ALow dispersionEasy mode controlMachine part testingMechanical apparatusTorsional waveEngineering

The invention provides an improved method and device for inspecting heat exchanger tubes from within the tube inside diameter that overcomes the shortcomings of the prior art. It adapts a guided-wave probe approach that makes use of a torsional wave mode instead of a longitudinal wave node disclosed in the prior art. The torsional wave mode has many advantages over the longitudinal wave mode for detecting defects. When energized by suitable instrumentation, the probe is caused to generate a torsional mode signal that is transmitted to the heat exchanger tube from the waveguide tube. When reflected signals from defects in the heat exchanger tube walls are returned to the inspection opening end of the heat exchanger tube, the reflected defect signals are transmitted to the probe waveguide tube for amplification, detection and characterization of the reflected signal.

Owner:SOUTHWEST RES INST

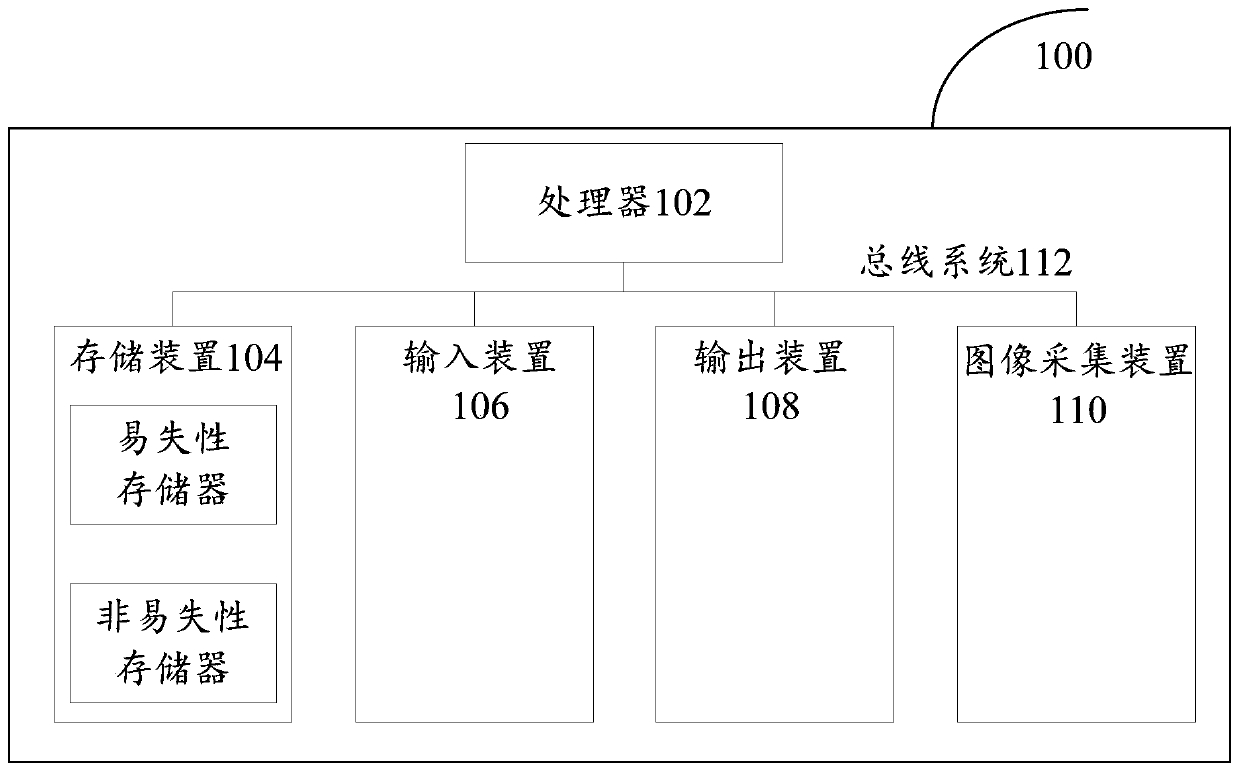

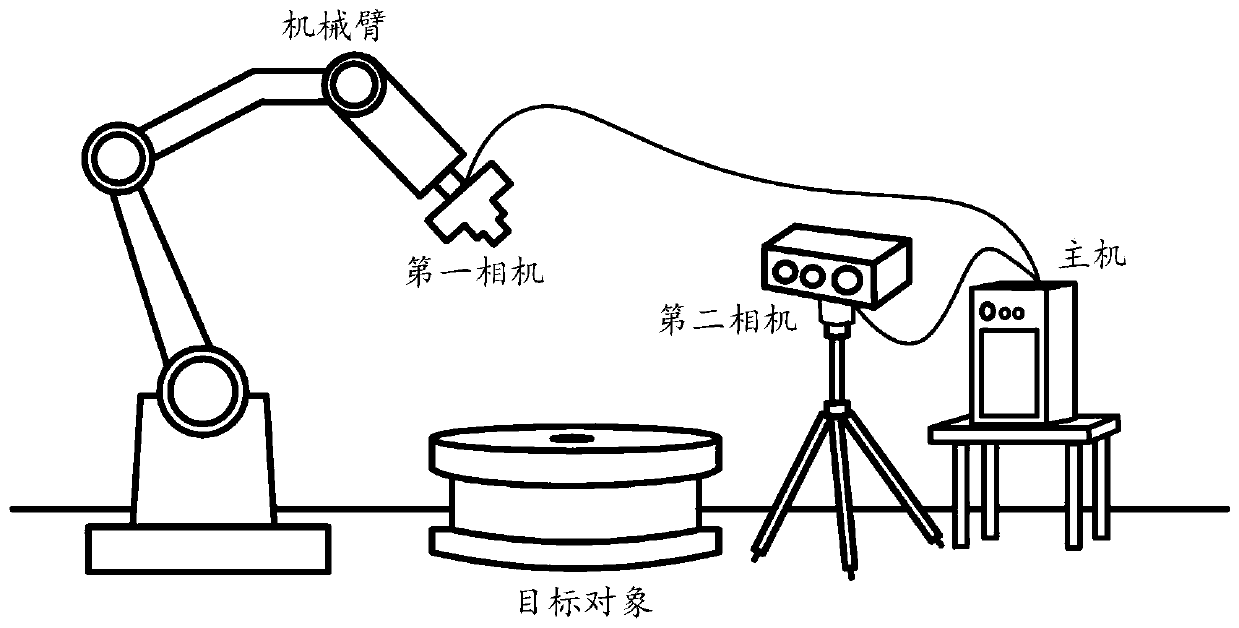

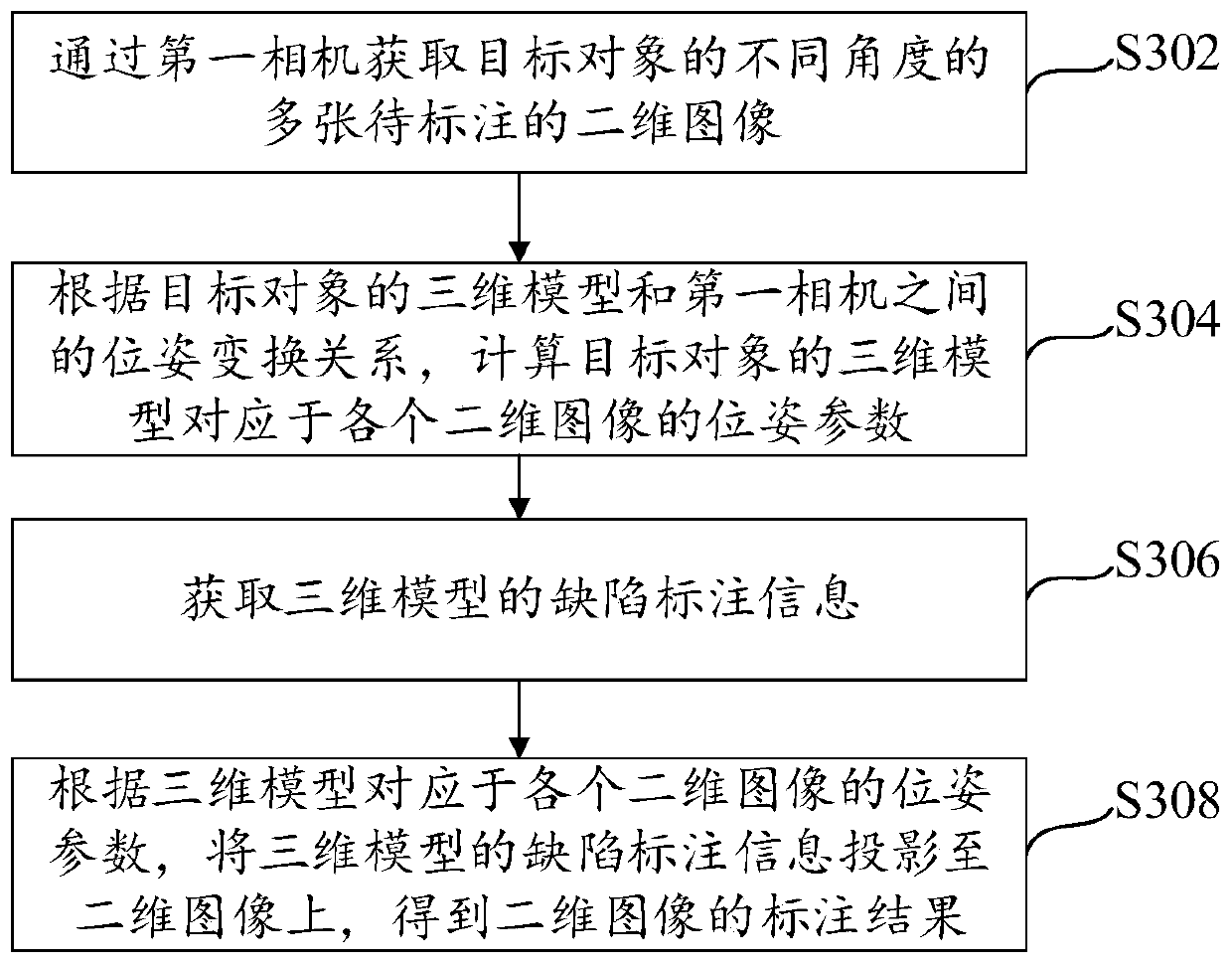

Image labeling method, device and system and host

PendingCN111127422AUniform qualityImprove defect detection performanceImage analysis3D modellingImaging processingPoint cloud

The invention provides an image annotation method, device and system and a host, and relates to the technical field of image processing, and the method comprises the steps: obtaining a plurality of to-be-annotated two-dimensional images of a target object at different angles through a first camera; calculating pose parameters of the three-dimensional model of the target object corresponding to each two-dimensional image according to a pose transformation relationship between the three-dimensional model of the target object and the first camera; wherein the three-dimensional model is a model during modeling of the target object or a model constructed based on three-dimensional point cloud data of the target object; acquiring defect labeling information of the three-dimensional model; and projecting defect labeling information of the three-dimensional model to the two-dimensional images according to the pose parameters of the three-dimensional model corresponding to the two-dimensional images to obtain labeling results of the two-dimensional images. The labeling efficiency can be effectively improved, the labeling cost is reduced, and the quality of labeling results can be well unified, so that the defect detection effect of parts can be improved.

Owner:BEIJING KUANGSHI TECH CO LTD

Outer package defect detection method

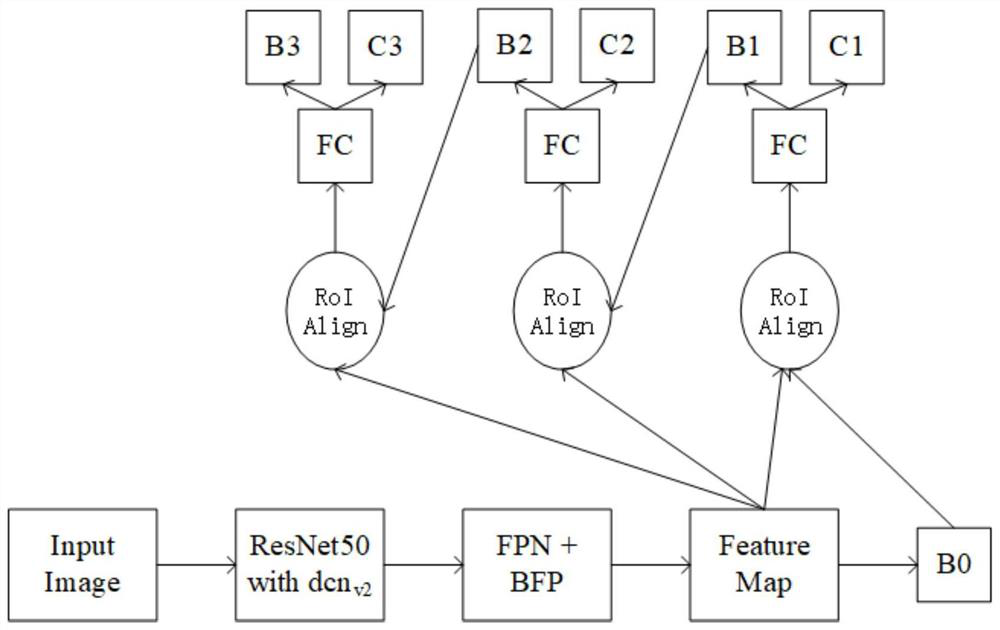

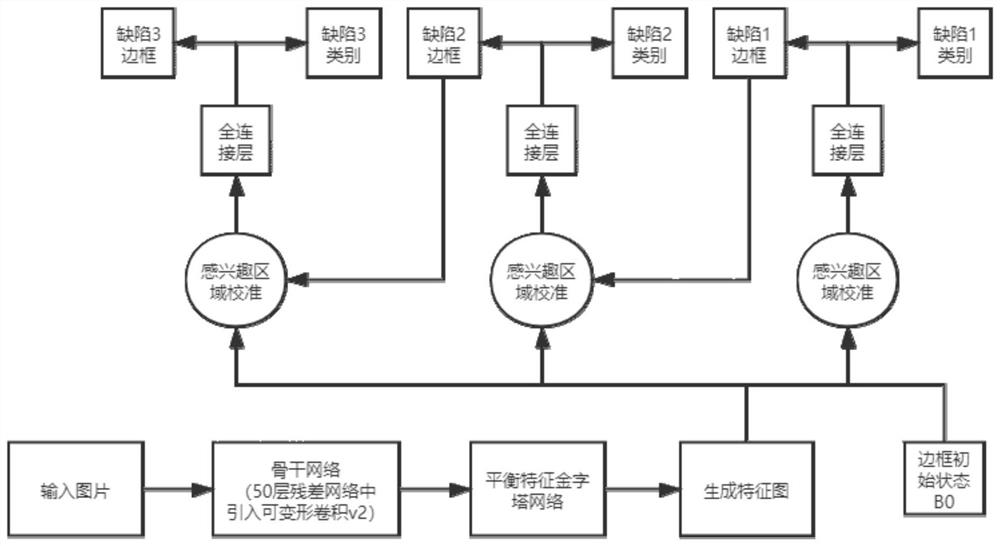

PendingCN112508090AImprove feature extractionUneven solutionCharacter and pattern recognitionNeural architecturesCluster algorithmData set

The invention provides an outer package defect detection method. The method comprises the steps of obtaining an outer package picture as a data set; performing data preprocessing on the data set; setting the size of a defect target candidate box through a clustering algorithm; inputting the preprocessed data set into a Cascade R-CNN model, and performing region-of-interest extraction on the data set; normalizing the size of the feature map of the region of interest; in the Cascade R-CNN model, adopting a pre-trained ResNet-50 with a deformable convolution v2 as a backbone network, carrying outconvolution, and extracting features; and S44, framing out defects and marking defect categories. The outer package defect detection method is simple in calculation process and capable of rapidly positioning and recognizing defects, the FPN feature extraction method is adopted, features with different resolutions are combined, the combined features are used for enhancing multi-level features in FPN, and recognition is more accurate.

