Ultrasonic C scanning path correcting method taking workpiece eccentric clamping errors into consideration

A technology of scanning path and correction method, which is applied in the direction of material analysis, measuring device and instrument using sonic/ultrasonic/infrasonic waves, which can solve the problems of decreased detection accuracy and clamping error.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047]The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but should not be used to limit the scope of the present invention.

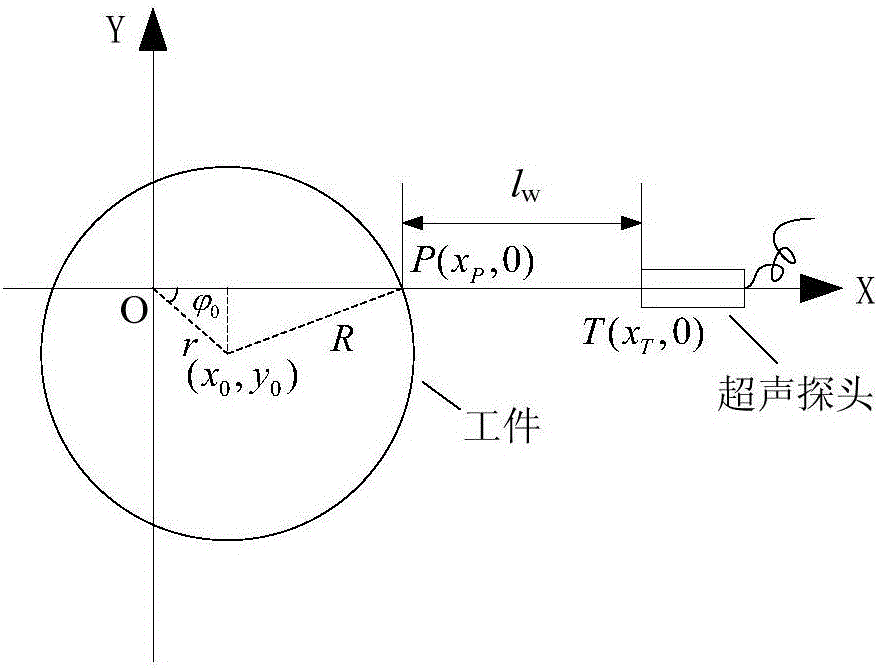

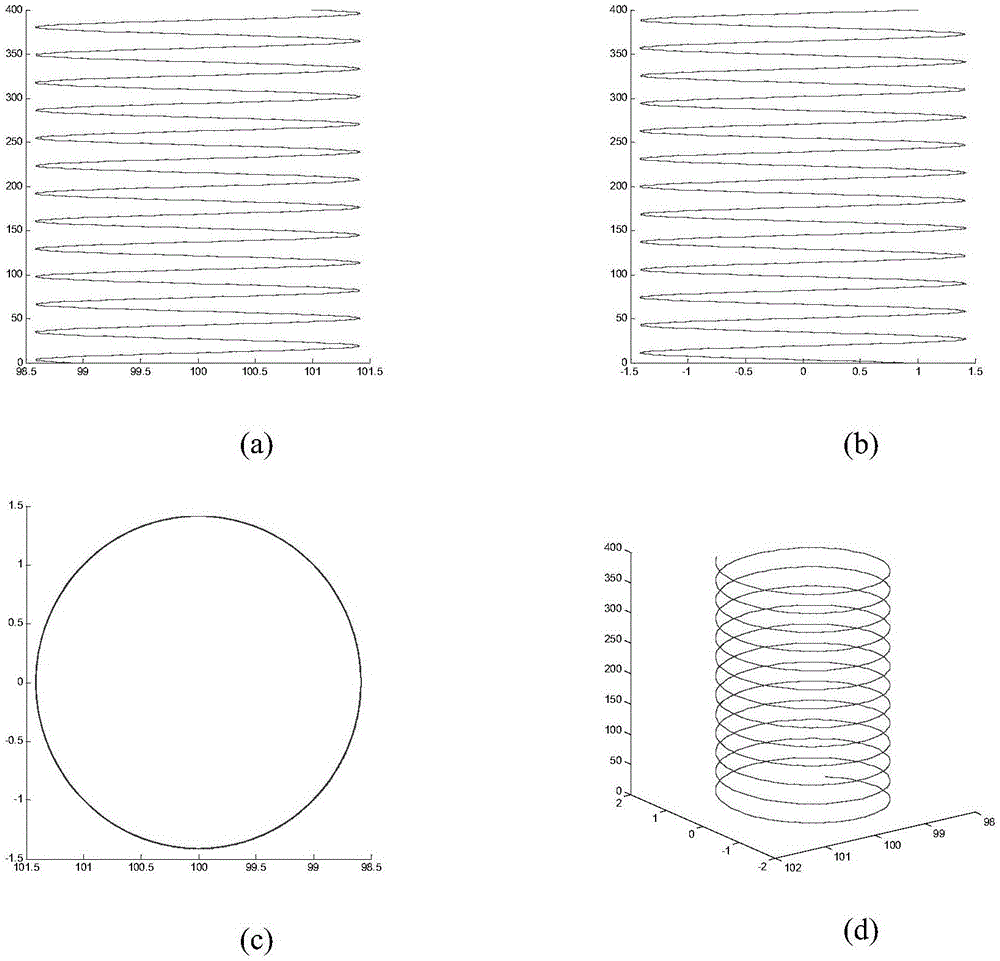

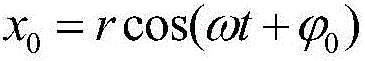

[0048] This specific embodiment takes the scanning of a cylindrical workpiece as an example. The present invention first fixes the tubular workpiece in a water tank filled with water, uses an ultrasonic pulse generator / receiver (also known as an ultrasonic instrument) to excite the ultrasonic longitudinal wave probe, and passes the ultrasonic longitudinal wave probe through The probe frame is clamped on the 7-DOF water immersion ultrasonic testing motion platform based on the Stäubli TX60L manipulator, and the movement of the motion platform is controlled by connecting the control circuit with the motion control card installed on the computer to adjust the position and posture of the ultrasonic longitudinal wav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com