Coupling and focusing ultrasonic detection method and detection device for polyethylene pipe hot melt butt joint

A technology of hot-melt butt jointing and focused ultrasound, which is applied in measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, and using sound waves/ultrasonic waves/infrasonic waves for material analysis, etc. Problems such as contour echo are generated to achieve the effect of improving detection sensitivity, improving detection sensitivity, and improving detection ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

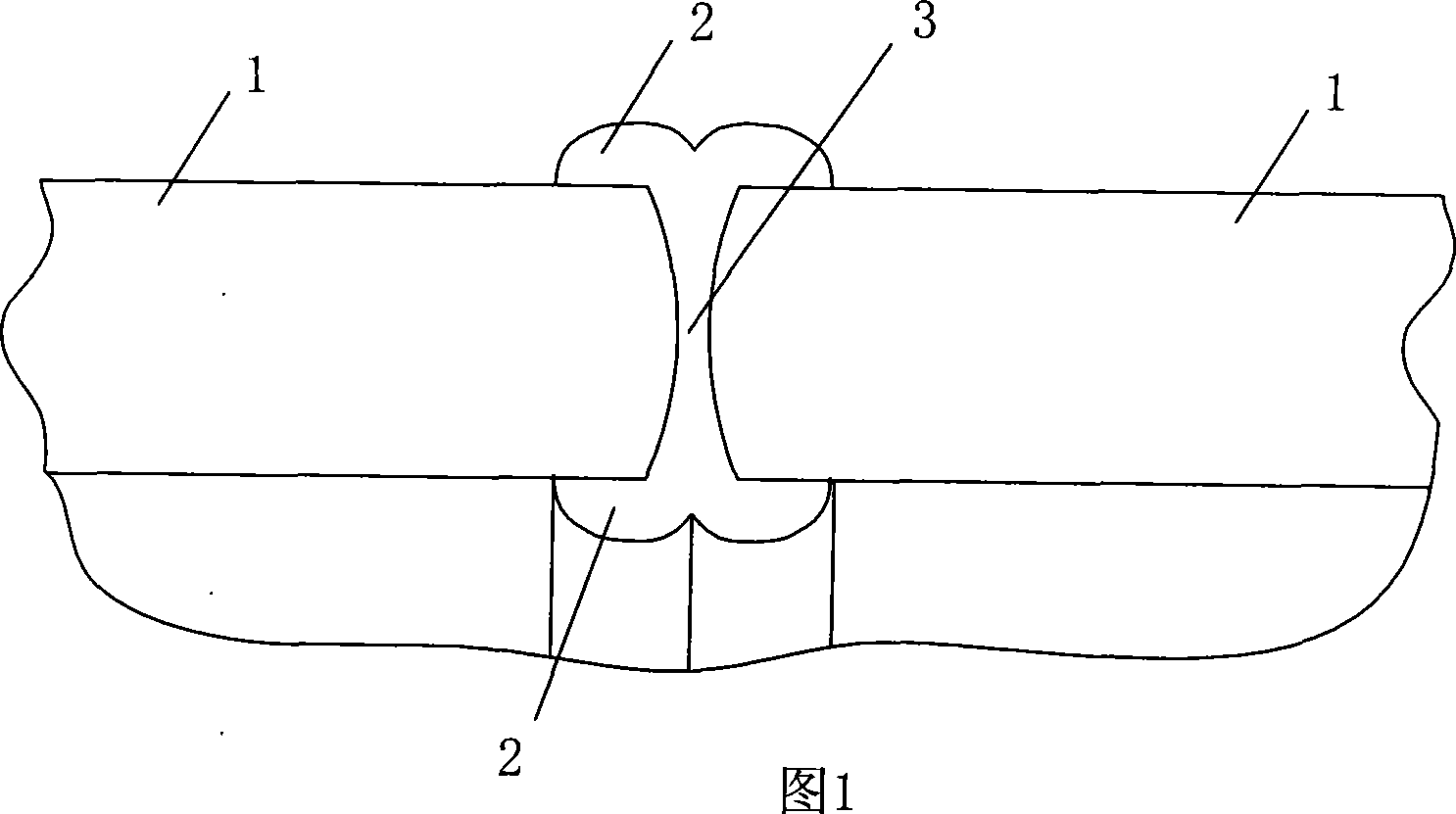

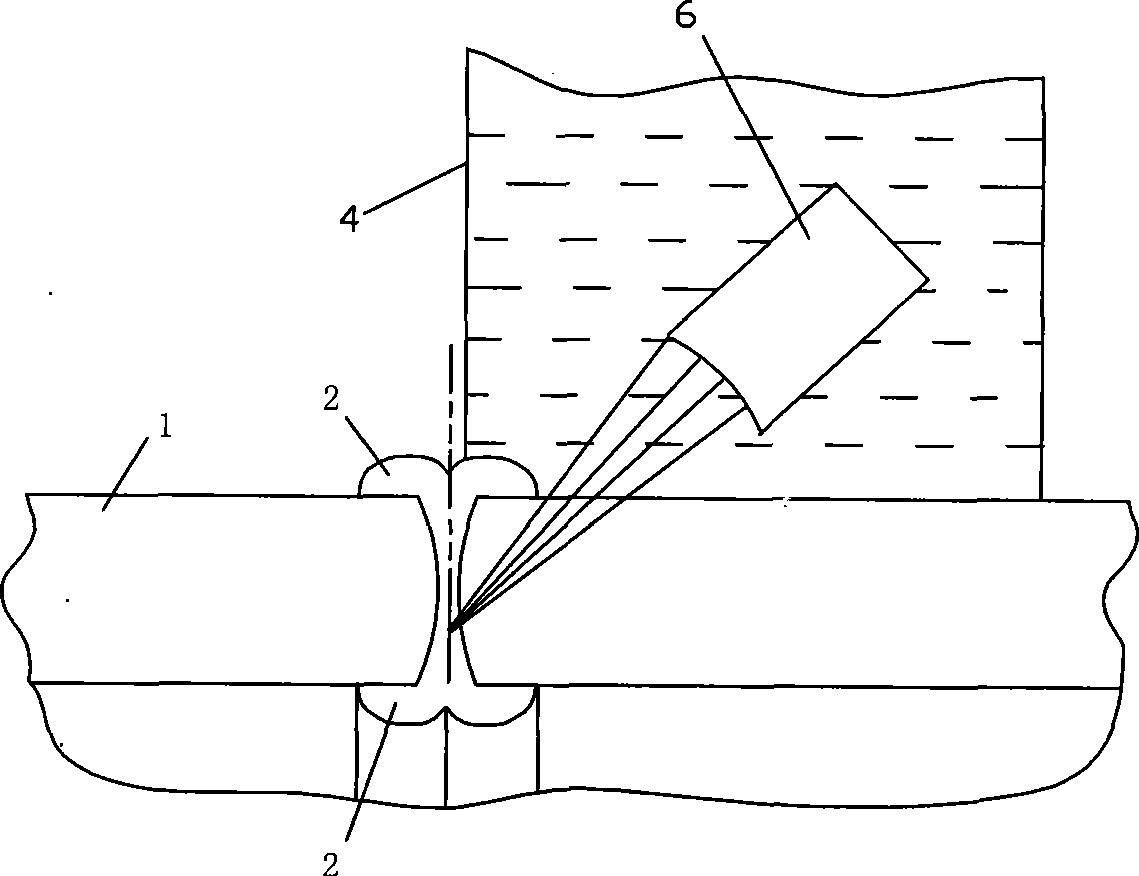

[0056] The specific process of the most commonly used hot-melt butt joint method for existing polyethylene pipes is: firstly, the cross-sectional end surface of the polyethylene pipe or pipe fitting is treated flat, and then