Owner:CHONGQING UNIV

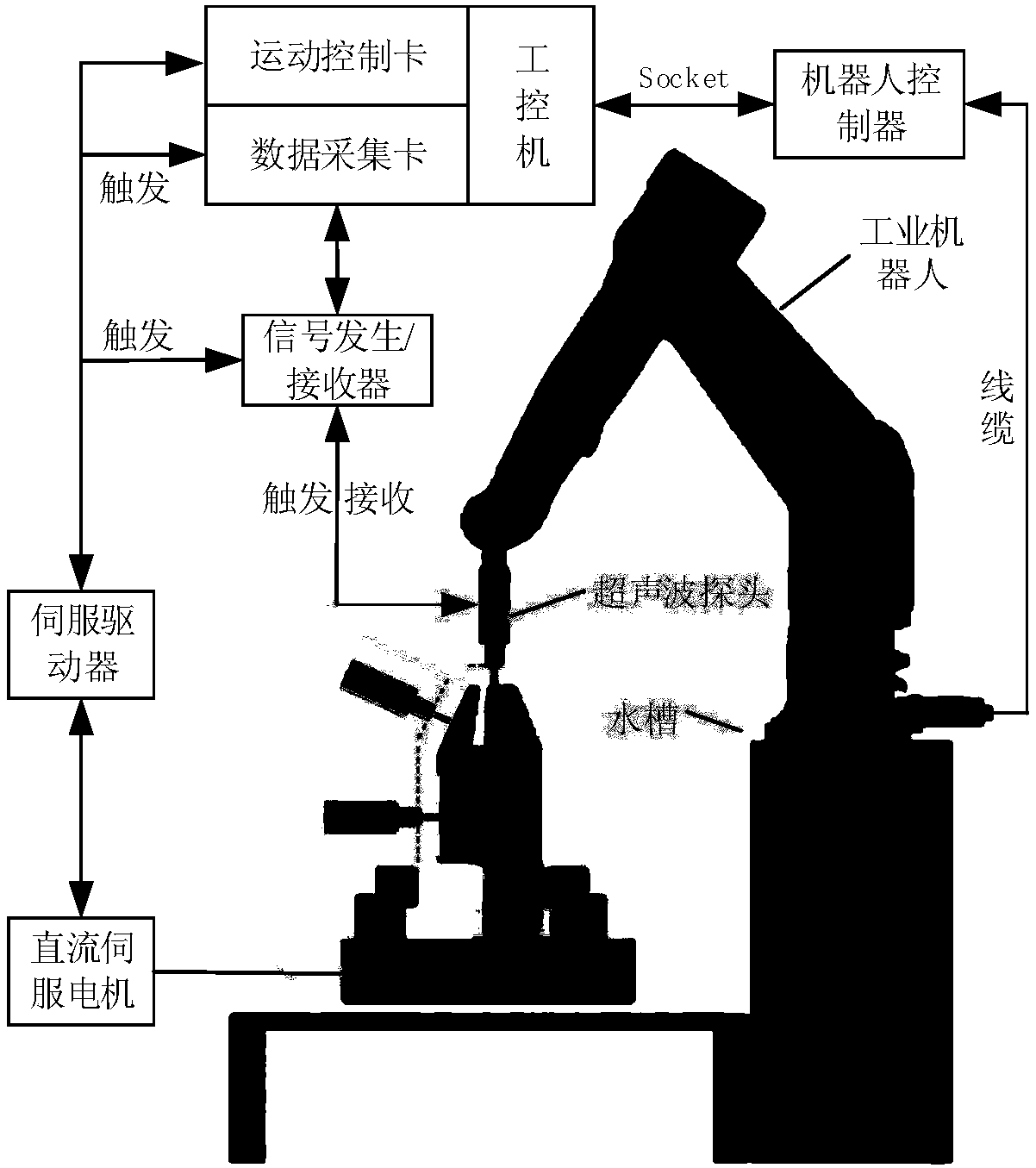

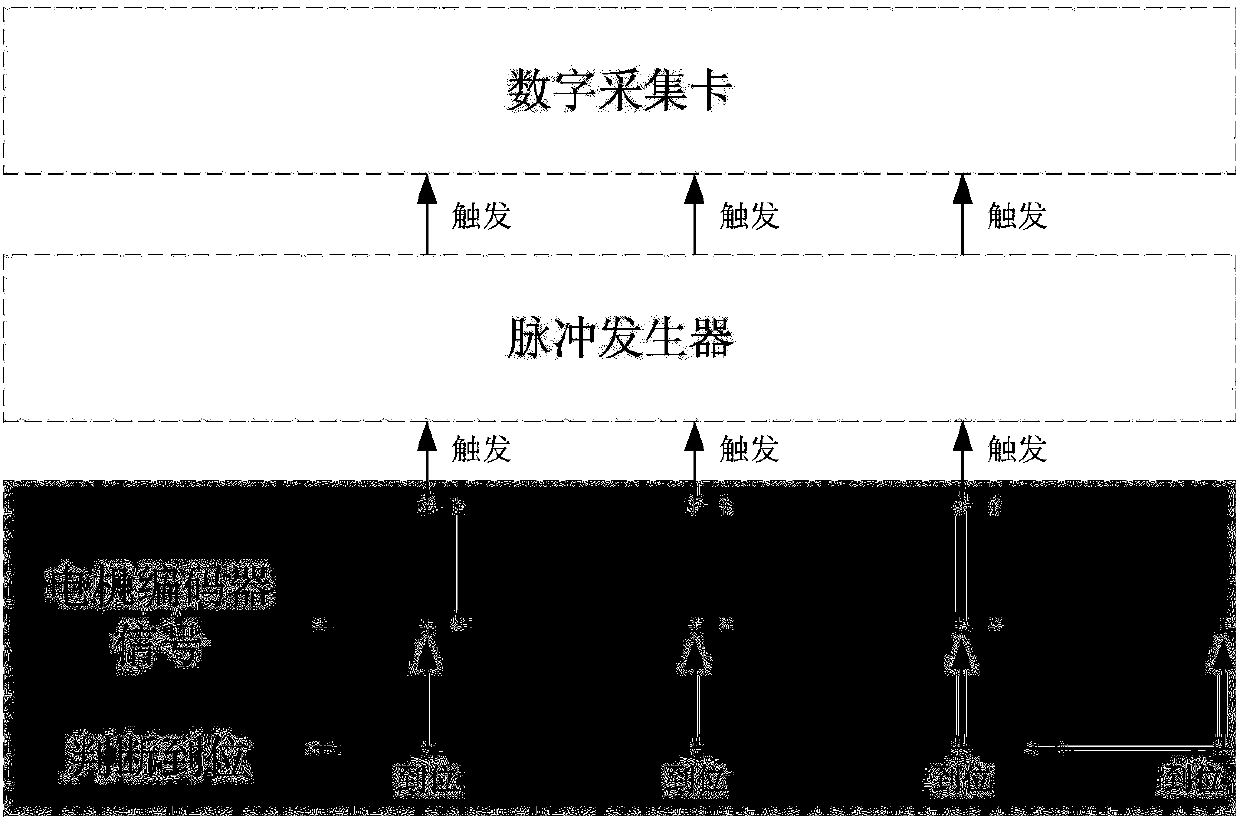

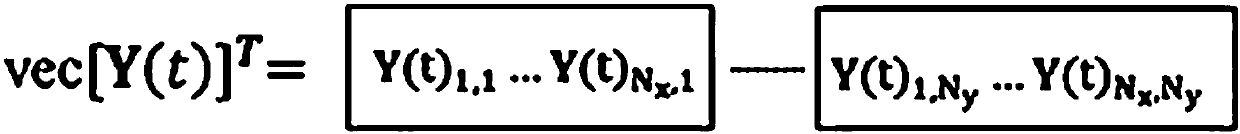

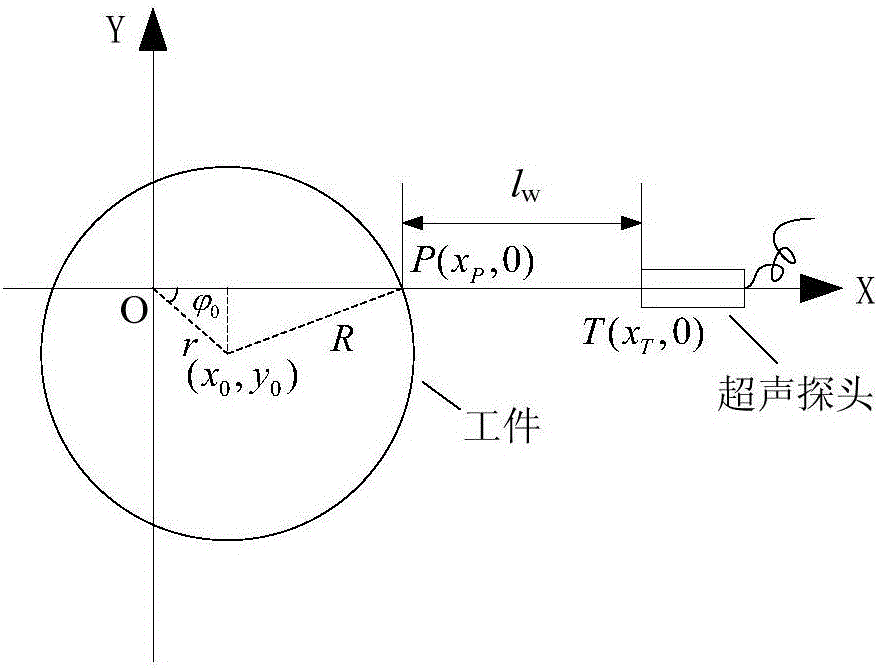

Ultrasonic automatic detection method capable of considering workpiece clamping error correction

ActiveCN106990171AIncreased ultrasonic energyImprove defect detection capabilitiesAnalysing solids using sonic/ultrasonic/infrasonic wavesTransformation matrixUltrasound probe

The invention discloses an ultrasonic automatic detection method capable of considering workpiece clamping error correction. Under the condition that a clamping error exists in the workpiece, an industrial robot carries an ultrasonic probe to perform C scanning detection route correction to realize clamping error compensation. The method particularly comprises the following steps: identifying the actual clamping error of the workpiece through a change rule of water sound distance along with time in the rotating process of the workpiece, calculating a route transformation matrix from a workpiece coordinate system to a world coordinate system, and performing route transformation calculation on a scanning target route under the workpiece coordinate system to obtain a moving route of a probe under the world coordinate system to obtain the corrected probe moving route.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH +1

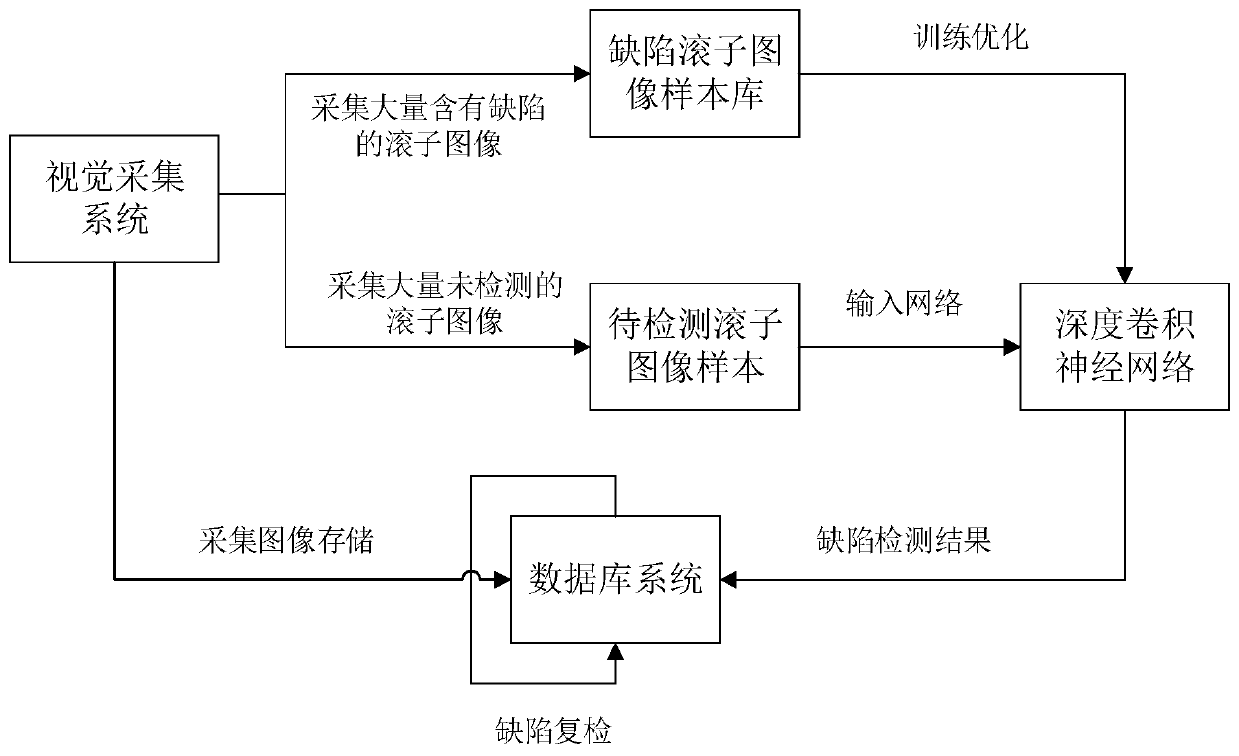

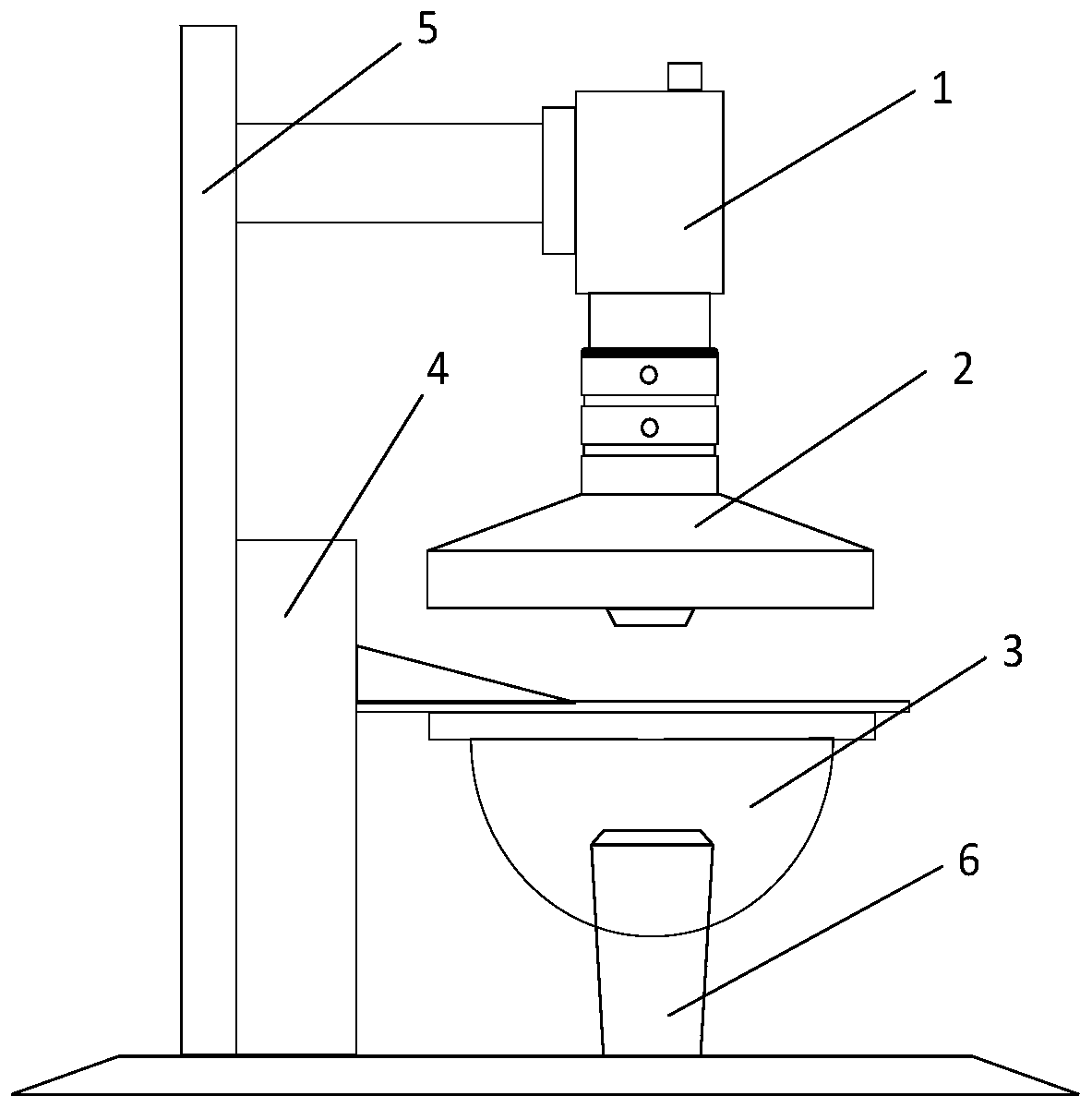

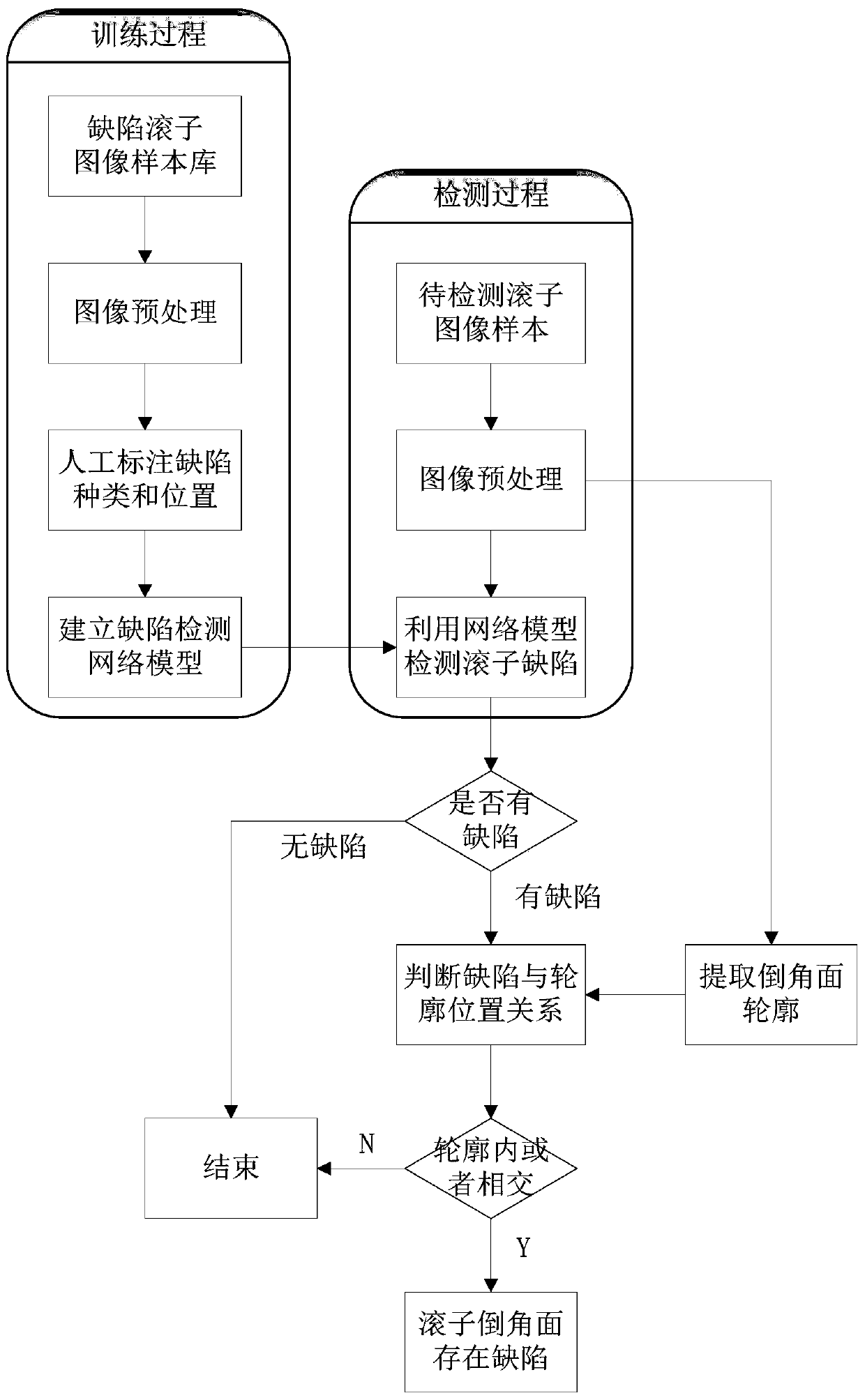

Bearing roller chamfering surface defect detection method based on machine vision

InactiveCN110927171AImprove detection efficiencyImprove stabilityImage enhancementImage analysisMachine visionAlgorithm

The invention discloses a bearing roller chamfered surface defect detection method based on machine vision. Aiming at the chamfering surface defect problem of the bearing roller in the production andtransportation process, a chamfering surface image of the bearing roller is collected, a chamfering surface missing part detection model is established by utilizing a deep learning algorithm based ona deep convolutional neural network, and rapid detection and position positioning of the chamfering surface defect are realized. According to the method, the deep learning model and the machine visionalgorithm are used for detecting the bearing roller chamfer defects in real time, the method has the advantages of being rapid in detection, accurate in positioning and high in recognition accuracy,a traditional manual detection method can be replaced, and the requirement for roller defect detection automation is met.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

