Air-coupled ultrasonic imaging method based on wavelet analysis and related algorithms

An ultrasonic imaging method and air coupling technology, which is applied in the direction of analyzing solids, analyzing materials, and processing detection response signals by using sound waves/ultrasonic waves/infrasonic waves. Problems such as poor ultrasonic imaging effect and low efficiency of air-coupled ultrasonic transduction can achieve optimal image signal-to-noise ratio, facilitate online data processing, and improve the ability to detect small defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

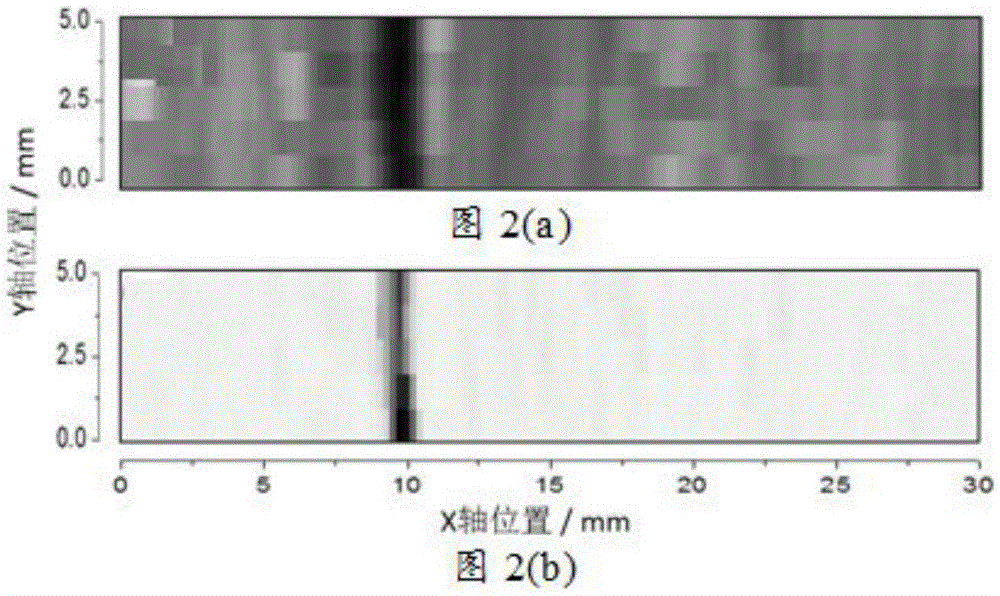

[0053] In this embodiment, air-coupled ultrasonic testing is performed on the seal of a soft package with a large defect with a width of 1.5 mm (1.5 times the probe focal diameter), and imaging is performed using the method of the present invention. The defect type is leakage channel type, the scanning area size is 30×5mm, the frequency of the point-focused air-coupled probe is 1MHz, the focus diameter is 1mm, the x-axis scanning step is 0.25mm, the y-axis scanning step is 1mm, and the signal sampling rate is 20MHz.

