An Ultrasonic Automatic Inspection Method Considering Workpiece Clamping Error Correction

An error correction and automatic detection technology, applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, measuring devices, etc. And the effect of improving efficiency, increasing ultrasonic energy, and improving defect detection ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but should not be used to limit the scope of the present invention.

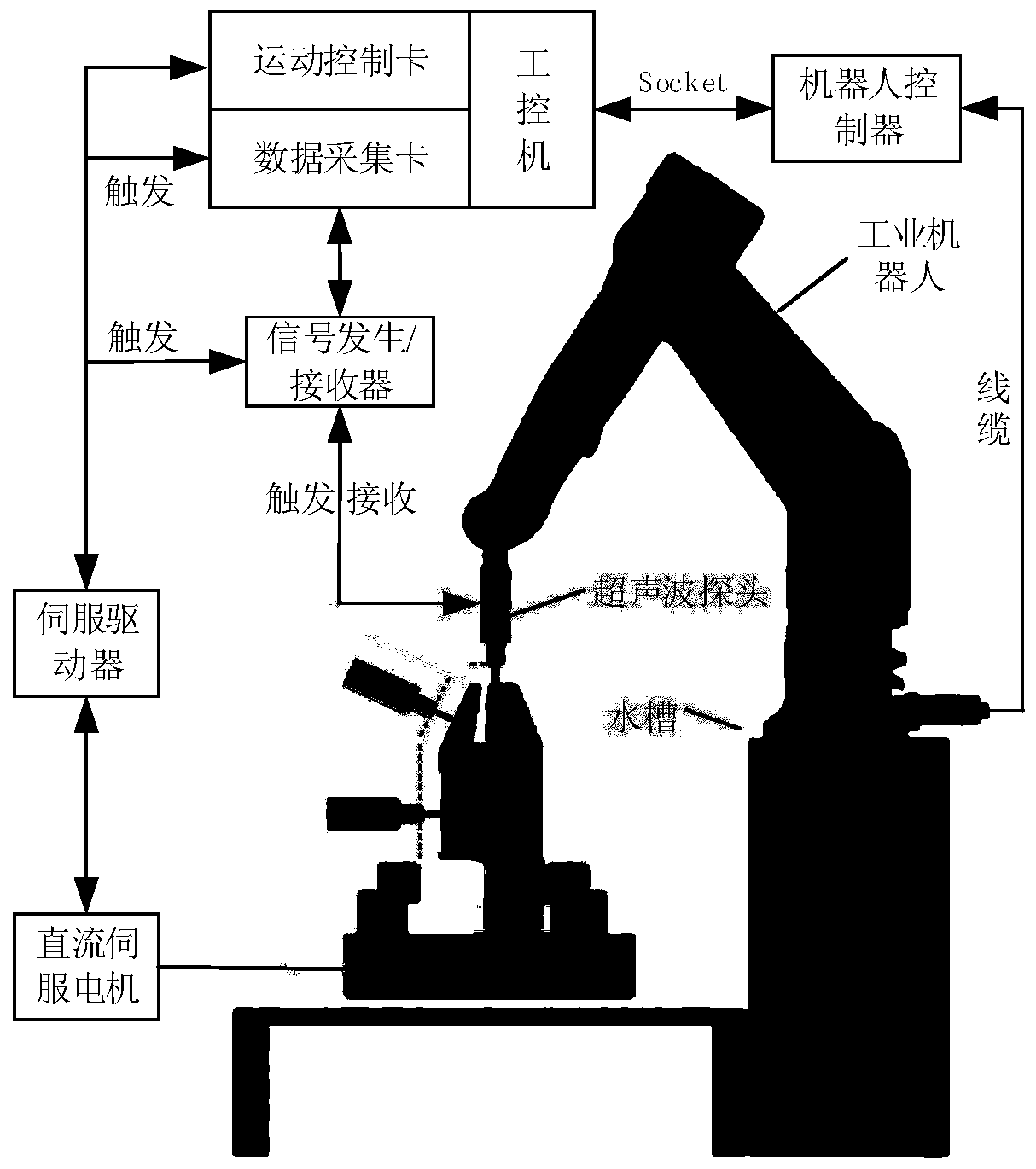

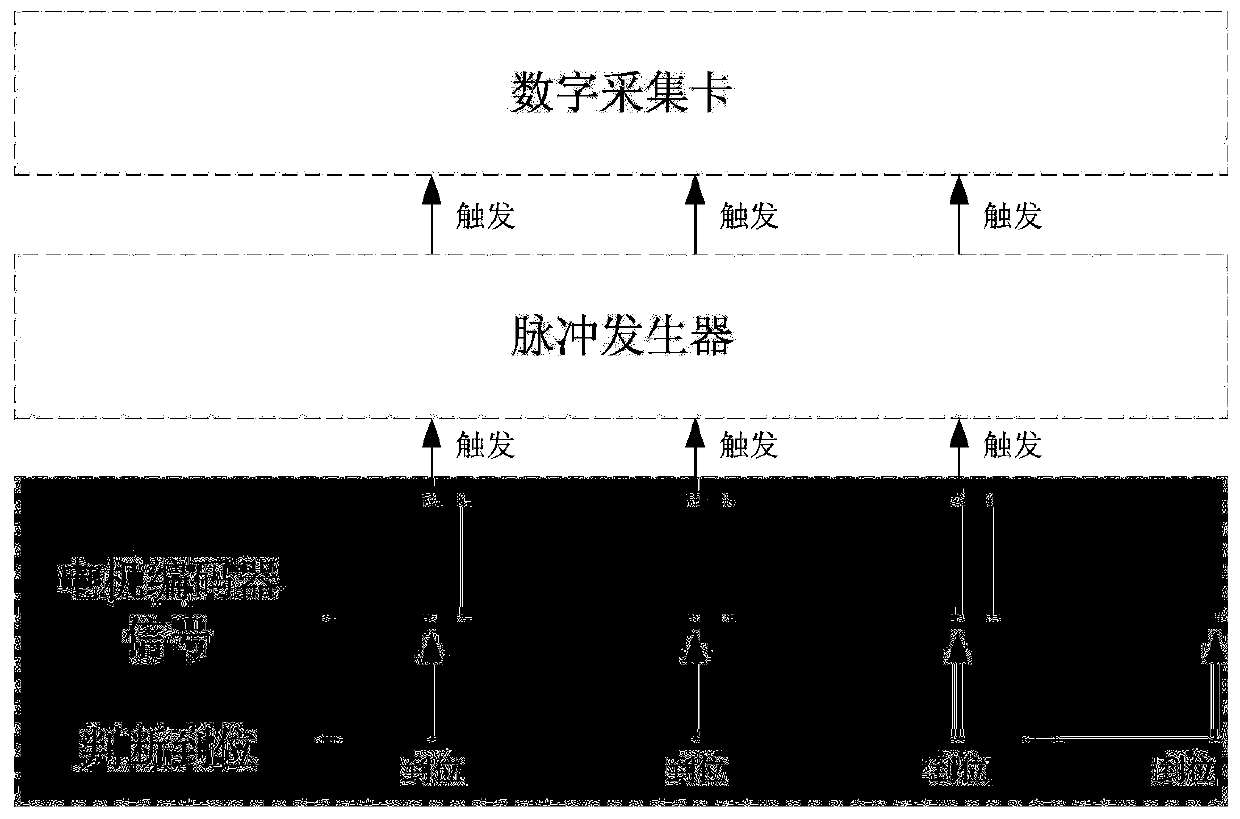

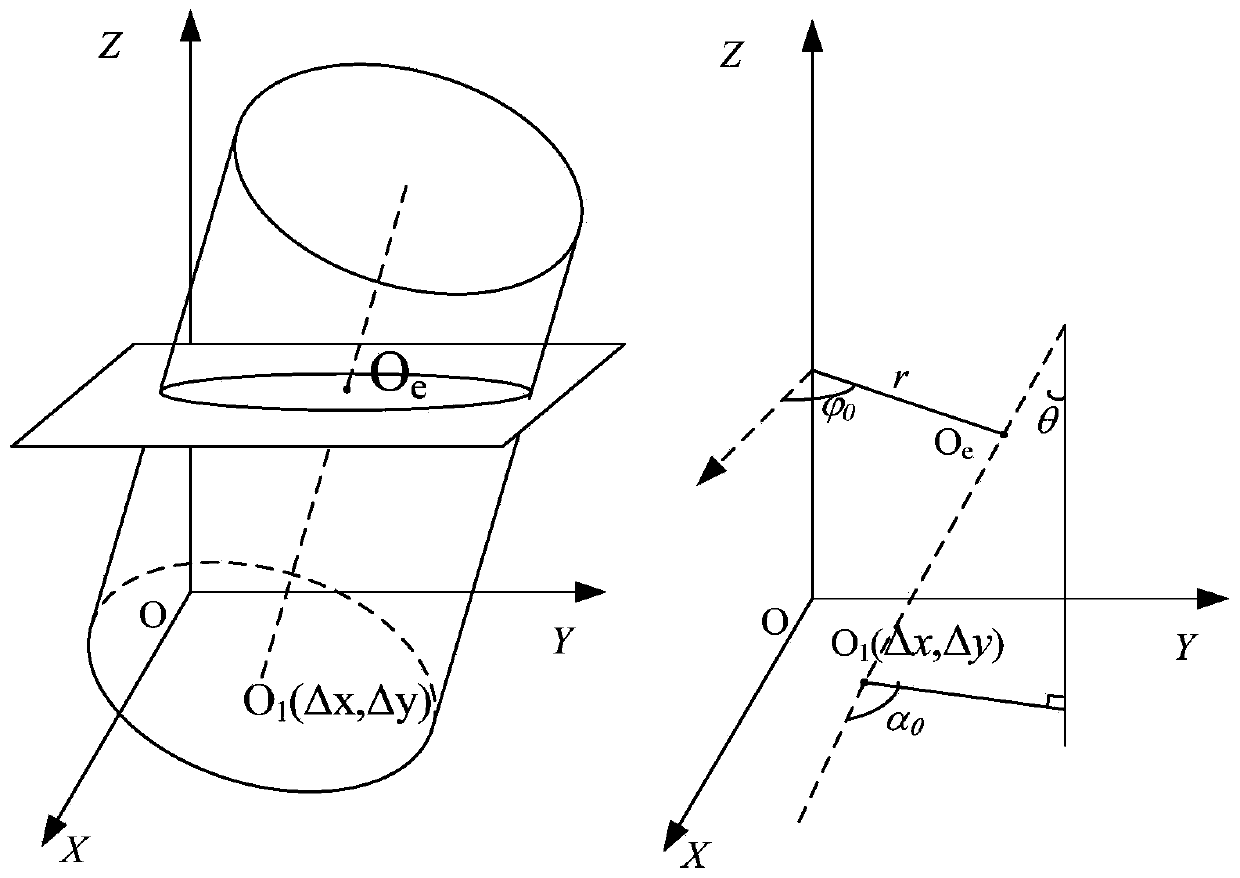

[0036] The hardware device adopted in this embodiment includes a 6-degree-of-freedom industrial robot, a robot controller, a water tank, a water circulation system, an independent turntable, a DC servo motor, a driver, an ultrasonic probe, a signal generator / receiver, an industrial computer (including a motion control card, a high-speed data acquisition card) and supporting cables, etc. During detection, the workpiece is placed vertically on the turntable driven by the servo motor at the bottom of the water tank, and is centered and clamped with a three-jaw chuck, and the turntable rotates at a specific speed. At the same time, the ultrasonic probe is clamped by an industrial robot and moves at a constant sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com