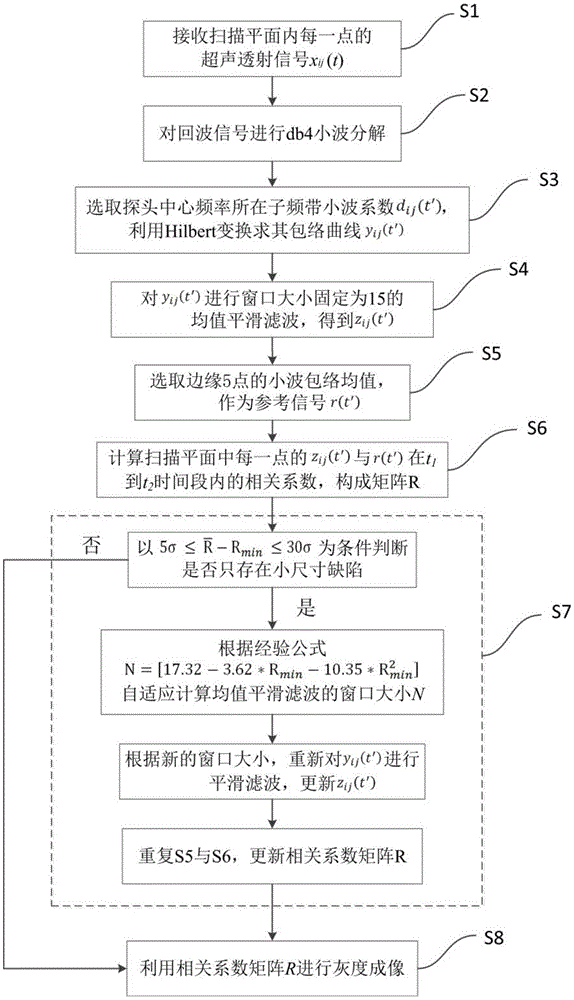

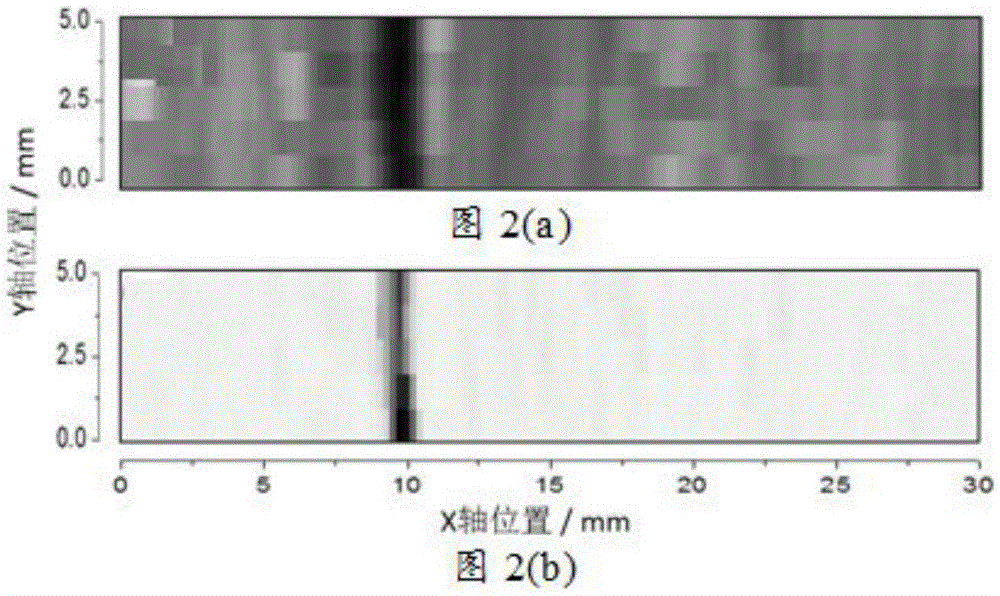

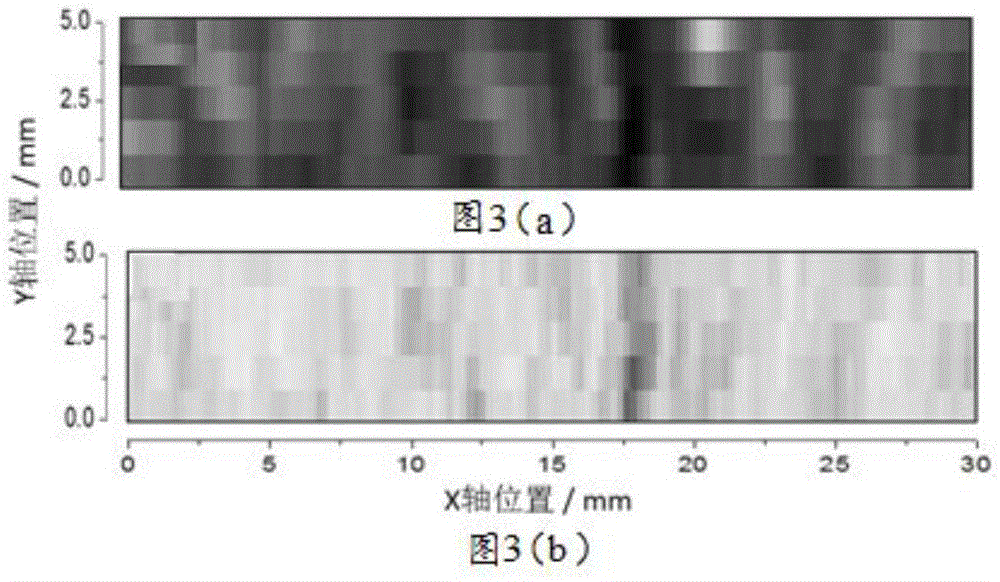

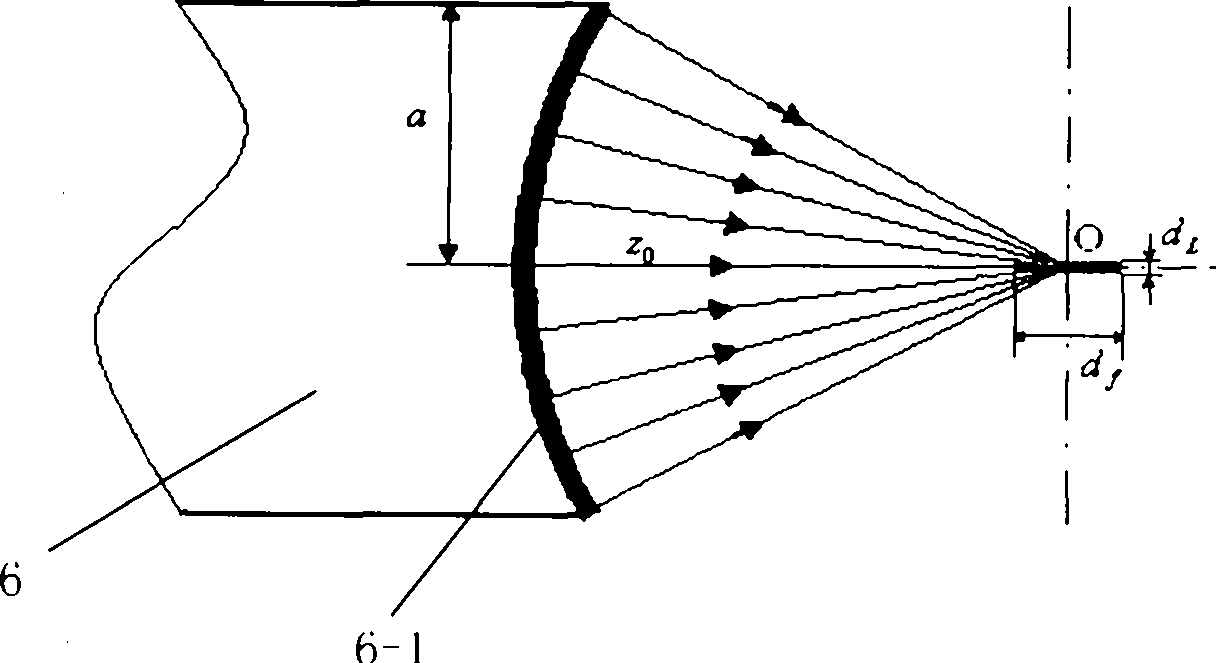

Air-coupled ultrasonic imaging method based on wavelet analysis and related algorithms

ActiveCN105572224AImprove image signal-to-noise ratioRemove Gaussian White NoiseAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalSonificationSignal-to-quantization-noise ratio

The invention discloses an air-coupled ultrasonic imaging method based on wavelet analysis and related algorithms. Imaging is carried out by using wavelet coefficients of a sub-band and related coefficients of a reference signal as characteristic quantities, enabling effective elimination measurement-induced white Gaussian noise and strength fluctuation noise of air-coupled ultrasonic transmitting signals and improving signal to noise ratio of an image. Meanwhile, whether small size defects exist or not is judged through minimum values of related coefficients, thus adaptively adjusting a smooth filter window, the size of the smooth window is enlarged upon a large defect size, thereby reducing background noise, the size of the window is reduced upon a small defect size, highlighting signal details and thereby implementing 'adaptive focusing' and improving the ability to detect small defects. The imaging method has a promising application prospect in the field of air-coupled ultrasonic detection.

Owner:GUANGDONG INST OF INTELLIGENT MFG

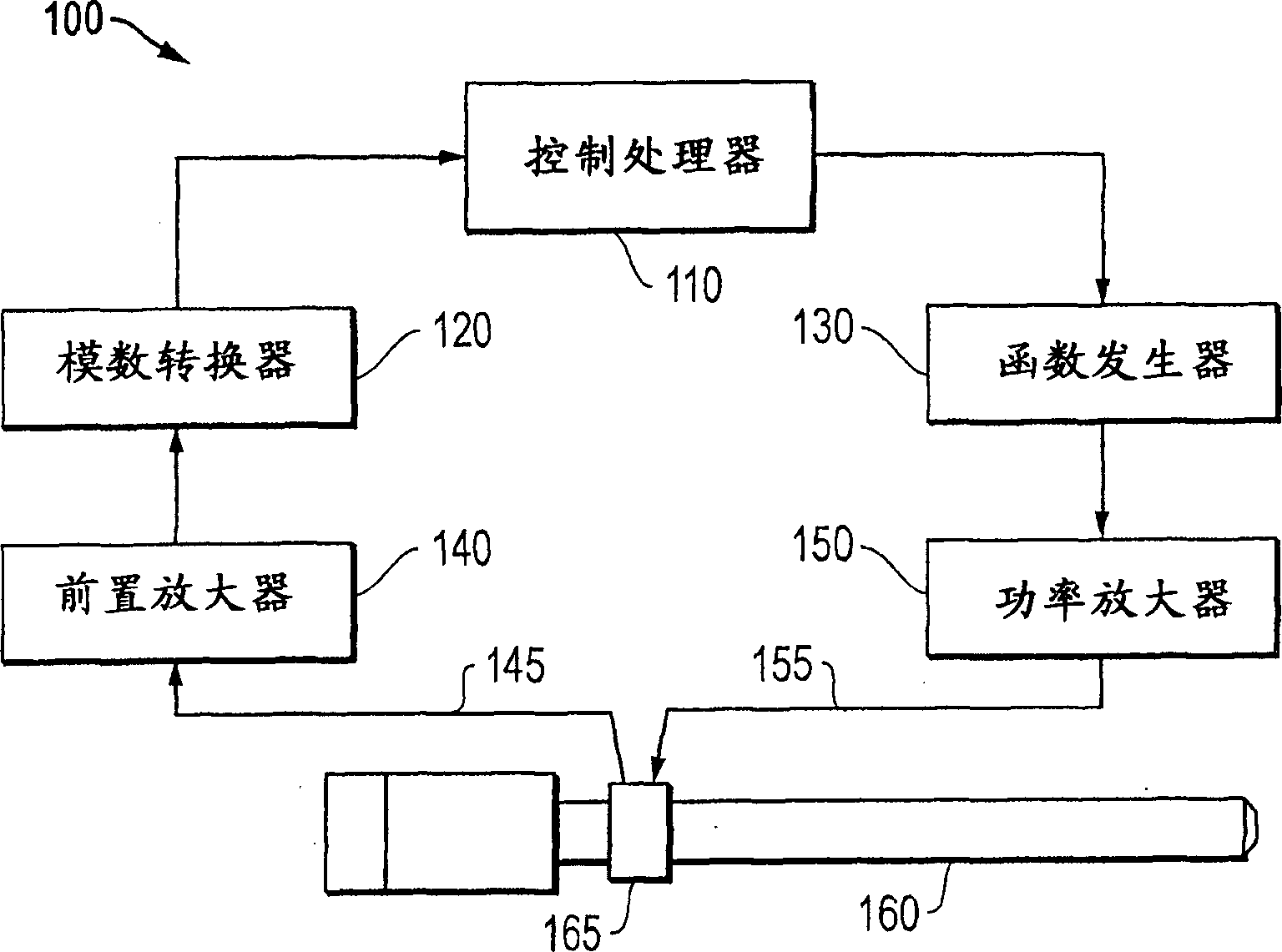

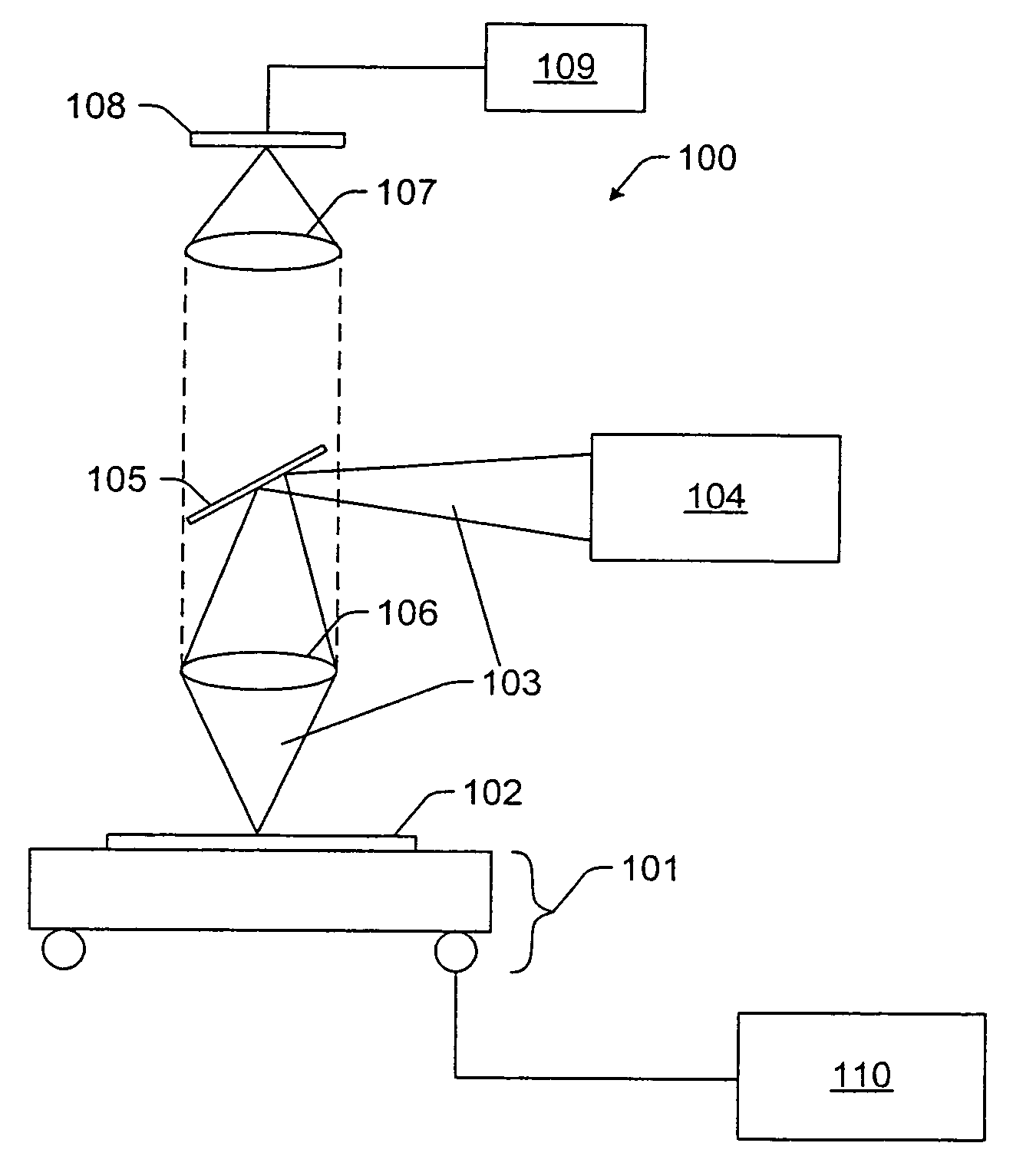

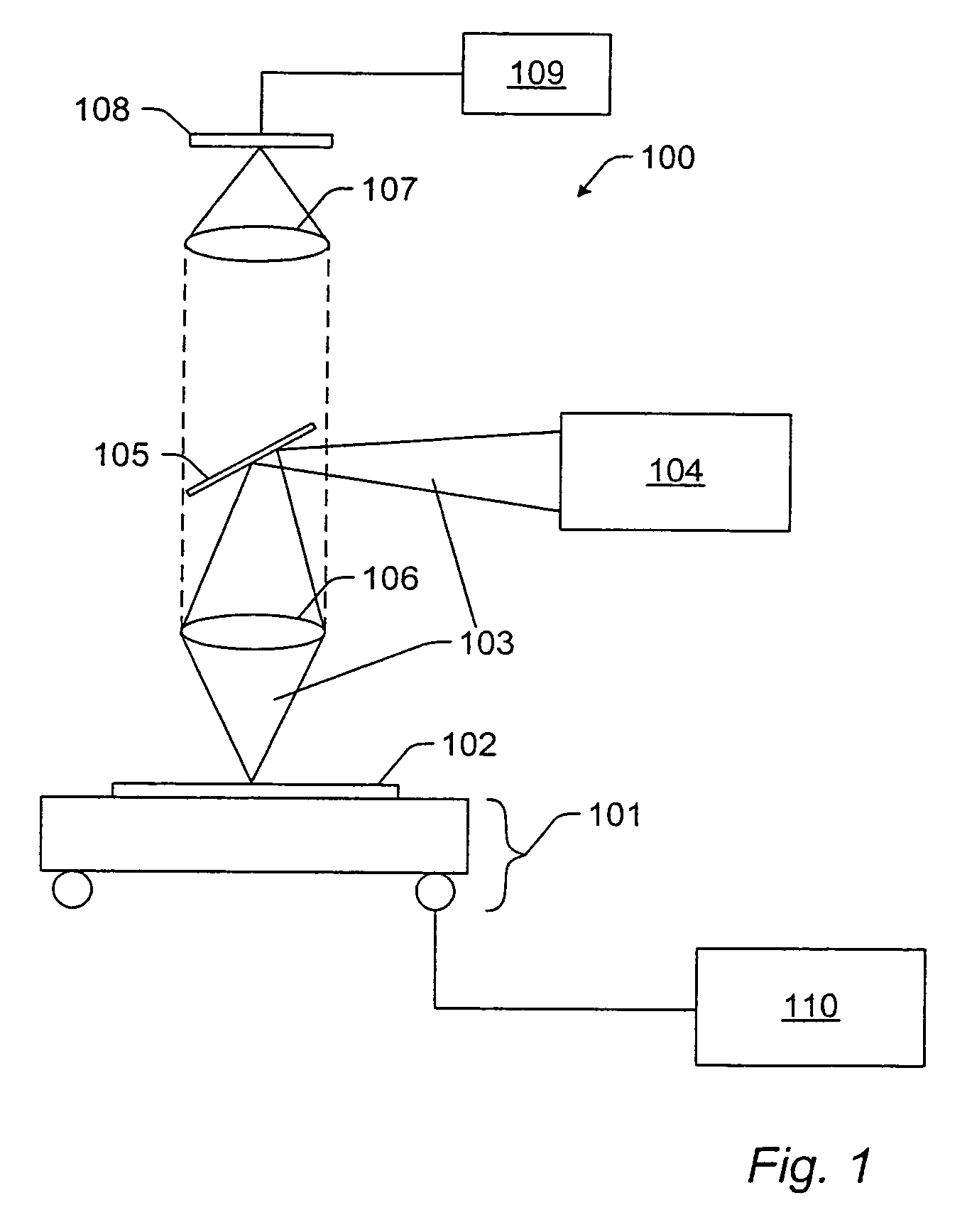

Optical inspection with alternating configurations

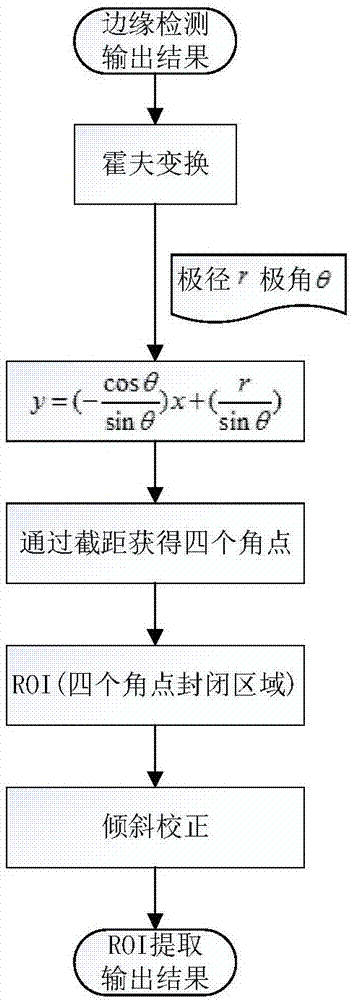

ActiveUS7397552B2Improve defect detection performanceMaterial analysis by optical meansOptical radiationVisual inspection

An imaging system for inspection of a sample includes an illumination module, which irradiates a surface of the sample with pulsed optical radiation. A mechanical scanner translates at least one of the sample and part of the imaging system so as to scan an area irradiated by the pulsed optical radiation over the surface in order to irradiate successive, partially overlapping frames on the surface by respective successive pulses of the pulsed radiation. A collection module collects the optical radiation scattered from the surface so as to capture a sequence of images of the irradiated frames. A system controller varies a configuration of the imaging system in alternation between at least first and second different optical configurations in synchronization with the pulsed optical radiation.

Owner:APPL MATERIALS ISRAEL LTD

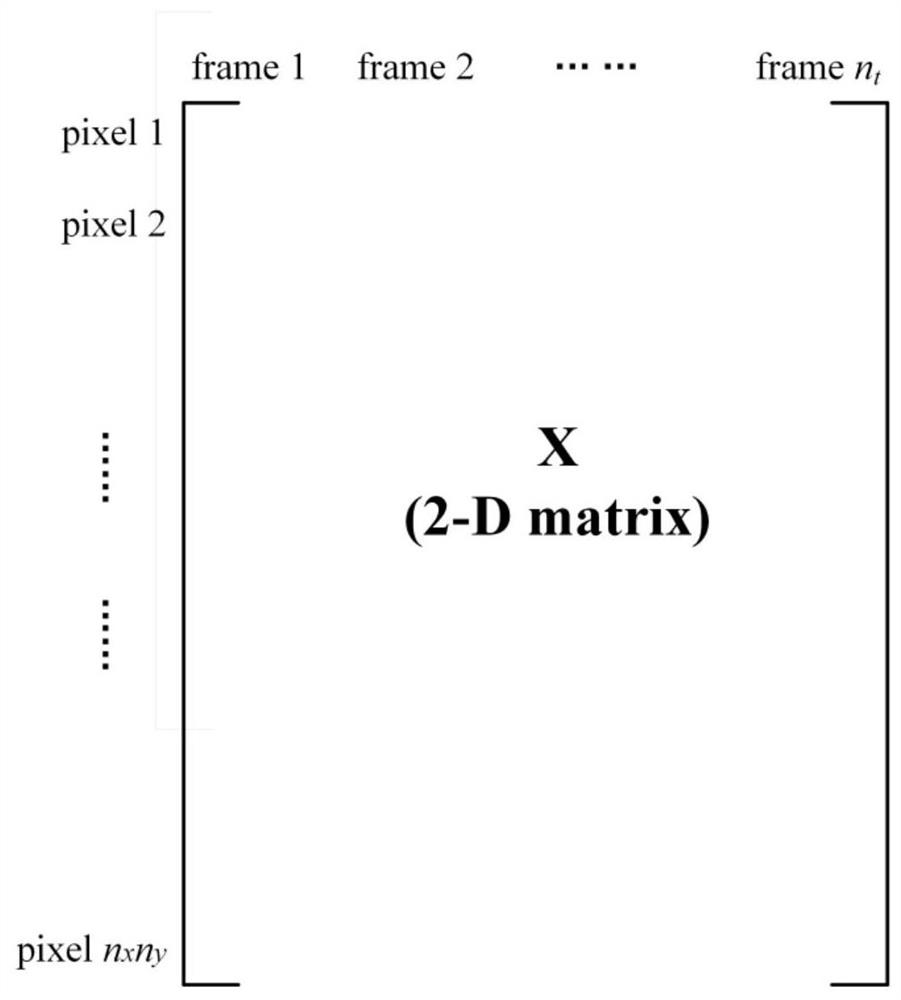

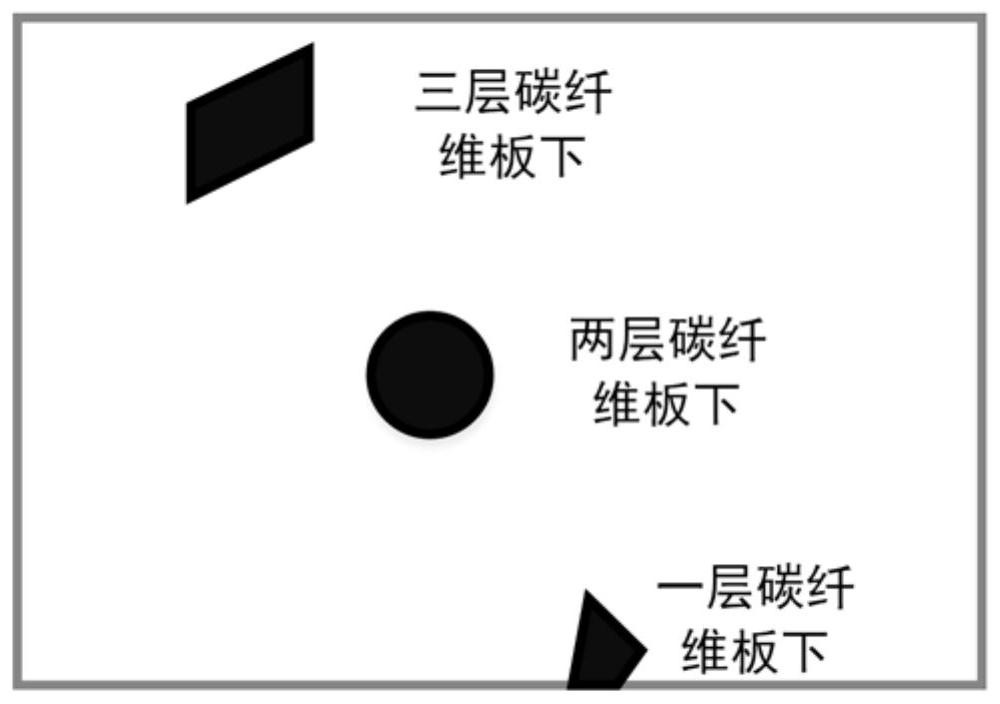

Microwave thermal imaging nondestructive testing system based on matrix decomposition and testing method

PendingCN107782748AGood heating uniformityImprove heating efficiencyFlaw detection using microwavesSpatial modelMicrowave detection

The invention relates to a microwave thermal imaging nondestructive testing system based on matrix decomposition. The nondestructive testing system comprises a microwave excitation device and a thermal imaging monitoring device, wherein the microwave excitation device comprises a microwave signal generator, a microwave signal amplifier, a microwave excitation sensor and a wave-absorbing material;the thermal imaging monitoring device comprises a thermal imager and a data acquisition and processing device; and the data acquisition and processing device is connected with the microwave signal generator and the thermal imager, so that temperature variation data of a measured objected is obtained. The microwave thermal imaging nondestructive testing system based on the matrix decomposition canbe used for solving the problems that fast imaging and separation are carried out on different types of defects, thermal spatial pattern feature extraction in a defect range is highlighted, an adjacent defect cannot be located and separated due to temperature aliasing and subsurface defect damage area is difficult to quantify effectively; and the problem of automatic separation on defects is solved, and fast imaging can be carried out on impact defect and damage area with different energy.

