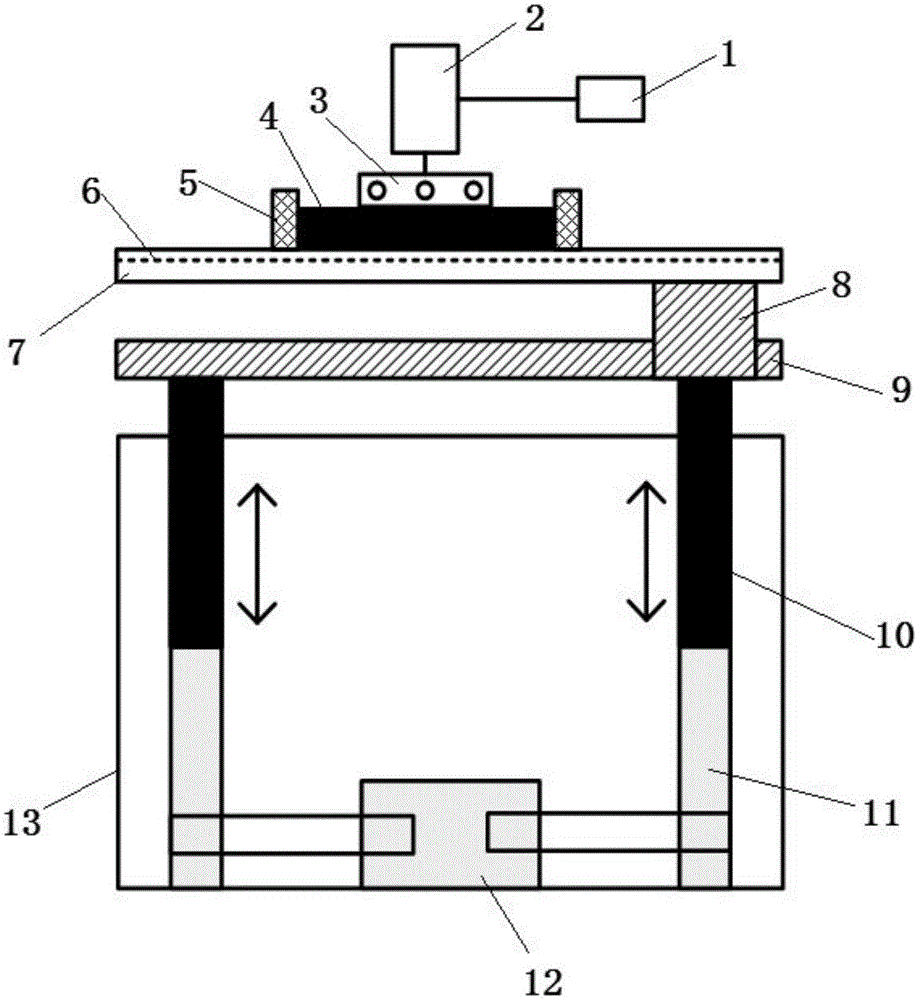

Phase weighting vector fully focusing imaging device and method for identifying forge piece cracks quantitatively

A quantitative identification and phase weighting technology, which is applied to measuring devices, processing detection response signals, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., can solve problems such as large quantitative errors, low signal-to-noise ratio and low resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

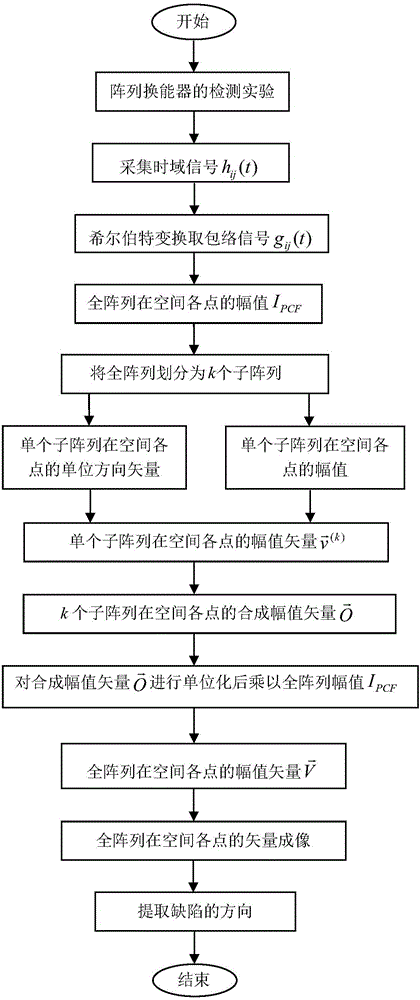

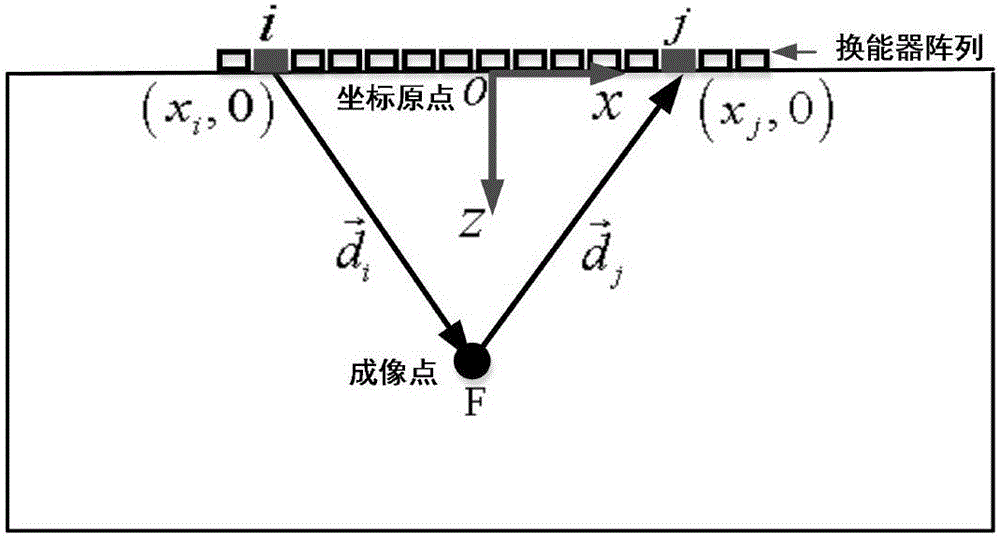

[0065] The vector omni-focus imaging method based on phase weighting that the present invention proposes, its basic principle is:

[0066] Assuming that the number of elements of the linear array transducer is N, then N×N sets of full matrix data h will be obtained ij (t), where i represents the excitation element, and j represents the receiving element.

[0067] By constructing complex analytic function H ij (t) = HI ij (t)+jHQ ij (t), the instantaneous phase of the signal can be obtained, the formula is as follows:

[0068]

[0069] where HI ij (t) is called the in-phase component, which is the signal h ij (t) itself; HQ ij (t) is called the quadrature component, which is the Hilbert transform of the original signal.

[0070] further will Normalized to [-π, π], since the normalized phase is periodic, there will be a discontinuity when the phase changes across the boundary between -π and π. This discontinuity has caused a huge change in the phase that originally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com