Design method of full-matrix linear ultrasonic transducer array

A technology of ultrasonic transducers and design methods, applied in computer-aided design, design optimization/simulation, instruments, etc., can solve the problems of reducing the number of array elements and having no special sensor array design method, so as to achieve uniform imaging quality and improve detection The effect of time efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

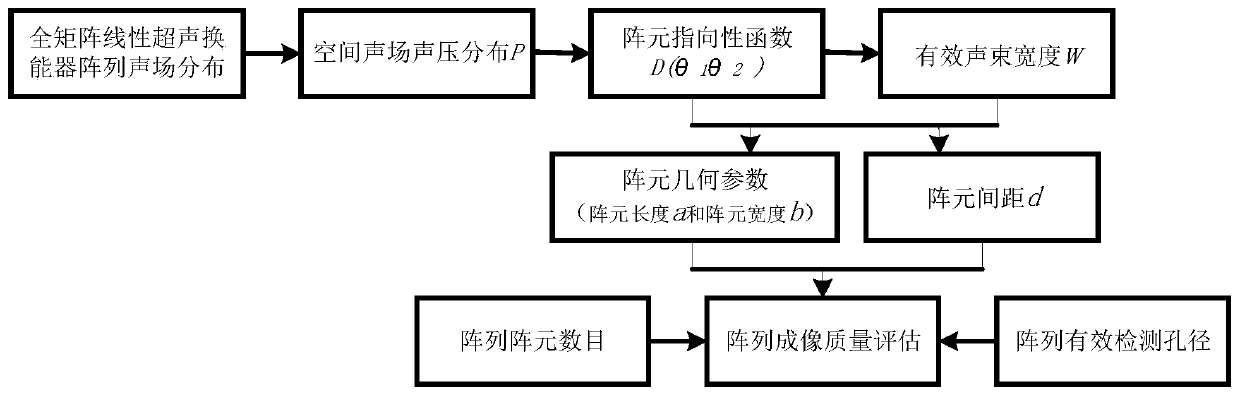

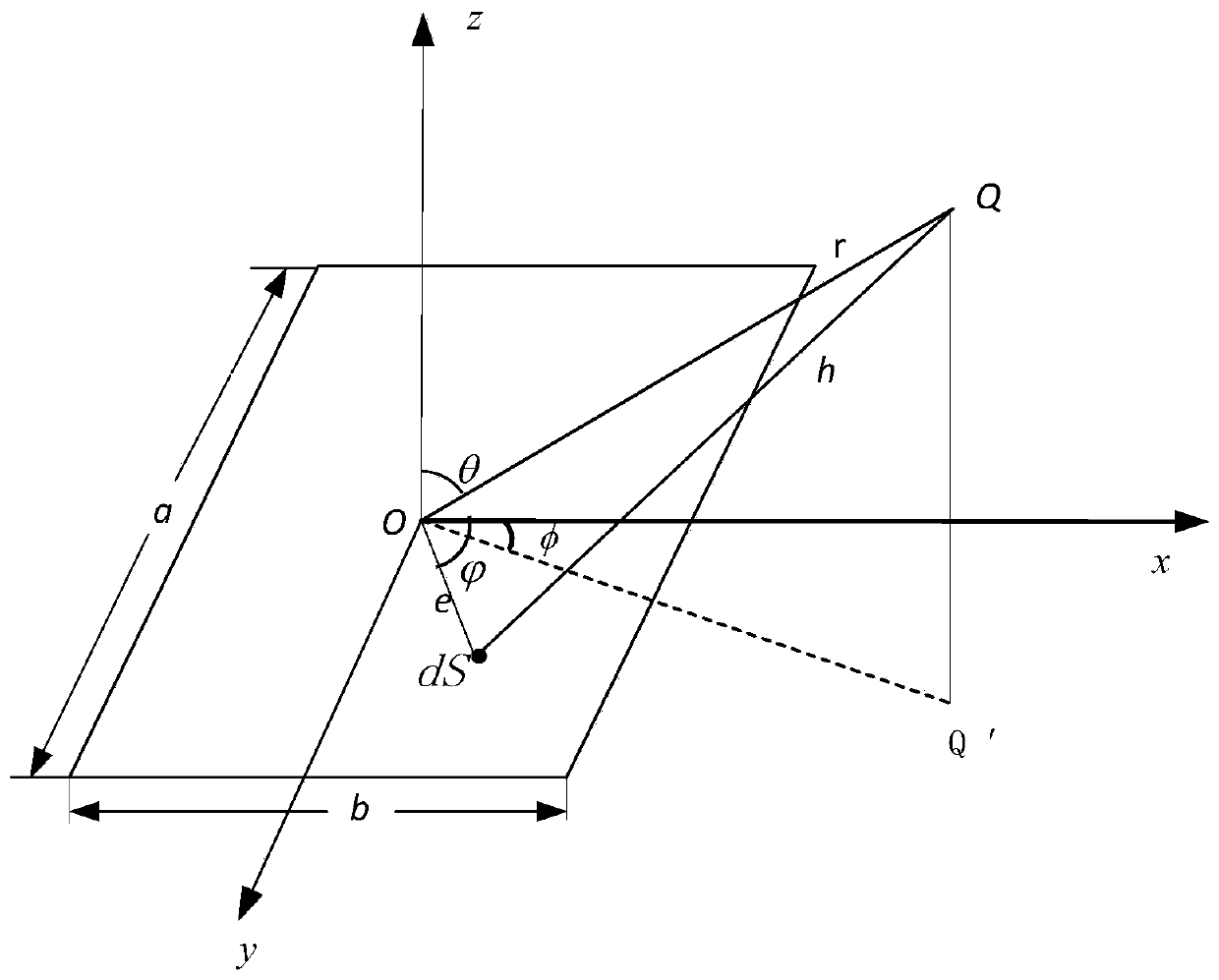

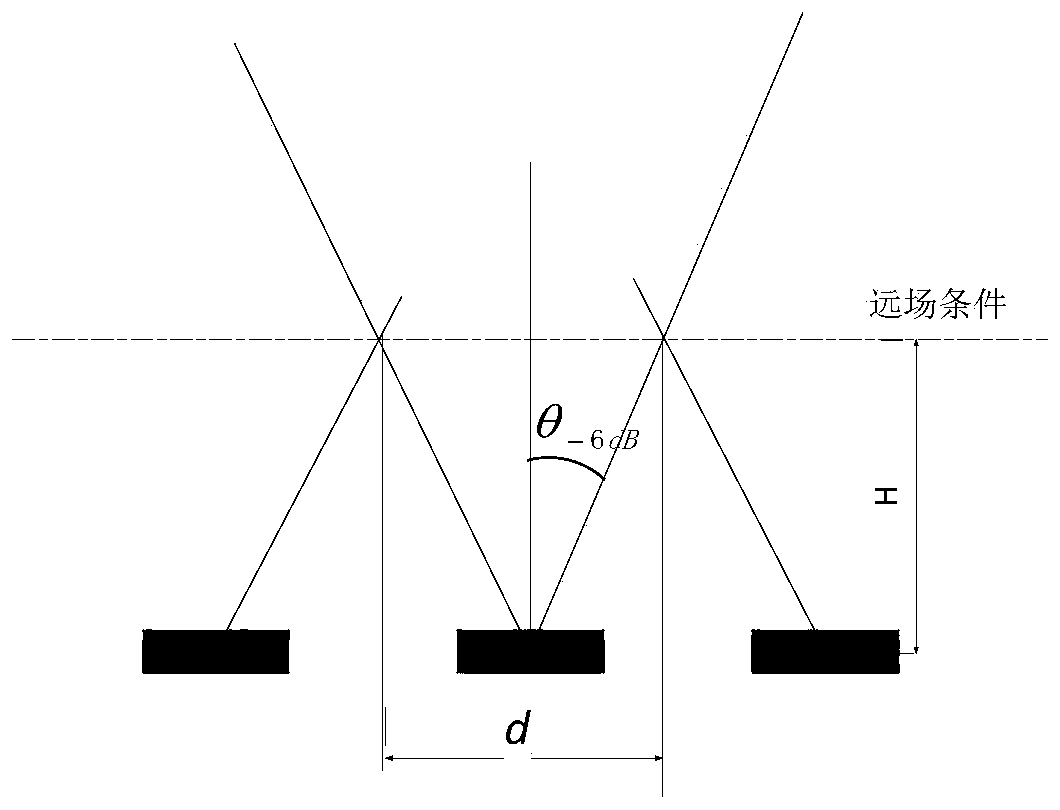

[0035] see figure 1 , according to the embodiment of the present invention, a brand-new full-matrix ultrasonic transducer array design method, starting from the principle of full-matrix ultrasonic imaging, according to the requirements of the full-matrix ultrasonic sensor line array on the sound field, and the geometric parameters of the array elements on the sound field distribution The relationship between the geometric parameters of the array element and the sound pressure of the sound field was obtained, and the relationship between the effective sound beam width of the sound field and the distance between the array elements was obtained through the far-field condition. Defect detection performance and effectiveness, including:

[0036] Step 1 establishes the spatial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com