Owner:FUQING BRANCH OF FUJIAN NORMAL UNIV

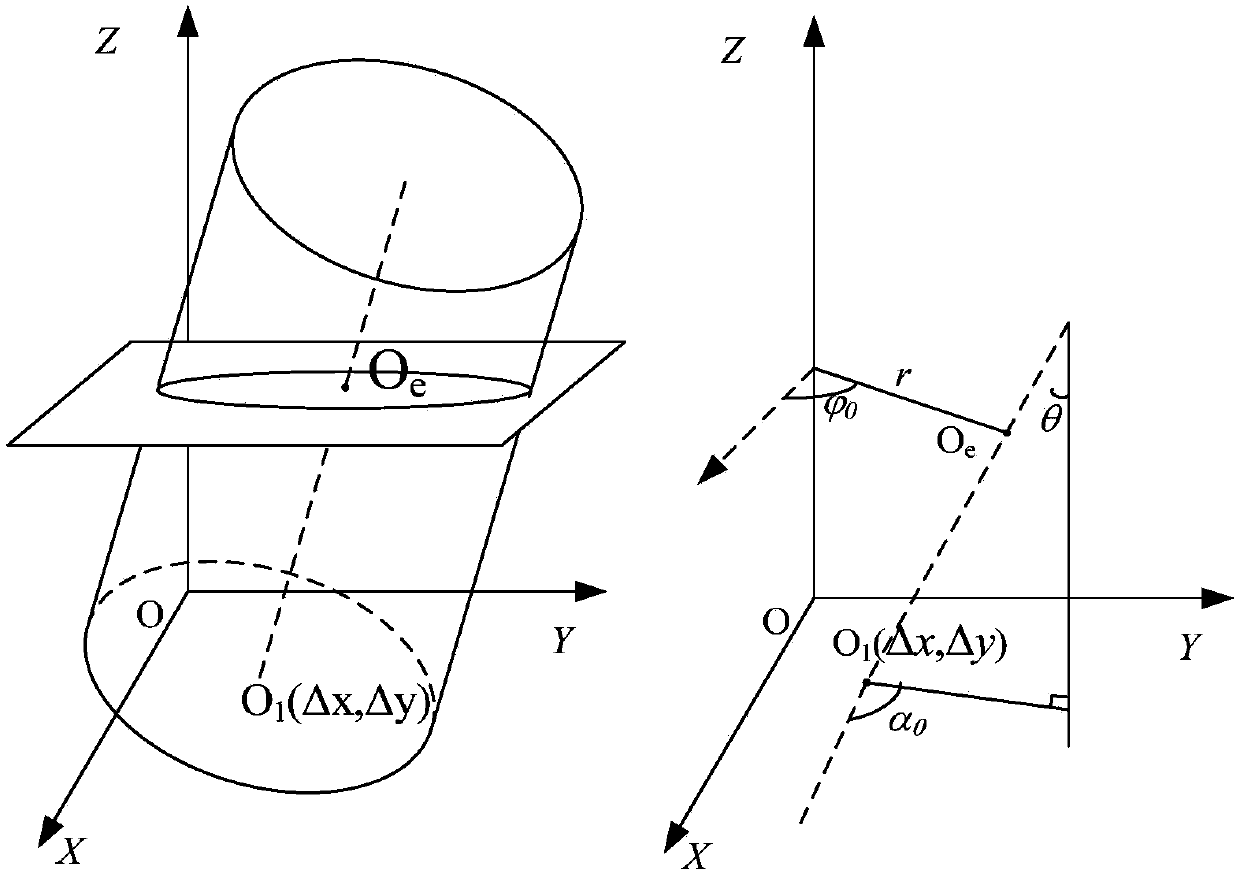

Ultrasonic C scanning path correcting method taking workpiece eccentric clamping errors into consideration

ActiveCN106290582ARealize full coverage scanningHigh precisionMaterial analysis using sonic/ultrasonic/infrasonic wavesLongitudinal waveCorrection method

The invention discloses a method for correcting and compensating ultrasonic C scanning paths under the circumstance that eccentric clamping between the center of a rotation body workpiece and a turnplate rotating shaft occurs when the ultrasonic longitudinal wave vertical incidence rotation body workpiece is adopted to detect inside defects. The method includes: detecting actual deviation of the workpiece through a fixed ultrasonic probe; calculating a path transformation matrix from a workpiece coordinate system to a world coordinate system; subjecting a scanning target path of the workpiece under the workpiece coordinate system to matrix transformation calculation to acquire moving paths of the probe under the world coordinate system.

Owner:CENT SOUTH UNIV

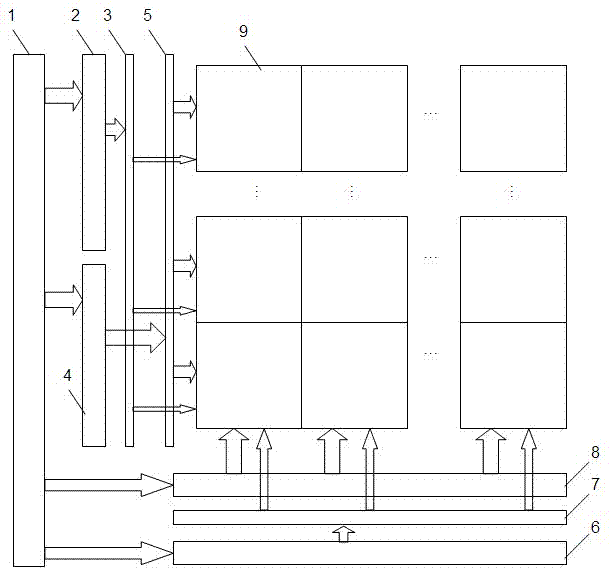

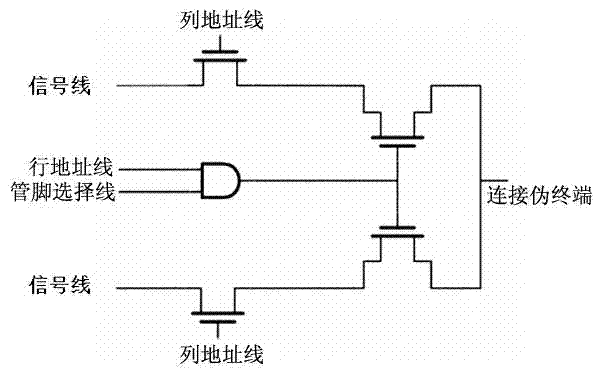

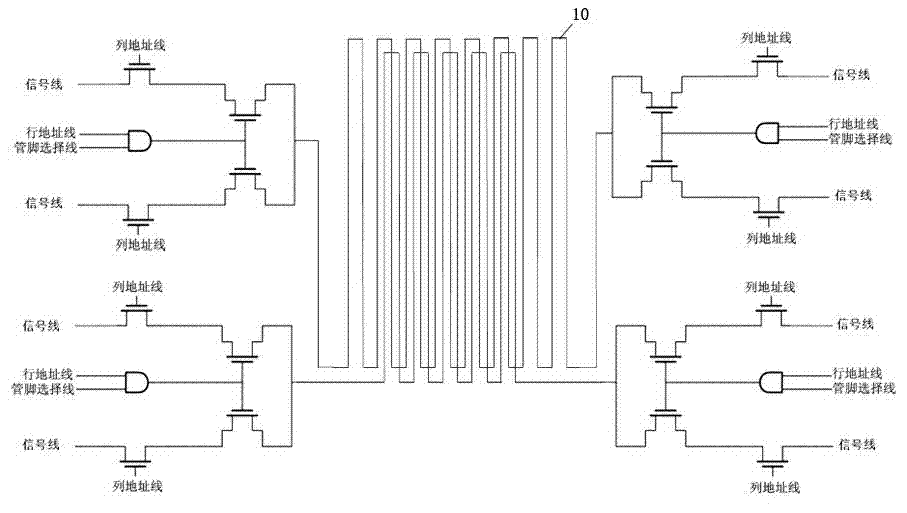

Addressable test chip and test method thereof

InactiveCN103811468AImprove defect detection capabilitiesReduce areaSemiconductor/solid-state device testing/measurementElectronic circuit testingTest structureSignal lines

The invention discloses an addressable test chip and a test method thereof. The test chip consists of an addressable circuit, a plurality of test frameworks and a plurality of test structure groups which are placed among the test frameworks, wherein the addressable circuit consists of a peripheral address decoding circuit and a plurality of switch circuits. The peripheral address decoding circuit consists of a row address decoding circuit, a column address decoding circuit and a pin selection decoding circuit. All the input ends of the row address decoding circuit, the column address decoding circuit and the pin selection decoding circuit are connected with a PAD set, and the output ends are connected with the switch circuits; the switch circuits are also connected to a PAD signal location by the plurality of signal lines; the switch circuits are connected with the test structure groups by the test frameworks. During test, the test frameworks are selected by row address signals and column address signals, signal selection pins are selected by pin selection signals, and test structures are tested by test signals. By means of the pin selection circuit, the addressable test chip and the test method can test the test structure group with a plurality of pins.

Owner:SEMITRONIX

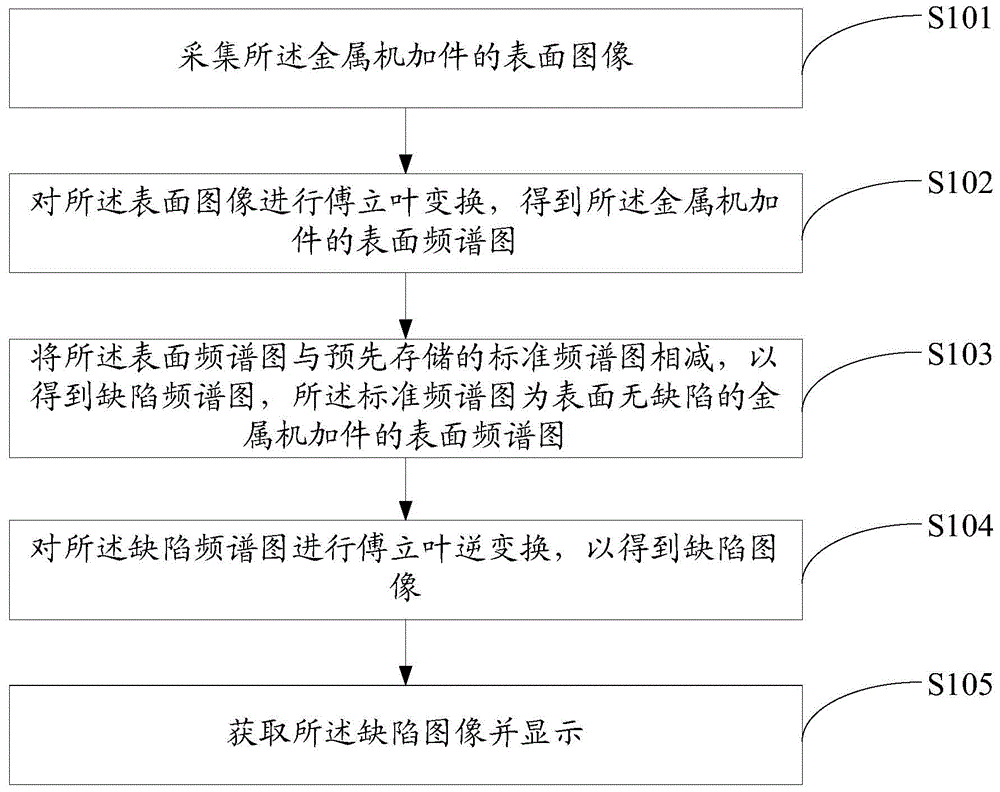

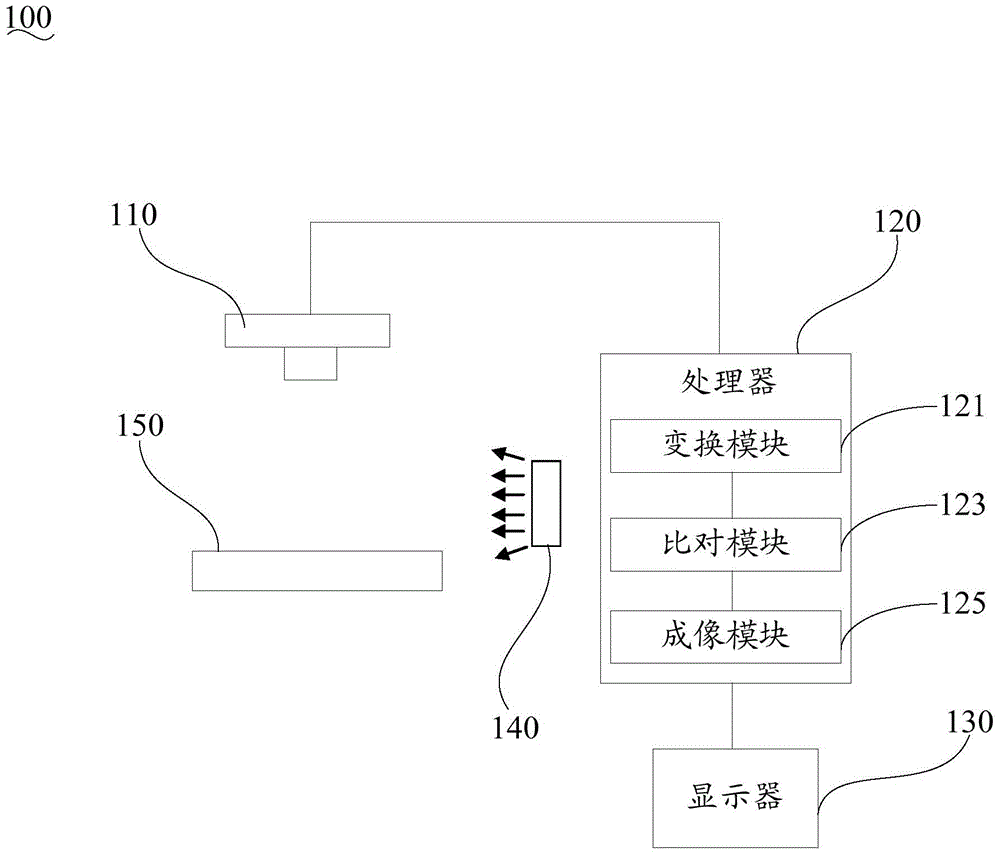

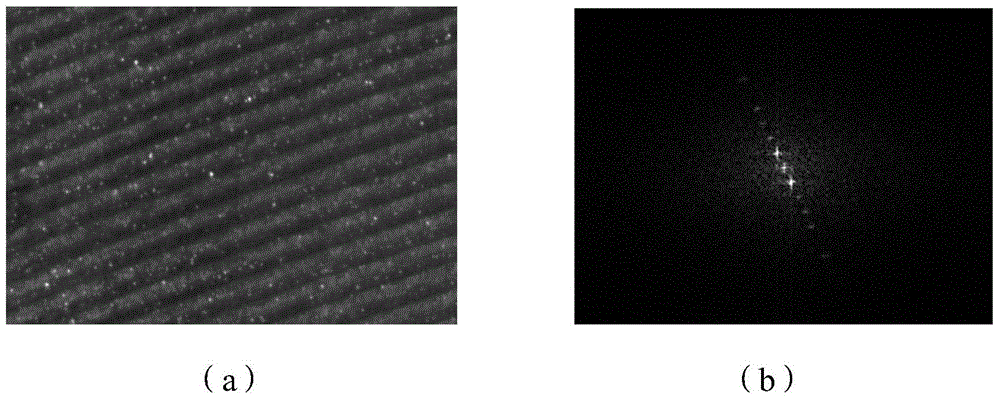

Detection device and method for surface defects

ActiveCN104101601AReduce distractionsImprove defect detection performanceOptically investigating flaws/contaminationFrequency spectrumMachine parts

The invention provides a detection method for surface defects. The detection method for surface defects comprises the following steps: the surface frequency spectrum of a metal machining part to be detected and the surface frequency spectrum of a metal machining part free of surface defects are subtracted, so as to obtain a frequency spectrum of defects; the frequency spectrum of defects is actually the frequency spectrum on which the frequency spectrum of the surface background of the metal machining part to be detected is removed; therefore, when the inverse Fourier transform is conducted on the frequency spectrum of the defects, the surface image on which the surface background of the metal machining part to be detected is removed is obtained; the surface image is displayed, the situation that whether the surface of the metal machining part to be detected has defects or not and the distribution of the defects can be clearly distinguished. Therefore, the detection device and the detection method for the surface defects can weaken the interferences of the surface background of the metal machining part to the detection process; the effect of the defect detection is improved and the speed of defect detection is increased. Moreover, the invention further provides a detection device for the surface defects.