the connection part is heated to a molten state with a heating plate with a certain pressure; The plate is heated and pressure is applied to forcefully press the two fused ends together, finally the two parts are joined and secured under steady pressure until the joint cools. The shape of one side of the joint after butt welding is shown in FIG. 1 ; there are upper and lower curls 2 and a fusion zone 3 in the middle area of the two pipes 1 .

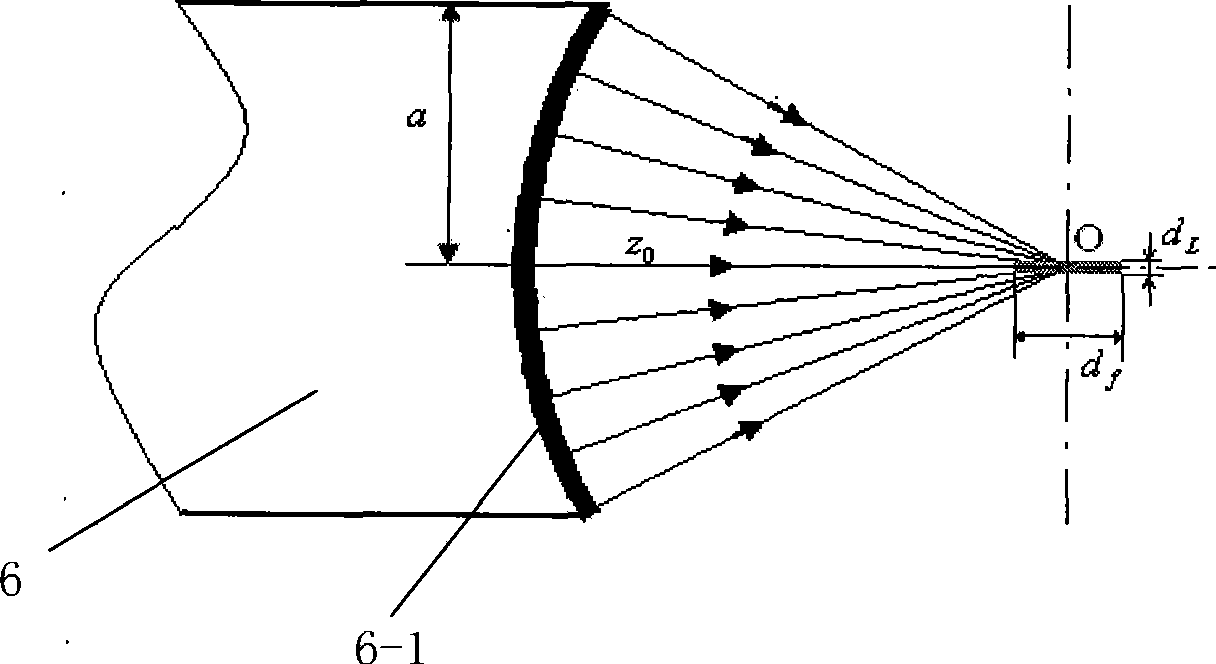

[0057] During the experimental research, it was found that the liquid immersion focusing technology, which is difficult to implement in metal welds, has unique advantages for ultrasonic testing of hot-melt joints of polyethylene pipes, which is mainly based on the acoustic characteristics of polyethylene materials a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com