Method and system for torsional wave inspection of heat exchanger tubes

A heat exchanger tube and torsional wave technology, applied in the field of inspection of heat exchanger tubes, can solve the problems of low efficiency, difficult mode control, poor defect detection ability, etc., and achieve the advantages of reducing interference, improving defect detection ability and reducing dispersion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

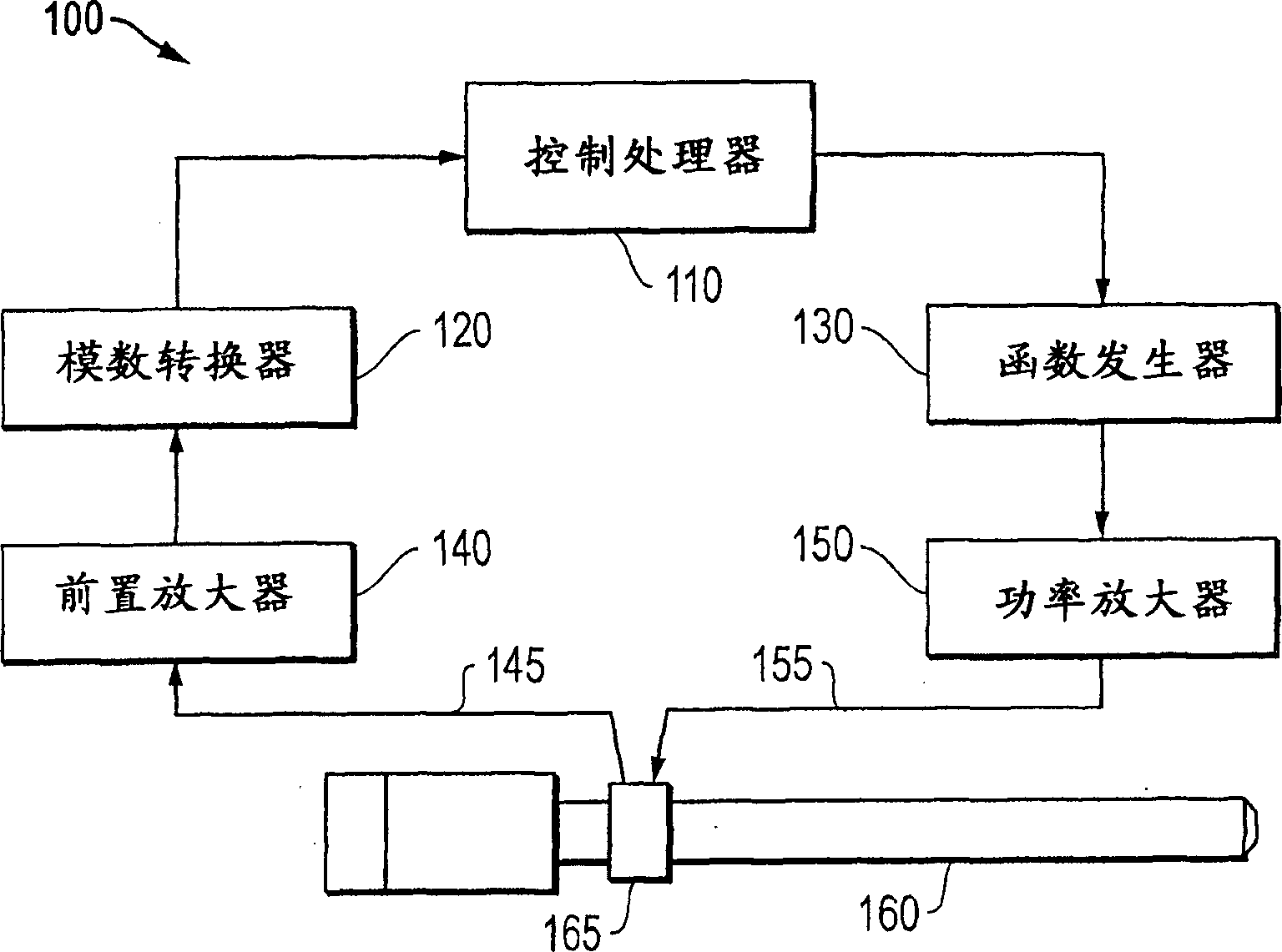

[0020] go to figure 1 , figure 1 A functional block diagram of a system 100 for implementing the present invention is shown. The control processor 110 commands the function generator 130 to start a fixed frequency current pulse, which is amplified by the power amplifier 150 . The amplified current pulse 155 is sent to a magnetostrictive sensor 165 located on the probe 160 . The amplified current pulse 155 causes the magnetostrictive transducer 165 to generate a torsional wave pulse that is sent into a probe waveguide coupled to the heat exchanger tube. When the torsional wave encounters a defect in the heat exchanger tube wall, the reflected torsional wave signal is sent back to the waveguide coupled to the heat exchanger tube. The reflected signal generates a voltage signal in the magnetostrictive sensor 165 which is amplified by the preamplifier 140 . The amplified signal is then converted to a digital signal using an analog-to-digital converter 120 and sent to the contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com