Owner:HANS LASER TECH IND GRP CO LTD +1

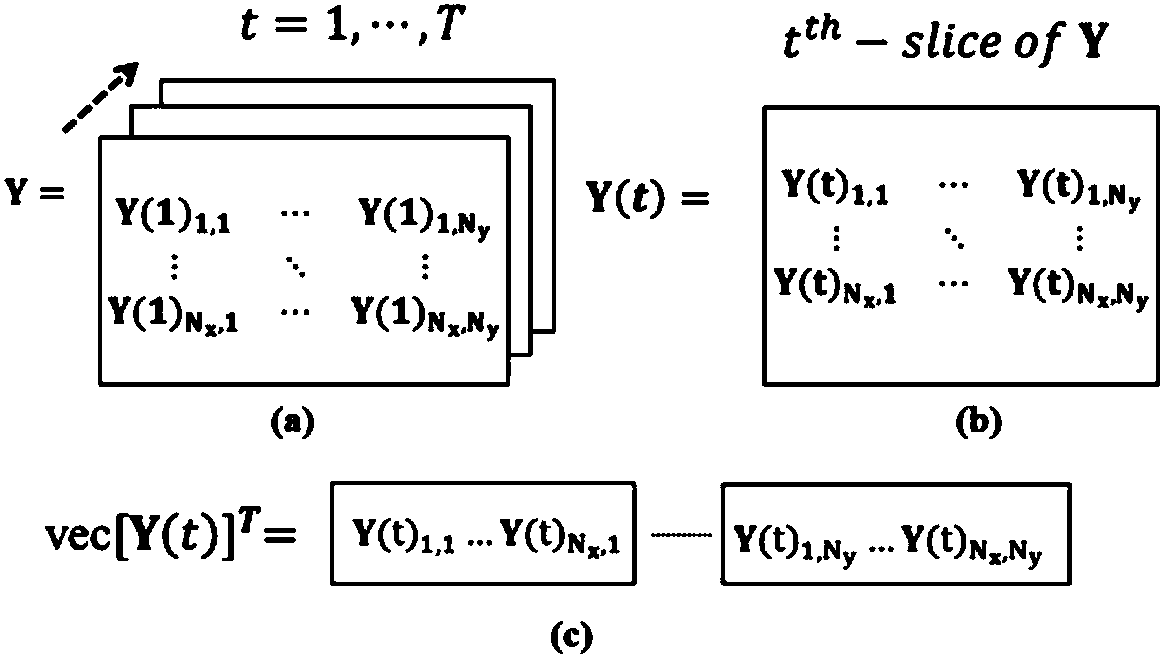

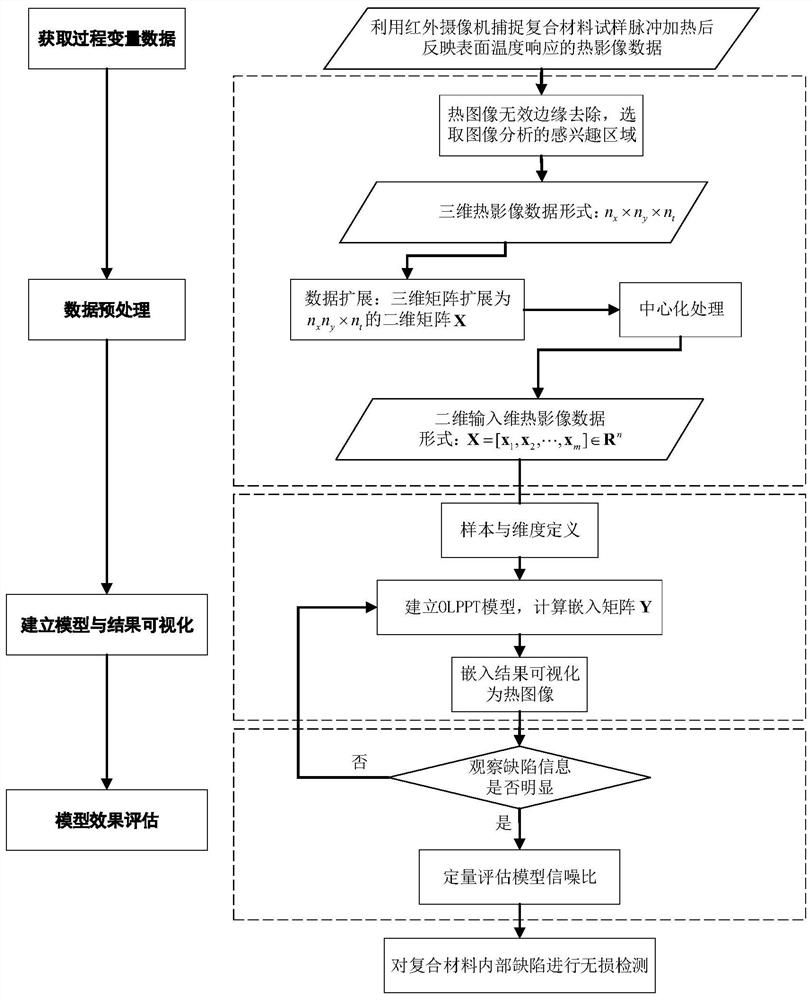

Infrared thermal image analysis method for nondestructive testing of defects of composite material

ActiveCN112461892AAbility to Facilitate Internal Defect IdentificationAbility to facilitate defect identificationRadiation pyrometryMaterial flaws investigationThermal infraredImaging data

The invention discloses an infrared thermal image analysis method for nondestructive testing of defects of a composite material, which comprises the following steps of (1) data acquisition: acquiringthermal image data of internal defects of a polymer composite material by using a thermal infrared imager, including two processes of pulse heating of a sample and capture of a thermal image on the surface of the sample, (2) data preprocessing: preprocessing the original thermal image data acquired by the sensor, wherein the preprocessing comprises the following three parts: a) selecting an effective area of the image, b) expanding the data, and c) centralizing the data, (3) constructing a defect detection thermal image data analysis model OLPPT: calculating an embedded matrix Y of a feature space, (4) carrying out OLPPT model result visualization: carrying out embedded projection y visualization, and (5) quantitatively evaluating the effect of the OLPPT model: calculating a signal-to-noise ratio index.

Owner:ZHEJIANG UNIV OF TECH

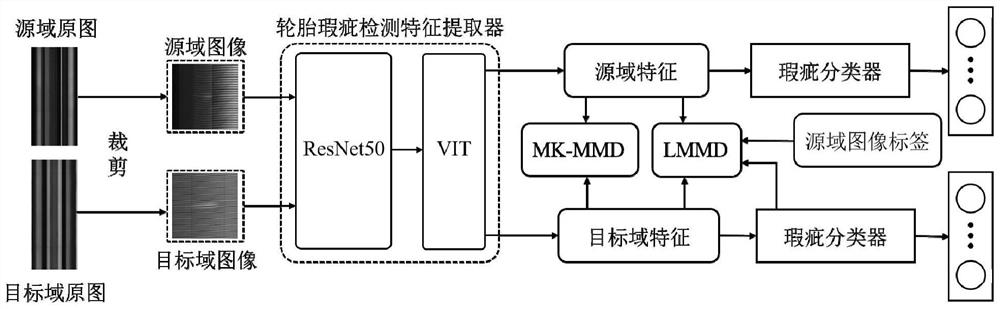

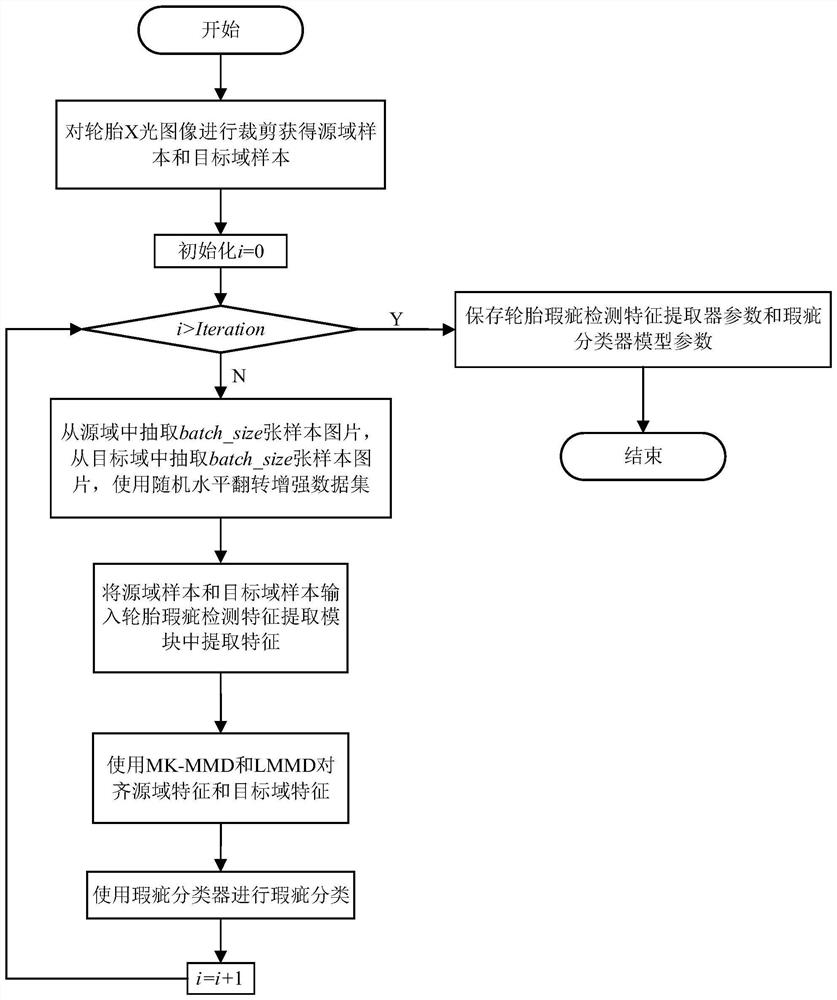

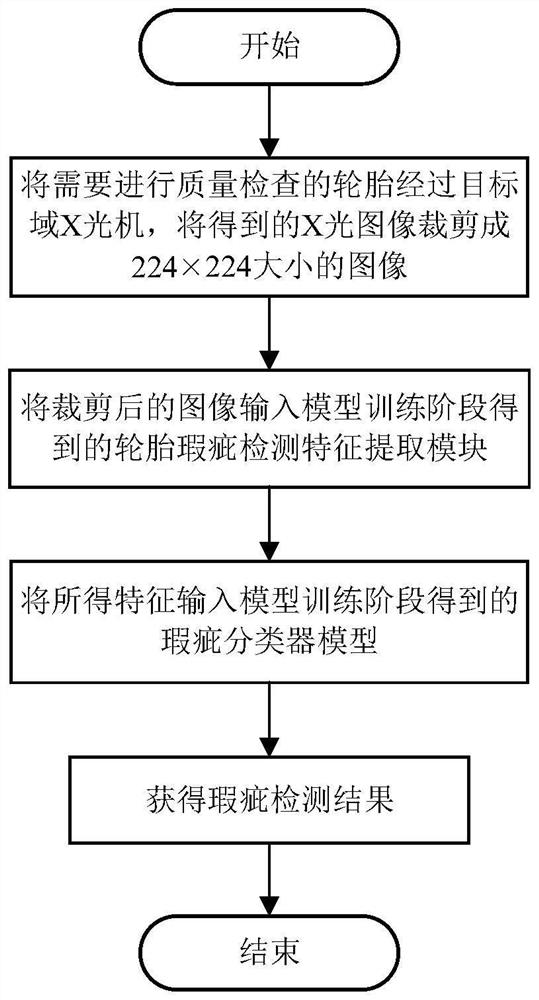

Tire flaw detection method and model based on self-attention mechanism and dual-field self-adaption

PendingCN114387207AImprove reusabilityImprove mobilityImage enhancementImage analysisFeature extractionEngineering

The invention provides a tire flaw detection method and model based on a self-attention mechanism and dual-field self-adaption, and the method comprises the steps: cutting a tire X-ray image in a model training stage, and inputting the cut tire X-ray image into a tire flaw detection feature extraction module composed of ResNet50 and a VIT model; carrying out marginal probability distribution adaptation on the obtained source domain features and target domain features by using MK-MMD, and carrying out conditional probability distribution adaptation on the same category of samples in the source domain and the target domain by using LMMD; and a defect detection result is obtained through a defect classifier subsequently, and the model is trained in a back propagation mode. In the flaw detection stage, after a tire X-ray image is cut, the tire X-ray image is directly input into the tire flaw detection feature extraction module obtained in the model training stage; and inputting the obtained features into a defect classifier obtained in the model training stage to output a defect detection result. According to the invention, domain offset between images sampled by different X-ray machines can be overcome, and the method has good performance in tire flaw detection with deficient data.

Owner:ZHEJIANG UNIV

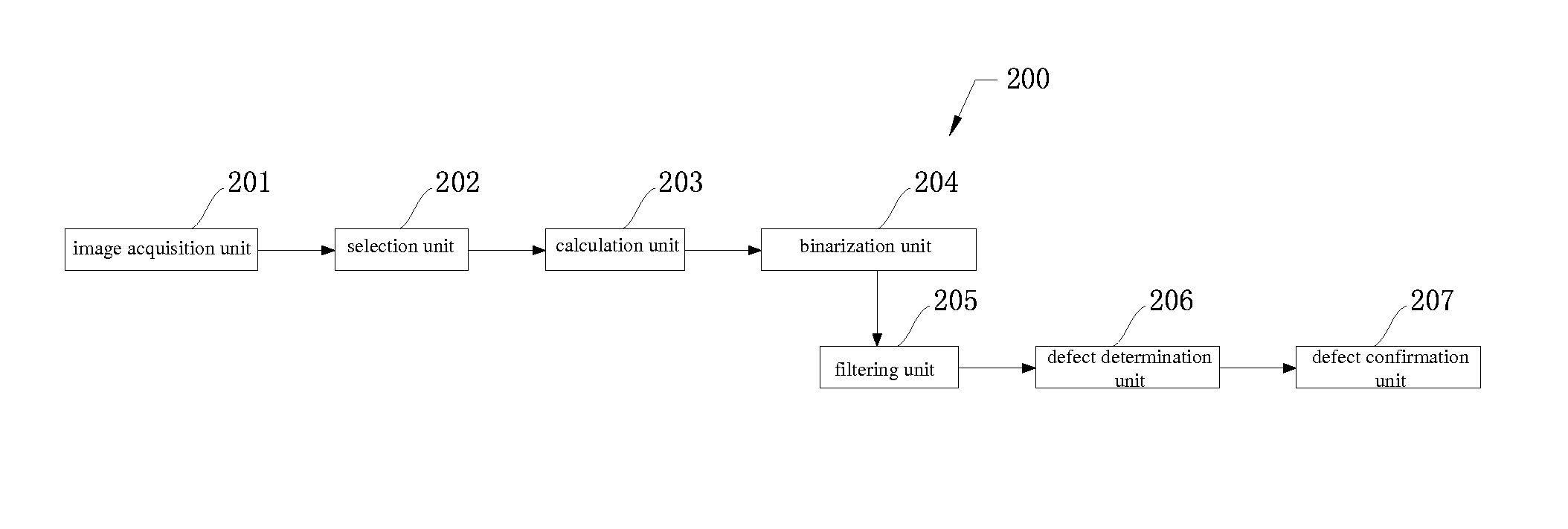

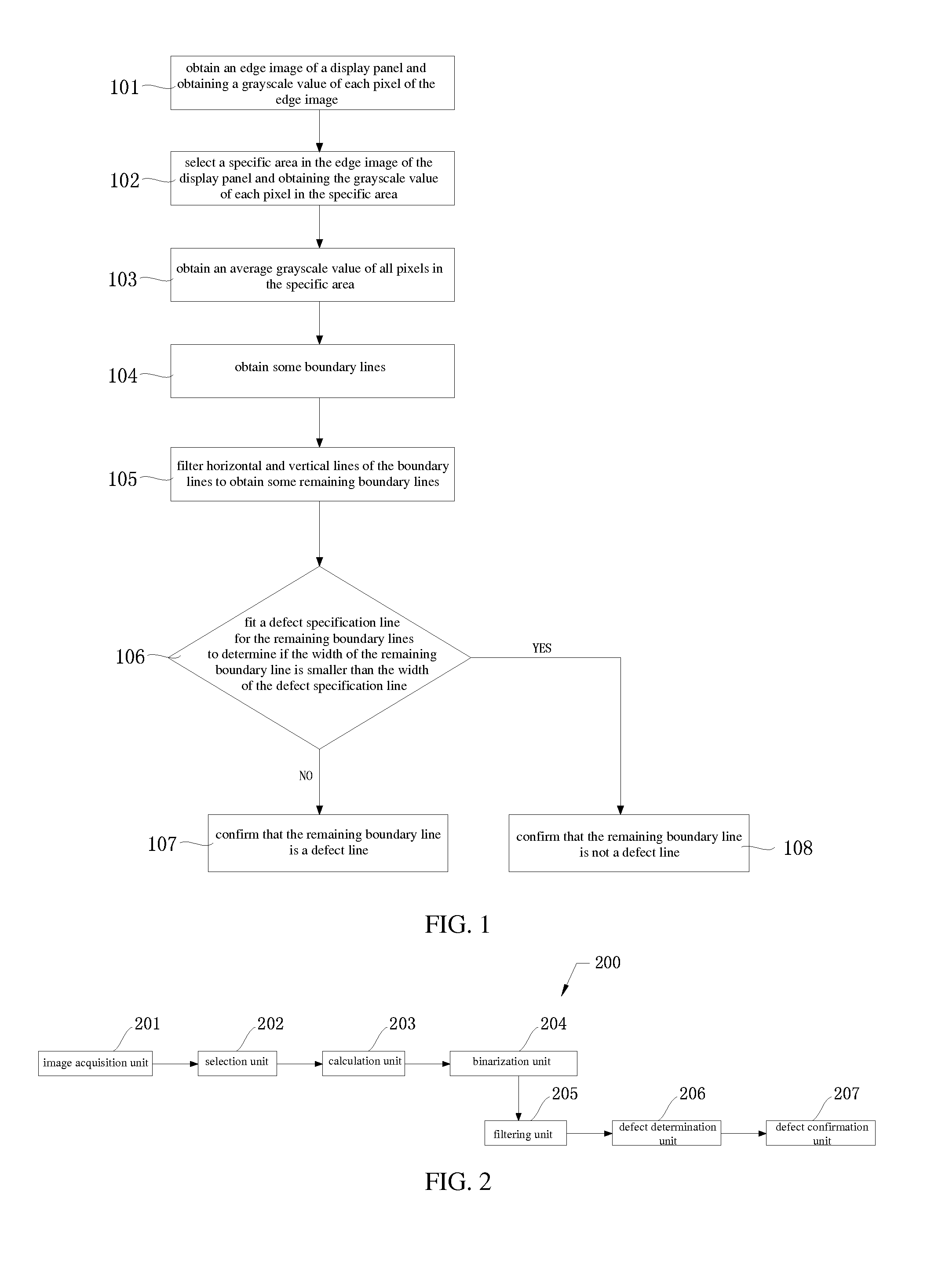

Defect inspection device for display panel and method for the same

ActiveUS20150187064A1Improve detection accuracyImprove defect detection performanceImage enhancementImage analysisComputer visionInspection method

The present invention provides a defect inspection method and device for a display panel. The defect inspection method comprises: A) obtaining an edge image of the display panel and obtaining a grayscale value of each pixel of the edge image; B) selecting a specific area in the edge image and obtaining a grayscale value of each pixel in the specific area; C) obtaining an average grayscale value of all pixels in the specific area; D) executing binarization for the grayscale value of each pixel in the specific area to obtain some boundary lines based on the average grayscale value, wherein the grayscale values of pixels on the boundary lines are different from grayscale values of the other pixels which are not on the boundary lines; E) filtering horizontal and vertical lines of the boundary lines to obtain some remaining boundary lines; and F) fitting a defect specification line for the remaining boundary lines, wherein, if widths of the remaining boundary lines are not smaller than a width of the defect specification line, confirming that the remaining boundary lines are defect lines.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

AOI image scanning detection processing method

InactiveCN105069770AEliminate distractions and errorsImprove defect detection capabilitiesImage enhancementMaterial analysis by optical meansCcd cameraHorizontal projection

The invention relates to an AOI image scanning detection processing method. The method includes the following steps that: 1, an AOI device is provided with a CCD camera and performs line-by-line scanning on a detected circuit board through the CCD camera, so that a panoramic picture of the circuit board can be obtained; 2, the panoramic picture is subjected to vertical projection, so that the left shade, right shade and adhesion of a component can be eliminated; 3, the panoramic picture is subjected to horizontal projection, so that the front shade, back shade and adhesion of the component can be eliminated; 4, the panoramic picture is converted into a black-and-white picture through adopting a gray-scale critical value; and 5, binaryzation processing is performed on the black-and-white picture. According to the AOI image scanning detection processing method of the invention, shade and adhesion removal processing is performed on the picture before the picture is converted into the gray-scale picture, so that interferences and errors due to shades can be eliminated for the black-and-white picture after gray-scale conversion, and defect detection capability can be improved.

