Unsupervised defect detection and positioning method based on multilevel feature reconstruction

A defect detection and positioning method technology, applied in the field of computer vision, can solve the problems of not satisfying the positioning of defect areas of different scales, and the generalization ability is too strong, so as to achieve the effects of cost reduction, strong adaptability and performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solution of the present invention will be specifically described below with reference to the accompanying drawings.

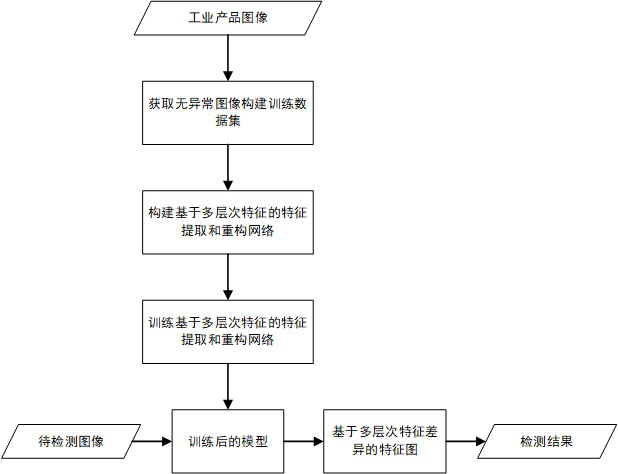

[0037] The non-supervised defect detection and positioning method based on multi-level feature reconstruction, combines the difference between multi-level features and reconstruction features, and realizes detection and positioning of defect samples under conditions without supervising learning. At the same time, the network model is used to calculate the cost of overhead, meet the performance requirements and real-time requirements of defect detection scenes.

[0038] According to a multi-level feature reconstruction, no monitoring defect detection and positioning method, including the following steps:

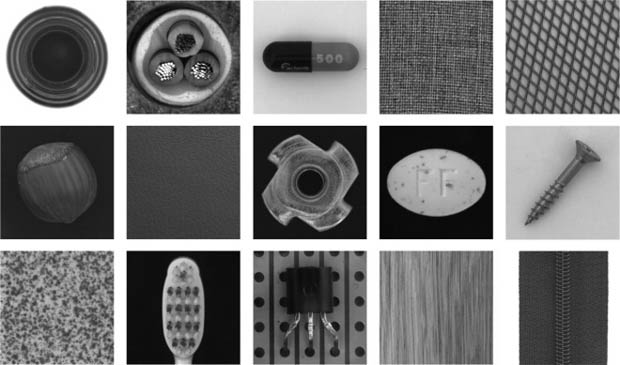

[0039] Step S1, obtain an abnormal image and abnormal image production data set of the target product;

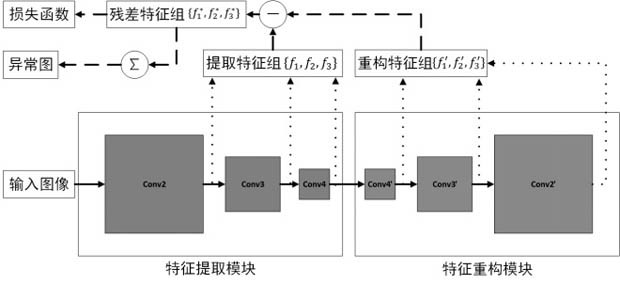

[0040] Step S2, construct a feature extraction and reconstruction network based on multi-level features;

[0041] Step S3, input the train...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com