Pipeline nondestructive testing equipment

A non-destructive testing and pipeline technology, used in measuring devices, material analysis by electromagnetic means, instruments, etc., can solve the problems of low coupling between excitation coil and receiving coil, low sensitivity of detection probe and low lift-off height, etc., to reduce cleaning degree requirements, the overall structure design is compact, and the effect of improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

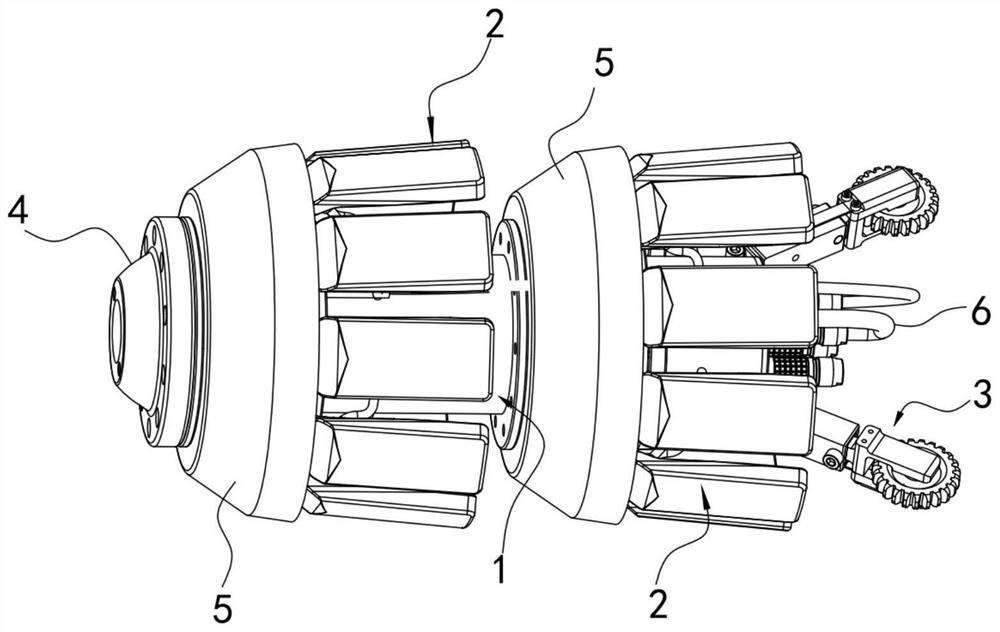

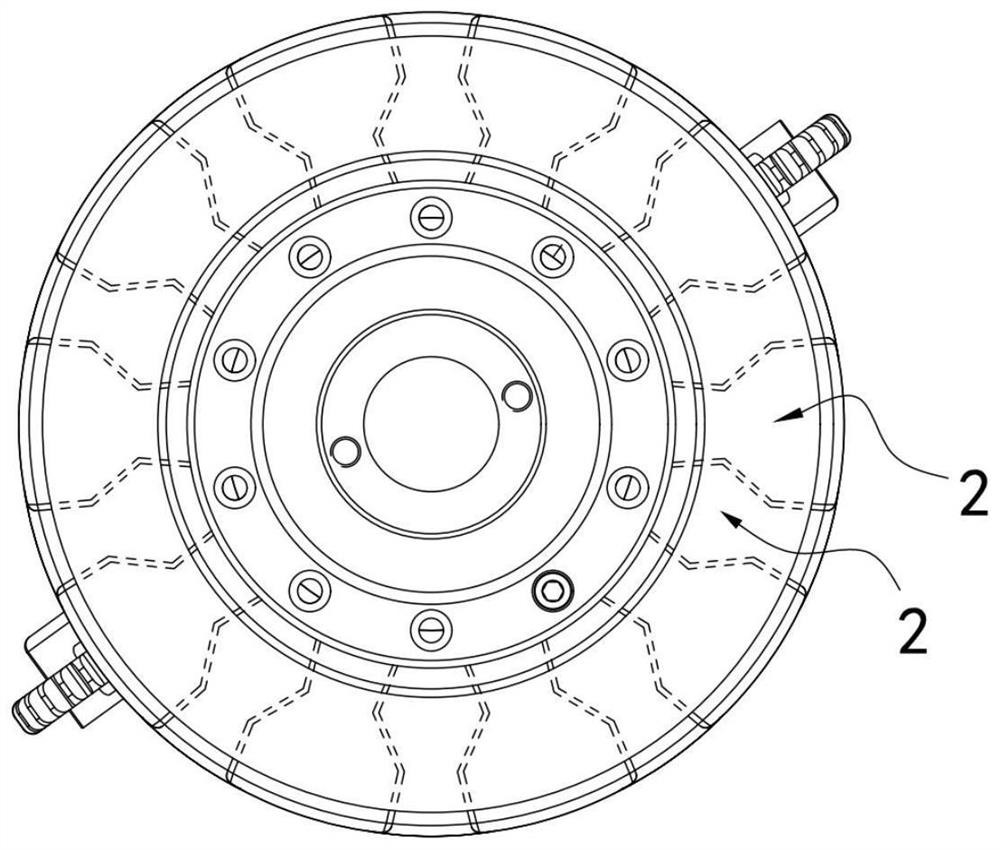

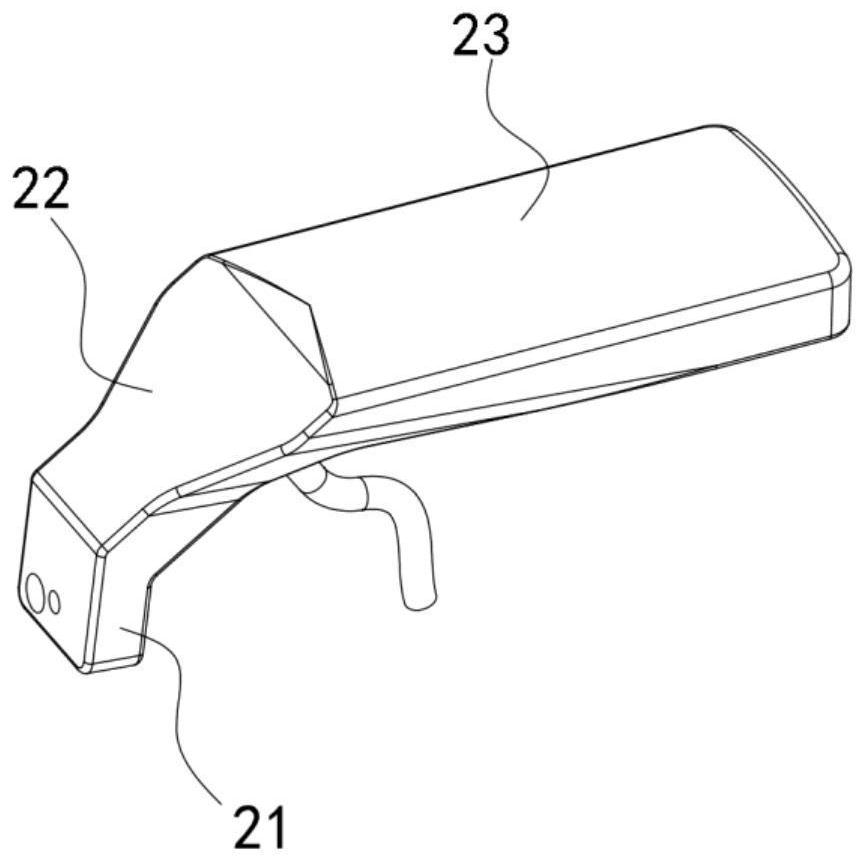

[0078] Such as figure 1 As shown, a pipeline non-destructive testing equipment provided by the present invention includes a mobile carrier 1 and a probe detection component 2. The probe detection component 2 is fixed or rotatably mounted on the mobile carrier 1, and the probe detection component 2 passes through the movement of the mobile carrier 1 in the pipeline. The inner wall of the pipeline is detected by moving, and the detection content of the probe detection component 2 can be determined according to the detection probe 24 with different detection functions that is carried according to actual needs.

[0079] Under normal circumstances, the axis line of the mobile carrier 1 is parallel to the axis line of the pipeline, and the mobile carrier 1 can automatically advance in the pipeline or advance with the flu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com