Owner:苏州威盛视信息科技有限公司

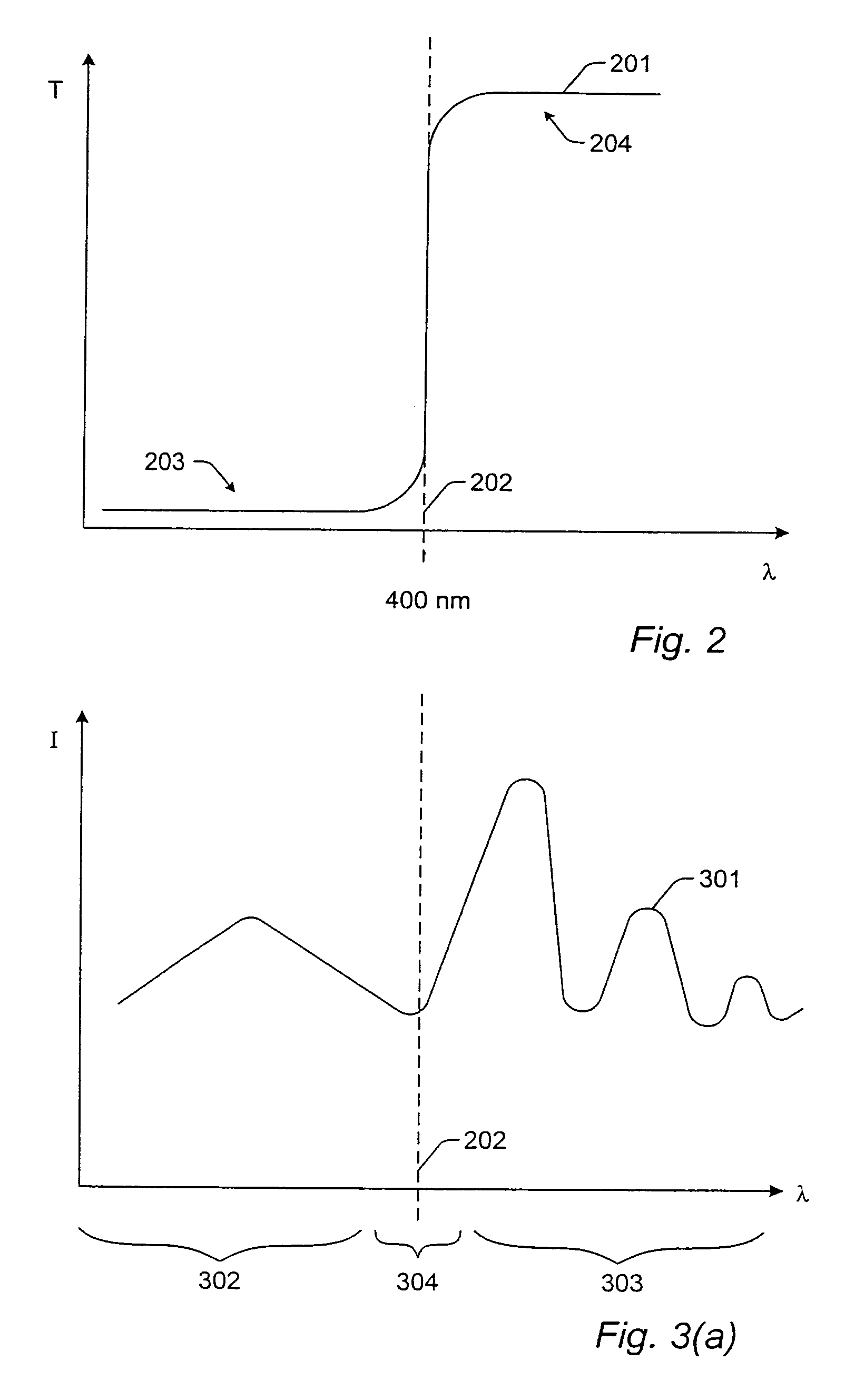

Methods and systems for inspection of a specimen using different inspection parameters

ActiveUS7738089B2Improve defect detection performanceOptically investigating flaws/contaminationBroadband light sourceLength wave

Methods and systems for inspection of a specimen using different parameters are provided. One computer-implemented method includes determining optimal parameters for inspection based on selected defects. This method also includes setting parameters of an inspection system at the optimal parameters prior to inspection. Another method for inspecting a specimen includes illuminating the specimen with light having a wavelength below about 350 nm and with light having a wavelength above about 350 nm. The method also includes processing signals representative of light collected from the specimen to detect defects or process variations on the specimen. One system configured to inspect a specimen includes a first optical subsystem coupled to a broadband light source and a second optical subsystem coupled to a laser. The system also includes a third optical subsystem configured to couple light from the first and second optical subsystems to an objective, which focuses the light onto the specimen.

Owner:KLA TENCOR TECH CORP

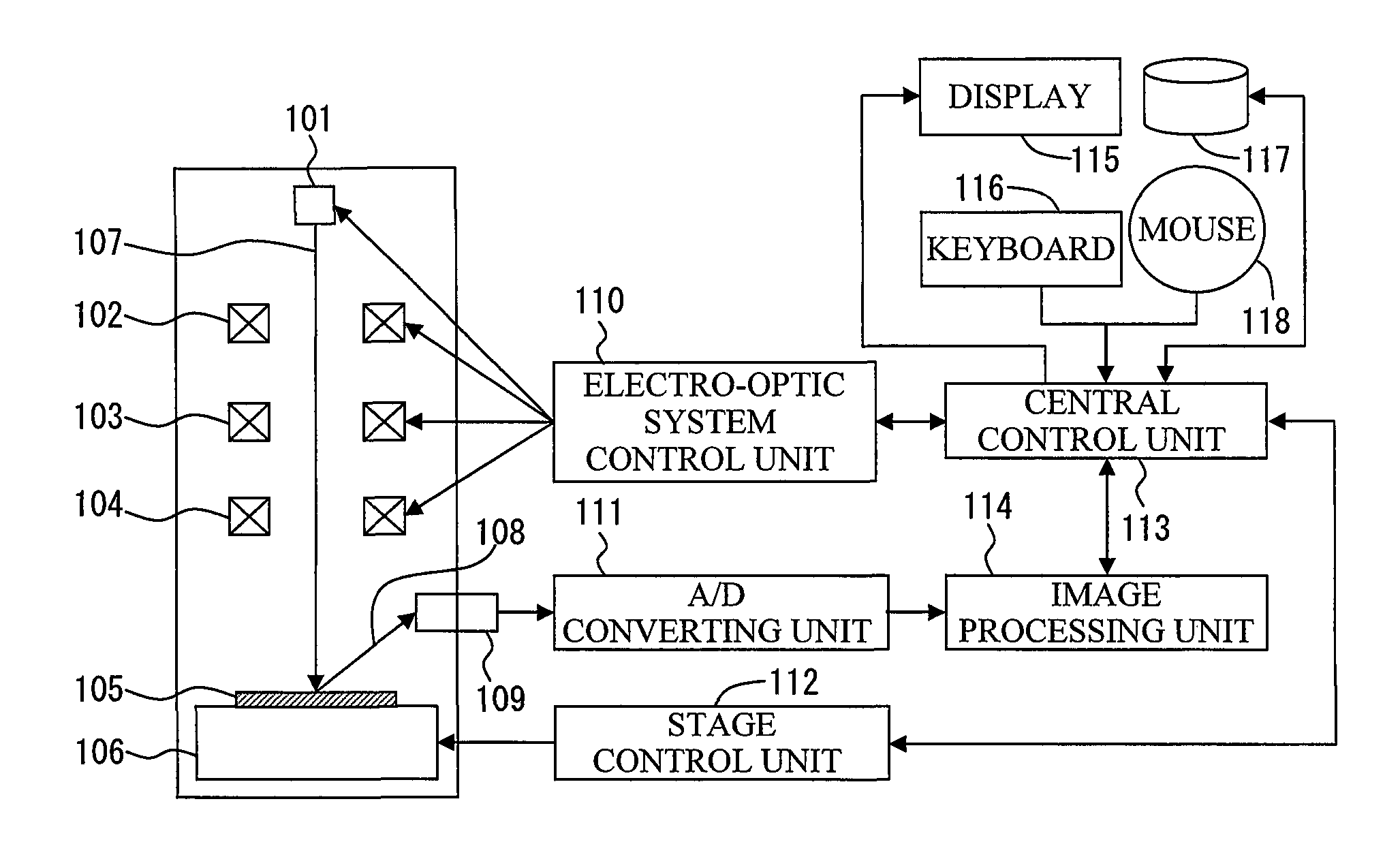

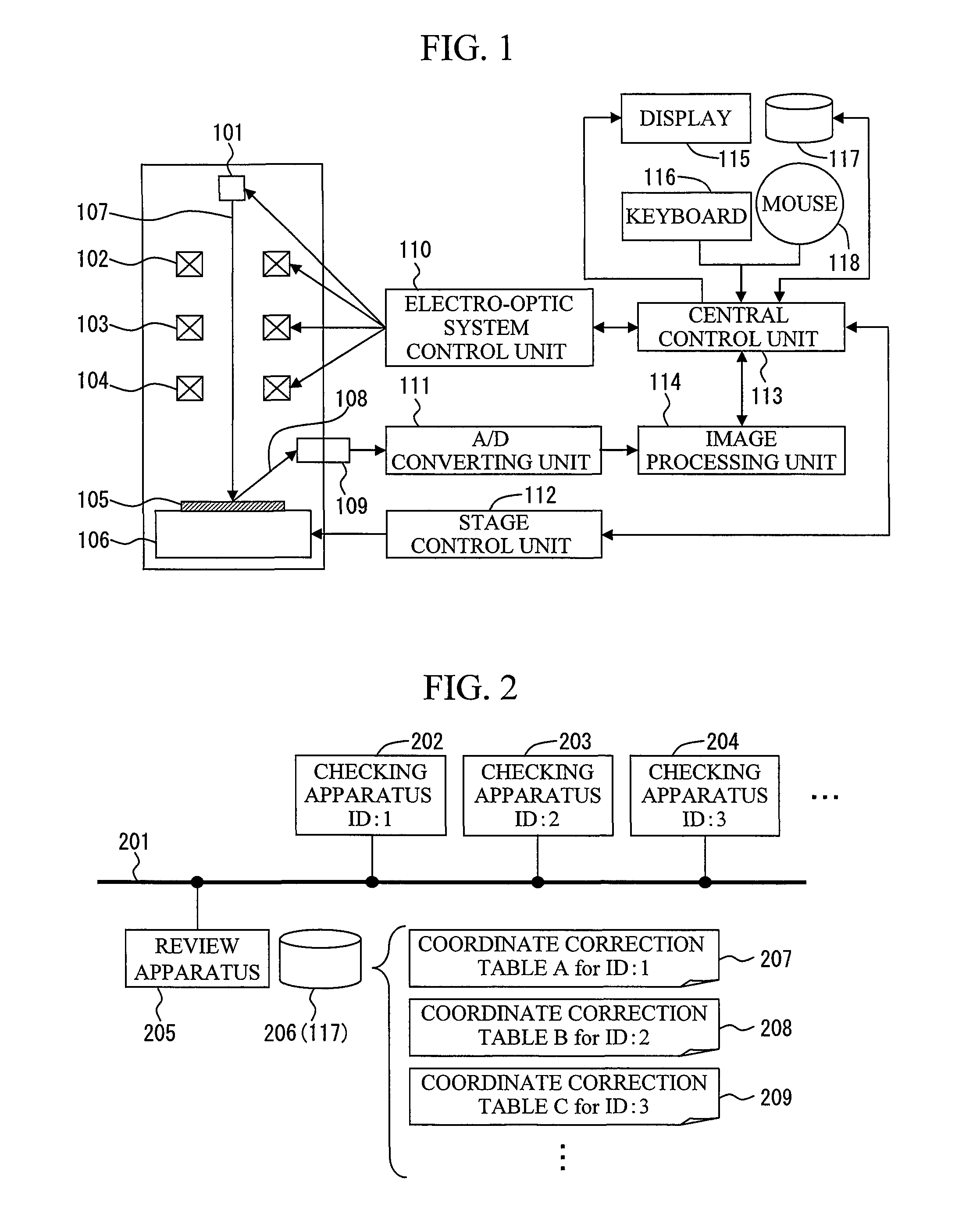

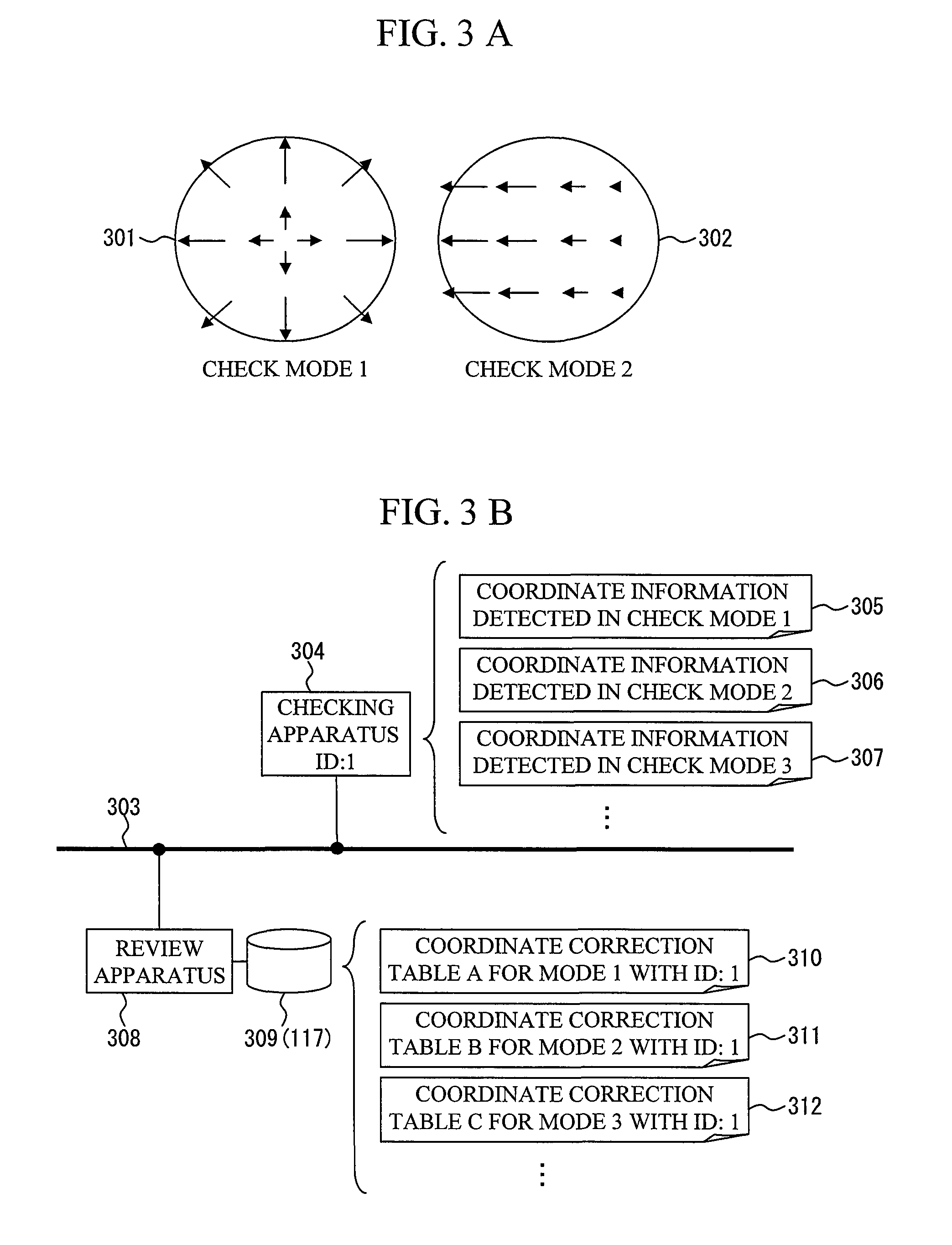

Method of correcting coordinates, and defect review apparatus

ActiveUS7752001B2The result is accurateReduce deviationSemiconductor/solid-state device testing/measurementElectric discharge tubesAlgorithmField of view

The present invention provides a method of correcting coordinates so as to quickly and properly arrange a sample in a field of view in a review apparatus for moving a sample stage onto the specified coordinates to review the sample. A review apparatus according to the present invention, which is a review apparatus for moving a sample stage onto coordinates previously calculated by a checking apparatus to review the sample, has a function of retaining a plurality of coordinate correction tables to correct a deviation between a coordinate value previously calculated by a checking apparatus and an actual sample position detected by the review apparatus. The review apparatus evaluates correction accuracy of the plurality of coordinate correction tables and applies one of the coordinate correction tables with the maximum evaluation value.

Owner:HITACHI HIGH-TECH CORP

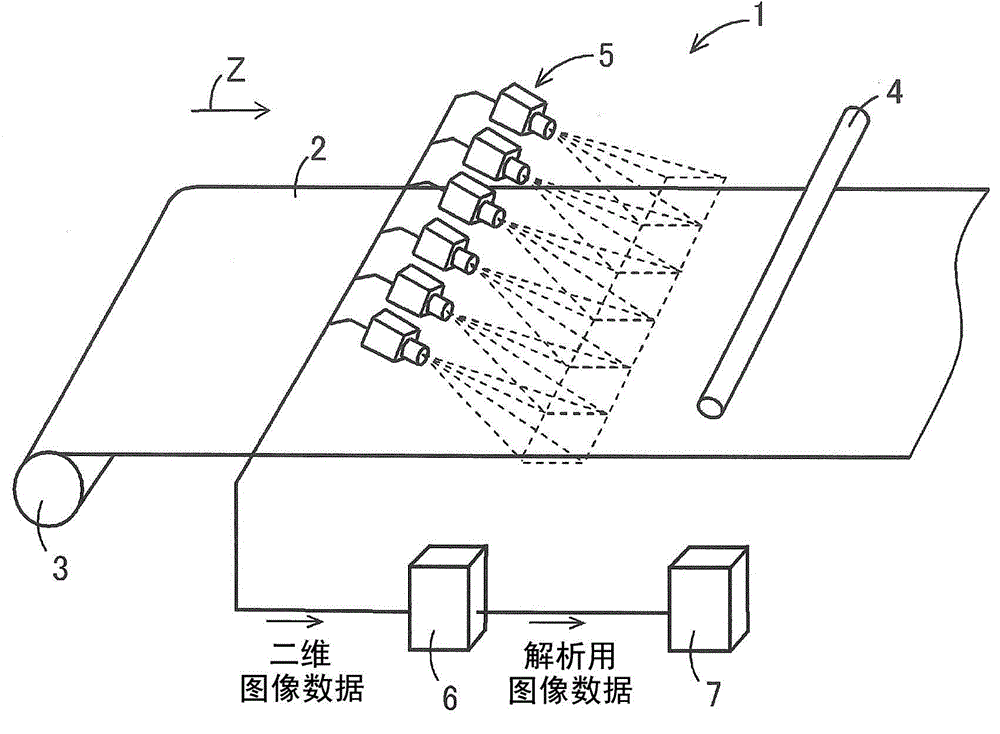

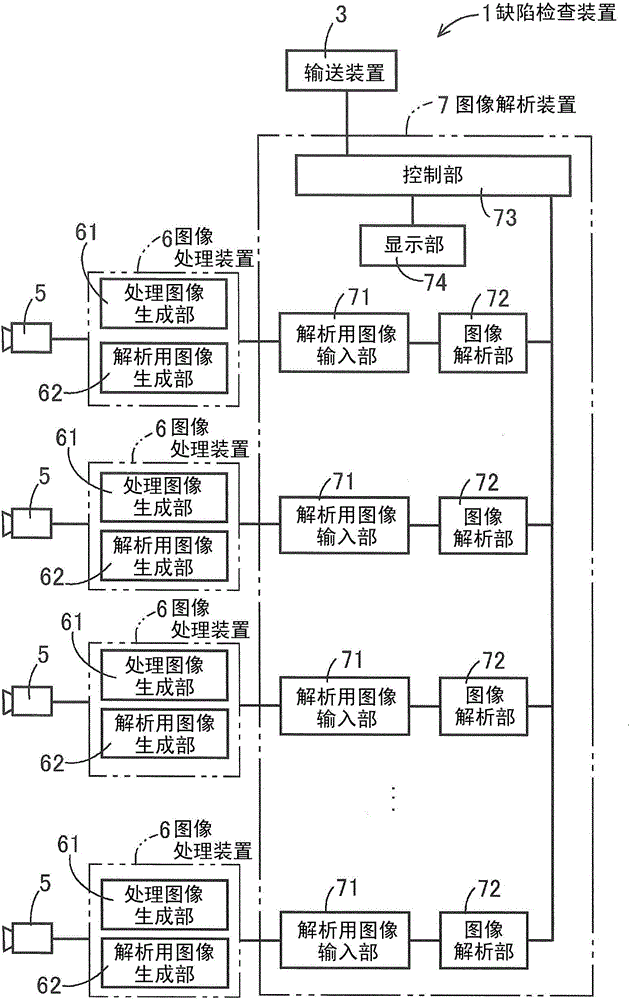

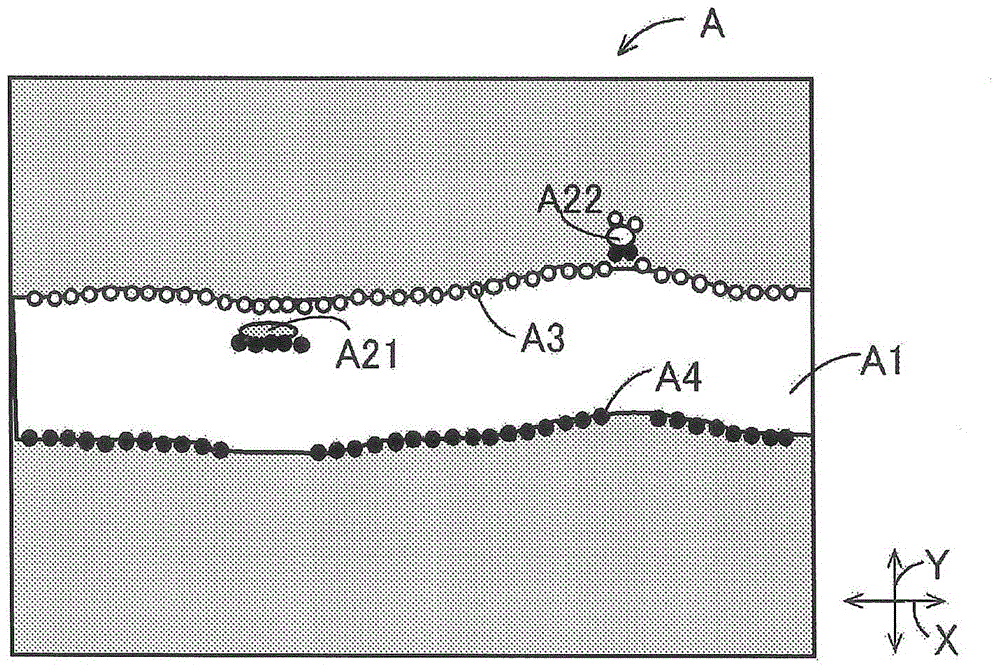

Defect inspection apparatus, and defect inspection method

ActiveCN104583761AAchieve high speedImprove inspection efficiencyMaterial analysis by optical meansUsing optical meansImaging dataImage generation

In a defect inspection apparatus (1), a processing image generation unit (61) calculates a feature quantity of each of pixels of two-dimensional image data, produced by an imaging device (5), by processing the two-dimensional image data with a predetermined algorithm. The processing image generation unit (61) extracts a pixel of a predetermined threshold value or more in the two-dimensional image data as a defect pixel. The processing image generation unit (61) generates processing image data such that the defect pixel is given a gradation value corresponding to the feature quantity while the remaining pixels other than the defect pixel are given zero gradation values. An analysis image generation unit (62) generates analysis image data consisting of one or a plurality of one-dimensional image data on the basis of the processing image data.