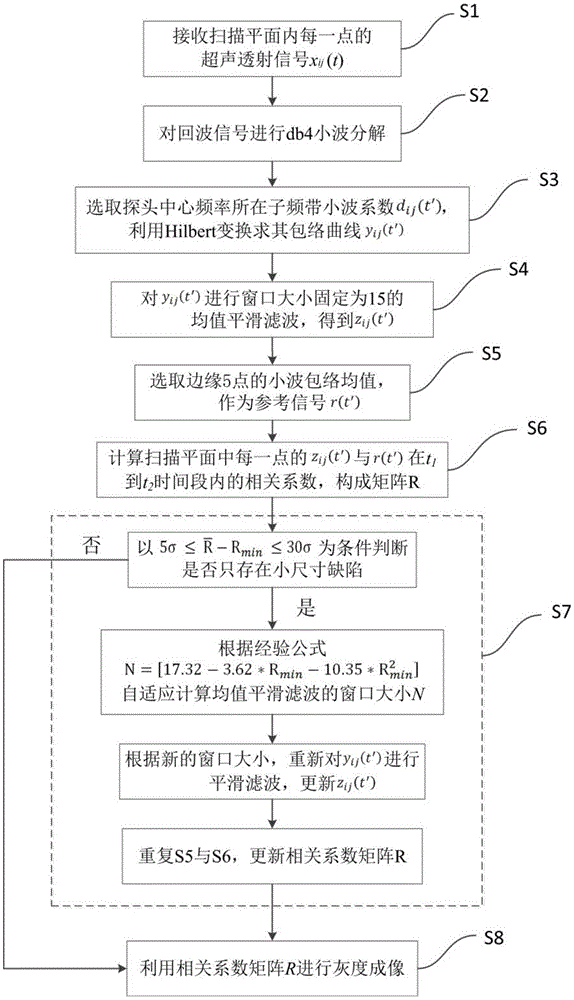

[0054] The specific process of imaging is as follows:

[0055] Air-coupled ultrasonic scanning is performed on each point in the XY plane, and the received transmission signal is denoted as x ij (t); the signal length is 6000 points in total.

[0056] Use db4 wavelet to x ij (t) Carry out 5 layers of wavelet decomposition.

[0057] The frequency band of the wavelet detail coefficient d4 is 0.625-1.25 MHz, so the wavelet coefficients of this sub-frequency band ...

Embodiment 2

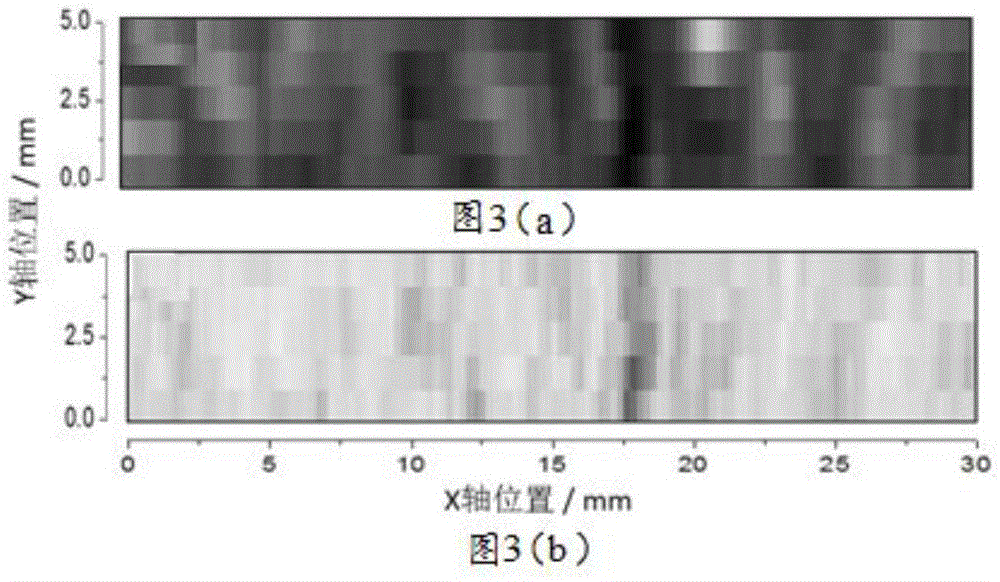

[0066] In this embodiment, air-coupled ultrasonic testing is performed on a soft package seal with a small-sized defect (0.5 times the focal diameter of the probe) with a width of 0.5 mm, and imaging is performed using the method of the present invention. The configurations of defect type, scanning sensor probe, data sampling rate, scanning step size, and scanning area size are the same as those in Embodiment 1.

[0067] The imaging processing flow S1-S6 in this embodiment is the same as that in Embodiment 1. The specific steps of S7's adaptive smoothing filter are as follows:

[0068] Step A: The minimum value R in the correlation coefficient R matrix calculated in the previous step min is 0.79, the mean value of the correlation coefficient is 0.97, and the standard deviation σ of the correlation coefficient is 0.03, satisfying Therefore, it is judged that there are small-sized defects in the scanned image, and it is necessary to re-smooth and filter the wavelet coeffi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com