Owner:SUMITOMO CHEM CO LTD

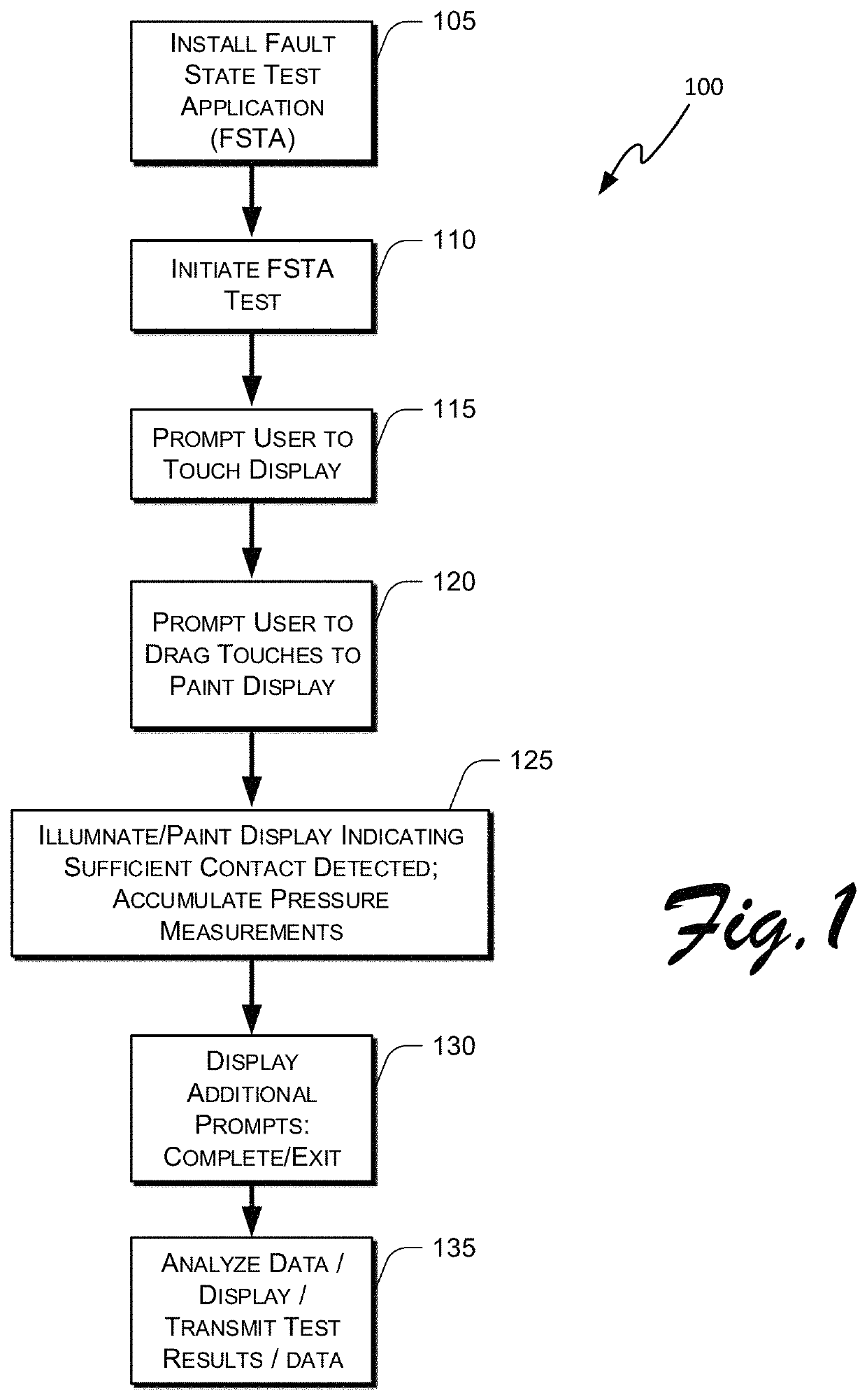

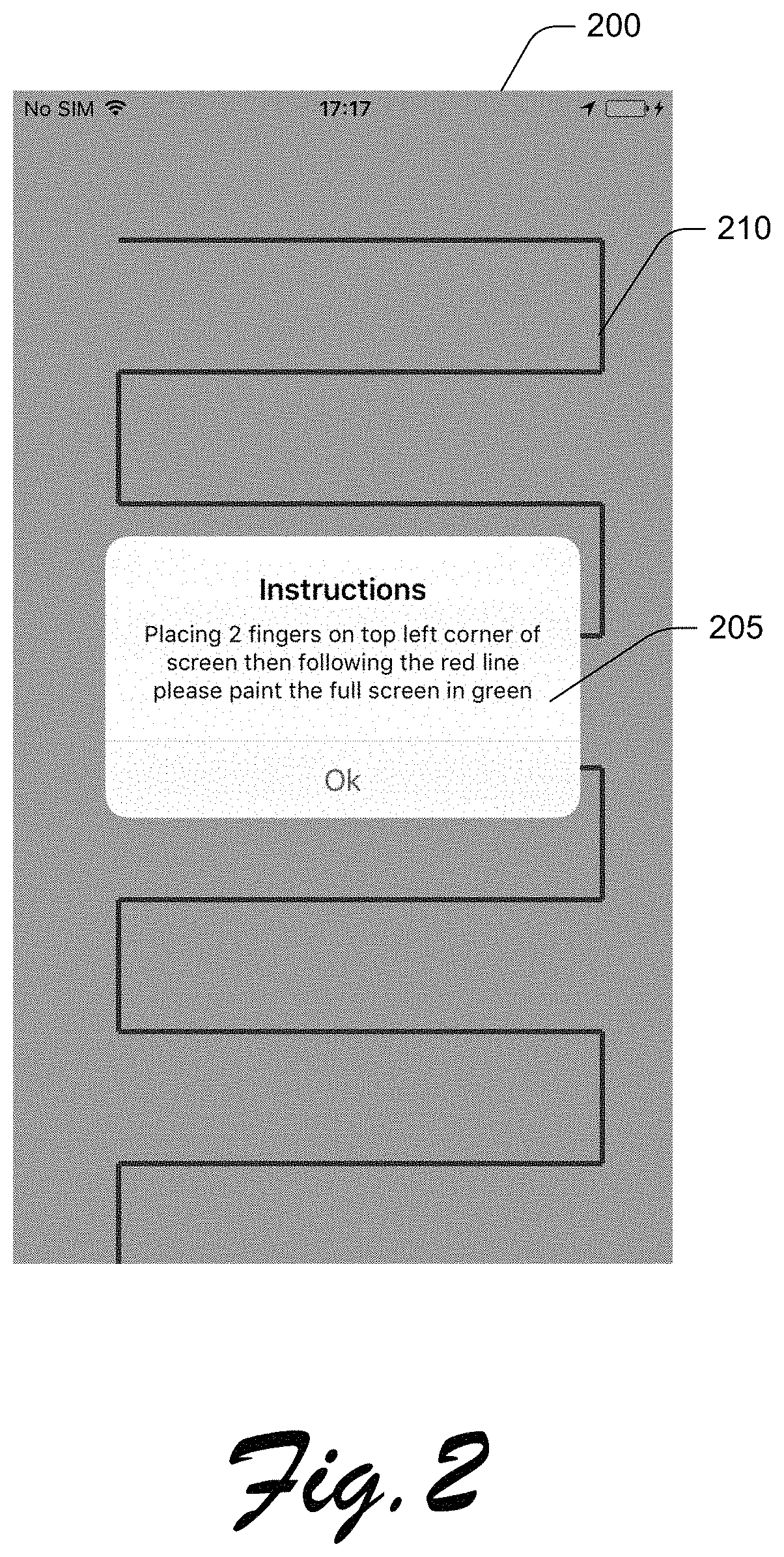

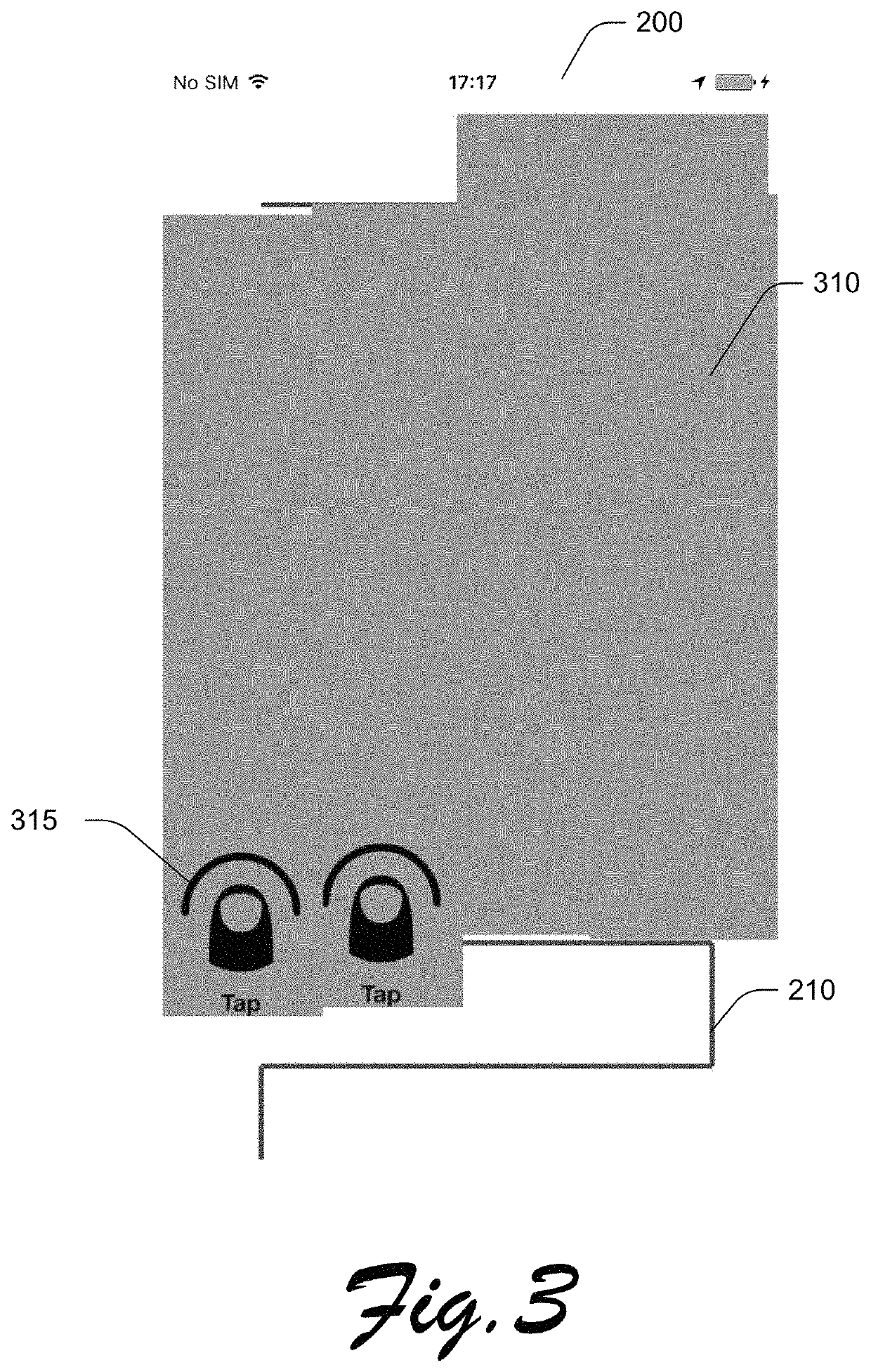

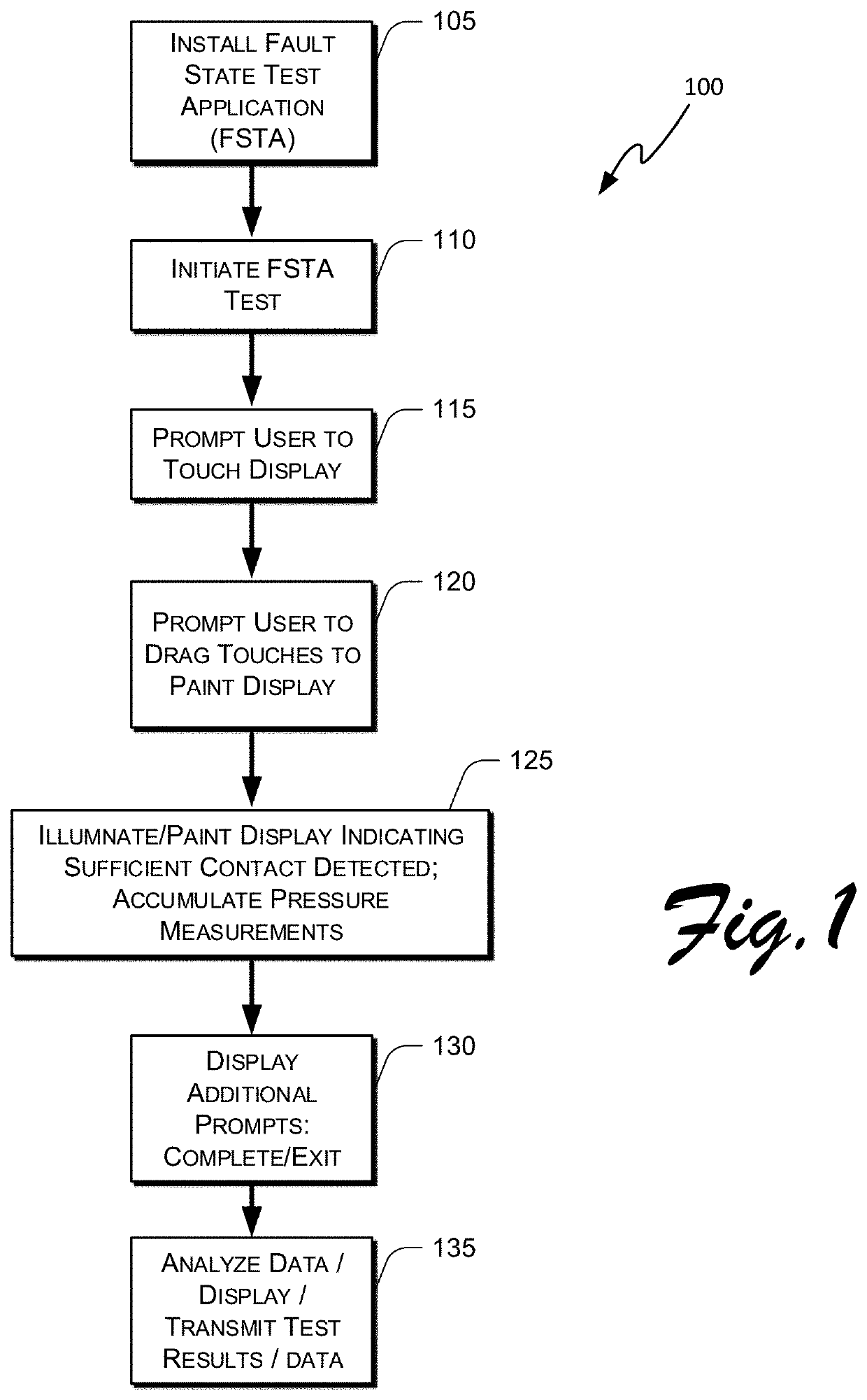

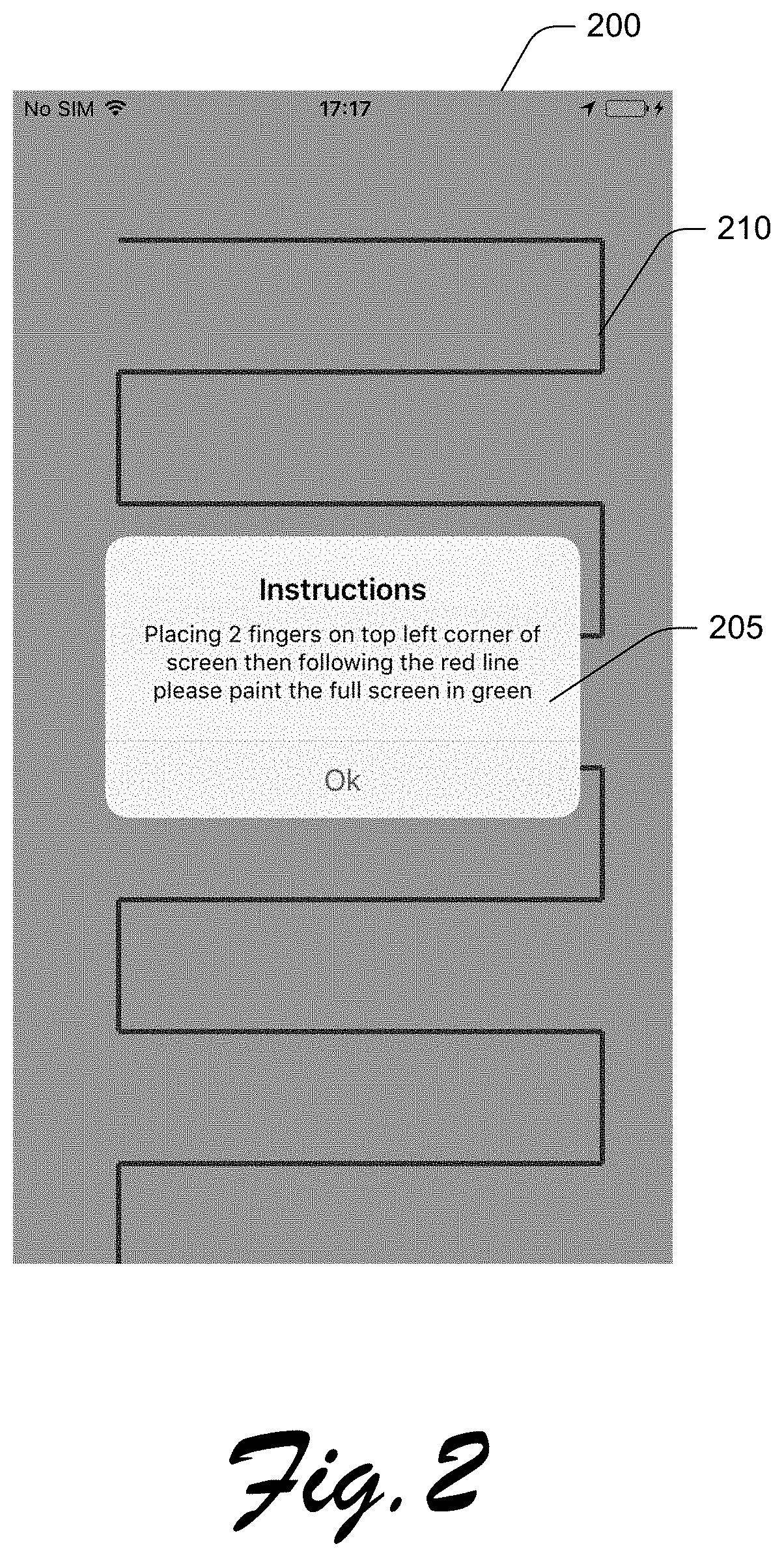

System and method for detection of mobile device fault conditions

ActiveUS11210777B2Improve defect detection performanceTelevision system detailsImage enhancementThird partyEngineering

There is presented a system and method for detecting mobile device fault conditions, including detecting fault conditions by software operating on the mobile device. In one embodiment, the present invention provides for systems and methods for using a neural network to detect, from an image of the device, that the mobile device has a defect, for instance a cracked or scratched screen. Systems and methods also provide for, reporting the defect status of the device, working or not, so that appropriate action may be taken by a third party.

Owner:BLANCCO TECH GRP IP OY

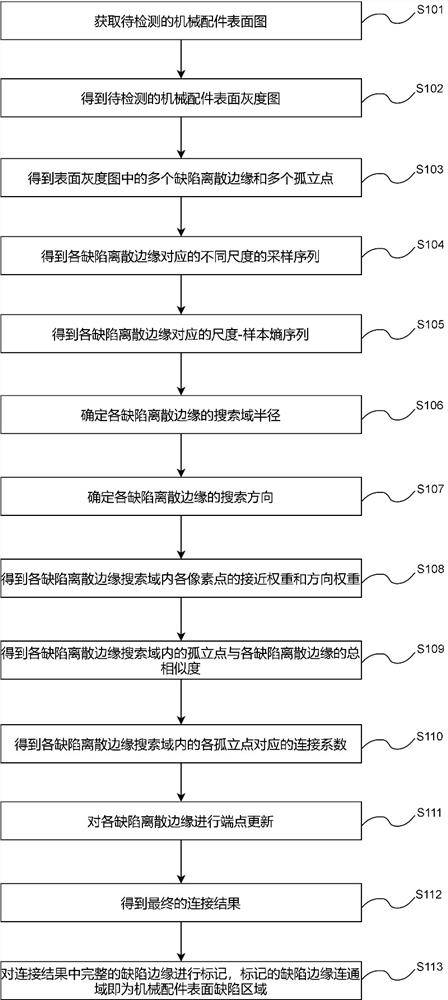

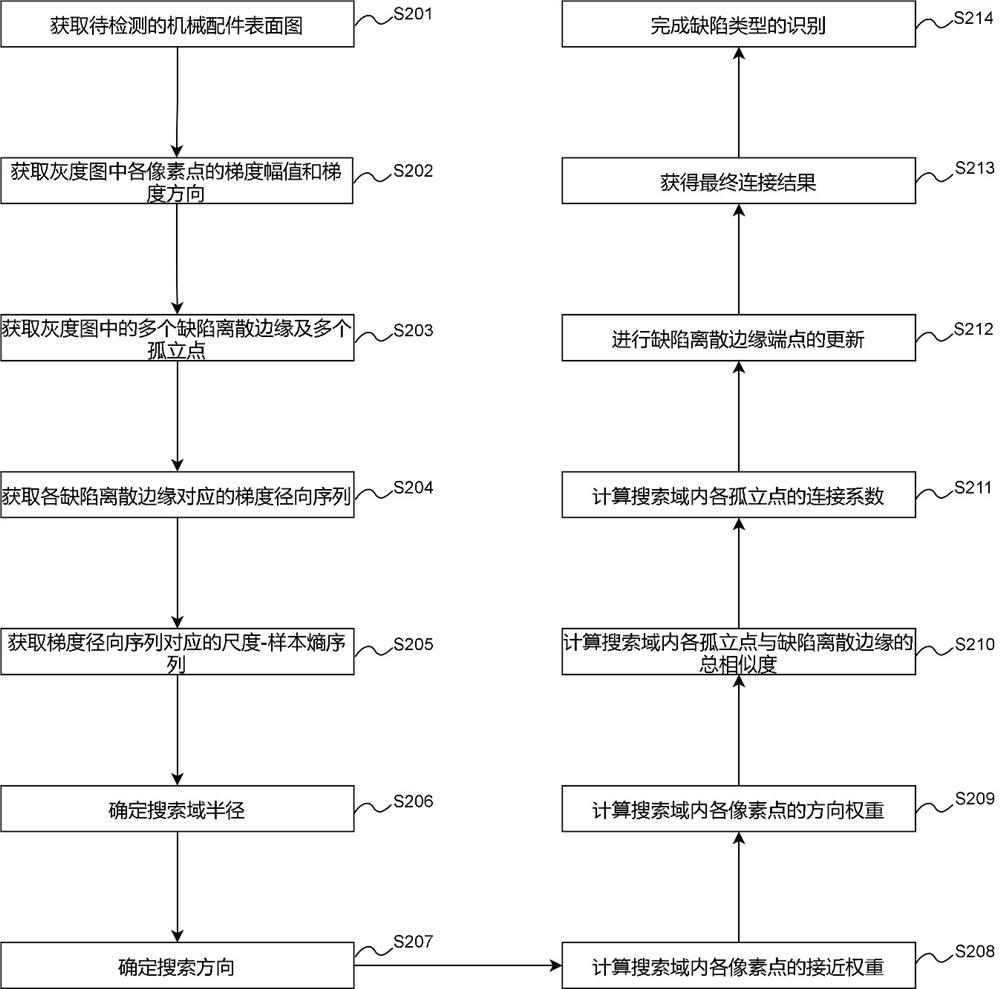

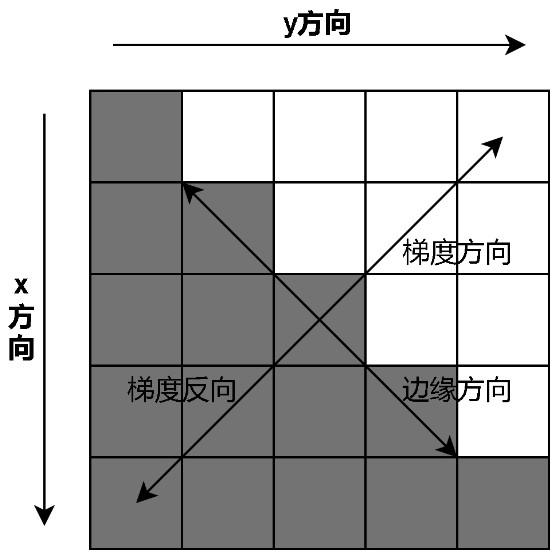

Mechanical part surface defect detection method based on image processing

PendingCN113989266AAchieve connectionImprove defect detection performanceImage enhancementImage analysisPattern recognitionImaging processing

The invention relates to the field of image processing, in particular to a mechanical part surface defect detection method based on image processing, which comprises the following steps: acquiring a surface map and a grey-scale map of a to-be-detected mechanical part; carrying out canny edge detection on the grey-scale map to obtain a plurality of defect discrete edges and isolated points in the grey-scale map; determining an endpoint search domain and an intra-domain weight of each discrete edge according to the gradient amplitude and the gradient direction of each pixel point; obtaining the total similarity of isolated points in each discrete edge search domain; obtaining a connection coefficient corresponding to each isolated point according to the total similarity of the isolated points and the corresponding weight; carrying out endpoint updating on each discrete edge according to the connection coefficient; and performing stopping condition judgment on each discrete edge after the end points are updated each time, obtaining a final connection result, and then obtaining a defect area. The method is used for carrying out defect detection on the surface of the mechanical part, a more complete defect edge can be obtained through the method, and the defect detection effect is improved.

Owner:WENSHANG HAIWEI MOTORCYCLE ACCESSORIES CO LTD

System and method for detection of mobile device fault conditions

InactiveUS20220122243A1Improve defect detection performanceImage enhancementTelevision system detailsThird partyMobile device

There is presented a system and method for detecting mobile device fault conditions, including detecting fault conditions by software operating on the mobile device. In one embodiment, the present invention provides for systems and methods for using a neural network to detect, from an image of the device, that the mobile device has a defect, for instance a cracked or scratched screen. Systems and methods also provide for, reporting the defect status of the device, working or not, so that appropriate action may be taken by a third party.

Owner:BLANCCO TECH GRP IP OY

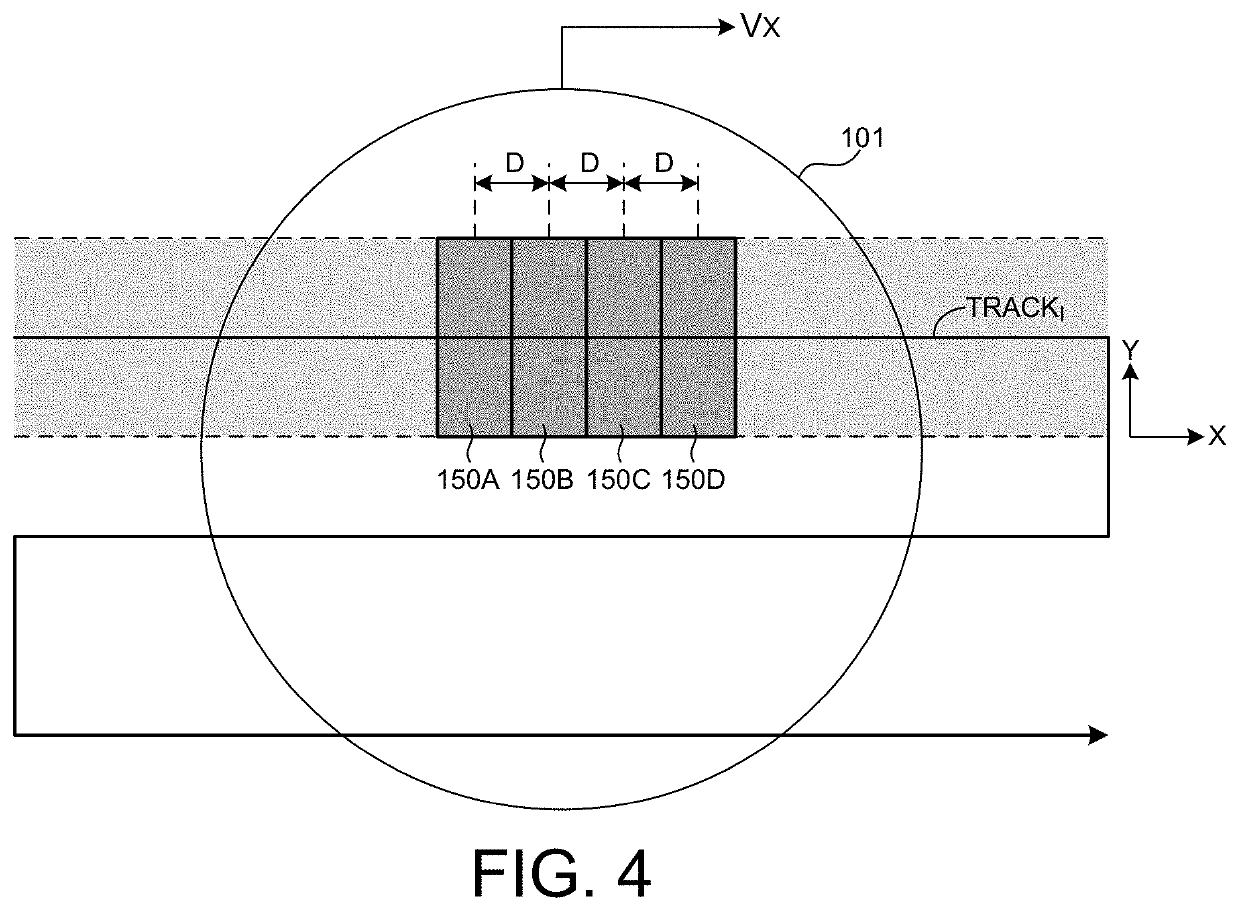

Differential Imaging For Single-Path Optical Wafer Inspection

ActiveUS20200202504A1Minimize compute timeMinimize memory requirementImage enhancementImage analysisWaferingNuclear medicine

Methods and systems for enhanced defect detection based on images collected by at least two imaging detectors at different times are described. In some embodiments, the time between image measurements is at least 100 microseconds and no more than 10 milliseconds. In one aspect, one or more defects of interest are identified based on a composite image of a measured area generated based on a difference between collected images. In a further aspect, measurement conditions associated with the each imaged location are adjusted to be different for measurements performed by at least two imaging detectors at different times. In some embodiments, the measurement conditions are adjusted during the time between measurements by different imaging detectors. Exemplary changes of measurement conditions include environmental changes at the wafer under measurement and changes made to the optical configuration of the inspection system.

Owner:KLA TENCOR TECH CORP

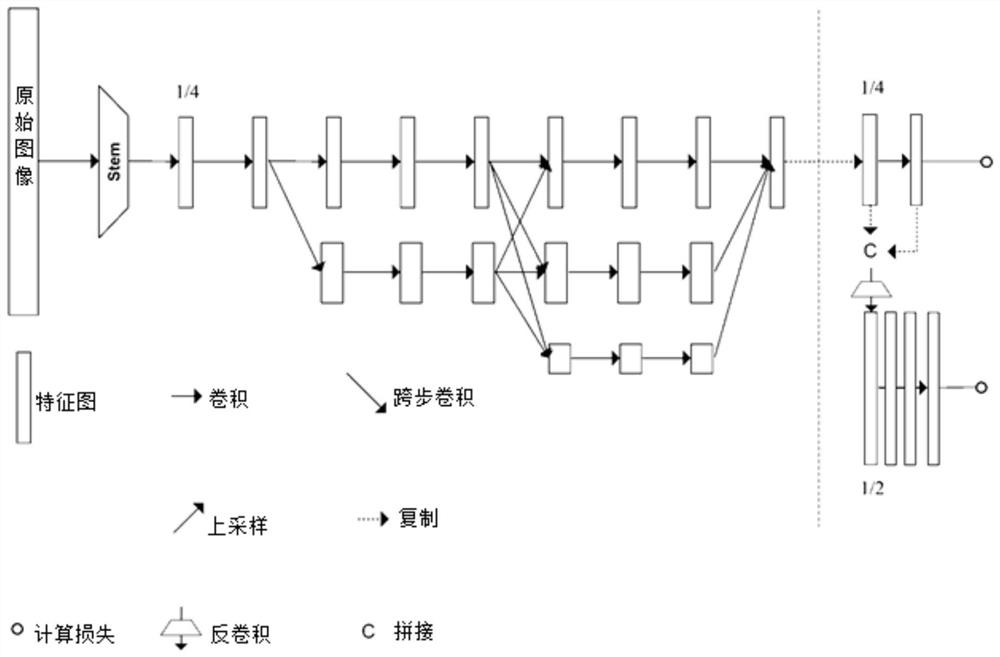

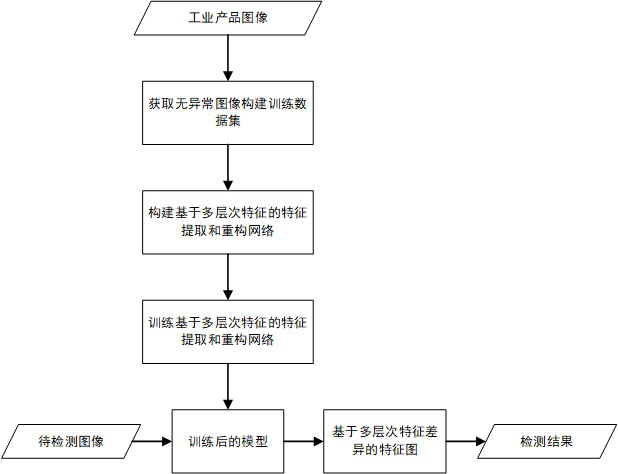

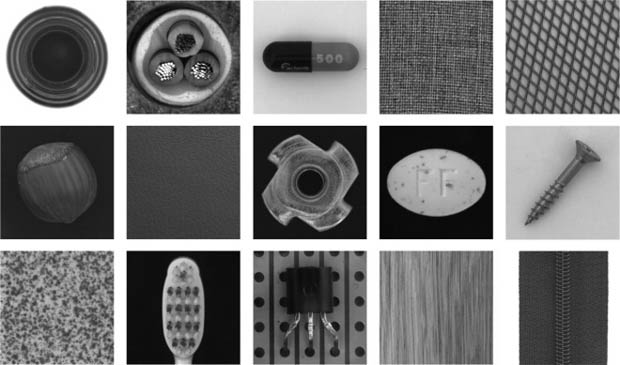

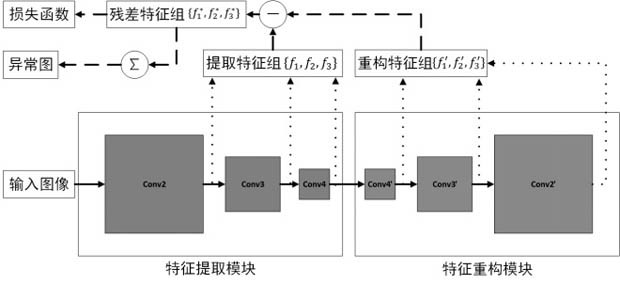

Unsupervised defect detection and positioning method based on multilevel feature reconstruction

PendingCN114332008APrecise positioningAdaptableImage analysisNeural architecturesFeature extractionRadiology

The invention relates to an unsupervised defect detection and positioning method based on multilevel feature reconstruction. The method comprises the following steps: acquiring a non-abnormal image of a product and abnormal images of different types of defects; extracting a multi-scale feature group by using a non-abnormal image input feature extraction network; inputting the feature of the highest dimension into a reconstruction network to reconstruct new feature groups corresponding to different scales layer by layer; constructing a loss function training reconstruction network for the two feature groups; and in the test stage, an anomaly graph and an anomaly score are calculated according to the difference condition of the two feature groups and used for judging anomaly and positioning a defect area. According to the method, the feature information difference of the non-abnormal image and the abnormal image in different dimensions is effectively utilized, and the defect area of the product can be detected, so that manual labeling is avoided, and the product quality detection efficiency is improved.

Owner:FUZHOU UNIV

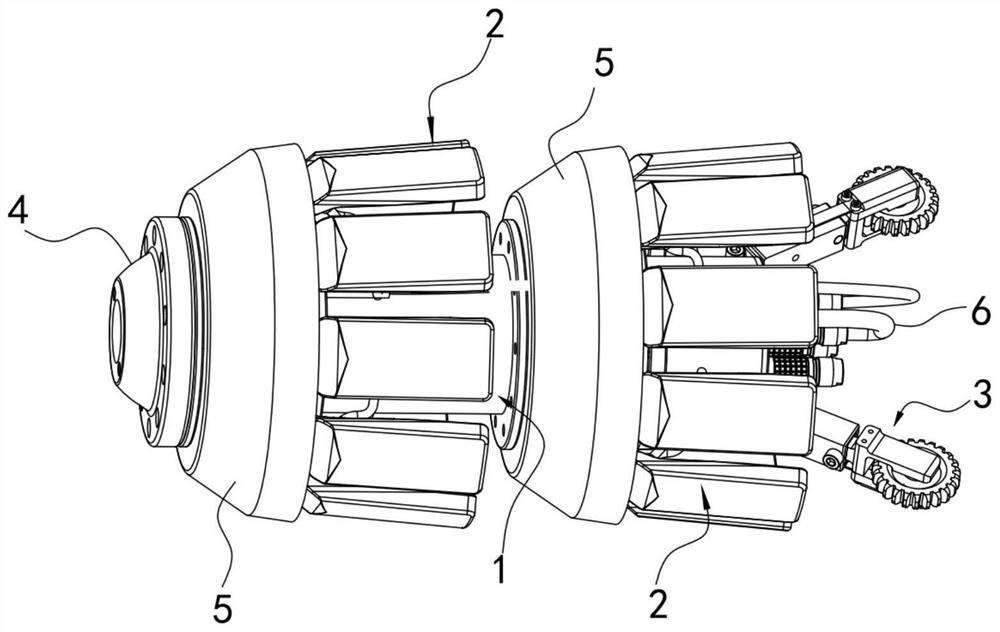

Pipeline nondestructive testing equipment

ActiveCN113640372AHigh sensitivityImprove defect detection performanceMaterial analysis by electric/magnetic meansPigs/molesSignal conditioningReceiver coil

The invention discloses pipeline nondestructive testing equipment, and relates to the technical field of nondestructive testing, wherein the pipeline nondestructive testing equipment comprises a mobile carrier and a probe detection assembly; the mobile carrier moves in a pipeline along with fluid in the pipeline or moves through an advancing mechanism; the probe detection assembly comprises a detection part mounted on the mobile carrier, the detection part is provided with a detection end, and a detection probe is packaged in the detection end; and the pipeline nondestructive testing equipment further comprises a data processing unit, a first signal conditioning unit and a second signal conditioning unit, the detection probe comprises an excitation coil, a receiving coil and a passive resonance coil, and the passive resonance coil is located between the excitation coil and the receiving coil. Magnetization treatment equipment does not need to be additionally introduced during detection, so that the size of the system is greatly reduced, the requirement of the detection system on the internal cleanliness of the pipeline is reduced, the pipeline passing ability of the detection system is improved, and the cost overhead of the system is greatly reduced.

Owner:SICHUAN DEYUAN PETROLEUM & GAS CO LTD

Coupling and focusing ultrasonic detection method and detection device for polyethylene pipe hot melt butt joint

ActiveCN101393170BReduce lossesHigh detection sensitivityAnalysing solids using sonic/ultrasonic/infrasonic wavesEngineeringUltrasound probe

The invention relates to a method for detecting the welding quality of a hot-melt even joint of a polyethylene pipeline and a detection device thereof. The aim of the invention is that the provided detection method and the detection device have the characteristics of high sensitivity, high detection precision, high reliability, high detection efficiency and low misoperation rate. The technical proposal is a method for the coupling focusing ultrasonic detection of the hot-melt even joint of the polyethylene pipeline, which comprises the following steps: (1) a coupling agent liquid is positioned on the outer surface of a pipeline joint fusion region; (2) an ultrasonic probe adopting a spherical curved wafer is immersed into the coupling agent liquid in order that the focus is positioned in the centerline of the pipeline joint fusion region; and (3) the ultrasonic probe does linear scanning motion along the diameter direction of the pipeline and does uniform scanning motion along the circumferential direction of the pipeline; and obtained signal data is processed by a computer to form a C scanning picture. The ultrasonic detection device comprises a coupling receiving device, the ultrasonic probe adopting the spherical curved wafer, a mechanical scanning device, a signal processing and controlling system, and the computer.

Owner:ZHEJIANG PROVINCIAL SPECIAL EQUIP INSPECTION & RES INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com